In the realm of small machinery, the efficiency of fuel delivery is crucial for optimal performance. A well-designed system ensures that the engine runs smoothly, maximizing power output and minimizing emissions. This section aims to explore the intricacies involved in these vital components.

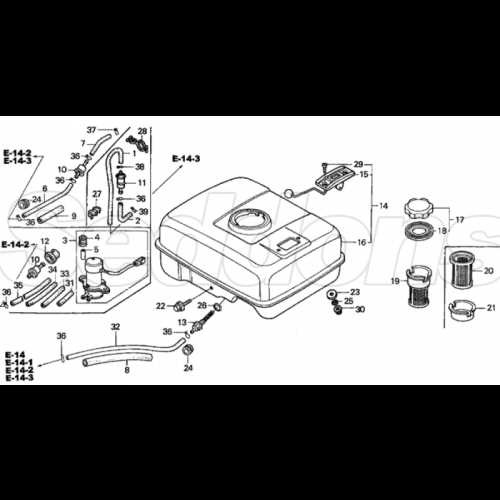

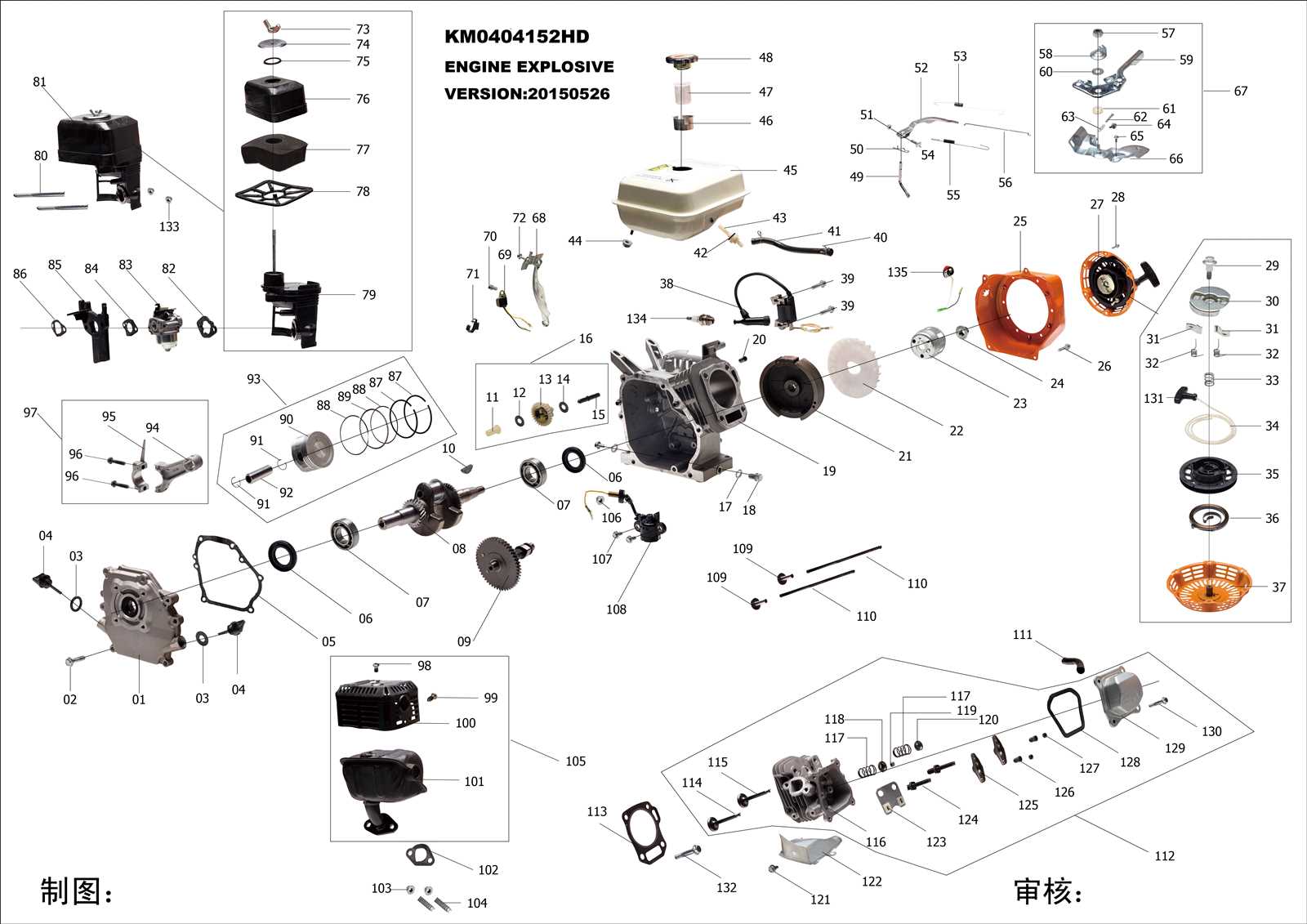

Identifying the essential elements within the fuel mechanism can greatly enhance maintenance practices and troubleshooting efforts. Familiarity with each component allows operators to recognize signs of wear or malfunction, leading to more informed repairs.

Moreover, detailed illustrations serve as a valuable resource for both novices and seasoned mechanics. By breaking down the assembly, users can better appreciate the function of each element, paving the way for a deeper understanding of engine operations.

Understanding the GX160 Engine

This section provides an overview of a specific engine model known for its reliability and performance in various applications. With a focus on its design and functionality, we aim to highlight key features that contribute to its effectiveness in powering equipment and machinery.

The engine is recognized for its robust construction and user-friendly operation, making it a popular choice among enthusiasts and professionals alike. Its efficient combustion process ensures optimal energy output while minimizing fuel consumption, an essential factor for those looking to maximize productivity.

Additionally, the engine’s versatility allows it to be used in a range of devices, from generators to agricultural machinery. Understanding its components and mechanisms can greatly enhance maintenance and troubleshooting, ensuring longevity and consistent performance over time.

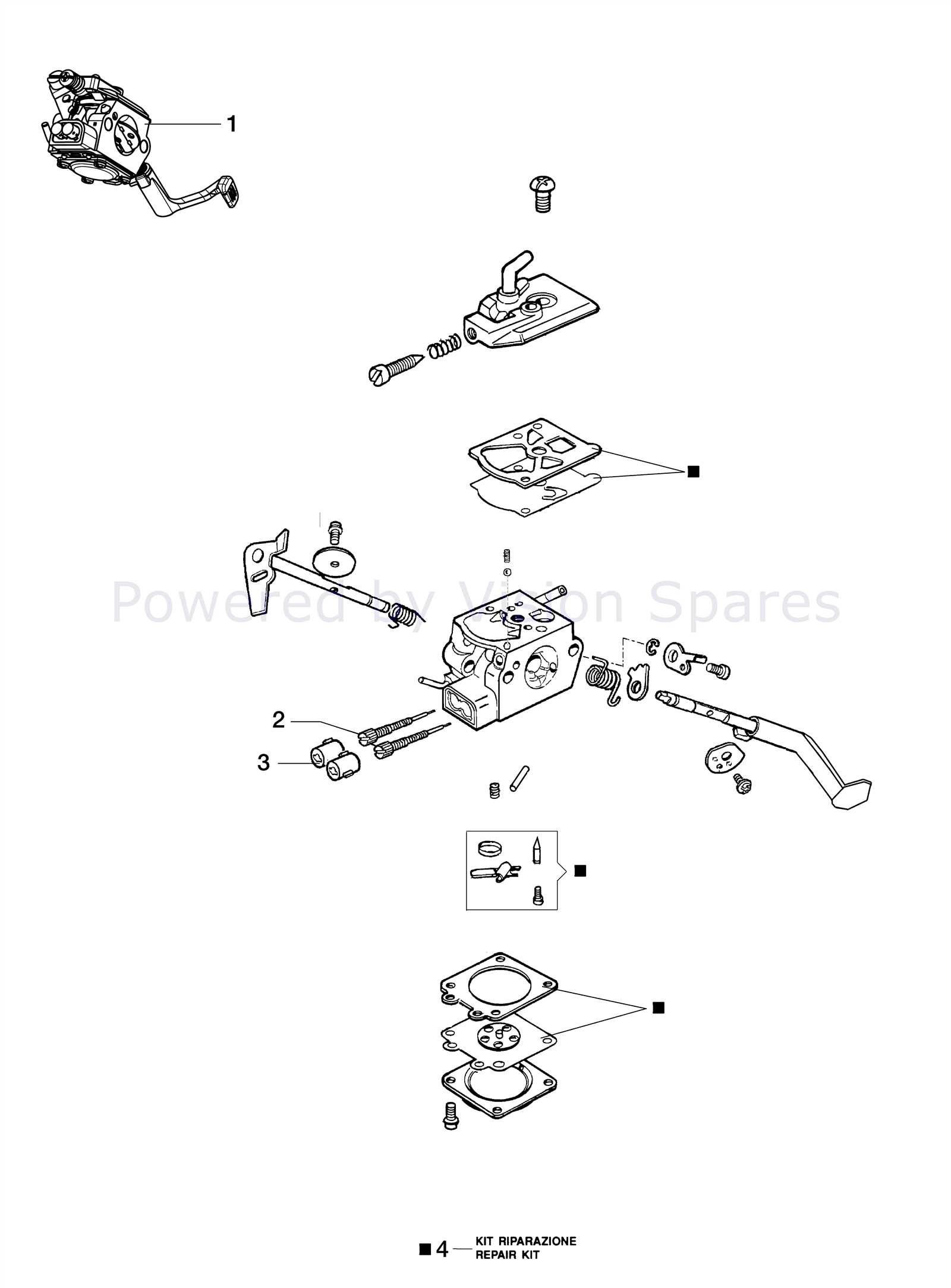

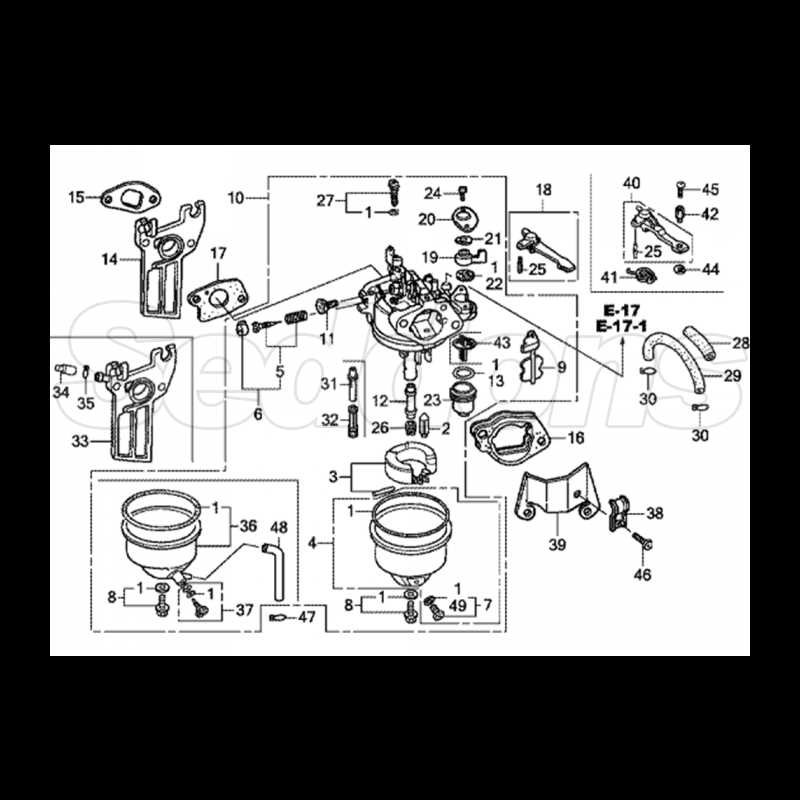

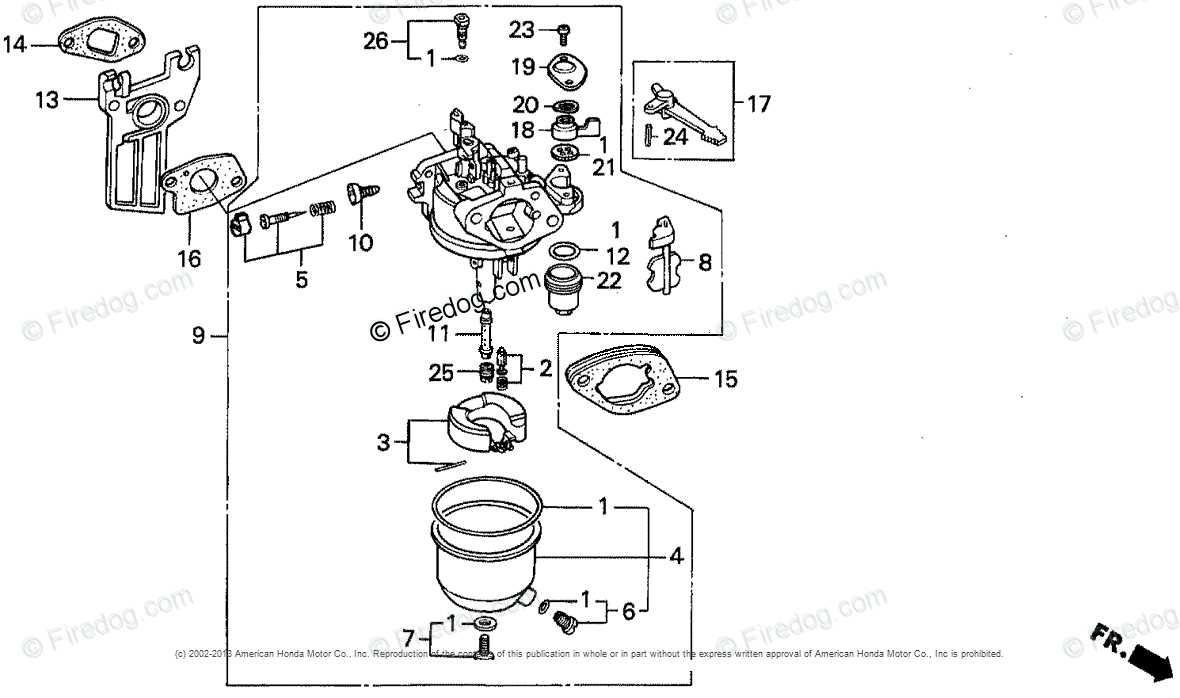

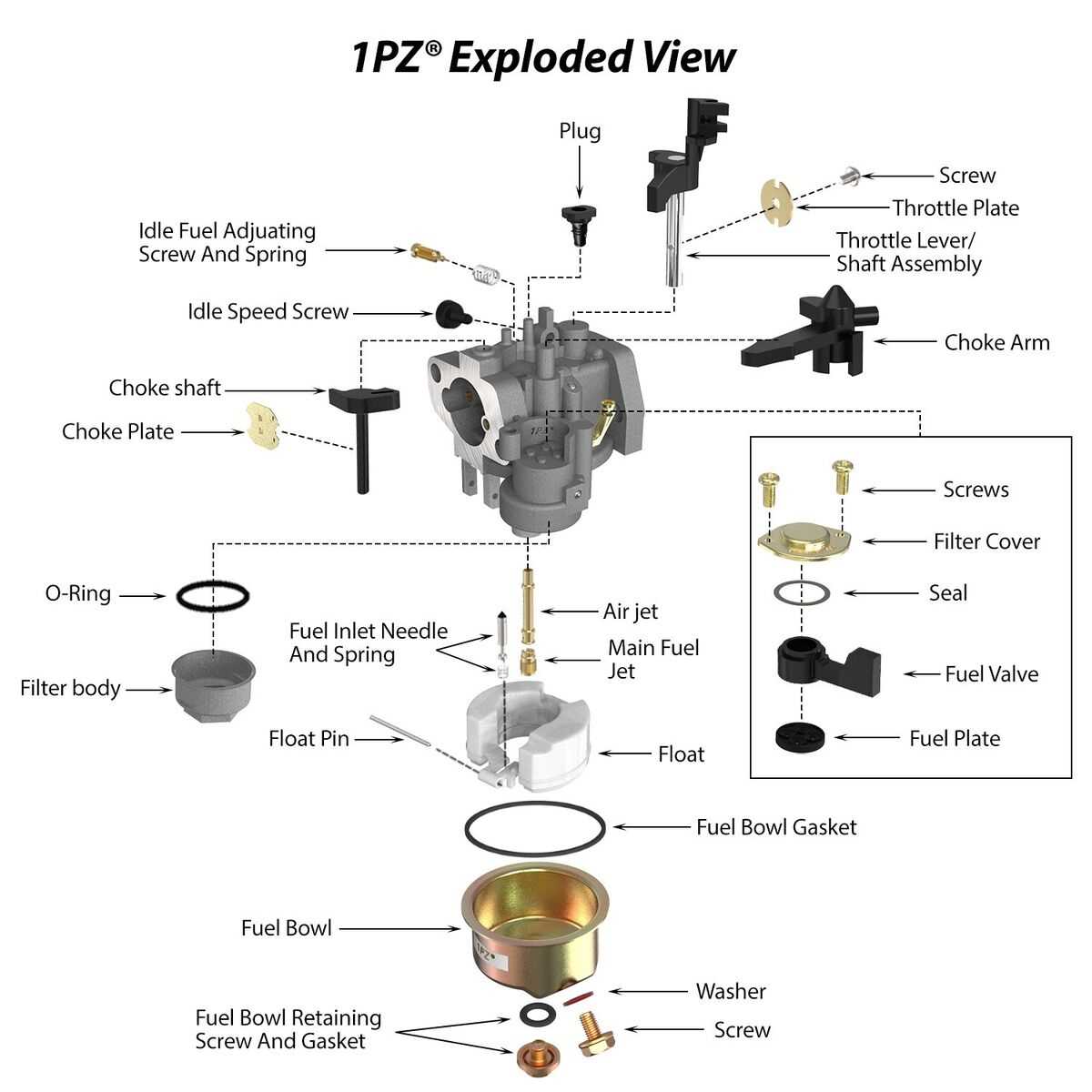

Key Components of GX160 Carburetor

The functioning of small engines relies heavily on a specific assembly that regulates the air-fuel mixture for optimal performance. Understanding the essential elements of this assembly is crucial for maintenance and repair, ensuring the engine runs smoothly and efficiently.

One of the primary elements is the float, which manages the fuel level within the chamber, allowing for consistent delivery. Another critical component is the needle valve, controlling the flow of fuel into the mixing area. Additionally, the throttle plate plays a vital role in regulating airflow, influencing engine speed and power output. Finally, the choke mechanism aids in starting the engine by enriching the fuel mixture during initial operation.

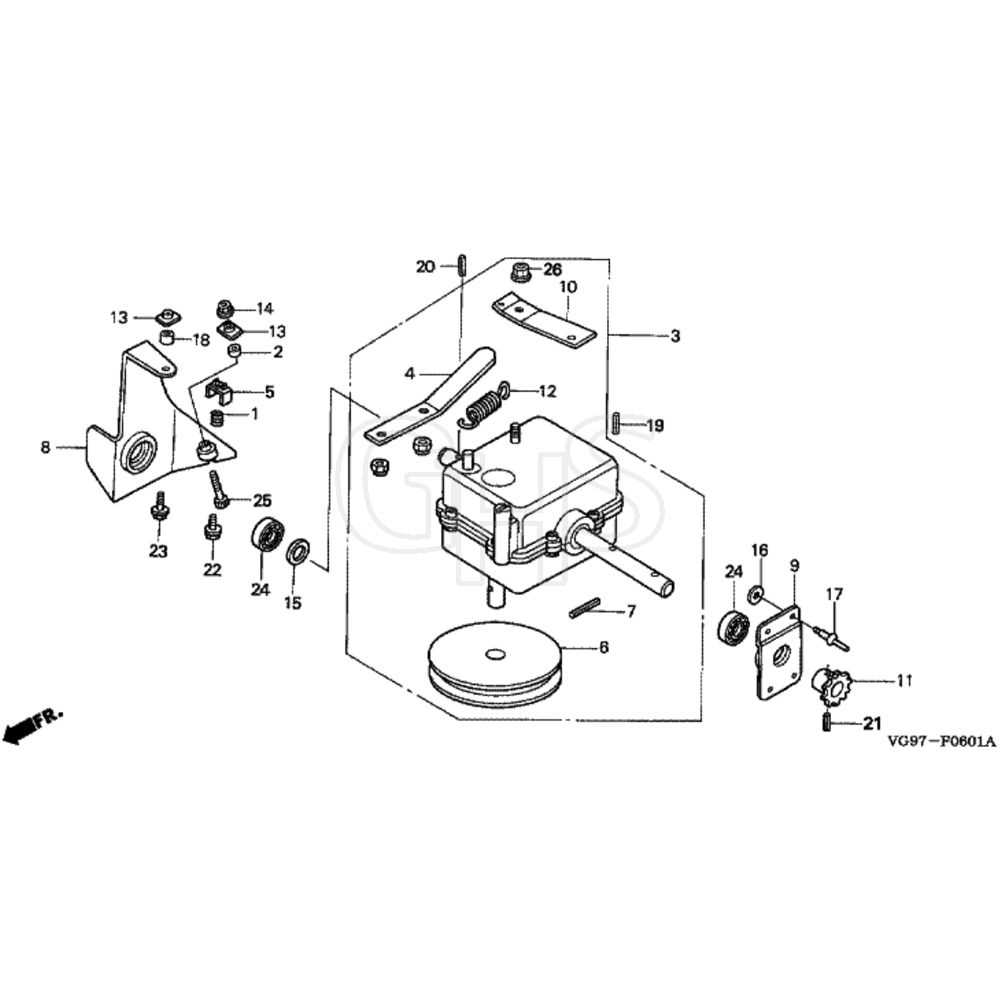

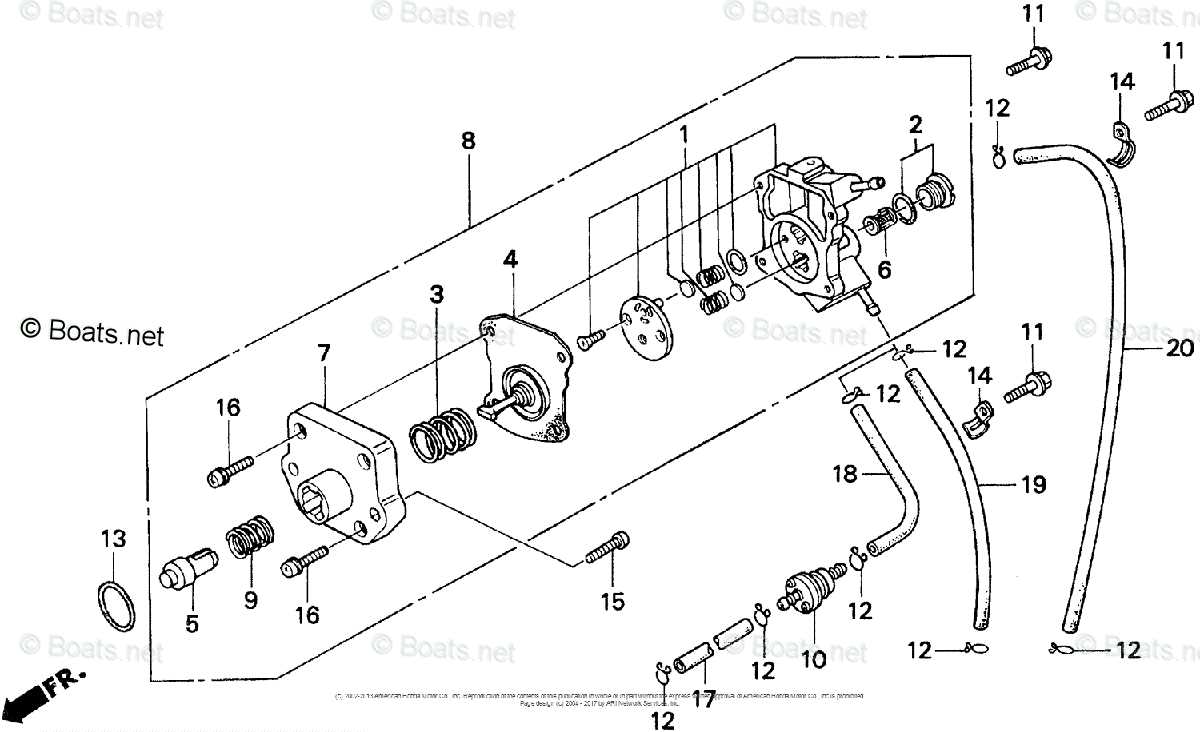

Identifying Parts in Diagrams

Understanding the components in technical illustrations is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality, and recognizing these parts can enhance both troubleshooting and assembly processes. Clear identification aids in ensuring that all elements are properly addressed during servicing.

Common Features to Look For

When examining illustrations, pay attention to the shape, size, and placement of each component. Labels often accompany illustrations, providing valuable information about each item. Additionally, color coding and numbering systems can help differentiate between similar pieces, making it easier to follow assembly instructions or disassembly guidelines.

Utilizing Reference Guides

Reference materials can significantly assist in identifying specific components. Manuals and online resources frequently contain detailed explanations and images that clarify the function and importance of each element. Cross-referencing these resources with the illustrations can help build a comprehensive understanding of the system.

Common Issues with Carburetors

When it comes to small engine performance, the fuel delivery system plays a crucial role in ensuring smooth operation. Several common problems can arise within this mechanism, often leading to a decline in efficiency or complete failure to start. Understanding these issues is essential for maintenance and troubleshooting.

Clogged Jets: One of the most frequent complications is the blockage of fuel jets. Debris or varnish buildup can obstruct fuel flow, resulting in poor acceleration and engine stalling. Regular cleaning can help mitigate this problem.

Incorrect Air-Fuel Mixture: An improper blend of air and fuel can lead to various performance issues. If the mixture is too rich, it can cause excessive smoke and fouling of the spark plug. Conversely, a lean mixture may result in overheating and damage to engine components.

Sealing Issues: Gaskets and seals can wear out over time, leading to vacuum leaks. Such leaks disrupt the intended air-fuel ratio, causing erratic engine behavior. Regular inspection and replacement of worn parts are advisable.

Float Problems: The float mechanism regulates the fuel level within the chamber. If it becomes stuck or damaged, it can lead to flooding or starvation of the engine. Ensuring proper float operation is key to maintaining reliable performance.

Vapor Lock: In hot conditions, fuel can vaporize before reaching the engine, causing a phenomenon known as vapor lock. This can result in starting difficulties or engine stalling. Shielding fuel lines or using fuel additives can help alleviate this issue.

Maintenance Tips for GX160

Proper upkeep of your small engine ensures longevity and optimal performance. Regular maintenance tasks can prevent issues and enhance efficiency, allowing for smooth operation during use.

Here are some essential maintenance tips to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil with fresh lubricant to maintain engine health. |

| Air Filter Cleaning | Every 25 hours | Remove and clean the filter to ensure proper airflow. |

| Fuel System Inspection | Every season | Check for leaks and ensure fuel is fresh to avoid performance issues. |

| Spark Plug Check | Every 100 hours | Inspect and replace if necessary to ensure efficient ignition. |

Following these guidelines will help maintain peak performance and extend the lifespan of your engine.

How to Clean the Carburetor

Maintaining optimal performance of your engine often involves ensuring that the fuel delivery system is clean and free from obstructions. Regular cleaning is essential for smooth operation and longevity, as it helps remove any buildup that may hinder efficiency. This guide will walk you through the necessary steps to effectively clean the fuel system component.

Step 1: Gather Your Materials

Step 2: Disassemble the Component

Carefully detach the fuel delivery unit from the engine. Take your time with this step to avoid damaging any connections. Place the removed unit on a clean, flat surface to make the next steps easier.

Step 3: Clean the Exterior

Using a soft brush and the cleaning solution, scrub the exterior surfaces to remove dirt and grime. This initial cleaning helps prevent contaminants from entering the internal mechanisms during further disassembly.

Step 4: Remove and Clean Internal Parts

Next, take apart the internal components. Pay close attention to each piece, as they may require individual cleaning. Soak smaller parts in the cleaning solution for a few minutes, then scrub gently with a brush to remove any residue. Rinse thoroughly with clean water and dry completely before reassembling.

Step 5: Reassemble and Test

Once all parts are clean and dry, carefully reassemble the unit, ensuring all seals and gaskets are properly placed. Reattach the unit to the engine and perform a test run to verify that everything is functioning smoothly. Check for any leaks or irregular sounds that may indicate improper assembly.

Tools Needed for Repairs

Effective maintenance and repair require the right set of instruments to ensure smooth operation and longevity of the equipment. Having a well-organized toolkit can significantly enhance the repair process, making it efficient and straightforward.

Below is a list of essential tools that will aid in the repair process:

- Screwdrivers: A variety of sizes, including flathead and Phillips, are necessary for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets will help in dealing with nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending components.

- Cleaners: Specialized cleaners will help remove dirt and debris from intricate areas.

- Gaskets and Seals: Always keep spare gaskets and seals to ensure a proper fit during reassembly.

Additional tools that may come in handy include:

- Torque Wrench: For ensuring components are tightened to the manufacturer’s specifications.

- Fuel Line Cutter: To make precise cuts for fuel lines without damaging them.

- Multimeter: Useful for checking electrical connections and diagnosing issues.

Being equipped with the right tools not only streamlines repairs but also enhances the overall performance of the machinery. Ensuring that your toolkit is complete will prepare you for any maintenance task that may arise.

Replacing Carburetor Parts Effectively

Maintaining the efficiency of your engine requires a clear understanding of how to substitute essential components within the fuel delivery system. A thorough approach can prevent malfunctions and ensure optimal performance. Knowing when and how to replace these components is crucial for longevity and reliability.

Steps for Effective Replacement

Begin by gathering the necessary tools and replacement items. Ensure you have a clean workspace to facilitate the process and prevent contamination. Following a systematic approach will help in avoiding mistakes and ensuring a successful installation.

Common Components to Replace

| Component | Function |

|---|---|

| Float | Regulates fuel level in the chamber |

| Jet | Controls fuel flow to the engine |

| Diaphragm | Maintains pressure balance |

| Gasket | Seals connections to prevent leaks |

By following these guidelines and focusing on the key elements of the system, you can effectively ensure your engine runs smoothly and efficiently.

Performance Enhancements for GX160

Boosting engine efficiency can significantly improve overall functionality and output. By optimizing various components, users can achieve greater power and responsiveness, making the machine more effective for its intended applications.

Upgraded Air Intake

Improving airflow is crucial for enhancing combustion. An upgraded air intake system allows for better air delivery, which can result in increased horsepower. This modification not only supports better engine performance but also enhances fuel efficiency.

Exhaust Modifications

Installing a high-performance exhaust system facilitates better gas flow, reducing back pressure. This change can lead to improved torque and throttle response, allowing the engine to operate at its ultimate potential. A well-designed exhaust not only enhances performance but also adds a sporty sound to the operation.

Resources for Further Learning

For those looking to enhance their understanding of engine components and maintenance, a variety of resources are available. These materials can provide valuable insights, technical knowledge, and practical skills to improve your expertise in this area.

Online Tutorials and Courses

Many websites offer comprehensive tutorials and structured courses that cover engine mechanics and tuning techniques. Engaging with these resources can deepen your knowledge and hands-on skills.

Books and Manuals

Textual resources, such as manuals and specialized books, provide in-depth information and detailed illustrations. They serve as excellent references for both beginners and seasoned enthusiasts.

| Resource Type | Description | Recommended Source |

|---|---|---|

| Online Course | Interactive learning modules covering various aspects of engine maintenance. | Coursera, Udemy |

| Technical Manual | Detailed guide with specifications and repair instructions. | Manufacturer Websites, Amazon |

| Video Tutorials | Visual learning through step-by-step video guides. | YouTube, Skillshare |