Maintaining and repairing machinery requires a clear understanding of its key elements. Every mechanical system consists of interconnected parts that need regular attention to ensure smooth operation. Whether you’re performing routine maintenance or addressing a specific issue, recognizing how various elements work together is crucial.

Detailed visual aids can greatly simplify this process. When each component is visually represented, it becomes easier to identify areas that require attention. From the engine to the smallest mechanisms, seeing how all elements are arranged offers valuable insight for anyone working on repairs.

For those handling such machinery, it’s essential to have a clear reference that outlines the arrangement of different elements. This not only enhances efficiency but also reduces the likelihood of mistakes, ensuring your machine functions at its best.

Understanding the LTX 1040 Mower Components

Exploring the key elements of a lawn machine helps to ensure optimal performance and longevity. Each part of the mower plays a specific role in making sure it operates smoothly, and knowing how these parts interact is essential for proper maintenance and repair.

Engine and Drive System

The engine is the heart of the mower, providing the necessary power to cut grass efficiently. Coupled with the drive system, it ensures the wheels rotate properly, allowing the machine to move across various terrains. Regular upkeep of the engine and drive system is critical for maintaining strong and reliable operation.

- Engine: Generates power for all other components.

- Drive System: Transfers power to the wheels, enabling movement.

Cutting and Blades Mechanism

The cutting system is responsible for

Exploring the Blade Assembly

The blade assembly plays a crucial role in the performance of any lawn mower. Understanding the components and how they function together is essential for maintaining efficient operation. This section will guide you through the main elements of the blade system, offering insights into their purpose and how to ensure they remain in optimal condition.

Main Components of the Blade Assembly

- Blades: Responsible for cutting grass evenly, the blades need regular sharpening to ensure a clean cut.

- Blade Spindle: This mechanism connects the blade to the motor, ensuring smooth rotation and proper cutting force.

- Deck: The platform housing the blade system, protecting both the blade and the operator during use.

Maintenance Tips for Longevity

- Regularly inspect the blade for wear and tear, sharpening or replacing as necessary.

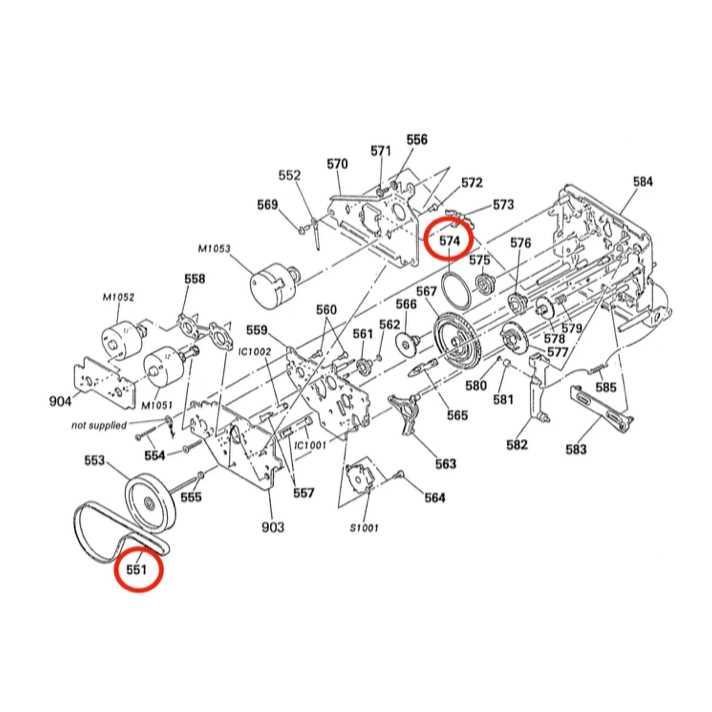

Identifying Key Parts of the Drive System

The drive system is a crucial component that ensures the smooth movement and operation of machinery. It consists of several interconnected elements that work together to transfer power from the engine to the wheels, allowing efficient control and maneuverability. Understanding these components is essential for maintaining the overall functionality and addressing any mechanical issues that may arise.

Transmission: The transmission is responsible for regulating the power and speed, ensuring that the machine operates at the desired pace. It adjusts the flow of energy from the engine to the drive system.

Drive Belt: The drive belt plays a critical role in connecting the engine to the transmission. Its purpose is to transfer power efficiently, making it an essential element for the system’s functionality.

Axle and Wheels: The axle supports the wheels, allowing the machine to move forward or backward. Together with the transmission and belt, it ensures smooth movement across different terrains.

Clutch Mechanism: The

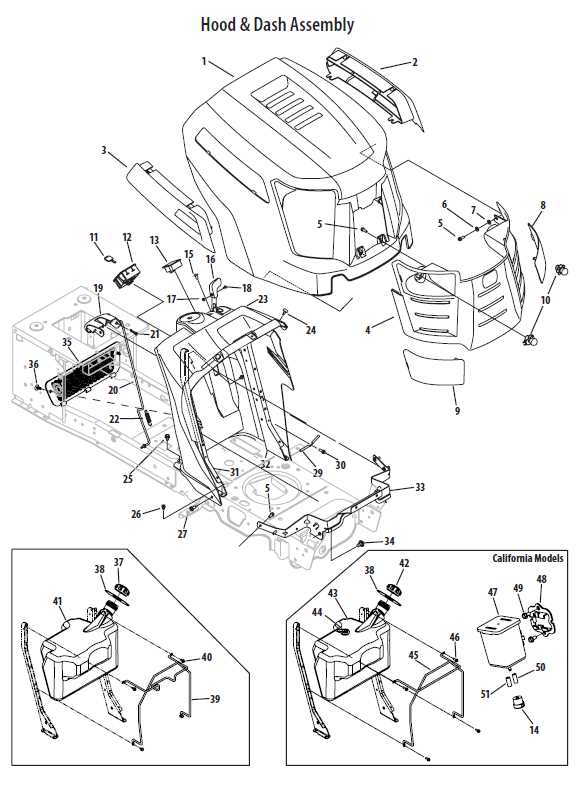

How the Deck Lift Mechanism Works

The deck lift system is designed to adjust the height of the cutting platform, allowing for better control over grass length. This mechanism ensures smooth movement and precise positioning, enhancing the performance of the machine in varying terrain and lawn conditions.

- Lever Operation: The height is adjusted through a lever connected to the lifting arms, which raises or lowers the platform depending on the desired setting.

- Lifting Arms: The arms are connected to the cutting deck and move in response to the lever’s action, allowing for a balanced lift on both sides.

- Support Brackets: These components stabilize the deck during movement, ensuring that it remains level while adjusting the height.

- Spring Assist: Springs are used to reduce the force needed to raise or lower the deck, making the adjustment process smoother and more efficient.

This mechanism allows

Details of the Engine and Fuel System

The engine and fuel system form the core of any machine’s performance. Understanding how these components interact is crucial for maintaining optimal functionality. This section explores the key aspects of the power unit and fuel delivery system, focusing on their roles in ensuring efficiency and reliability.

Engine Overview

The power unit consists of several essential parts that work together to generate motion. Each component plays a critical role in the overall operation, from the combustion chamber to the exhaust system. A well-maintained engine provides smooth and consistent power output.

- Combustion process and power generation

- Importance of proper lubrication

- Cooling systems and temperature regulation

Fuel System Components

The fuel delivery system is responsible for supplying the engine with the necessary amount of fuel for combustion. This process must be precise to ensure efficient energy conversion and minimize waste. Regular inspection of

Checking the Steering Assembly for Wear

Maintaining the steering system in good condition is essential for ensuring smooth and precise handling. Over time, different components may show signs of aging, affecting the overall control and stability. Regular inspections help identify issues before they become serious problems.

Signs of Wear to Look For

When checking the steering assembly, look for loose or unresponsive steering, as these can indicate worn-out parts. Pay attention to any unusual noises, such as clicking or grinding, when turning the wheel. Additionally, check for excessive play in the steering mechanism, which can compromise safe operation.

Inspecting Key Components

Key areas to examine include the steering linkage, tie rods, and bushings. Look for cracks, rust, or any visible damage. Ensure that all bolts and joints are tightly secured. If any part feels loose or shows signs of wear, it may need replacement or adjustment to restore proper functionality.

Examining the Transmission and Belts

The transmission and belt systems are crucial components that play a key role in ensuring smooth and efficient operation. Regular inspection and maintenance of these elements are essential for sustaining performance and avoiding potential mechanical issues. These systems are responsible for transferring power from the engine to the wheels, making it important to monitor their condition closely.

Check for signs of wear or damage, such as fraying or cracking on the belts, and ensure that the transmission engages smoothly without any unusual noises. Proper tension and alignment of the belts also contribute to the overall functionality. Keeping these components in optimal condition will help extend the lifespan of your equipment and ensure reliable operation.

Understanding the Electrical Wiring Diagram

Gaining a clear comprehension of the electrical schematic is essential for effective maintenance and troubleshooting of machinery. This visual representation serves as a guide to the intricate network of connections and components that power the device.

Key Elements: The schematic typically illustrates various elements such as switches, connectors, and power sources, highlighting their relationships and functions. By analyzing these components, one can identify potential issues and understand how to restore proper functionality.

Importance of Clarity: A well-structured schematic not only aids in problem-solving but also enhances the overall efficiency of repairs. Familiarity with this visual tool empowers operators to navigate electrical systems confidently and minimize downtime during maintenance activities.

Replacing Filters and Fluids Effectively

Maintaining optimal performance in machinery requires regular attention to essential components such as filters and fluids. These elements play a crucial role in ensuring the smooth operation and longevity of the equipment. Understanding how to effectively replace and maintain these components can significantly enhance functionality and prevent potential issues.

Importance of Regular Maintenance

Routine maintenance is vital for extending the lifespan of your equipment. Over time, filters can become clogged with debris, and fluids can degrade, leading to reduced efficiency. By regularly checking and replacing these components, you ensure that your machinery operates at peak performance.

Steps for Effective Replacement

To replace filters and fluids, start by identifying the specific components that need attention. Follow the manufacturer’s guidelines for removal and installation. Always use high-quality replacements to maintain performance. After replacing the filter, refill the fluid reservoirs with the appropriate type and quantity of fluid. Finally, check for any leaks and run the equipment to confirm everything is functioning correctly.

Maintenance Tips for the Cutting Deck

Regular upkeep of the mowing platform is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances the efficiency of the machine but also contributes to a cleaner and more aesthetically pleasing lawn.

Routine Cleaning

After each use, it is crucial to clean the cutting deck to prevent grass buildup and corrosion. Follow these steps for effective cleaning:

- Remove any clippings and debris with a brush or scraper.

- Rinse the surface with water, if necessary, to eliminate stubborn residues.

- Ensure the deck is completely dry before storage to prevent rust.

Blade Maintenance

Keeping the blades sharp is vital for achieving a clean cut and minimizing stress on the engine. Regularly check and maintain the blades by:

- Inspecting the blades for wear or damage before each mowing session.

- Sharpening the blades at least once a season or more frequently with heavy use.

- Replacing blades that are chipped or excessively worn.

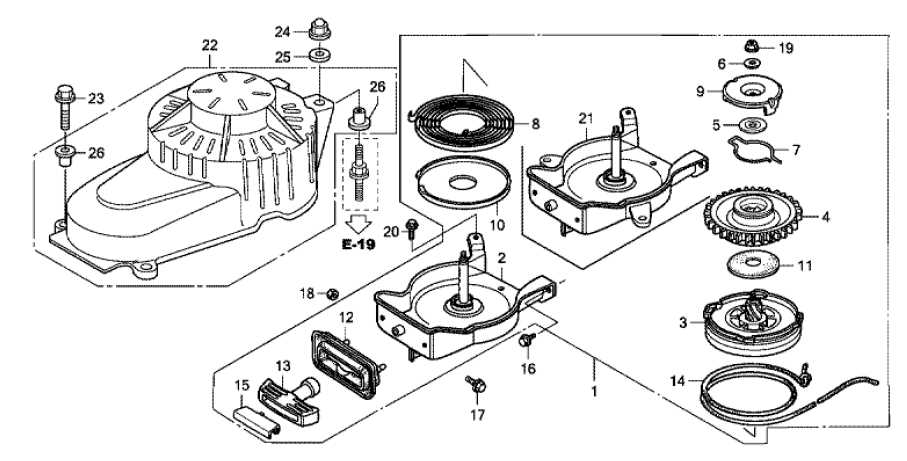

Troubleshooting the Mower’s Ignition System

When facing issues with the mower’s starting mechanism, it’s essential to systematically evaluate the ignition system. This section provides guidance on identifying and resolving common problems that may prevent the engine from starting effectively.

Common Symptoms

- Engine fails to start

- Intermittent starting issues

- Unusual noises when attempting to start

Diagnostic Steps

- Check the battery voltage and connections to ensure proper power supply.

- Inspect the ignition switch for any signs of wear or damage.

- Examine the spark plug for carbon build-up or wear; replace if necessary.

- Verify that the ignition coil is functioning correctly by testing its resistance.

- Assess the wiring for any frays or breaks that could interrupt the electrical flow.

By following these troubleshooting steps, you can pinpoint the issue within the ignition system and take the necessary actions to restore functionality.

How to Maintain the Tires and Axles

Proper upkeep of the wheels and axles is crucial for ensuring optimal performance and longevity of your equipment. Regular maintenance not only enhances safety but also improves efficiency during operation. This section outlines essential practices to keep these components in excellent condition.

Regular Inspection

Consistently check the tires for signs of wear, damage, or improper inflation. Ensure that the tread depth meets safety standards and that there are no visible cracks or bulges. For axles, look for any signs of bending or rust that could indicate wear and tear.

Proper Inflation and Alignment

Maintaining the correct tire pressure is vital for stability and traction. Refer to the manufacturer’s specifications for the ideal pressure levels. Additionally, ensure that the wheels are properly aligned to prevent uneven wear and enhance overall handling.

Overview of Safety Mechanisms and Switches

Ensuring the protection of operators and bystanders is paramount in the design of outdoor power equipment. Various safety features are implemented to prevent accidents and enhance user confidence while operating machinery. These mechanisms serve as essential components that help maintain a secure working environment, making it crucial to understand their roles and functionalities.

Key Safety Features

Among the most significant safety elements are the emergency stop switches, which allow for immediate shutdown in case of emergencies. Additionally, interlock systems are commonly integrated to prevent the engine from starting unless certain conditions are met, such as the operator being seated. These features collectively enhance the reliability and safety of the equipment.

Importance of Regular Maintenance

Regular inspection and maintenance of these safety systems are vital to ensure they function correctly. Neglecting to check the condition of switches and mechanisms may lead to malfunctions, increasing the risk of accidents. Users should prioritize these safety components to ensure the equipment remains operational and secure during use.