In the realm of internal combustion engines, the efficient delivery of fuel is crucial for optimal performance. Various components work in unison to ensure the proper mixture of air and fuel reaches the combustion chamber. A comprehensive understanding of these elements aids in maintaining and tuning the system for improved efficiency and reliability.

The intricate layout of these components reveals the relationship between each piece, showcasing how they contribute to the overall functionality. By examining the configurations and roles of these elements, one can better appreciate the mechanics involved in the fuel delivery process. This knowledge is essential for anyone looking to enhance their understanding of engine operations.

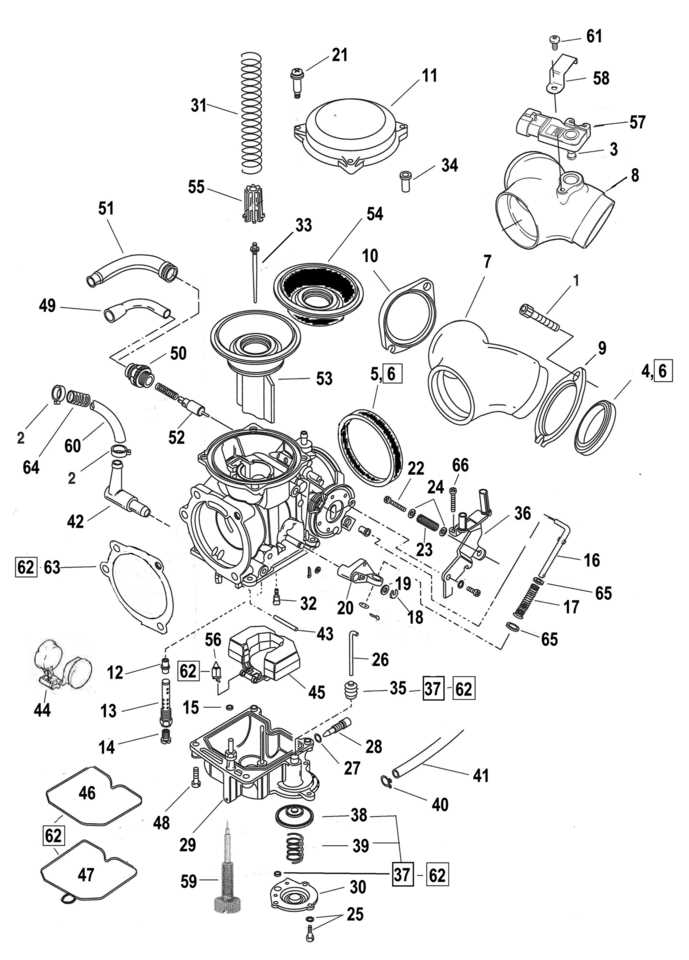

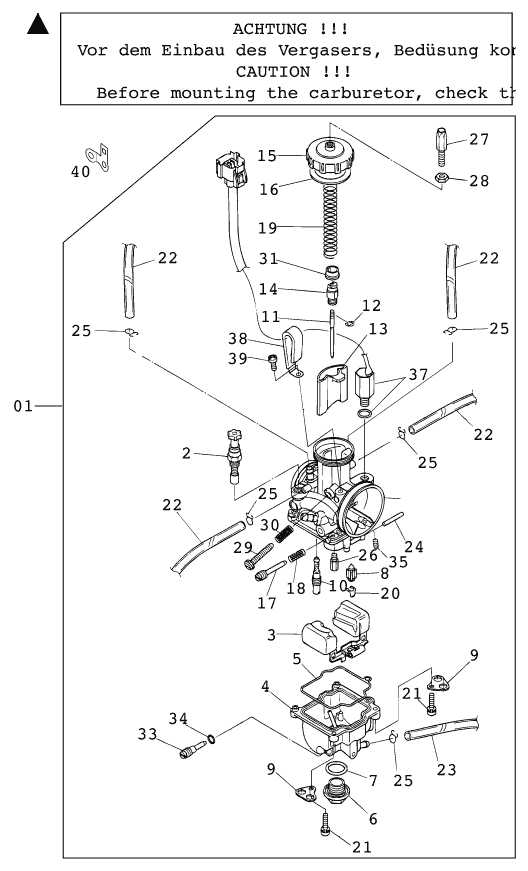

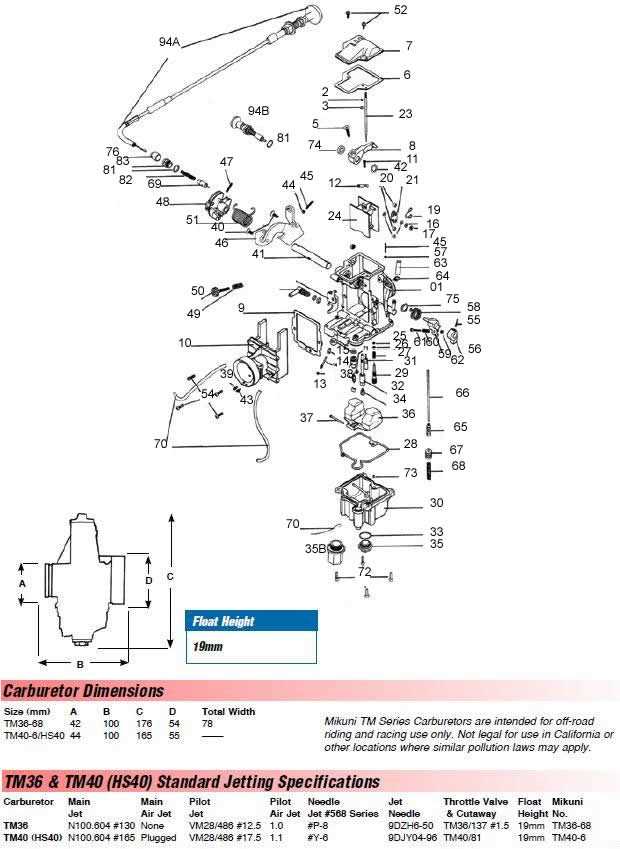

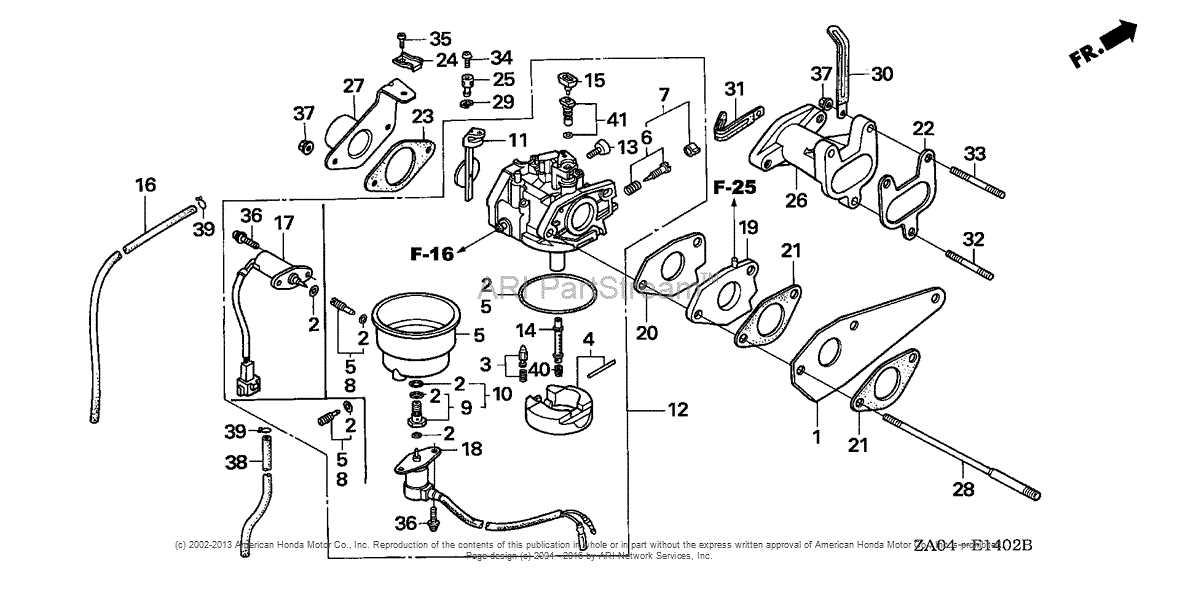

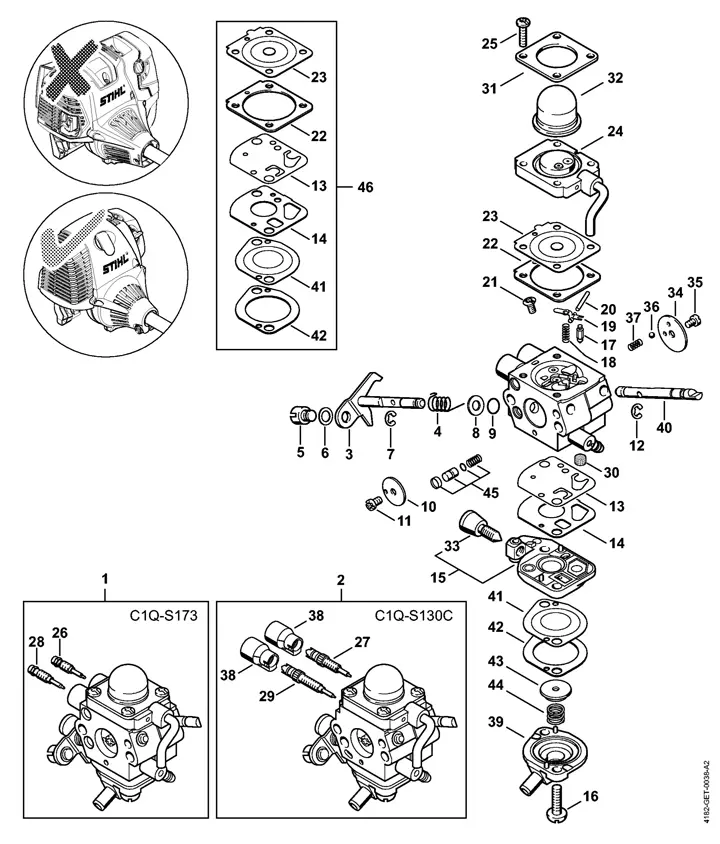

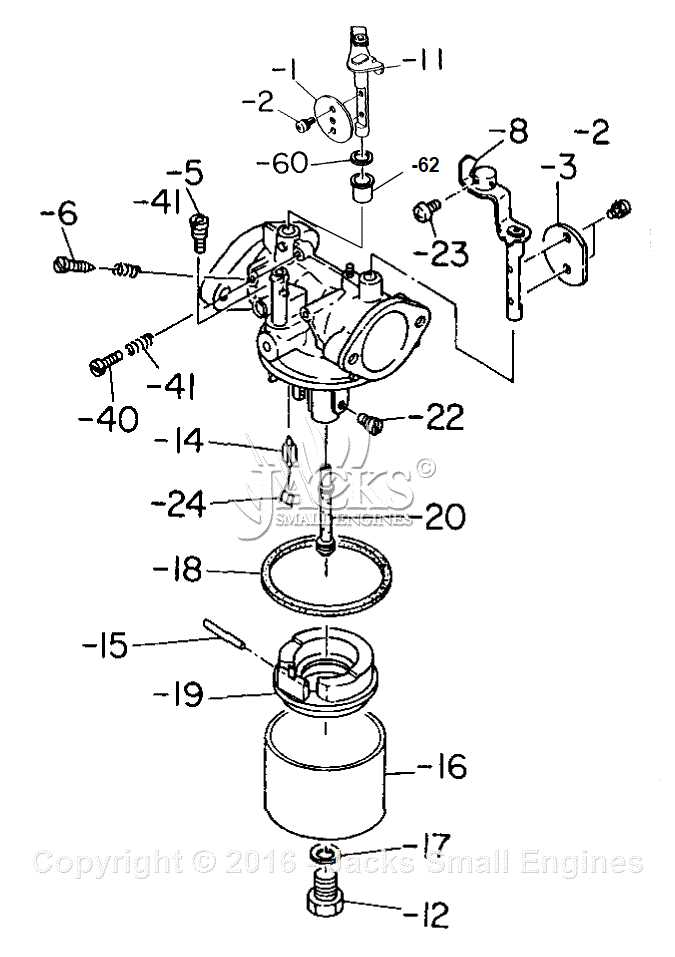

Detailed illustrations serve as valuable references, allowing enthusiasts and technicians to identify and understand each component’s purpose. Whether for maintenance, repair, or performance enhancement, familiarity with these diagrams can lead to more informed decisions and successful modifications. Knowledge in this area is key to unlocking the full potential of an engine’s performance.

Understanding Keihin Carburetor Components

This section delves into the essential elements of a specific fuel mixing device commonly used in various engines. These components work together to ensure optimal performance by regulating fuel and air flow, allowing for efficient combustion. Understanding these elements is crucial for maintenance, troubleshooting, and performance tuning.

Key Elements of the System

The assembly comprises several integral components, each playing a vital role in the overall functionality. From the float mechanism to the throttle body, every piece contributes to the precise operation of the device. Familiarity with these elements enables users to identify potential issues and implement effective solutions.

Component Overview

| Component | Description |

|---|---|

| Float Chamber | Maintains a steady level of fuel for proper mixing. |

| Main Jet | Regulates the amount of fuel entering the air stream. |

| Throttle Valve | Controls the air-fuel mixture entering the engine. |

| Choke Valve | Reduces airflow during cold starts to enrich the mixture. |

| Needle Valve | Controls fuel flow into the float chamber based on engine demand. |

Parts and Their Functions Explained

This section delves into the essential components of fuel delivery systems, focusing on their roles and interactions. Understanding how each element contributes to overall performance is crucial for effective maintenance and troubleshooting.

Fuel Chamber: The fuel chamber is responsible for storing gasoline and ensuring a consistent supply to the system. It regulates the fuel level, allowing for efficient combustion.

Throttle Valve: The throttle valve controls the amount of air-fuel mixture entering the engine. Adjusting this valve influences engine speed and power output, making it a vital component for performance.

Jet: Jets are crucial for regulating fuel flow into the air stream. They come in various sizes to accommodate different engine demands, affecting fuel mixture and overall efficiency.

Float: The float maintains the correct fuel level within the chamber. It rises and falls with fuel levels, ensuring a consistent supply while preventing overflow.

Needle Valve: The needle valve works in conjunction with the float to control fuel entry into the chamber. Its precise adjustment is vital for maintaining the optimal fuel level.

Air Filter: The air filter ensures that only clean air enters the system, preventing debris from contaminating the mixture. A clean filter is essential for maintaining engine performance and longevity.

Accelerator Pump: The accelerator pump provides an additional fuel supply during rapid throttle openings. This feature enhances engine response, particularly during acceleration.

Understanding these components and their respective functions enhances the ability to diagnose issues and optimize performance. Regular maintenance and knowledge of each part’s role are essential for effective operation.

Common Issues with Carburetor Components

When dealing with fuel delivery systems, various challenges may arise that can hinder optimal performance. Understanding these issues is essential for maintaining efficiency and ensuring reliable operation. Components can become worn, clogged, or misaligned, leading to inefficiencies and operational problems.

Fuel Flow Restrictions

One of the most prevalent concerns involves obstructions within the fuel pathways. Dirt, debris, or varnish buildup can restrict the flow of fuel, causing hesitation during acceleration or stalling. Regular maintenance and cleaning are crucial to prevent these issues.

Air-Fuel Mixture Imbalances

Another common problem is an improper balance between air and fuel, which can lead to performance issues. If the mixture is too rich or too lean, it may result in poor combustion, excessive emissions, and reduced power output. Adjustments to the air intake or fuel delivery mechanisms may be necessary to restore balance.

Maintenance Tips for Keihin Carburetors

Regular upkeep is essential for ensuring optimal performance of fuel delivery systems in various engines. Proper maintenance not only extends the lifespan of these components but also enhances overall efficiency. Following a few key practices can significantly improve functionality and reduce the risk of malfunctions.

Start by keeping the fuel system clean. Regularly inspect and clean the filtration elements to prevent debris from obstructing fuel flow. Additionally, periodic disassembly and thorough cleaning of internal surfaces help eliminate any build-up of residues or deposits that may interfere with performance.

Next, ensure that all seals and gaskets are in good condition. Worn or damaged seals can lead to leaks and affect the air-fuel mixture. Replacing these components as needed will maintain proper function and efficiency.

Lastly, pay attention to adjustments. Periodically check and fine-tune the air-fuel mixture to align with engine specifications. This adjustment is crucial for achieving optimal combustion and preventing issues such as stalling or poor acceleration.

Identifying Key Components in Diagrams

Understanding the fundamental elements depicted in schematic representations is essential for effective troubleshooting and assembly. These illustrations serve as valuable resources, offering insight into the structure and function of various assemblies. By familiarizing oneself with these crucial elements, individuals can enhance their comprehension of complex systems.

When examining these illustrations, it’s important to recognize the various sections and how they interact with one another. Key components often include valves, float chambers, and fuel inlets, each playing a specific role in the overall functionality.

| Component | Description |

|---|---|

| Valve | Regulates the flow of air and fuel into the combustion chamber. |

| Float Chamber | Maintains a steady level of fuel for optimal performance. |

| Fuel Inlet | Allows fuel to enter the assembly for combustion. |

| Throttle Plate | Controls the amount of air entering the system, affecting power output. |

Types of Keihin Carburetors Available

When it comes to fuel delivery systems, various models cater to distinct applications and performance needs. Each design offers unique features that enhance efficiency, throttle response, and overall engine performance. Understanding these different configurations helps enthusiasts and mechanics choose the right option for their specific requirements.

Round Slide Models are known for their simplicity and reliability, often used in standard motorcycles and scooters. Their design facilitates smooth airflow, making them an excellent choice for beginners and everyday riders.

Flat Slide Variants excel in high-performance scenarios, providing quicker throttle response and improved airflow. These are typically preferred by racers and those seeking enhanced acceleration and power.

Variable Venturi Designs adapt to engine demands, offering versatility across various RPM ranges. This type ensures optimal performance under changing conditions, making it suitable for both street and off-road applications.

Each type serves a distinct purpose, contributing to the engine’s overall functionality and performance, allowing users to achieve their desired riding experience.

How to Assemble Carburetor Parts

Assembling the various components of an engine fuel delivery system requires precision and a systematic approach. Proper assembly ensures optimal performance and efficiency, making it essential to follow a few key steps carefully. This section provides a detailed guide on how to effectively piece together these critical elements.

Preparation and Inspection

Before starting the assembly process, it’s important to inspect each component thoroughly. Look for any signs of wear, damage, or debris that could affect functionality. Clean each element to remove any contaminants, ensuring a smooth operation once everything is reassembled. Having all necessary tools and components ready will streamline the process.

Step-by-Step Assembly

Begin the assembly by organizing the components according to the assembly sequence. Start with the base element and gradually add each subsequent piece, ensuring they fit together seamlessly. Consult the manufacturer’s guidelines if available, as they often provide crucial information about torque specifications and alignment requirements. Double-check each connection for a snug fit to prevent leaks or malfunctions.

Importance of Accurate Component Diagrams

Having precise representations of mechanical elements is crucial for effective maintenance and troubleshooting. These visuals serve as valuable references, ensuring that technicians can identify and understand the various components involved in a system. With clear illustrations, users can easily follow assembly instructions, pinpoint issues, and perform replacements accurately.

Enhancing Repair Efficiency

When individuals rely on accurate visuals, they can streamline the repair process significantly. Detailed illustrations enable quicker identification of components, minimizing the time spent searching for parts or deciphering instructions. This efficiency leads to faster repairs and reduced downtime, which is essential for both personal and professional applications.

Preventing Mistakes and Misunderstandings

Clear representations help avoid errors that can occur during assembly or repair tasks. Misidentifying a component can lead to improper installations or modifications, causing further complications. Accurate diagrams mitigate these risks, promoting confidence in the assembly process and ensuring that each element is positioned correctly.

Upgrades and Modifications for Performance

Improving the efficiency and responsiveness of your engine can significantly enhance your riding experience. By implementing various enhancements and adjustments, you can optimize fuel delivery and air intake, leading to increased power and throttle response. These upgrades not only elevate performance but can also contribute to overall engine longevity when done correctly.

Aftermarket Components such as high-flow filters and specialized intake manifolds can dramatically improve airflow, allowing for a more efficient combustion process. Additionally, adjustable jets provide the flexibility to fine-tune fuel mixtures for specific conditions, ensuring that the engine operates at its peak efficiency.

Another effective modification includes upgrading to a performance accelerator pump. This component enhances the initial throttle response, allowing for quicker acceleration when needed. Combining these modifications can result in a smoother and more powerful ride, making your vehicle stand out on the road.

Tools Required for Carburetor Repair

Repairing fuel delivery systems requires a specific set of tools to ensure accuracy and efficiency. Having the right equipment not only simplifies the process but also enhances the quality of the repair work. Understanding the essential tools can make the task less daunting and more manageable.

To begin with, a set of screwdrivers in various sizes is crucial for removing and securing components. Additionally, wrenches are necessary for loosening and tightening bolts. A gasket scraper helps in cleaning surfaces to prevent leaks, while a cleaning solution is essential for maintaining the internal parts. Finally, having a torque wrench ensures that all components are secured to the manufacturer’s specifications, promoting optimal performance.

Frequently Asked Questions about Keihin Carburetors

This section addresses common inquiries regarding a specific type of fuel delivery system, offering clarity and understanding for users and enthusiasts alike. The following questions and answers aim to demystify various aspects of this mechanism, including its function, maintenance, and troubleshooting.

-

What is the primary function of this fuel delivery system?

This system mixes air and fuel in the correct ratio, ensuring optimal engine performance.

-

How do I know if the system needs cleaning?

Signs include poor engine performance, difficulty starting, or irregular idling.

-

What tools are necessary for maintenance?

Basic tools include:

- Screwdrivers

- Wrenches

- Cleaning solvents

- Replacement gaskets

-

Can I adjust the fuel-air mixture?

Yes, adjustments can be made to optimize performance based on specific conditions.

-

What are the common issues I might encounter?

Common problems include:

- Clogged jets

- Leaking seals

- Incorrectly set mixture ratios