In the world of machinery maintenance, having a clear understanding of component schematics is essential for ensuring optimal performance and longevity. These visual representations serve as crucial guides, illustrating the intricate relationships between various elements. By focusing on specific identification codes, users can streamline their search for replacement items and enhance repair efficiency.

Each equipment model possesses its own unique set of identifiers, which allow enthusiasts and professionals alike to pinpoint the exact components required. This targeted approach not only simplifies the process of locating necessary items but also promotes a deeper understanding of the machinery’s overall design. Whether for casual use or professional repairs, accessing these schematics can significantly improve one’s maintenance strategy.

By delving into the intricacies of these illustrations, users can ultimately save time and resources, ensuring their machines operate at peak capacity. Recognizing the value of such resources empowers individuals to tackle repairs with confidence and precision.

Parts Overview

This section provides a comprehensive look at the components used in lawn maintenance equipment. Understanding these elements is crucial for effective upkeep and repair, ensuring optimal performance and longevity of the machinery.

Key components can be categorized into several groups:

- Engine Components:

- Cylinders

- Pistons

- Carburetors

- Transmission System:

- Belts

- Gears

- Drive Shafts

- Cutting Mechanism:

- Blades

- Decks

- Spindles

- Electrical System:

- Batteries

- Wiring Harnesses

- Ignition Components

- Chassis and Frame:

- Wheels

- Axles

- Support Brackets

Identifying and sourcing these elements is essential for maintenance tasks. Each component plays a vital role in the overall functionality of the equipment, and knowing where to find the right replacements can save time and enhance productivity.

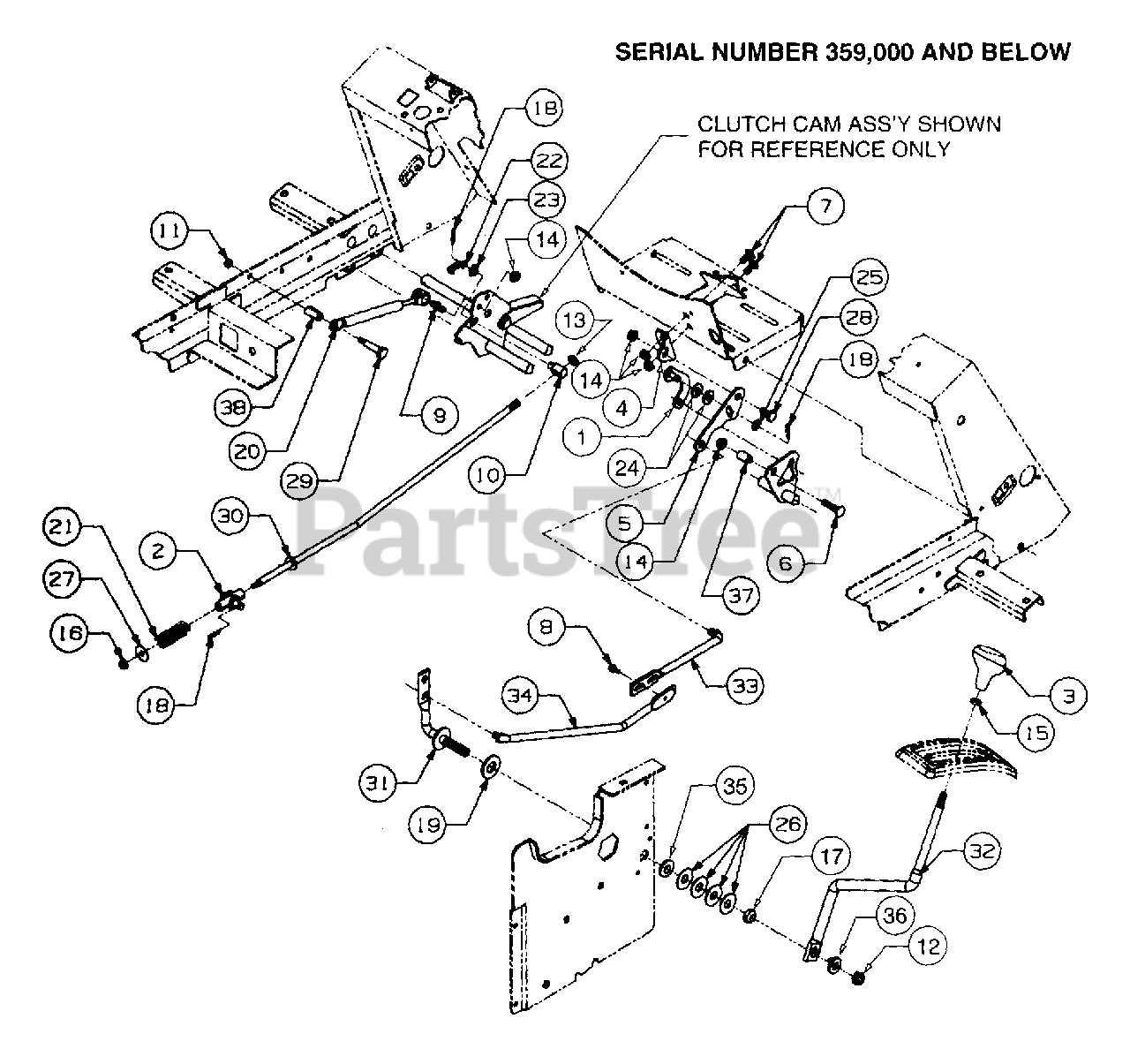

Understanding Serial Numbers

Every machine has a unique identifier that provides essential information about its origin and specifications. This alphanumeric code helps users and manufacturers track and manage equipment effectively.

Here are some key points to consider:

- Purpose: The identifier indicates the model and production details.

- Location: You can usually find this code on the machine itself, often on a label or plate.

- Importance: Knowing this code is crucial for sourcing the right components and understanding the machine’s history.

By recognizing the significance of this identifier, you can ensure proper maintenance and support for your equipment.

Importance of Accurate Diagrams

Precise illustrations are essential in any mechanical field, providing clarity and guidance for maintenance and repairs. These visual aids serve as crucial references, enabling users to understand complex systems and facilitate efficient problem-solving.

Benefits of Accurate Illustrations

- Enhances Understanding: Clear visuals help users grasp the structure and functionality of components.

- Improves Efficiency: With accurate references, users can quickly locate parts and perform necessary tasks.

- Reduces Errors: Detailed representations minimize the risk of mistakes during assembly or repairs.

- Saves Time: Quick access to the right information accelerates the troubleshooting process.

Impact on Maintenance

- Facilitates Training: New users can learn faster when provided with reliable visual tools.

- Promotes Safety: Accurate illustrations help identify potential hazards, ensuring safer handling of equipment.

- Increases Longevity: Understanding the correct assembly and maintenance of components prolongs the lifespan of machinery.

Finding Your Model’s Diagram

Locating the right visual reference for your equipment can significantly enhance your maintenance and repair efforts. Understanding the specific components and their arrangement is crucial for effective troubleshooting.

To start, follow these steps:

- Identify your equipment model by checking the label or documentation.

- Access reliable online resources or manufacturer websites that provide detailed illustrations.

- Consider joining forums or communities where enthusiasts share insights and helpful links.

With the right visual guide, you can effectively navigate through repairs and replacements, ensuring optimal performance of your machine.

Common Parts and Their Functions

Understanding the essential components of outdoor machinery is crucial for maintaining optimal performance. Each element plays a specific role, contributing to the overall functionality and efficiency of the equipment. Familiarity with these elements allows users to troubleshoot issues more effectively and ensure their machines operate smoothly.

Engine Components

The engine serves as the heart of the machinery, converting fuel into mechanical energy. Key elements include the carburetor, which mixes air and fuel for combustion, and the spark plug, responsible for igniting this mixture. Additionally, the air filter prevents dirt and debris from entering the engine, promoting longevity and performance.

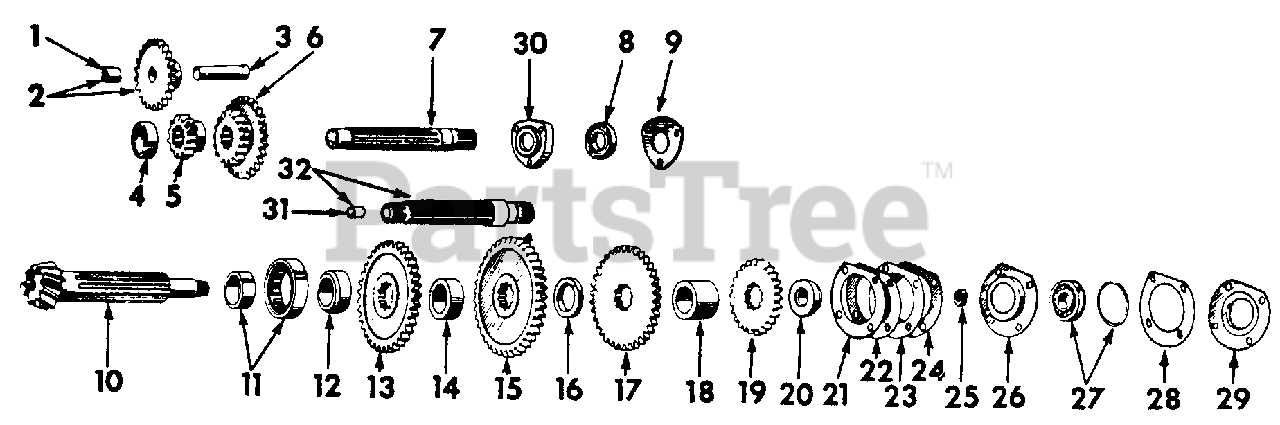

Drive System Elements

The drive system facilitates movement and control. Important components include the transmission, which transfers power from the engine to the wheels, and the belt, which links various parts together. The wheels and axles are also vital, providing stability and maneuverability for the machine.

How to Read Diagrams Effectively

Understanding visual representations of machinery components is essential for successful maintenance and repairs. These illustrations serve as a roadmap, guiding users through the complex relationships and functions of various elements within a system. Mastering the art of interpreting these visuals can significantly enhance your efficiency and confidence in handling equipment.

Familiarize Yourself with Symbols

Every visual guide uses a set of standardized icons and symbols to convey specific information. Take the time to learn these representations, as they often indicate different types of components, connections, and functions. Recognizing these symbols will help you quickly identify the parts you need to focus on during your tasks.

Follow the Flow of the Illustration

To effectively utilize these visuals, pay attention to the layout and flow of the information presented. Typically, the arrangement of elements is designed to show how parts interact with each other. By tracing the lines and connections, you can gain insight into the assembly process and understand the sequence of operations, which is crucial for troubleshooting and repairs.

Locating Replacement Parts Online

Finding the right components for your equipment can be a straightforward process with the right approach. The internet offers a wealth of resources that can guide you to the exact items you need for maintenance or repairs. Utilizing various online platforms can streamline your search and ensure you obtain quality replacements efficiently.

Utilizing Manufacturer Websites

Visiting the official websites of manufacturers is one of the best ways to locate the required items. These sites often feature comprehensive catalogs and search tools that allow you to browse through available options based on specific criteria. Additionally, they provide valuable information regarding compatibility and installation.

Exploring Third-Party Retailers

Numerous third-party retailers specialize in equipment components and offer competitive prices. It is advisable to compare multiple sites to find the best deals. Reading customer reviews can also be beneficial in determining the reliability of the products offered. Always ensure that the retailer is reputable to avoid issues with quality.

Tips for Maintaining Your Equipment

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By implementing a few simple strategies, you can avoid costly repairs and keep your tools in prime condition. This guide provides practical advice to help you achieve ultimate efficiency and reliability.

Routine Inspections

Performing consistent checks is crucial. Look for signs of wear and tear, such as frayed cables or loose components. Addressing these issues promptly can prevent more serious problems down the line.

Proper Cleaning

Keeping your equipment clean not only enhances performance but also extends its lifespan. Use appropriate cleaning solutions and tools to remove dirt and debris, ensuring all parts function smoothly. Regular maintenance goes a long way in preserving your investment.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining and repairing machinery, the choice between original equipment manufacturer (OEM) components and third-party alternatives is crucial. Each option has its own advantages and disadvantages that can significantly affect performance, durability, and overall satisfaction.

Advantages of OEM Components

- Quality Assurance: OEM components are designed and manufactured to meet strict standards, ensuring reliability and compatibility with the original machinery.

- Perfect Fit: These components are specifically engineered for the equipment, which means they fit perfectly and work seamlessly.

- Warranty Protection: Using OEM components often preserves the warranty of the machinery, providing peace of mind for the owner.

- Longevity: OEM parts typically have a longer lifespan, which can lead to fewer replacements over time.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket options can be significantly cheaper, making them appealing for budget-conscious users.

- Variety: There is often a wider range of options available, allowing users to select parts that best suit their specific needs.

- Innovation: Some aftermarket manufacturers offer advanced features that may not be available in OEM products.

- Accessibility: These components are generally more readily available, reducing wait times for repairs and maintenance.

Ultimately, the decision between OEM and aftermarket components should be based on individual needs, preferences, and the specific requirements of the machinery in question.

Frequently Asked Questions About Diagrams

This section aims to address common inquiries related to visual representations of components and their identification. Understanding these illustrations can enhance maintenance and repair processes significantly.

What are the benefits of using these visuals? They provide a clear overview of individual elements and their arrangement, making it easier to locate specific items when performing repairs or replacements.

How can I find the right illustration for my equipment? Typically, the best way to locate the appropriate visual is by consulting the manufacturer’s resources, often available online, where you can input relevant identifiers.

Are these visuals applicable to all models? Generally, each model has its unique representation. Always ensure that the illustration corresponds to your specific equipment to avoid confusion.

Can I rely solely on these visuals for repairs? While they are incredibly helpful, it’s recommended to use them in conjunction with detailed manuals or guides for the most accurate and comprehensive understanding.

What should I do if I can’t find a specific illustration? If you encounter difficulties, reaching out to customer support or checking forums dedicated to your equipment can provide assistance and additional resources.

Resources for Further Assistance

When facing challenges with machinery or equipment, finding reliable sources for support can greatly enhance your experience. Accessing the right information helps ensure that you can maintain and troubleshoot effectively, leading to improved functionality and longevity.

Online Communities

Participating in forums and discussion groups allows enthusiasts and professionals alike to share insights and solutions. These platforms can be invaluable for gaining unique perspectives and troubleshooting tips.

Manufacturer Support

Reaching out to the official support channels of the manufacturer is always a wise choice. Their expertise can provide definitive answers and access to specific resources that are tailored to your needs.