When maintaining a garden or yard, having the right machine to handle tough tasks is essential. Ensuring that all mechanical elements are in top condition is key to prolonging the life of your equipment. Understanding how the various elements are connected helps to avoid breakdowns and keep the machine running smoothly for years to come.

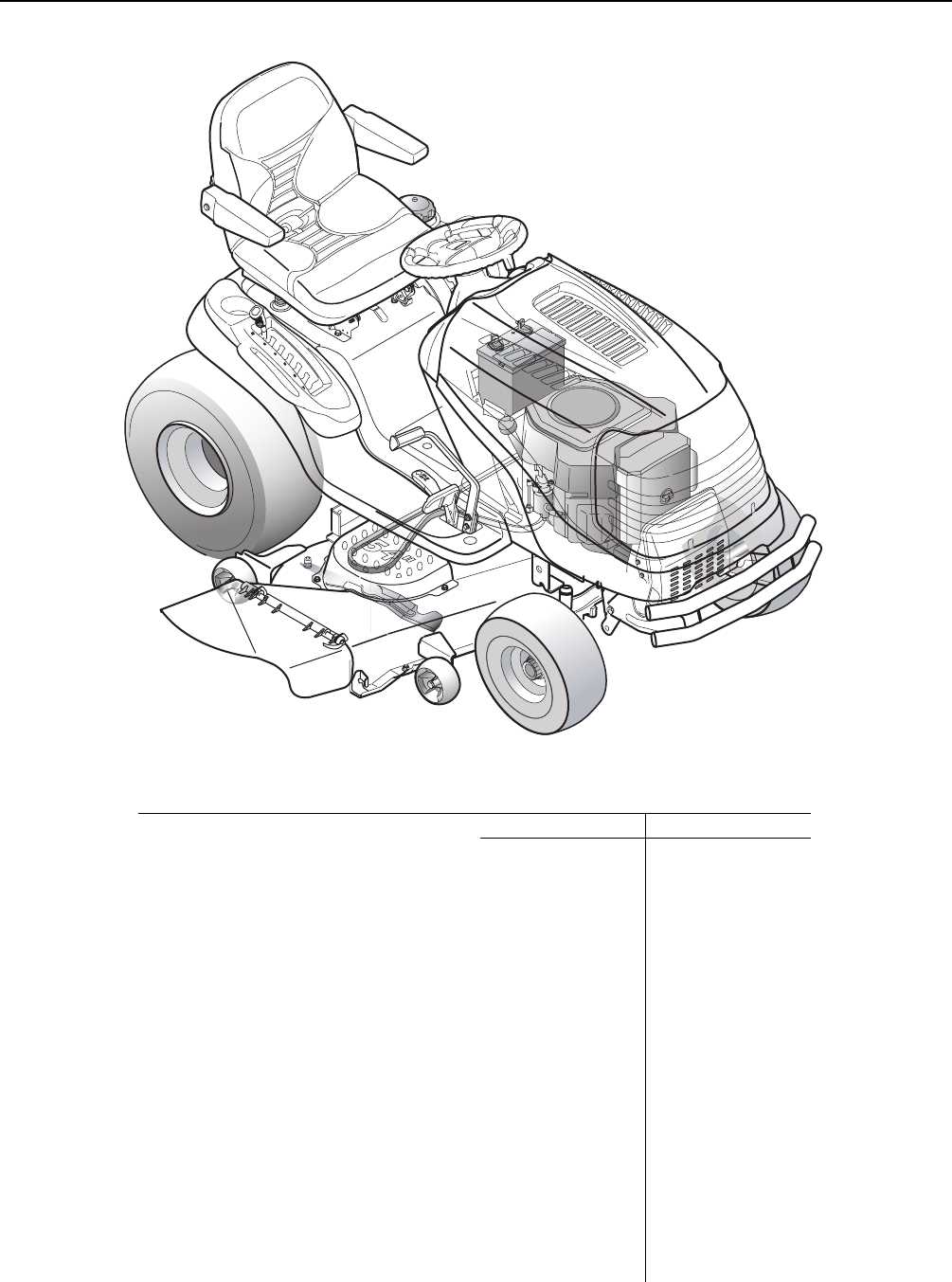

The anatomy of a lawn tractor is complex, with various elements working together to deliver optimal performance. From the powertrain to the cutting mechanism, each component plays a crucial role in ensuring the smooth operation of the machine. Knowing the layout and arrangement of these parts can make maintenance much easier, whether you’re dealing with routine checks or replacements.

In this guide, we’ll walk through the key sections of the machine, breaking down each area to give you a clearer picture of how it functions. By familiarizing yourself with the structure, you can confidently tackle any maintenance challenges that may arise.

Overview of Cub Cadet SLT1554 Components

Understanding the various mechanical elements of a garden tractor is crucial for maintaining its performance and ensuring smooth operation. These components work together to provide efficiency in lawn care, and knowing their roles can help in troubleshooting and regular maintenance.

Engine and Transmission

The engine serves as the powerhouse, driving all essential functions. Paired with the transmission, it controls the machine’s speed and direction. A well-maintained engine ensures reliable performance, while the transmission system guarantees smooth gear transitions.

Steering and Cutting System

The steering mechanism offers precise control, allowing easy maneuvering around obstacles. The cutting system, featuring sharp blades and adjustable deck height, ensures even grass trimming. Regular inspection of these systems can prevent uneven cuts and steering difficulties.

Engine Parts for Cub Cadet SLT1554

The heart of any powerful lawn tractor lies in its robust engine, responsible for delivering the strength and efficiency needed for consistent performance. To maintain peak operation, it is important to understand the components that make up the core of this machine.

- Cylinder Head: This crucial element plays a role in controlling air and fuel flow within the motor.

- Crankshaft: Converts the up-and-down motion of the pistons into rotational force, driving the tractor’s wheels.

- Pistons: Vital for creating the combustion needed to generate power, ensuring smooth engine operation.

- Oil Filter: Keeps the motor clean by trapping dirt and debris, prolonging the life of the equipment.

- Carburetor: Mixes air and fuel in the right pr

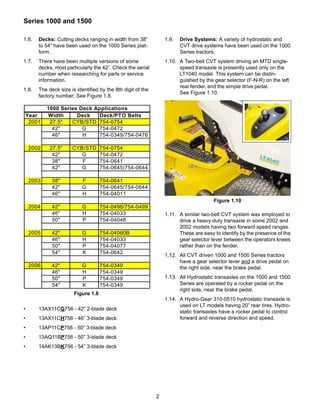

Transmission Assembly Breakdown

The drive mechanism of your machine is a complex system that ensures smooth movement and power distribution. Understanding the individual elements that work together can help in troubleshooting and maintaining the system effectively. Each component plays a specific role in translating energy into motion, and knowing how they interact provides insight into the overall functionality.

Main Components

- Gearbox: Responsible for adjusting the torque and speed during operation.

- Clutch: Engages or disengages power from the motor to the wheels.

- Axles: Serve as the main shafts that transfer rotation to the wheels.

Common Issues and Maintenance

- Slipping: Often caused by worn belts or misaligned gears, which can reduce efficiency.

SLT1554 Deck and Mower Blades

The cutting deck and blades are key components that ensure efficient mowing, delivering a smooth and even cut across your lawn. Understanding their configuration, maintenance, and replacement will help prolong the lifespan of your equipment while keeping performance optimal.

- The deck houses the blades and is designed to channel grass clippings effectively for a clean finish.

- Mower blades, responsible for the actual cutting, require regular sharpening to maintain their efficiency.

- Over time, blades may need to be replaced due to wear or damage from obstacles like rocks or branches.

- Proper blade alignment and secure attachment are essential for preventing uneven cuts or potential damage to the machine.

Routine inspection and maintenance of these parts ensure the smooth operation of your lawn care tool, minimizing the risk of costly repairs and downtime.

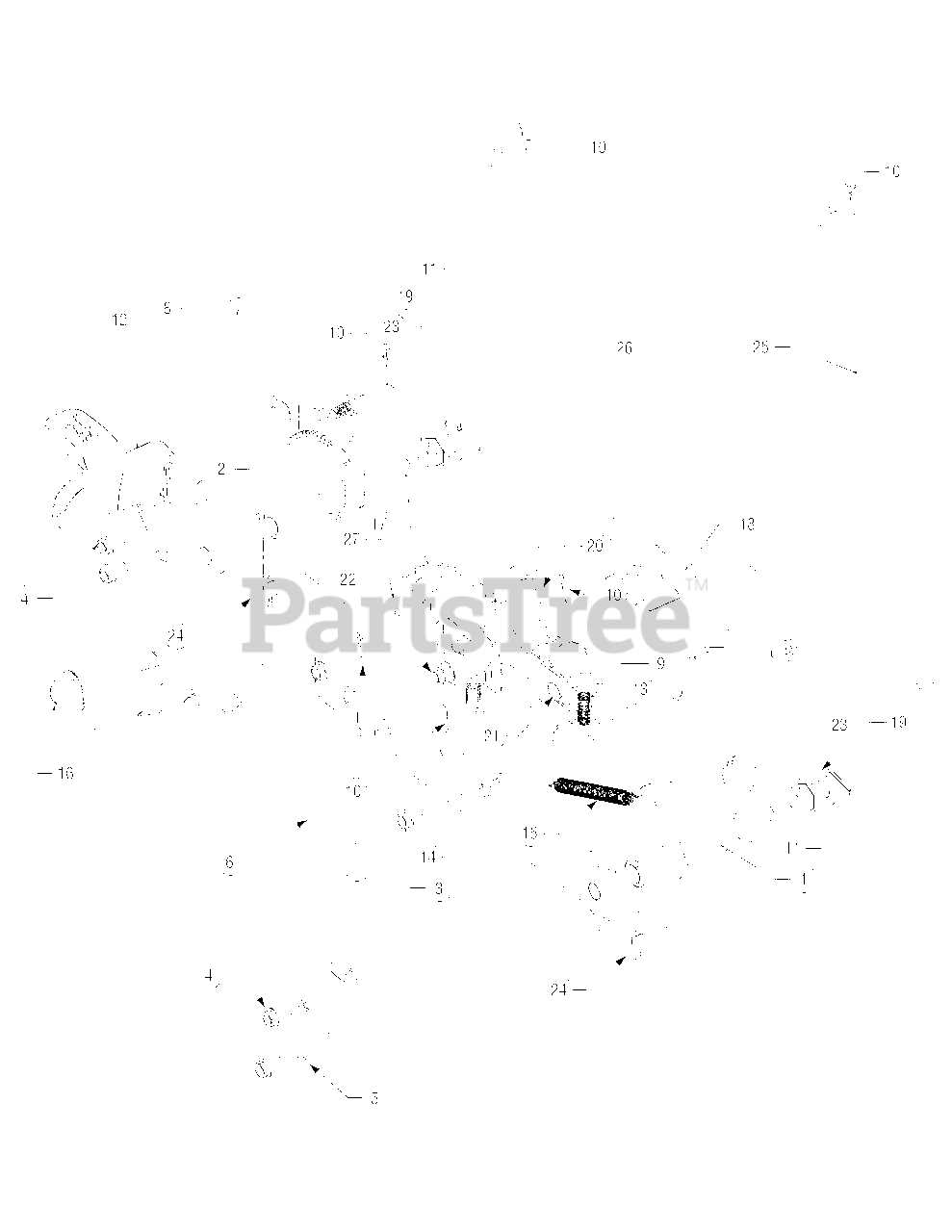

Steering System and Front Axle Diagram

The steering mechanism and front axle play a crucial role in ensuring smooth handling and maneuverability of the machine. Understanding how these components interact allows you to maintain better control and stability, particularly when navigating challenging terrain. Both systems work together to deliver precision and strength to the vehicle’s movement.

The front axle assembly is designed to bear the load of the vehicle while also supporting the steering motion. The linkage connects various components, ensuring fluid movement from the steering wheel to the wheels. Proper alignment and condition of these elements are vital for safe and responsive steering.

Over time, wear can affect these parts, leading to decreased performance or difficulty in controlling the vehicle. Regular inspections and maintenance help prevent issues and ensure that the steering system remains reliable and efficient.

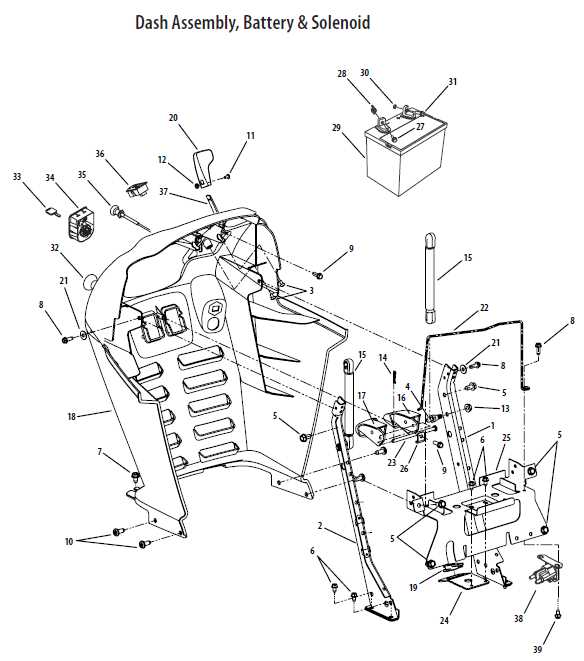

Understanding the Electrical Wiring Layout

The electrical system plays a crucial role in ensuring smooth operation and functionality. Knowing how different connections are organized and linked can help in identifying potential issues and maintaining the equipment effectively. This section will walk you through the key elements of the wiring layout and provide an overview of the main components involved.

- Wiring Paths: The routes for electrical connections that interlink various components, ensuring seamless communication between different systems.

- Key Connections: Understanding which terminals are critical to the performance of the system can aid in troubleshooting and diagnostics.

- Grounding Points: These locations are essential for safety, preventing electrical faults by allowing excess current to dissipate.

- Power Sources: The primary energy feeds that fuel the machinery

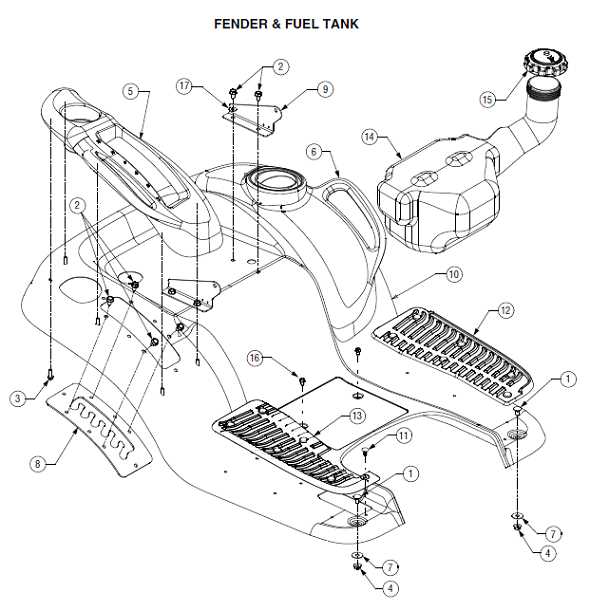

Fuel System Components and Layout

The fuel system is designed to efficiently deliver the necessary energy to the engine, ensuring smooth operation and optimal performance. By examining its various elements and the arrangement, one can better understand how fuel is processed from the tank to the engine. This system includes multiple components that work together to regulate the flow and maintain the proper mixture for combustion.

Component Function Fuel Tank Stores the fuel and supplies it to the engine when required. Fuel Lines Transports fuel from the tank to other parts of the system. Fuel Filter Removes impurities from the fuel before it reaches the engine. Fuel Pump Brake Mechanism and Pedal Assembly

The braking system is essential for ensuring safety and control during operation. It consists of various components that work together to provide effective stopping power. Understanding the functionality of this mechanism is crucial for maintenance and repairs.

Components Overview

The assembly typically includes a pedal, linkage, and actuator. The pedal is the primary interface for the operator, allowing for easy engagement and disengagement of the brakes. The linkage transmits the force applied on the pedal to the actuator, which in turn activates the braking mechanism.

Maintenance and Adjustments

Regular inspection of the brake system is vital to ensure optimal performance. Check for any signs of wear on the pedal and linkage, as well as ensuring proper alignment. Making necessary adjustments can enhance responsiveness and prolong the life of the braking components.

Seat, Frame, and Body Components

This section focuses on the essential elements that make up the structure and seating area of the riding machine. Understanding the arrangement and function of these components is crucial for maintenance and repair, ensuring optimal performance and comfort during operation.

Overview of Components

The assembly includes a robust frame that supports the entire unit, along with a comfortable seat designed for stability and ease of use. Each element plays a vital role in the overall functionality, contributing to both safety and efficiency.

Table of Key Components

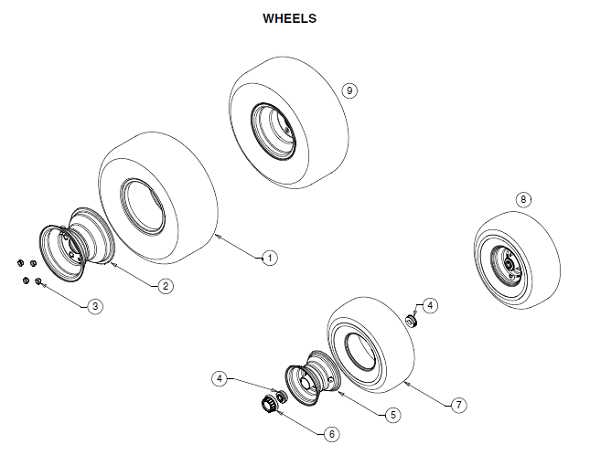

Component Description Function Seat Ergonomically designed to provide comfort during extended use. Supports the operator and enhances driving comfort. Frame Sturdy construction that serves as the backbone of the machine. Holds all other components in place and absorbs impact. Body Shell A protective covering that houses various mechanisms. Protects internal components from debris and weather elements. Tires, Wheels, and Suspension System

The interaction between tires, wheels, and the suspension framework plays a vital role in the overall performance and comfort of any outdoor machinery. These components work together to ensure stability, control, and a smooth ride across various terrains. Understanding their functionality is essential for maintaining optimal performance and enhancing the longevity of the equipment.

Tires serve as the primary contact point with the ground, influencing traction and maneuverability. The selection of appropriate tire types can significantly impact the handling and efficiency of the machine, particularly when traversing uneven surfaces. Different tread patterns and rubber compounds are designed to suit specific environments, whether it be soft soil, hard pavement, or slippery grass.

Wheels contribute not only to the aesthetics but also to the functionality of the vehicle. Their construction, material, and size affect how the machinery responds to steering inputs and weight distribution. Proper wheel alignment and maintenance are crucial to avoid uneven wear and ensure safe operation.

The suspension system connects the wheels to the main chassis, absorbing shocks and maintaining ground contact. A well-designed suspension system enhances stability, providing a smoother ride while reducing strain on the machinery’s components. Regular inspection and adjustment of this system can prevent premature wear and improve overall performance.

Exploring the Cub Cadet SLT1554 Controls

The controls of a lawn mower play a crucial role in its overall functionality and user experience. Understanding how each component operates can enhance your ability to effectively manage your mowing tasks. This section delves into the essential controls, highlighting their functions and the convenience they provide during operation.

- Steering Wheel: The steering wheel is the primary interface for navigation. It allows users to easily maneuver the machine around obstacles and navigate through tight spaces.

- Throttle Control: This lever regulates the engine speed, giving you the flexibility to adjust power based on the terrain and task requirements. A proper setting ensures optimal performance.

- Blade Engagement Switch: Activating this switch engages the cutting blades, allowing for precise lawn maintenance. It typically features a safety mechanism to prevent accidental operation.

- Speed Control Lever: This lever enables users to set their desired speed, offering a range of options from slow maneuvering to faster travel for larger areas.

- Ignition Key: The ignition system ensures that the machine starts securely. Using the correct key prevents unauthorized operation, adding an extra layer of safety.

Each control element is designed to provide ease of use and enhance the overall efficiency of the machine. Familiarity with these components allows for a smoother operation, ensuring that mowing tasks are completed effectively.