Every piece of equipment used for lawn care is made up of essential elements that ensure its efficient operation. By having a clear overview of these components, owners can maintain the machine’s performance and extend its lifespan. Whether it’s addressing wear and tear or simply understanding how different elements interact, recognizing the significance of individual pieces is crucial for optimal care.

Proper identification and knowledge of these elements allow users to handle repairs more effectively. It becomes easier to determine which part may need replacement, how certain sections contribute to overall functionality, and what steps to take to keep the equipment running smoothly. This knowledge not only

Cub Cadet RZT54 Essential Components Overview

This section provides an overview of the primary mechanical and operational elements of a zero-turn lawn machine. Understanding how these key systems interact ensures smoother performance and longer operational life. By familiarizing yourself with the core structures and how they work together, you can easily maintain your equipment and enhance its efficiency.

Engine and Power System

The heart of any lawn machine is its power source. The engine delivers the necessary energy to drive the machine, power the blades, and control various functions. Proper care and routine checks of the engine are vital for maintaining performance. Regularly inspect for wear and ensure the

Understanding the Cutting Deck Assembly

The cutting deck assembly is a critical part of a lawn maintenance machine, responsible for ensuring an even and efficient trim. This section covers the components involved in the deck assembly and their role in maintaining optimal performance. Understanding how these parts work together can help in maintaining and troubleshooting issues that arise over time.

Main Components of the Deck

The deck consists of several key elements, each playing a crucial role in the cutting process. These include the blades, pul

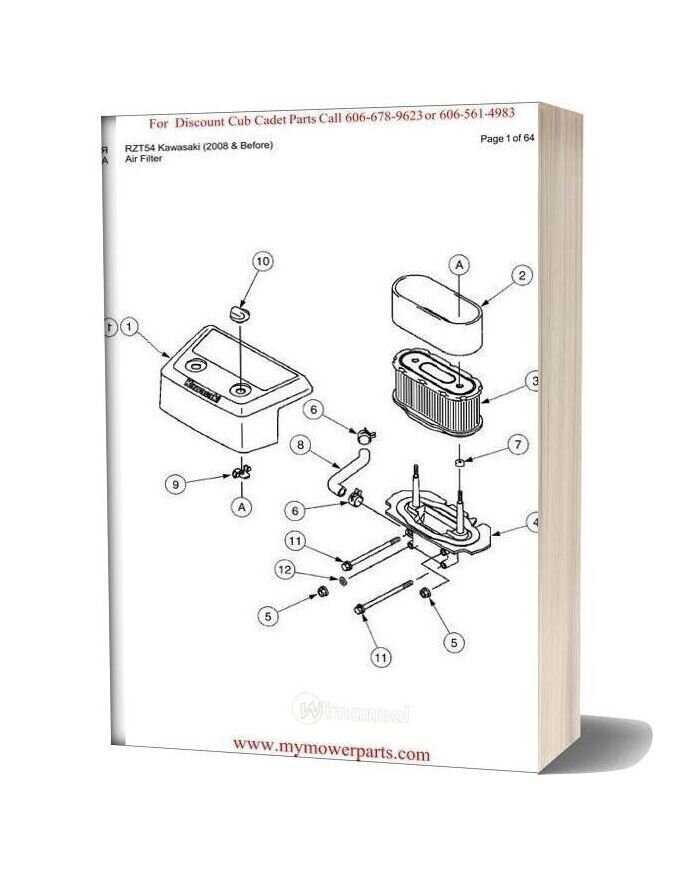

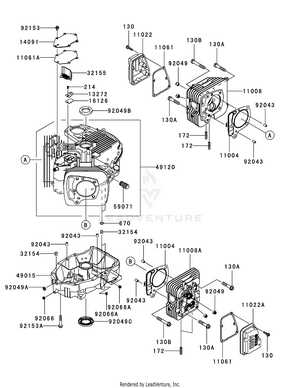

Key Elements of the Engine System

The engine is at the heart of any powerful machine, providing the necessary force to drive all functions. Understanding the core components that make up this system is crucial for effective operation and maintenance. Each part plays a vital role, working together to ensure smooth and efficient performance.

Primary Components

The engine system consists of several key elements that contribute to its overall function. These include the fuel delivery system, which ensures the correct amount of fuel reaches the engine, and the ignition mechanism,

Steering Mechanism and Its Maintenance

The steering system is an essential component that ensures smooth navigation and control of the vehicle. A well-maintained system enhances maneuverability, making it easier to handle different terrains. Over time, components within the steering assembly may wear out, requiring regular checks and timely upkeep to ensure optimal performance.

Proper maintenance involves inspecting key elements of the steering setup, addressing any signs of wear or damage, and ensuring all moving parts function efficiently. Below is a table outlining some of the critical aspects to monitor during routine maintenance

Examining the Drive Belt Configuration

Understanding the arrangement of the drive belt is essential for ensuring smooth and efficient operation of your equipment. This section explores how the belt is positioned and what role it plays in transferring power between different components. By focusing on the layout, you can identify potential areas that may require maintenance or adjustments.

- The belt acts as a link that channels force from the engine to the wheels.

- Proper tension and alignment are crucial for preventing slippage or wear.

- The positioning of pulleys affects the path and movement of the belt.

- Regular inspection helps to avoid disruptions in performance.

Ensuring the correct configuration not only prolongs the life of the belt but also improves overall efficiency. Maintenance routines should include checking the belt for signs of damage, verifying tension, and adjusting components as necessary to keep the system running smoothly.

Blade Engagement and Control System

The mechanism responsible for activating the cutting blades plays a crucial role in the overall functionality of lawn maintenance equipment. This system allows for seamless control over blade engagement, ensuring efficient operation during mowing tasks. Understanding its components and operation can enhance user experience and maintenance practices.

Key Components

- Engagement Lever: This lever allows the operator to easily engage or disengage the blades while in operation.

- Linkage System: A series of rods and pulleys that connect the engagement lever to the blades, translating user input into blade action.

- Blade Spindle: This component houses the blade and allows it to rotate when engaged.

- Safety Switch: An important feature that ensures the blades do not engage unless the operator is in the correct position, enhancing safety during use.

Operating Instructions

- Begin by ensuring the equipment is on a flat surface and the engine is turned off.

- Locate the engagement lever and familiarize yourself with its position.

- To engage the blades, pull the lever upward or forward, depending on the model.

- To disengage, push the lever back to its original position.

- Always check the safety switch before starting to ensure it functions properly.

Transmission System Breakdown

The transmission mechanism plays a crucial role in converting engine power into motion, allowing the vehicle to navigate various terrains efficiently. Understanding the components and their interactions is essential for effective maintenance and troubleshooting.

Key Components of the Transmission

- Gearbox: Responsible for adjusting the speed and torque delivered to the wheels.

- Clutch: Facilitates smooth engagement and disengagement of power from the engine.

- Drive Shaft: Transfers power from the gearbox to the wheels, ensuring optimal movement.

- Torque Converter: Enhances performance by allowing the engine to continue running while the vehicle is stationary.

Maintenance Tips

- Regularly check fluid levels to ensure proper lubrication and cooling.

- Inspect belts and hoses for signs of wear or damage.

- Schedule periodic service to clean filters and replace worn components.

- Pay attention to unusual noises or performance issues that may indicate a problem.

Hydrostatic System Functionality

The hydrostatic system is a crucial component in modern lawn care machines, providing seamless control over movement and speed. By utilizing hydraulic fluid under pressure, this system allows for smooth operation and efficient power transfer, making it an essential feature for both residential and commercial applications. Its design enables operators to achieve precise maneuverability, ensuring optimal performance across various terrains.

Key Components of the Hydrostatic System

This system comprises several integral parts that work in unison to deliver reliable functionality. Each component plays a specific role in ensuring the overall efficiency of the hydrostatic mechanism. Understanding these elements can help users troubleshoot issues and maintain their equipment effectively.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates hydraulic pressure needed for movement. |

| Hydraulic Motor | Converts hydraulic energy back into mechanical energy for propulsion. |

| Hydraulic Fluid | Transfers power and lubricates moving parts within the system. |

| Control Valves | Regulate the flow of hydraulic fluid to control speed and direction. |

Benefits of Hydrostatic Systems

Hydrostatic systems offer numerous advantages, including enhanced control, reduced wear on mechanical components, and improved operator comfort. The ability to adjust speed smoothly without shifting gears allows for a more enjoyable and efficient mowing experience. This technology not only boosts performance but also contributes to the longevity of the machinery, making it a preferred choice for users seeking reliability and ease of use.

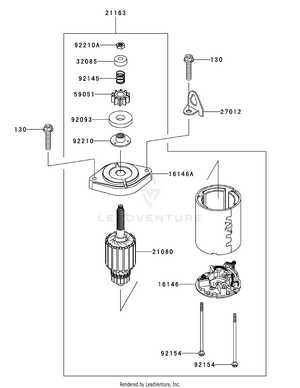

Electrical System Components

The electrical system of a lawn maintenance machine plays a vital role in ensuring its optimal performance and functionality. This network of components works together to provide power, facilitate control, and enable communication between different systems, enhancing the overall user experience.

Key Elements of the Electrical System

- Batteries: These devices store electrical energy and supply it to the various systems as needed, ensuring reliable operation.

- Wiring Harness: A collection of wires and connectors that facilitate the distribution of electrical power throughout the machine.

- Ignition System: This component is essential for starting the engine, converting electrical energy into mechanical energy.

- Fuses: Safety devices designed to protect the electrical circuits by preventing overloads and short circuits.

- Switches: Control elements that enable the operator to turn the electrical systems on or off, affecting various functionalities.

- Relays: Electromechanical devices that act as switches, allowing low-power signals to control high-power circuits.

Functionality and Maintenance

Understanding the role of each component is essential for effective troubleshooting and maintenance. Regular inspections can help identify potential issues before they escalate, ensuring the longevity of the machine. Proper care and attention to the electrical system can greatly enhance performance and reliability.

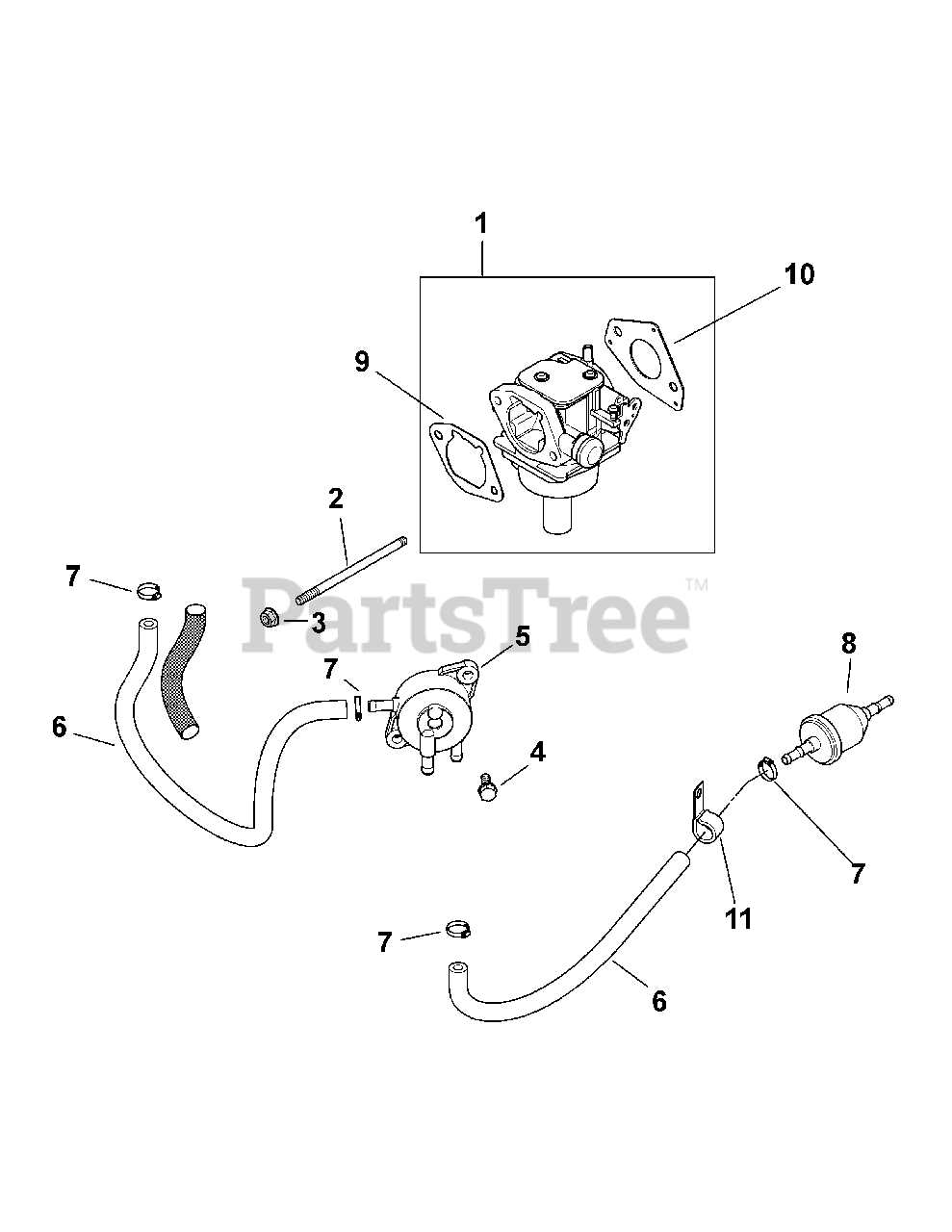

Fuel System Parts and Layout

The fuel delivery mechanism in lawn care equipment is essential for optimal performance and efficiency. Understanding the various components involved in this system can help in maintenance and troubleshooting, ensuring a smooth operation.

- Fuel Tank: The primary reservoir that stores the liquid fuel needed for the engine to operate.

- Fuel Lines: Hoses that transport fuel from the tank to the engine. They must be in good condition to prevent leaks.

- Fuel Filter: A critical component that removes impurities from the fuel before it reaches the engine, protecting it from damage.

- Fuel Pump: This device is responsible for drawing fuel from the tank and delivering it to the engine at the appropriate pressure.

- Carburetor: A mechanism that mixes air and fuel in the correct proportions for combustion in the engine.

- Fuel Shutoff Valve: A valve that allows the operator to stop the flow of fuel, facilitating maintenance and repairs.

Proper arrangement and condition of these components are crucial for the reliability of the equipment. Regular checks and replacements can lead to enhanced efficiency and longevity of the machine.