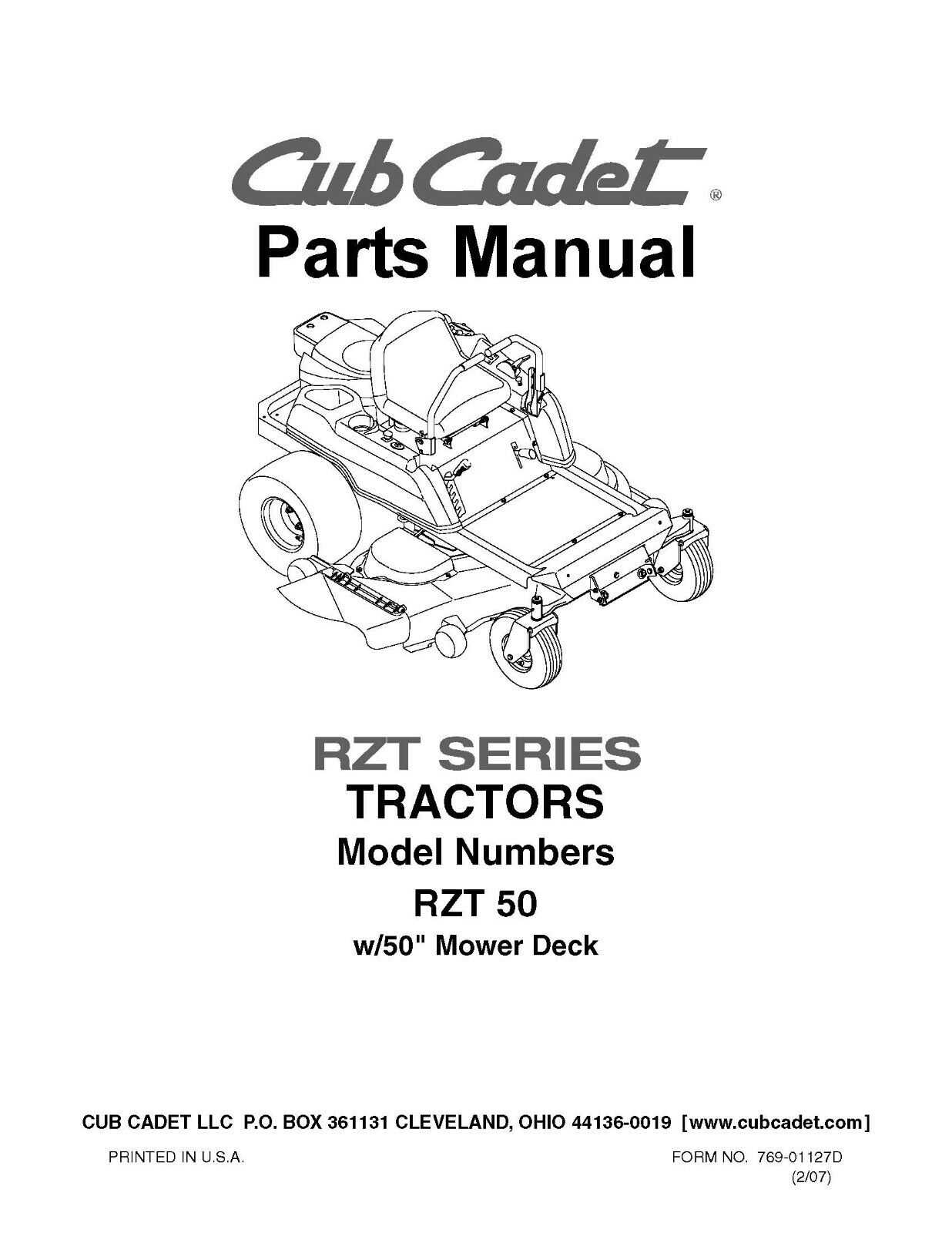

Understanding the various elements that make up modern lawn care equipment is crucial for anyone looking to maintain or repair their machinery. Whether you’re a professional or a home gardener, knowing the key mechanical features and how they interact will help you keep your equipment in top working condition.

This guide delves into the individual mechanisms that contribute to the efficient operation of mowing machines designed for sharp turns. By breaking down each segment and explaining its role, we aim to provide you with a thorough understanding of what makes these machines perform so effectively.

Each section will cover a different part of the system, highlighting its importance and giving insights into common issues and maintenance tips. This way, you’ll be well-equipped to identify and address any problems before they become larger concerns.

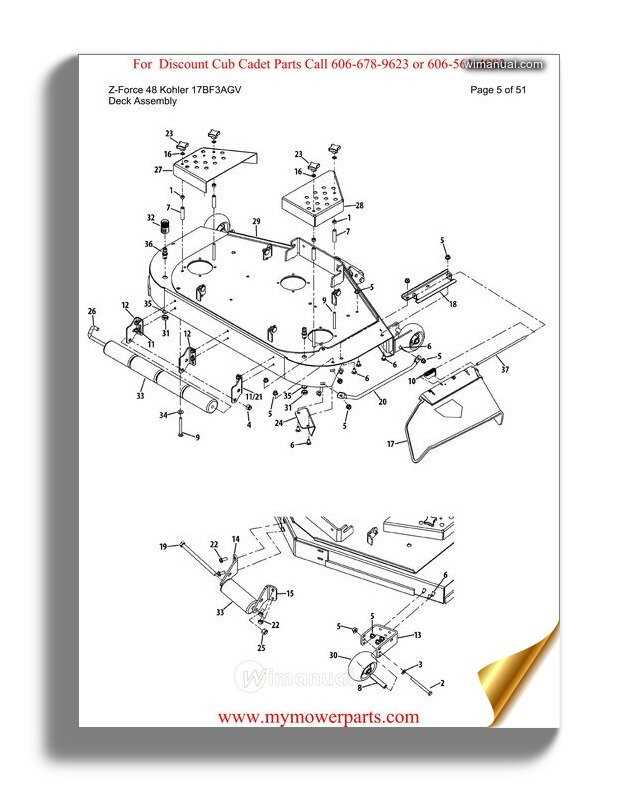

Cub Cadet Zero-Turn Parts Overview

This section provides an in-depth look at essential elements and components that play a vital role in ensuring the functionality and efficiency of a zero-radius mower. Understanding these different mechanical elements will help maintain optimal performance and extend the machine’s life span.

Key Components

- Engine: The powerhouse driving the system, ensuring smooth operation and sufficient power output.

- Blades: Precision cutting instruments designed to handle various types of grass and terrain with ease.

- Transmission: A crucial mechanism responsible for controlling the speed and maneuverability of the machine.

Additional Elements

- Steering System: Provides the control needed for sharp turns and efficient mowing patterns.

Key Components of Zero-Turn Mowers

A lawn mower designed for optimal maneuverability and efficiency consists of several critical elements that work together to deliver precise control and cutting performance. Understanding these components can help in maintaining and maximizing the functionality of your equipment.

- Engine: The heart of the mower, providing the necessary power to drive the cutting blades and wheels. A reliable engine ensures smooth operation and long-lasting performance.

- Hydraulic System: This system is responsible for controlling the movement of the mower, allowing for precise steering and control. It’s essential for achieving the agility these machines are known for.

- Cutter Deck: The part of the machine where the blades are housed. The deck’s width determines how much grass

Steering System and Its Importance

The steering system plays a crucial role in the overall operation of any machine, as it directly influences maneuverability and control. Understanding how this system works and its components is essential for maintaining efficiency and safety. Whether for everyday use or more demanding tasks, a well-functioning steering mechanism ensures smooth performance.

Here are some of the key benefits of a reliable steering system:

- Improved precision: A proper steering setup allows for accurate turns and smooth directional control.

- Enhanced safety: A responsive system minimizes the risk of accidents, especially in tight or complex environments.

- Ease of operation: With an efficient steering mechanism, operators experience less fatigue during extended use.

Maintaining the steering

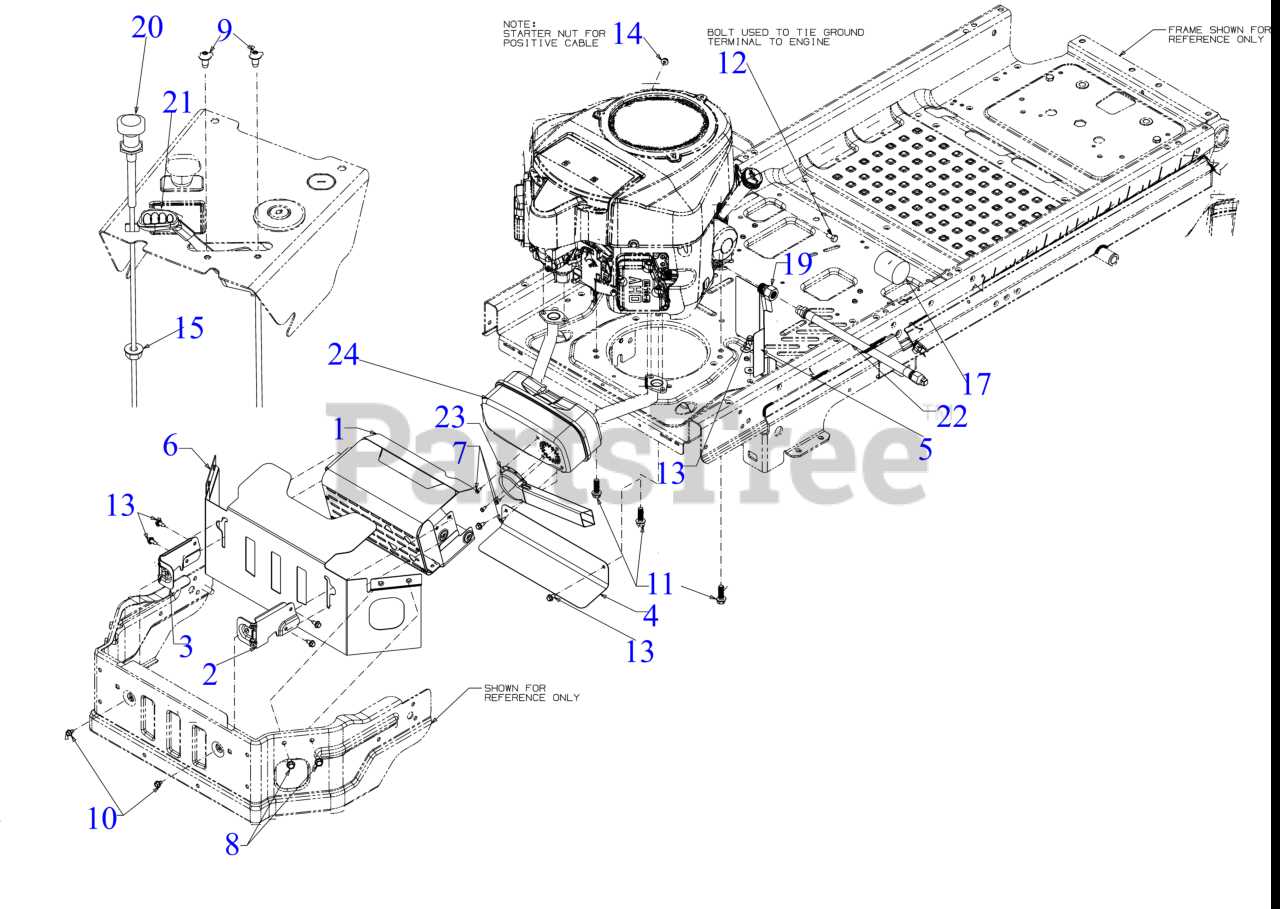

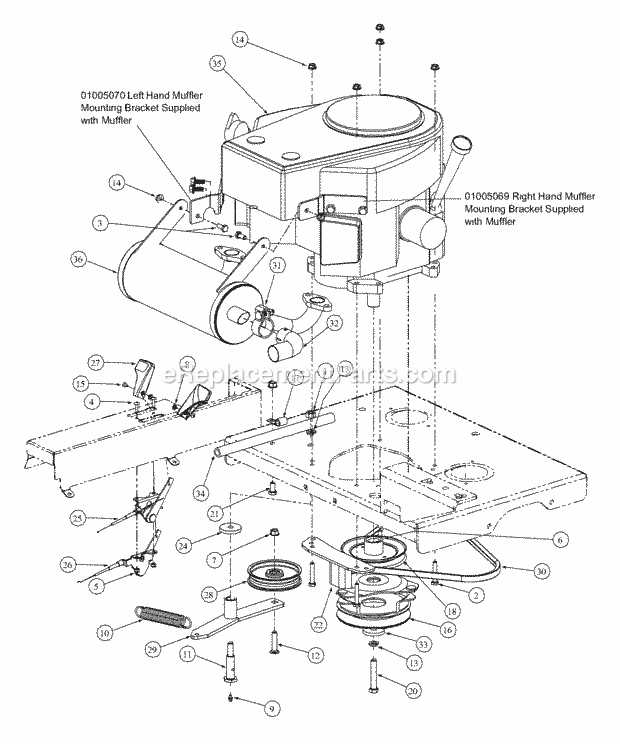

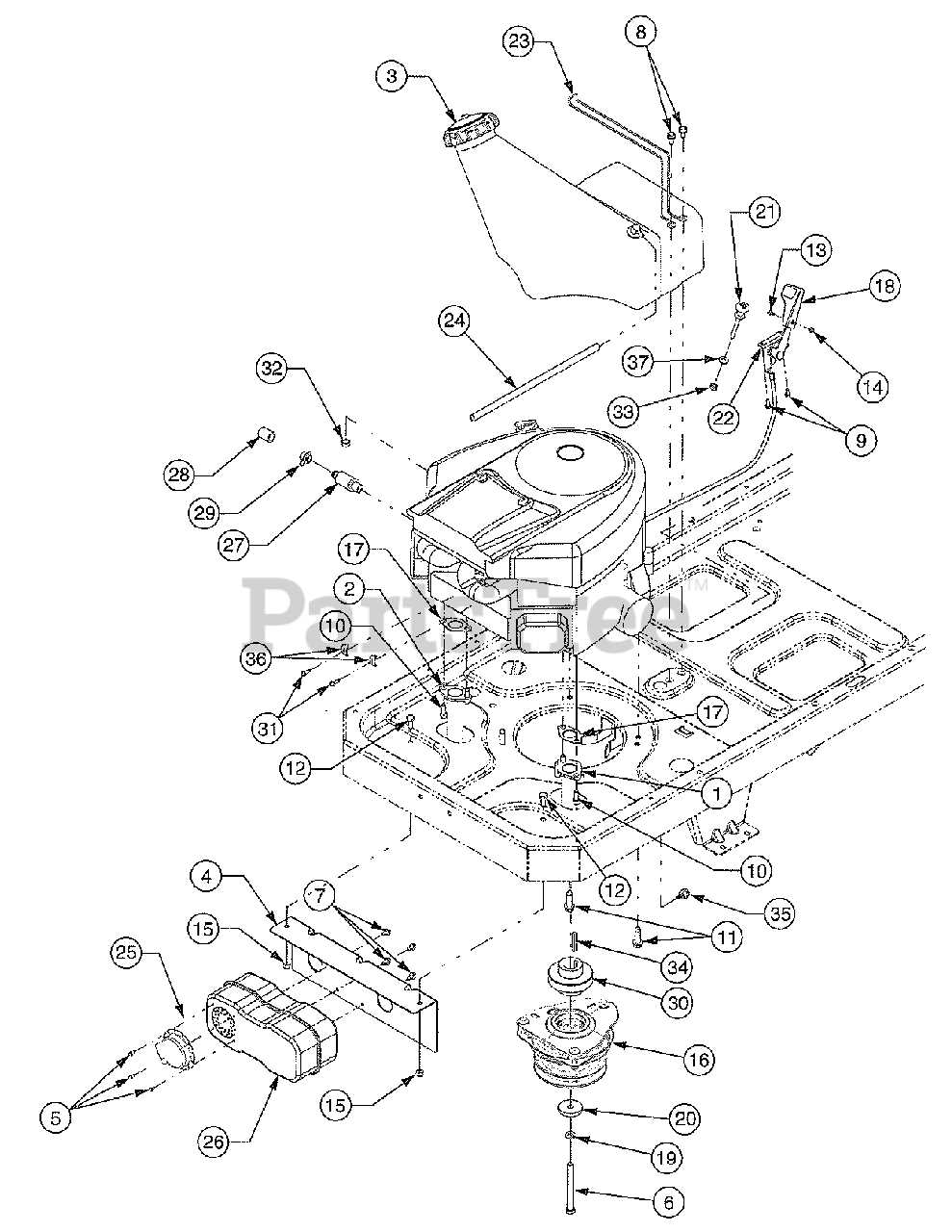

Understanding the Engine Setup

The engine is the core component of any riding mower, providing the power needed for various operations. A solid understanding of how the engine is configured helps in maintaining its efficiency and extending its lifespan. By knowing the layout of key engine components, you can easily perform regular maintenance and address issues before they become serious.

Main Engine Components

The engine consists of several crucial parts that work together to deliver smooth operation. The air filter ensures clean airflow, preventing debris from entering the system. The carburetor manages the fuel-to-air ratio, while the spark plug ignites the mixture for combustion. Keeping these components in good condition is essential for optimal engine performance.

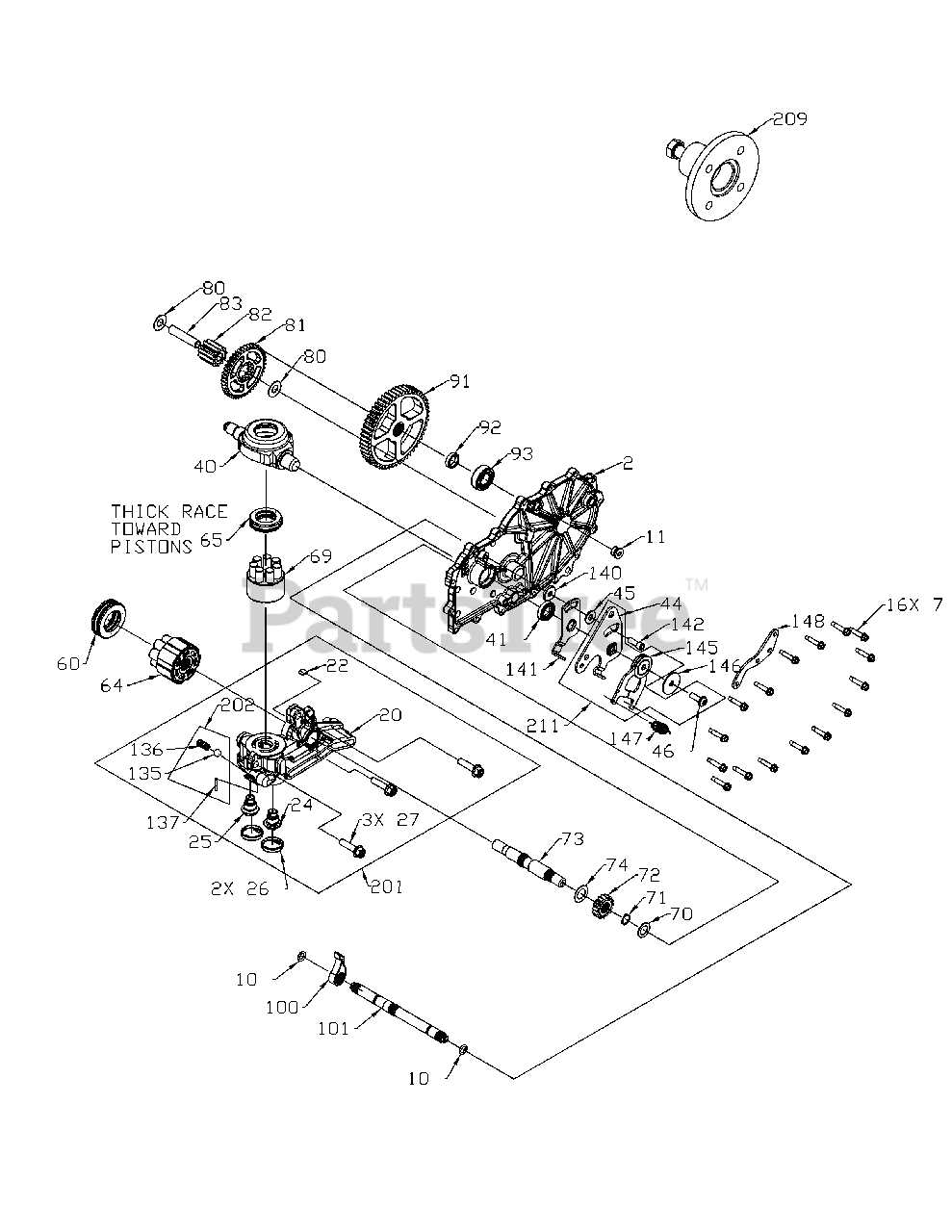

Hydraulic System Explained

The hydraulic system is an essential component of modern machinery, enabling smooth and efficient operation. By using pressurized fluid to transmit power, it provides controlled force to various mechanical functions. Understanding how this system works is key to maintaining optimal performance and ensuring long-lasting reliability.

Main Components of a Hydraulic System

At the core of any hydraulic setup are three critical elements: the pump, which generates pressure, the valves that control flow, and the actuators that convert hydraulic energy into mechanical motion. These components work together to regulate fluid movement, creating the power needed to perform specific tasks efficiently.

Fluid Dynamics and Control

The fluid within the system plays a vital role in transferring energy. This movement is carefully controlled through

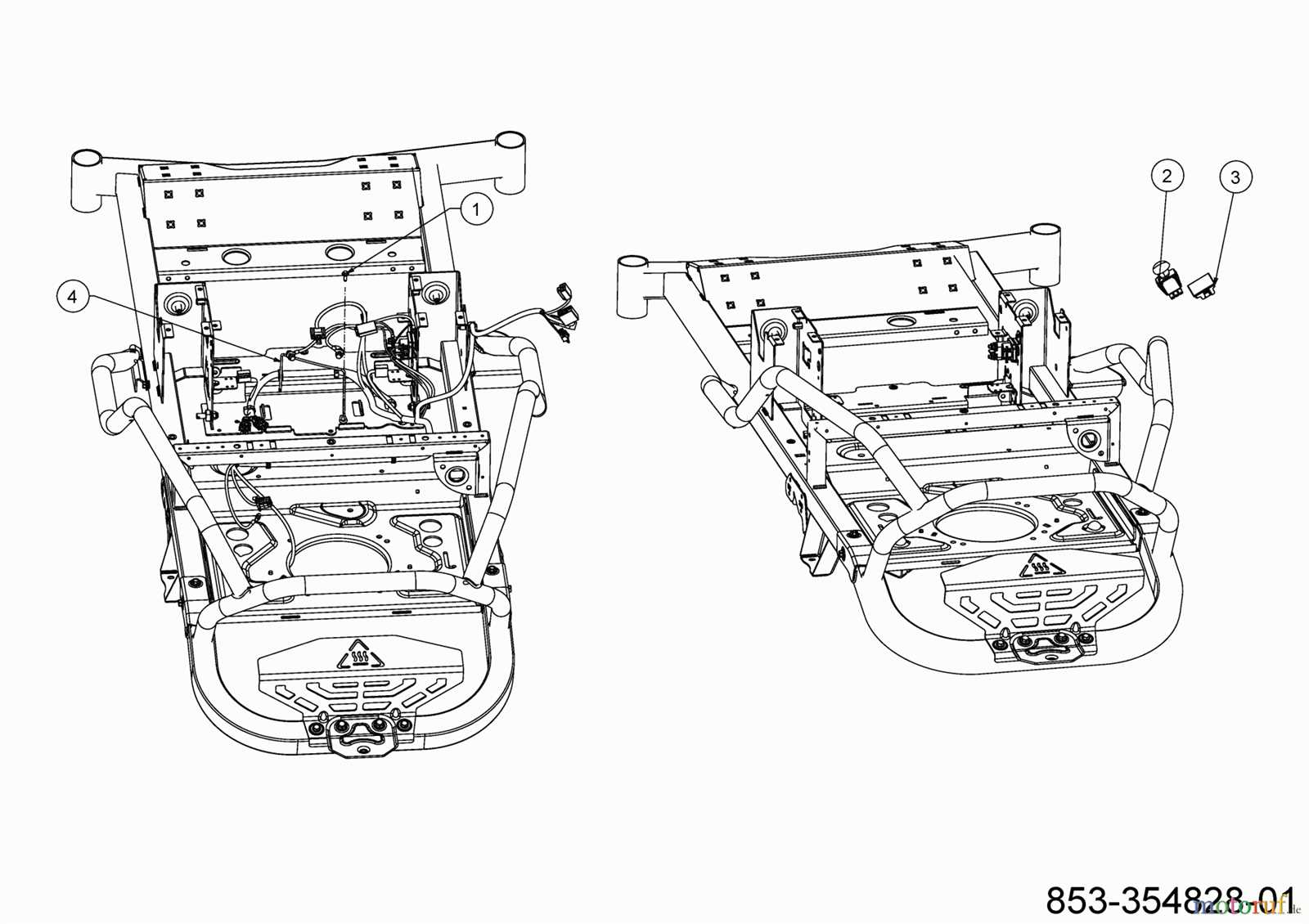

Mower Deck and Blade Mechanism

The mower deck and blade assembly play a crucial role in the performance and efficiency of a lawn care machine. Understanding their design and functionality helps users maintain their equipment effectively and achieve optimal cutting results.

The deck serves as the housing for the blades, providing a sturdy platform that supports the cutting mechanism. It is typically constructed from durable materials to withstand the stresses of operation while ensuring a clean cut. Proper deck height adjustment is essential for achieving desired grass length and preventing scalping.

The blades, which are often made of high-strength steel, rotate at high speeds to slice through grass with precision. The cutting action is influenced by blade sharpness, pitch, and the configuration within the deck. Regular maintenance, including sharpening and replacement, is necessary to keep the blades operating efficiently.

Furthermore, the mechanism may include a belt-driven system that connects the engine to the blades, allowing for seamless power transfer. Understanding this system enables users to troubleshoot issues related to cutting performance and noise, ensuring the machine operates at its best.

Maintenance Tips for Drive Belts

Proper care of drive belts is essential for the efficient operation of your equipment. Regular maintenance can help extend the lifespan of these components and prevent costly repairs. Understanding how to check, adjust, and replace belts will ensure optimal performance and reliability.

Regular Inspection

Routine inspections are crucial for identifying wear and tear on drive belts. Look for fraying, cracking, or any signs of damage. Ensure the belts are properly tensioned and aligned, as misalignment can lead to premature failure. Checking for debris or obstructions in the drive system is also important to maintain smooth operation.

Cleaning and Lubrication

Keeping the drive belts clean is vital for preventing slippage and extending their lifespan. Use a soft brush or cloth to remove dirt and debris. Additionally, avoid using lubricants on the belts, as this can cause slippage and reduce traction.

Maintenance Task Frequency Notes Inspect for wear Every 25 hours Look for cracks or fraying Clean belts Monthly Use a soft brush Check tension Every 50 hours Adjust as necessary Replace worn belts As needed Follow manufacturer’s guidelines Role of the Electric Clutch in Operation

The electric clutch plays a crucial role in the functionality of lawn maintenance equipment. It serves as an essential component that enables the operator to engage or disengage the cutting mechanism efficiently. This feature enhances the overall performance of the machinery and ensures optimal cutting results.

When activated, the electric clutch engages the blades, allowing them to spin at high speeds, effectively trimming grass and other vegetation. This mechanism not only improves efficiency but also provides greater control over the cutting process. Furthermore, the ability to easily disengage the clutch when necessary helps in maneuvering the equipment safely around obstacles.

In summary, the electric clutch is vital for seamless operation, contributing to the machine’s versatility and user-friendliness. Proper maintenance of this component ensures longevity and reliable performance, making it an integral part of any effective lawn care strategy.

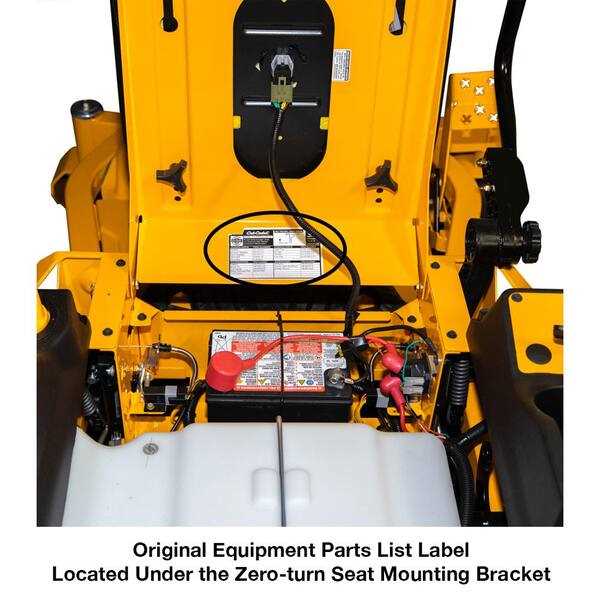

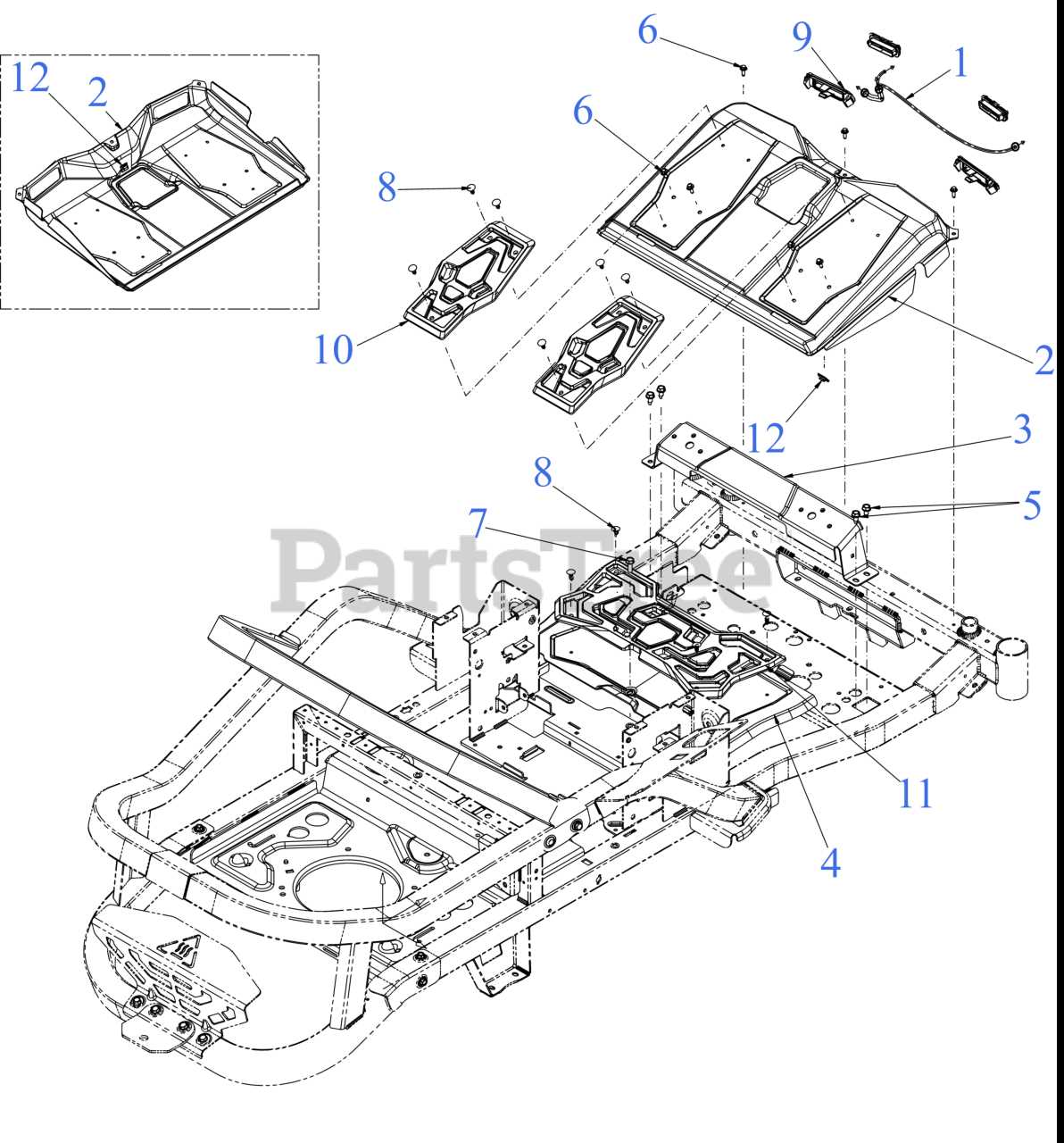

Seat and Safety Features Guide

The comfort and protection of the operator are paramount when using any type of lawn maintenance equipment. This section provides an overview of essential seating and safety elements designed to enhance the user experience while ensuring safety during operation.

Ergonomic Seat Design: A well-designed seat contributes significantly to operator comfort. It should provide ample cushioning and support to reduce fatigue during extended use. Additionally, adjustable seating can accommodate various user heights and preferences, ensuring optimal positioning for better control.

Safety Belts: Safety belts are crucial for preventing accidents. They secure the operator in place, minimizing the risk of injury during unexpected movements. Users should always ensure that the safety belt is fastened before starting the equipment.

Operator Presence Control: This feature ensures that the machine will not operate unless the operator is seated. It automatically stops the blades when the operator leaves the seat, preventing unintended accidents and enhancing safety.

Rollover Protection System (ROPS): A ROPS is a vital safety feature that helps protect the operator in case of a rollover. This structure provides additional support and minimizes injury risk during unforeseen events.

Understanding and utilizing these features not only enhances the overall operation experience but also significantly increases safety during usage. Regular checks and maintenance of these elements are essential for optimal performance and safety assurance.

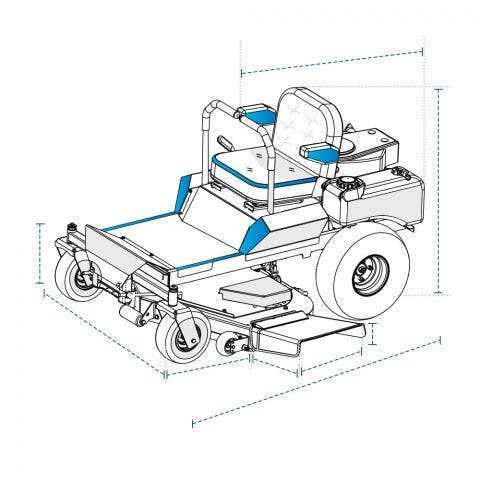

Wheels and Tire Specifications

This section delves into the crucial elements concerning the wheels and tires of your equipment. Understanding the specifications and characteristics of these components is essential for optimal performance and longevity. Proper maintenance and selection ensure the machine operates effectively in various terrains.

Wheel Dimensions

The dimensions of the wheels play a significant role in the handling and stability of the machine. Generally, wheel sizes can vary, influencing traction and maneuverability. It is vital to refer to the specific measurements recommended by the manufacturer to maintain safety and functionality.

Tire Types and Features

Tires are available in various types, each designed for specific conditions. For example, turf tires provide excellent grip on grassy areas while reducing damage to the surface. All-terrain tires are suitable for rugged terrains, offering enhanced durability and traction. Regular inspection for wear and proper inflation is critical to ensure performance and safety.

Fuel System Components Breakdown

The efficiency of any outdoor equipment relies heavily on its fuel system. Understanding the various elements that constitute this system can help ensure optimal performance and longevity. In this section, we will explore the essential components that facilitate fuel delivery and management, highlighting their functions and significance.

Key Components

- Fuel Tank: The primary reservoir where fuel is stored before being transported to the engine.

- Fuel Pump: This device is responsible for moving fuel from the tank to the engine, ensuring a steady supply during operation.

- Fuel Filter: A crucial component that removes impurities and contaminants from the fuel, preventing damage to the engine.

- Fuel Lines: These tubes connect the fuel tank to the pump and the pump to the engine, allowing for seamless fuel flow.

- Carburetor: This part mixes air and fuel in the correct ratio for combustion, playing a key role in engine performance.

Maintenance Tips

- Regularly check and replace the fuel filter to maintain fuel quality.

- Inspect fuel lines for any leaks or damage that may disrupt flow.

- Ensure the fuel tank is clean and free of debris to avoid contamination.

- Keep the carburetor adjusted properly for efficient fuel-air mixture.

By understanding these components and maintaining them effectively, users can enhance the reliability and performance of their equipment, ensuring a smoother operation and prolonged service life.

Electrical System and Battery Functions

The electrical framework of a mower is crucial for its operation, ensuring all components work harmoniously. This system is responsible for powering the ignition, lights, and various electronic features that enhance user experience and functionality. A reliable power source is essential for starting the engine and maintaining its performance.

Battery specifications play a vital role in the mower’s functionality. A well-maintained battery ensures that all electrical systems operate efficiently, providing the necessary energy for various tasks. Proper care and timely replacement of the battery are essential to avoid potential operational issues.

Understanding the connections and layout of the electrical system can assist users in troubleshooting any malfunctions. Familiarity with the components and their functions can lead to more effective maintenance and improved longevity of the equipment.

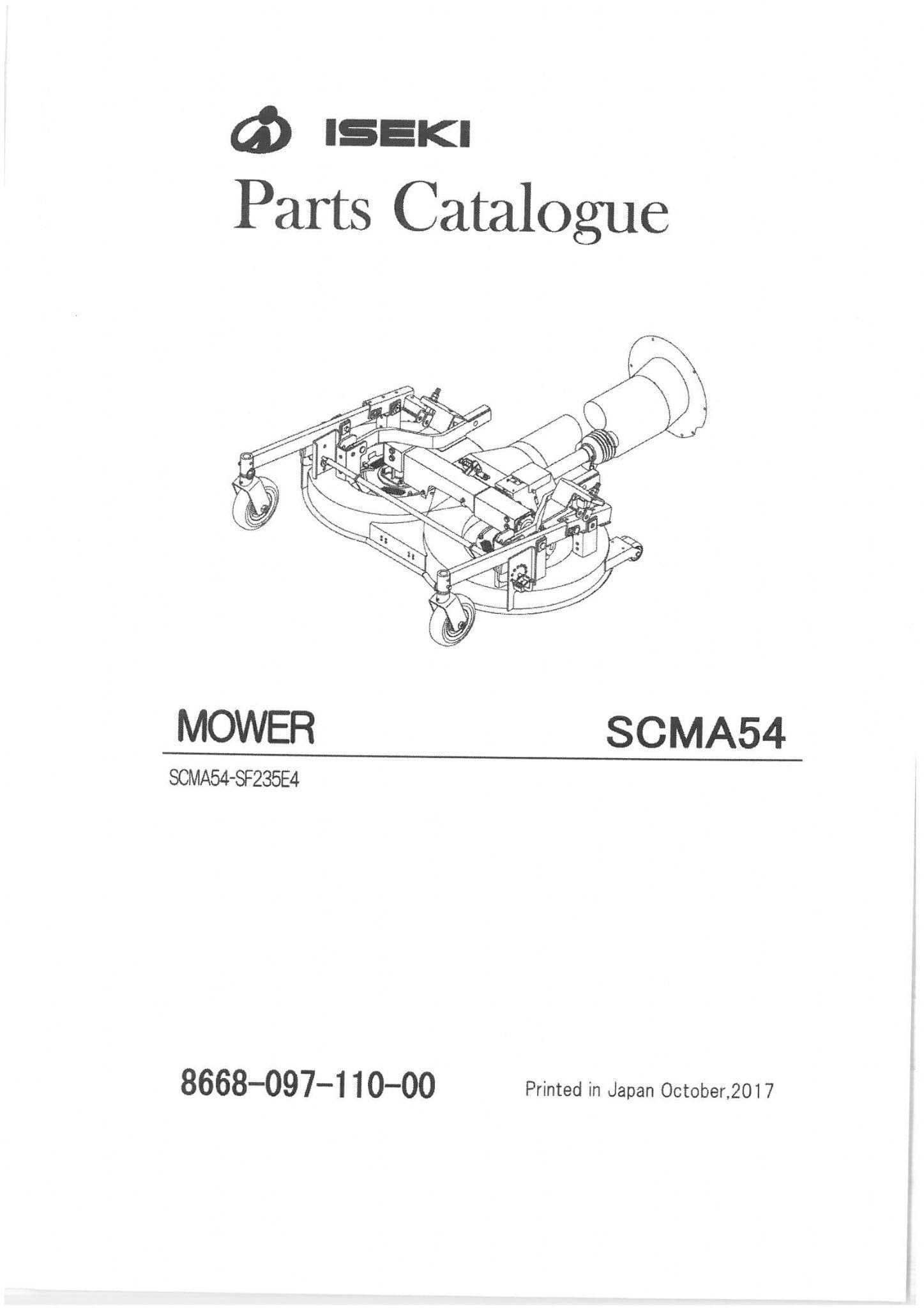

How to Identify and Replace Parts

Understanding how to recognize and substitute components in your machinery is essential for maintaining optimal performance. Proper identification ensures that you choose the right replacements, which can enhance efficiency and prolong the lifespan of your equipment. This section will guide you through the process of pinpointing necessary elements and executing successful replacements.

Recognizing Components

To effectively identify the various components, start by consulting the user manual that accompanies your machine. This manual typically contains detailed illustrations and descriptions of each part, making it easier to recognize them in your equipment. Additionally, take note of any serial numbers or model specifications, as these will help in sourcing the correct replacements from suppliers.

Replacing Parts

Once you have identified the components that require replacement, the next step is to proceed with the installation. Gather the necessary tools, such as wrenches and screwdrivers, to facilitate the process. Carefully remove the old component, ensuring not to damage surrounding parts. When installing the new piece, follow the instructions provided in the manual, and double-check that all connections are secure to guarantee proper functionality.