The efficiency and performance of a lawn tractor are greatly influenced by the intricate design and arrangement of its components. Each element plays a crucial role in the overall functionality, ensuring that the machine operates smoothly and effectively. Familiarizing yourself with these individual pieces can enhance maintenance efforts and prolong the lifespan of the equipment.

In this section, we will explore the various elements that constitute your lawn care machinery. By gaining insights into the layout and interconnection of these components, users can make informed decisions regarding repairs and replacements. A comprehensive understanding of the structure will facilitate better upkeep and ensure optimal performance throughout the seasons.

Whether you are a seasoned operator or new to lawn maintenance, recognizing the significance of each component is essential. This knowledge empowers users to troubleshoot issues more effectively and optimize their machine’s operation. Dive into the details to discover how each segment contributes to the overall efficiency of your gardening tool.

This section aims to provide a comprehensive understanding of a specific model of lawn care equipment, focusing on its essential components and their functions. By dissecting the various elements, users can better grasp how each part contributes to the overall performance of the machine.

Key Features and Specifications

Exploring the main characteristics of this lawn mower reveals insights into its design and operational capabilities. Some noteworthy aspects include:

- Engine type and power output

- Cutting width and height adjustment options

- Fuel capacity and efficiency ratings

- Transmission system and drive type

Component Functionality

Understanding the roles of individual components enhances maintenance and troubleshooting efforts. Key components include:

- Engine: Powers the mower and drives the blades.

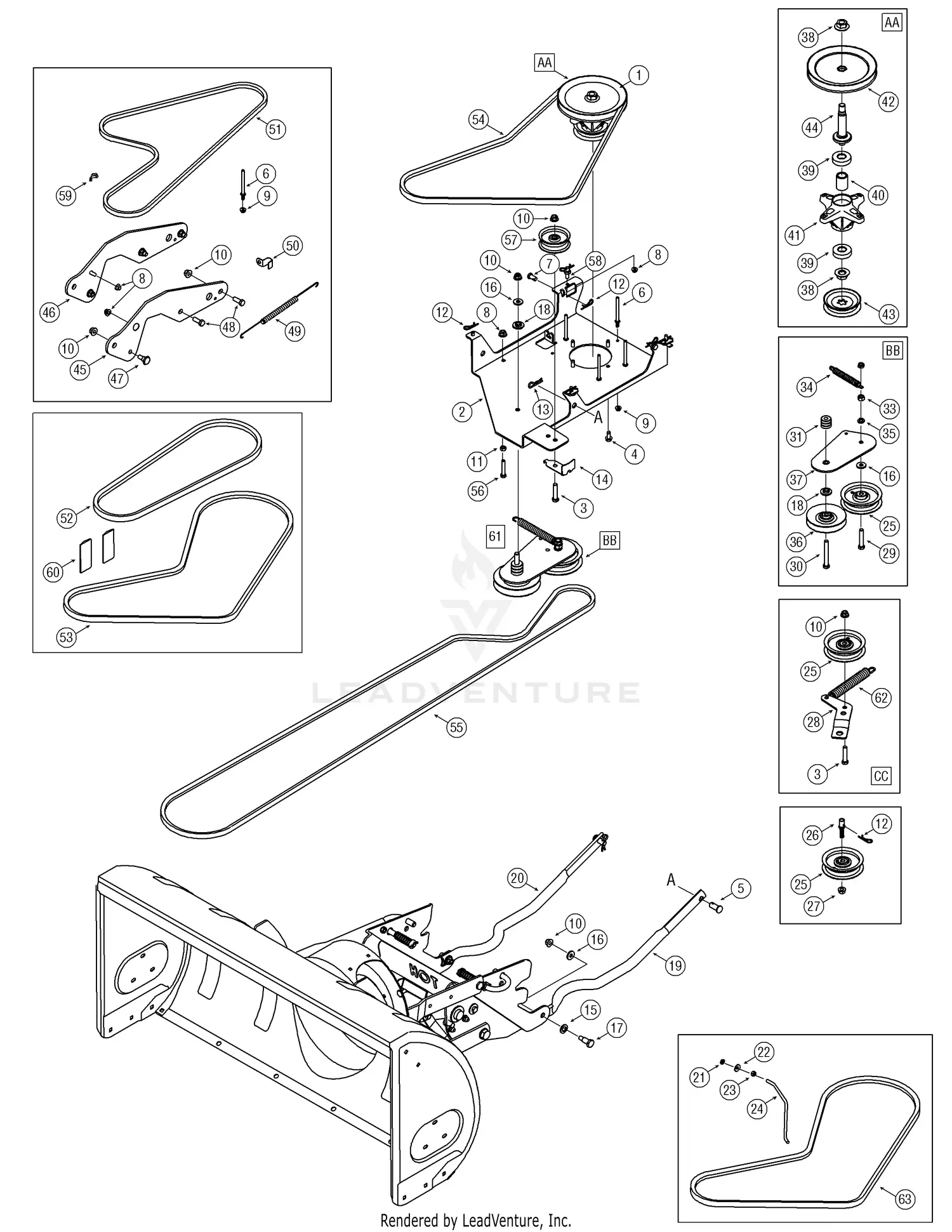

- Blades: Responsible for cutting grass efficiently.

- Deck: Houses the blades and supports the mower structure.

- Wheels: Provide mobility and stability on various terrains.

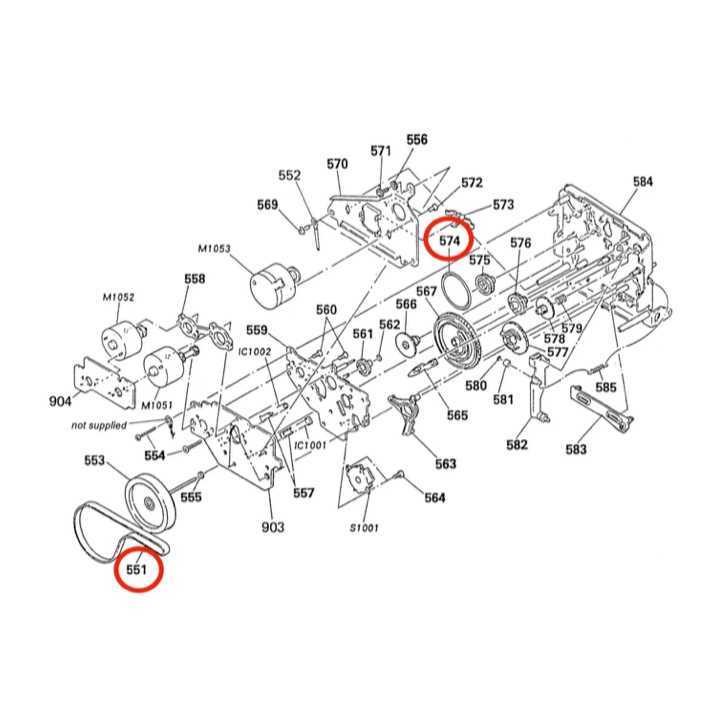

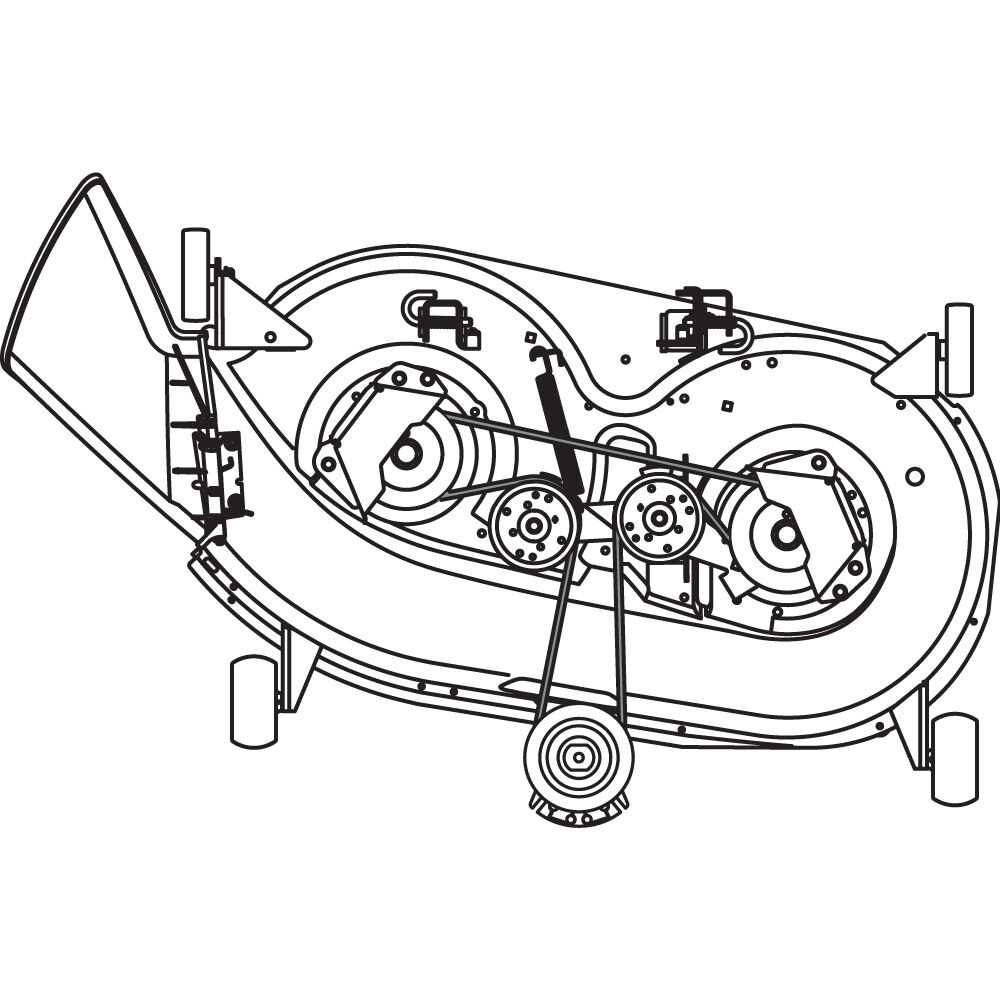

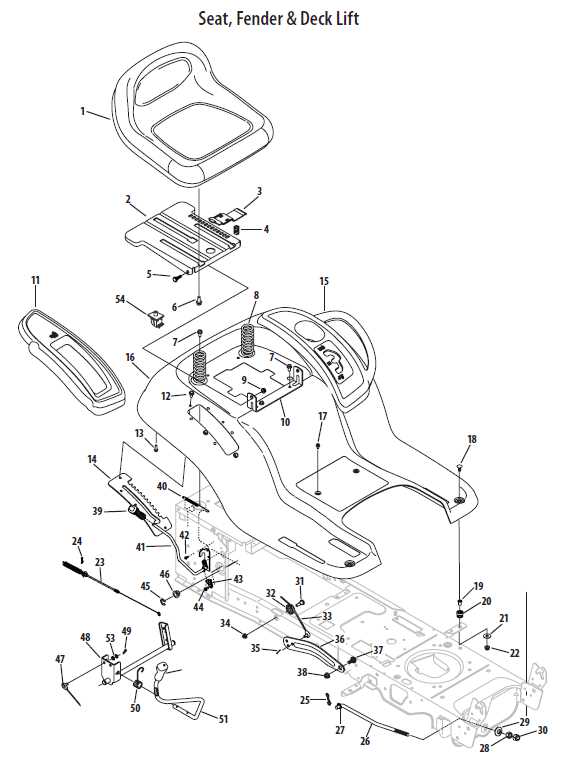

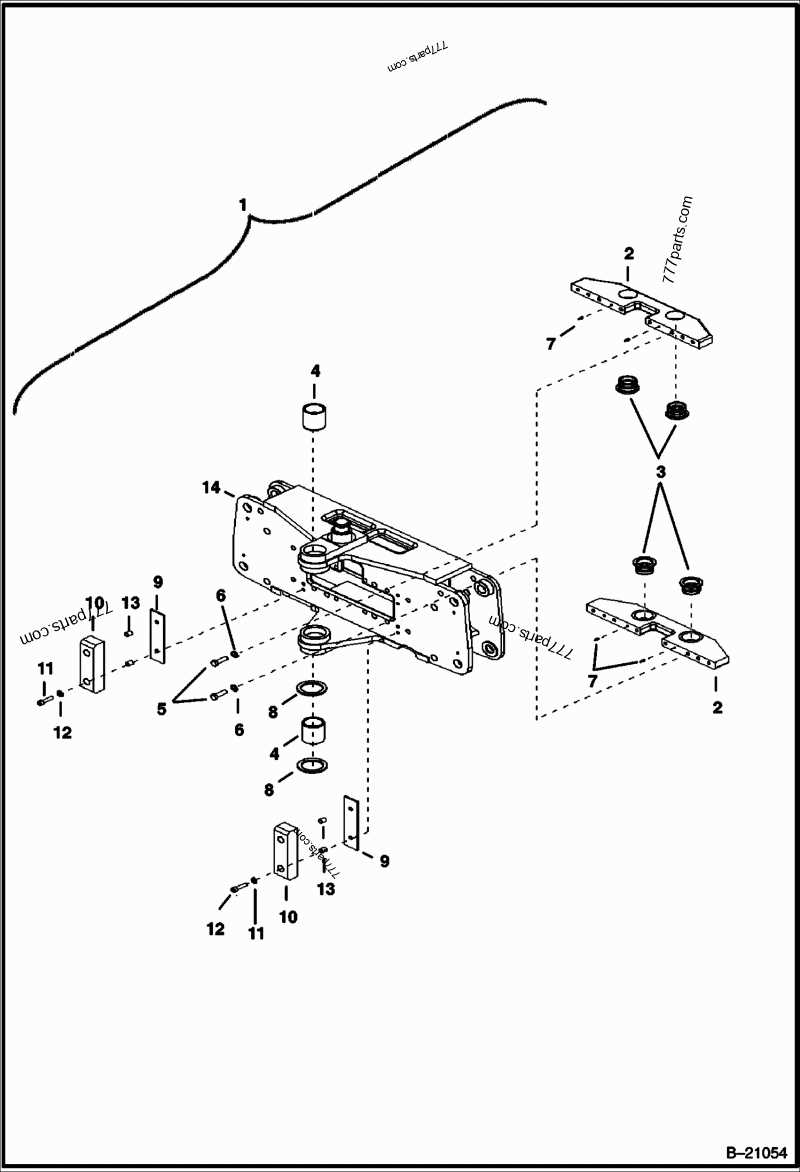

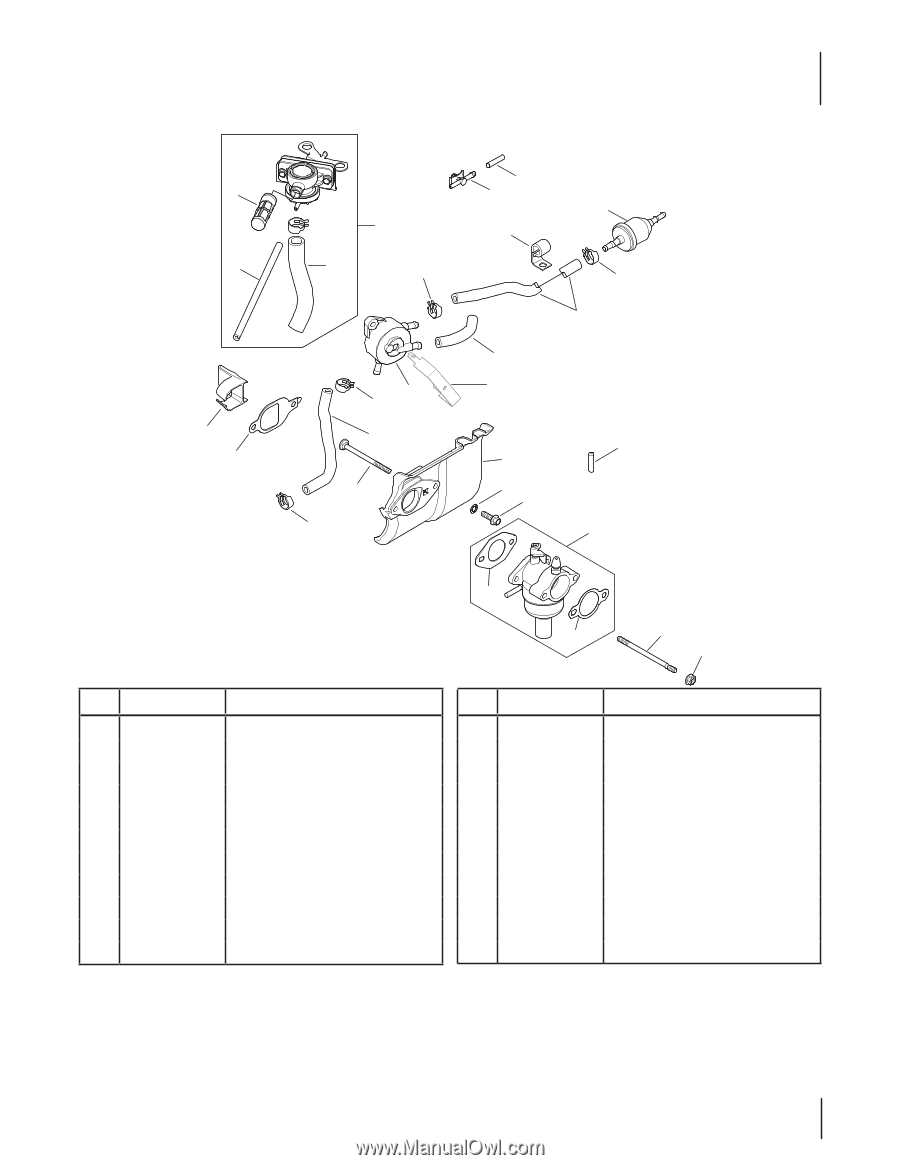

Understanding the Parts Diagram

The visual representation of components serves as an essential tool for both identification and organization. It provides users with a clear layout, allowing for efficient navigation through various elements that make up the machinery. By grasping the structure and function of each element, one can enhance maintenance and repair processes significantly.

Importance of Visual Representations

Visual guides are invaluable for understanding the relationship between different components. They simplify the process of locating specific sections, making it easier to address issues or perform upgrades. This clarity aids both seasoned professionals and beginners in their endeavors, ensuring that each step is executed accurately.

Navigating the Layout

Familiarizing oneself with the layout facilitates quicker access to necessary information. By examining the arrangement, individuals can develop a better understanding of how components interact, which ultimately leads to improved performance and longevity of the equipment. Mastery of the layout is crucial for effective troubleshooting and enhancing operational efficiency.

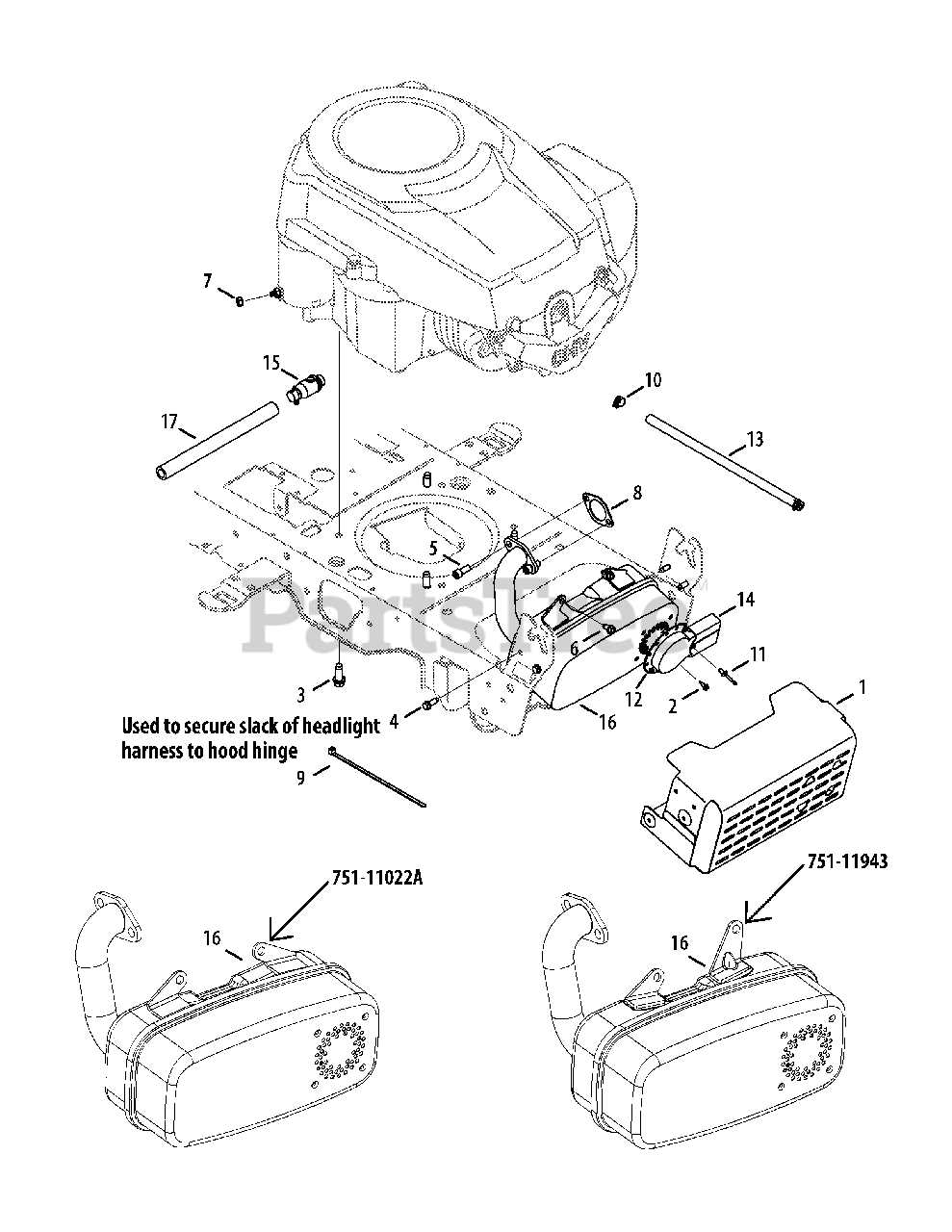

Key Components of the LTX 1040

This section explores the essential elements that contribute to the efficient operation of the machine. Each component plays a vital role in enhancing functionality and overall performance, ensuring a smooth and effective user experience.

Engine Assembly

The heart of the system is its engine, which provides the necessary power for various tasks. Equipped with a robust motor, it ensures reliable performance, making it suitable for a range of applications. The engine’s design promotes durability and efficiency, allowing for extended use without compromising on power delivery.

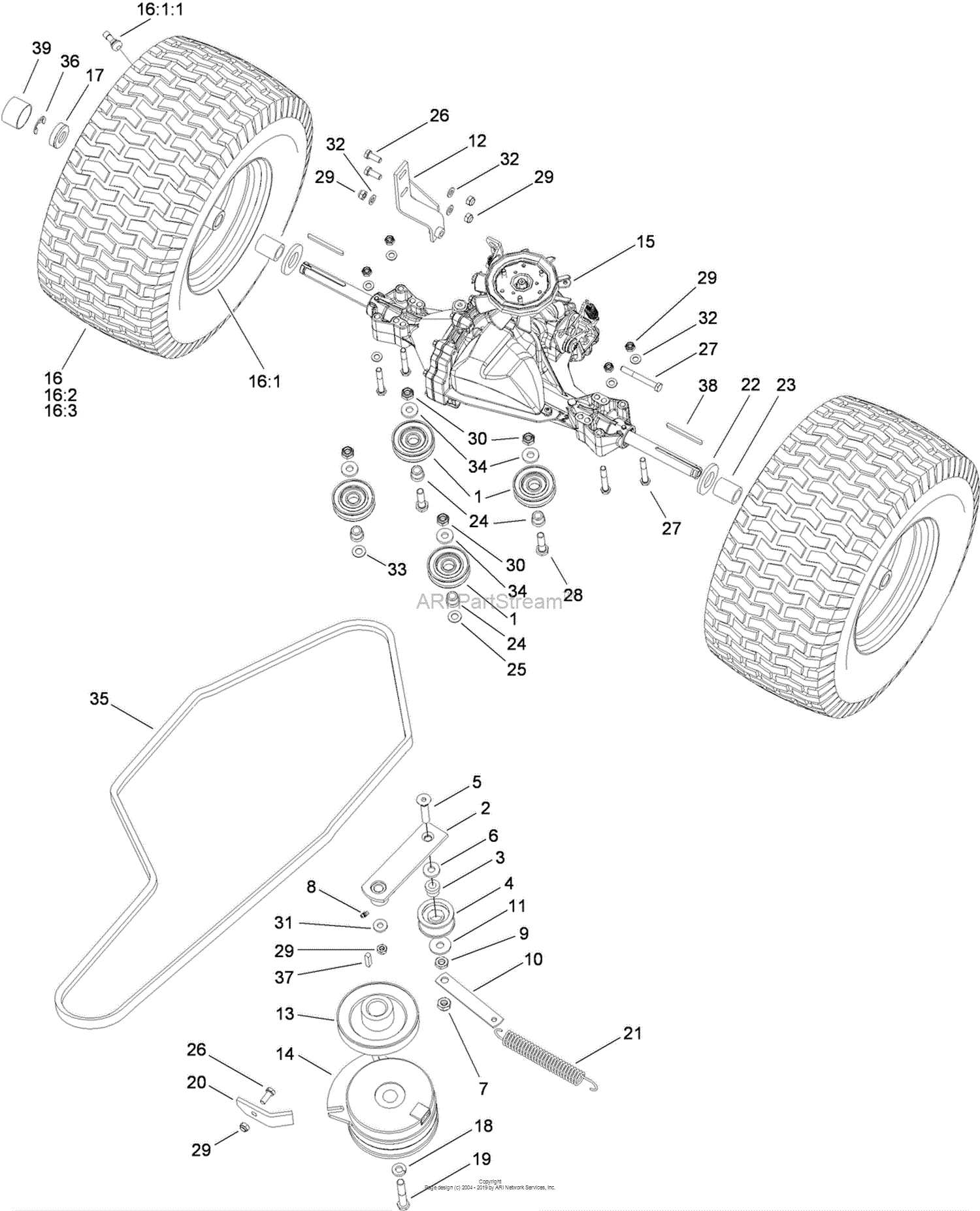

Transmission System

The transmission system facilitates smooth movement and control. It is designed to manage speed and torque effectively, enabling the operator to navigate different terrains effortlessly. This assembly enhances maneuverability, making the equipment versatile for both flat and uneven surfaces.

Importance of Maintenance and Repair

Regular upkeep and timely repairs play a crucial role in enhancing the longevity and efficiency of machinery. Ensuring that equipment is well-maintained not only minimizes the risk of unexpected breakdowns but also optimizes performance. By addressing wear and tear promptly, users can prevent minor issues from escalating into significant problems, ultimately saving time and resources.

Enhancing Performance

Consistent maintenance contributes to the smooth operation of the equipment. Routine checks and services help identify potential issues early, allowing for adjustments that can enhance functionality. This proactive approach not only ensures reliability but also improves the overall user experience.

Cost Efficiency

Investing in regular upkeep can lead to substantial cost savings in the long run. By avoiding major repairs and extending the lifespan of the machinery, users can reduce operational expenses. Furthermore, well-maintained equipment tends to consume less fuel and operate more efficiently, providing an additional layer of financial benefit.

Identifying Common Issues

Understanding the typical challenges that arise with outdoor equipment can significantly enhance maintenance and performance. Recognizing these frequent problems early allows for prompt intervention and helps prevent more severe complications.

Here are some prevalent concerns to monitor:

- Engine Difficulties: Common symptoms include hard starting, stalling, or irregular running.

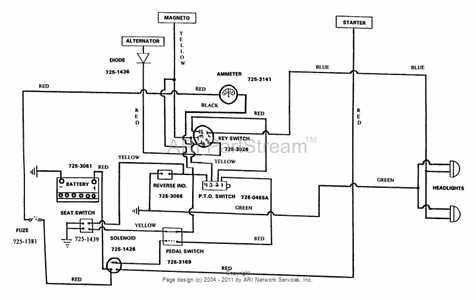

- Electrical Failures: Issues such as dead batteries, malfunctioning lights, or faulty ignition systems are frequent.

- Transmission Problems: Look out for unusual noises, slipping gears, or difficulty shifting.

- Blade Malfunctions: Dull or damaged blades can lead to uneven cutting and poor performance.

- Fuel System Issues: Blockages or leaks in the fuel lines can hinder operation and efficiency.

Regular inspections and timely repairs can help mitigate these concerns, ensuring optimal functionality and longevity of the machine.

Replacement Parts Availability

Access to essential components is crucial for maintaining and repairing outdoor equipment. Knowing where to find these elements can save both time and effort, ensuring that machines operate smoothly and efficiently. Various sources offer a range of options, from original manufacturer supplies to aftermarket alternatives, catering to different needs and budgets.

Sources for Components

Authorized dealers provide high-quality items that meet the original specifications, ensuring compatibility and performance. Additionally, many online retailers specialize in aftermarket options, often at competitive prices. Local repair shops may also stock necessary components, providing personalized service and advice.

Considerations for Selection

When choosing replacements, it’s essential to consider factors such as compatibility, warranty, and quality. Original equipment manufacturer (OEM) options often guarantee a perfect fit, while aftermarket alternatives may offer cost savings but could vary in quality. Always verify the part number and specifications to ensure proper installation and functionality.

Step-by-Step Repair Guide

This section offers a comprehensive approach to fixing common issues encountered with garden equipment. Following a structured method not only enhances efficiency but also ensures safety throughout the repair process. Each step is designed to guide you through essential tasks, from initial inspection to the final adjustments, ensuring your machine operates smoothly.

Start by gathering all necessary tools and materials. Having everything at hand will streamline the repair process. Before disassembling any components, make sure to disconnect the power source to prevent accidents. Carefully inspect the equipment for any visible signs of wear or damage.

Once you have identified the problematic areas, begin by removing the outer casing or cover. This may involve unscrewing several fasteners; keep them organized to avoid misplacement. With the casing removed, conduct a thorough examination of the internal mechanisms, looking for broken parts or loose connections.

After pinpointing the issue, replace any damaged components with suitable replacements. Ensure that all parts are compatible and securely fitted. Reassemble the equipment by reversing the disassembly steps, taking care to align everything properly.

Finally, test the machine to confirm that the repair was successful. Run it through various functions to ensure all systems are operational. If any issues persist, revisit the earlier steps to double-check your work. Following this guide will help maintain your equipment’s performance for years to come.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving optimal results. A well-stocked toolkit not only streamlines the repair process but also ensures safety and efficiency. Below are the key instruments that can aid in various repair operations.

Essential Hand Tools

Basic hand tools form the foundation of any repair effort. These typically include screwdrivers, wrenches, and pliers. A variety of sizes and types will allow you to tackle different fasteners and components. Additionally, a socket set is invaluable for loosening and tightening bolts in confined spaces.

Power Tools and Equipment

Incorporating power tools can significantly enhance the efficiency of your repair work. A drill with various bits is crucial for creating holes or driving screws quickly. Furthermore, a multimeter is useful for diagnosing electrical issues, ensuring that all connections are functioning properly. Having a reliable mechanical lift can also simplify access to hard-to-reach areas.

Enhancing Performance with Upgrades

Improving the efficiency and capabilities of your equipment can lead to a more enjoyable and productive experience. Various enhancements can significantly boost the functionality and reliability of your machine, making it more adept at tackling tasks with ease. Understanding the potential upgrades available is essential for optimizing performance and ensuring longevity.

Key Areas for Improvement

- Engine Enhancements

- Transmission Modifications

- Chassis Improvements

- Cutting Deck Upgrades

Recommended Upgrades

- High-Performance Air Filter: Enhances airflow, improving combustion and overall engine efficiency.

- Heavy-Duty Tires: Provide better traction and stability, allowing for improved handling on various terrains.

- Upgraded Blades: Offer a cleaner cut and improved mulching capabilities, resulting in healthier grass.

- Enhanced Suspension: Increases ride comfort and stability, especially on uneven surfaces.

By investing in these enhancements, users can achieve a remarkable difference in performance, leading to a more effective and reliable machine tailored to their specific needs.

Safety Precautions During Repair

When undertaking maintenance or repair work on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to proper guidelines and being aware of potential hazards can significantly reduce risks during the repair process. Ensuring a safe working environment not only protects the individual performing the tasks but also safeguards the equipment and surrounding area.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This may include safety glasses to shield the eyes from debris, gloves to protect hands from sharp edges or chemicals, and steel-toed boots to prevent foot injuries. Ensuring that clothing is suitable for the task at hand can further minimize the risk of entanglement or exposure to harmful substances.

Work Area Organization

Maintaining a clean and organized workspace is vital for safety. Clutter can lead to slips, trips, and falls, while properly storing tools and materials reduces the chance of accidents. Additionally, having adequate lighting allows for better visibility, making it easier to identify potential hazards and complete tasks effectively. Ensuring proper ventilation is also essential when working with chemicals or in confined spaces.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and components of a popular lawn care machine. Understanding these aspects can enhance the overall performance and longevity of the equipment.

- What is the recommended maintenance schedule?

Regular upkeep is essential for optimal functioning. It is advisable to follow a routine that includes:

- Checking oil levels and changing the oil every 50 hours of operation.

- Inspecting air filters and replacing them as needed.

- Sharpening the blades at the beginning of each season.

- Cleaning the machine after each use to prevent debris buildup.

- Where can I find replacement components?

Replacement elements can typically be sourced from:

- Authorized dealers or service centers.

- Online retailers specializing in lawn care equipment.

- Local hardware stores that carry garden machinery supplies.

- How can I troubleshoot performance issues?

Common problems may arise that affect efficiency. To resolve these, consider the following:

- Ensure the fuel is fresh and properly mixed if applicable.

- Check for blockages in the cutting deck or discharge chute.

- Inspect spark plugs and replace if worn out.

- Verify that the battery is fully charged and connections are secure.

- What safety precautions should I take?

Prioritizing safety is crucial when operating machinery. Remember to:

- Wear appropriate protective gear such as gloves and safety goggles.

- Read the user manual thoroughly before use.

- Avoid operating on steep slopes to prevent accidents.

- Never bypass safety features installed on the equipment.