The intricacies of fuel mixing devices play a crucial role in the efficient operation of various engines. A comprehensive understanding of their inner workings is essential for enthusiasts and mechanics alike. By examining the relationships between different elements, one can gain insight into how these mechanisms optimize performance and maintain reliability.

In this section, we will explore the essential features and functionalities that contribute to the overall effectiveness of these devices. Through a detailed breakdown, we aim to clarify the roles of each component and how they interact within the system. This knowledge is invaluable for anyone looking to enhance their skills in maintenance or restoration.

Furthermore, understanding the layout and configuration of these elements can aid in troubleshooting and repair. By familiarizing oneself with the specific arrangements, users can more effectively diagnose issues and implement solutions. This guide serves as a resource for those eager to delve deeper into the world of fuel mixing technology.

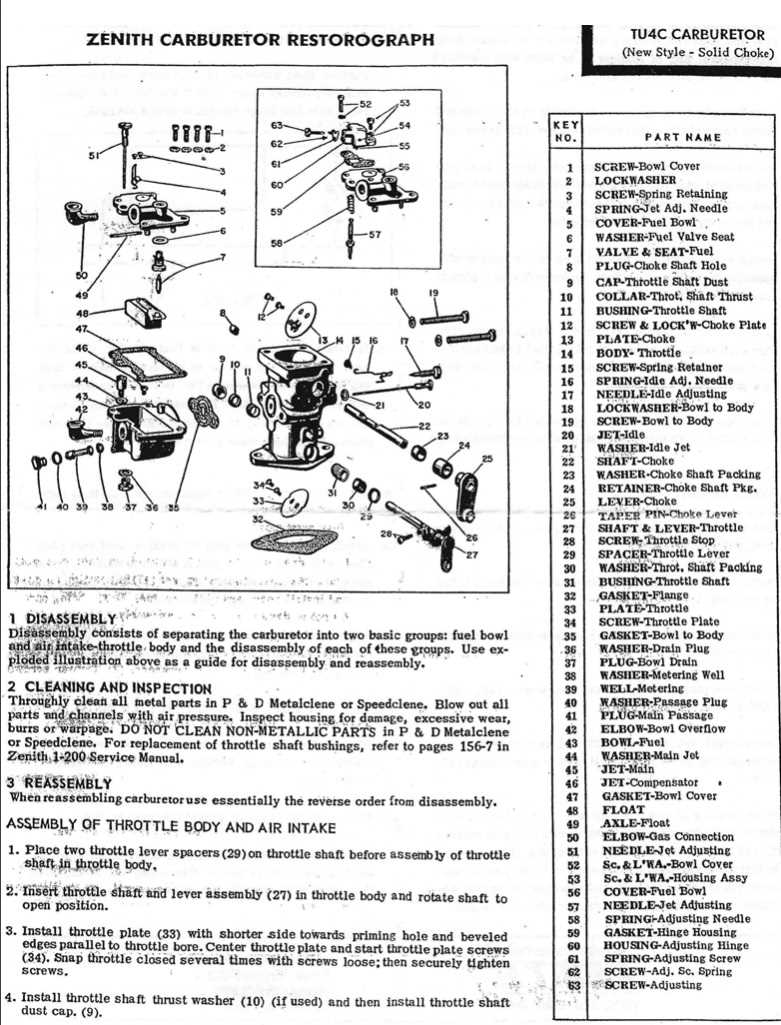

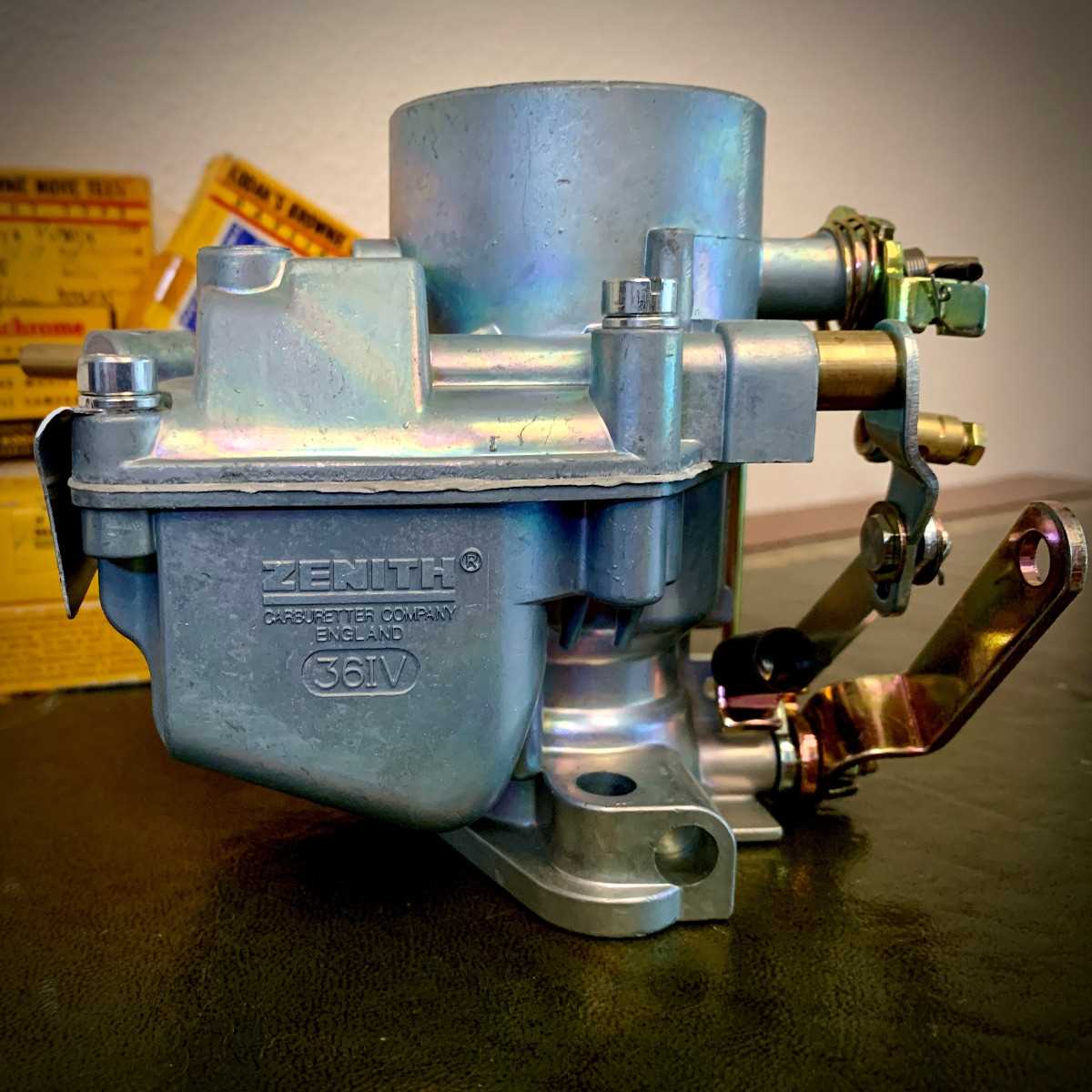

Understanding Zenith Carburetor Functionality

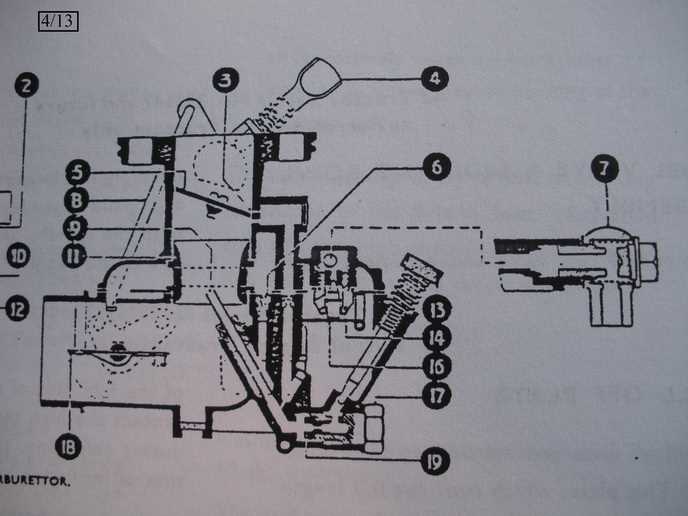

The operation of this essential component is pivotal in the management of fuel-air mixtures within an engine. By converting liquid fuel into a vapor and facilitating its integration with air, it ensures optimal combustion and efficiency. Mastering its intricacies is crucial for maintaining engine performance and longevity.

Key Mechanisms at Play

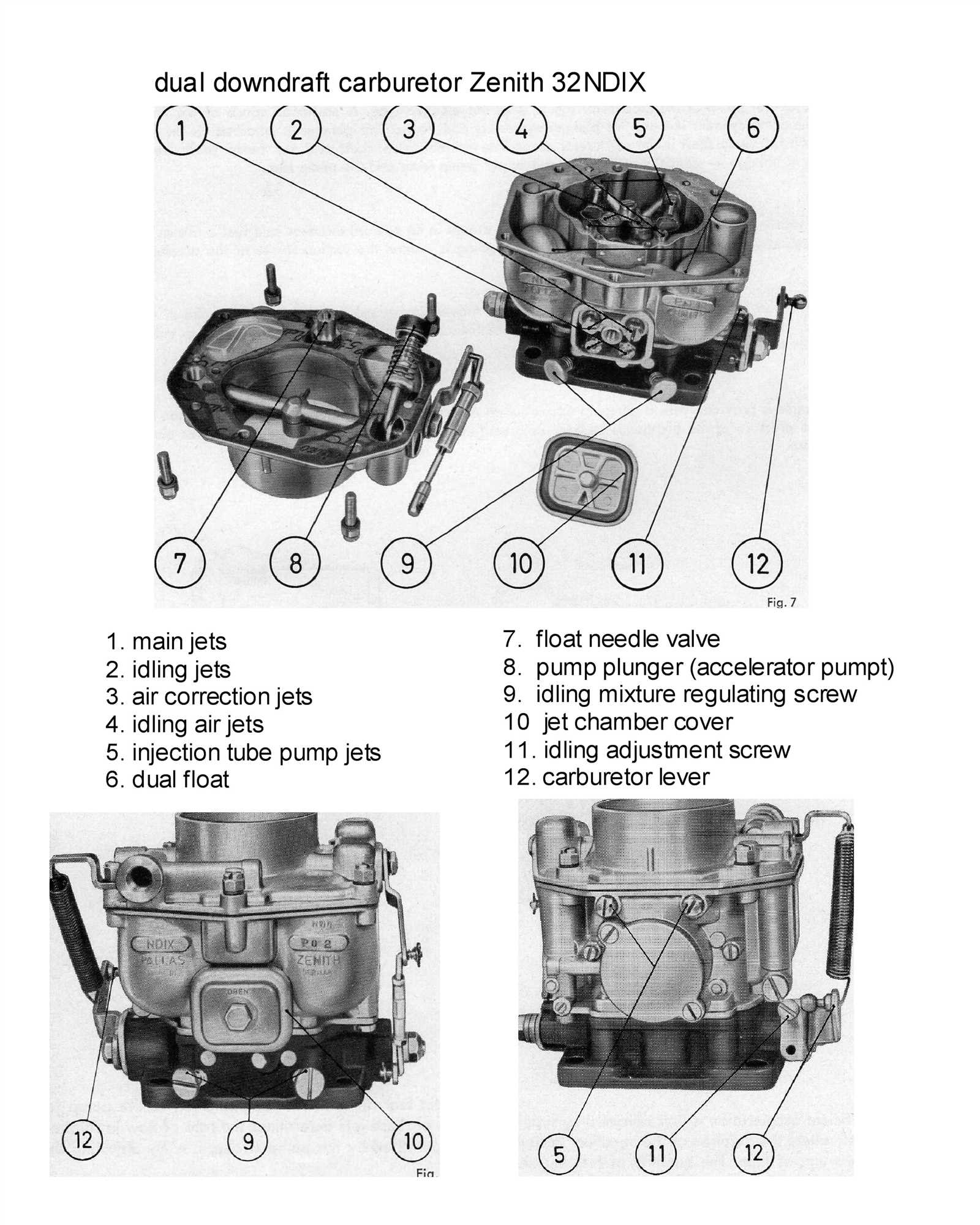

This device utilizes a combination of jets, floats, and chambers to regulate fuel flow and pressure. Each mechanism plays a specific role, contributing to the precise delivery of the mixture needed for different engine demands, whether at idle or full throttle.

Common Issues and Solutions

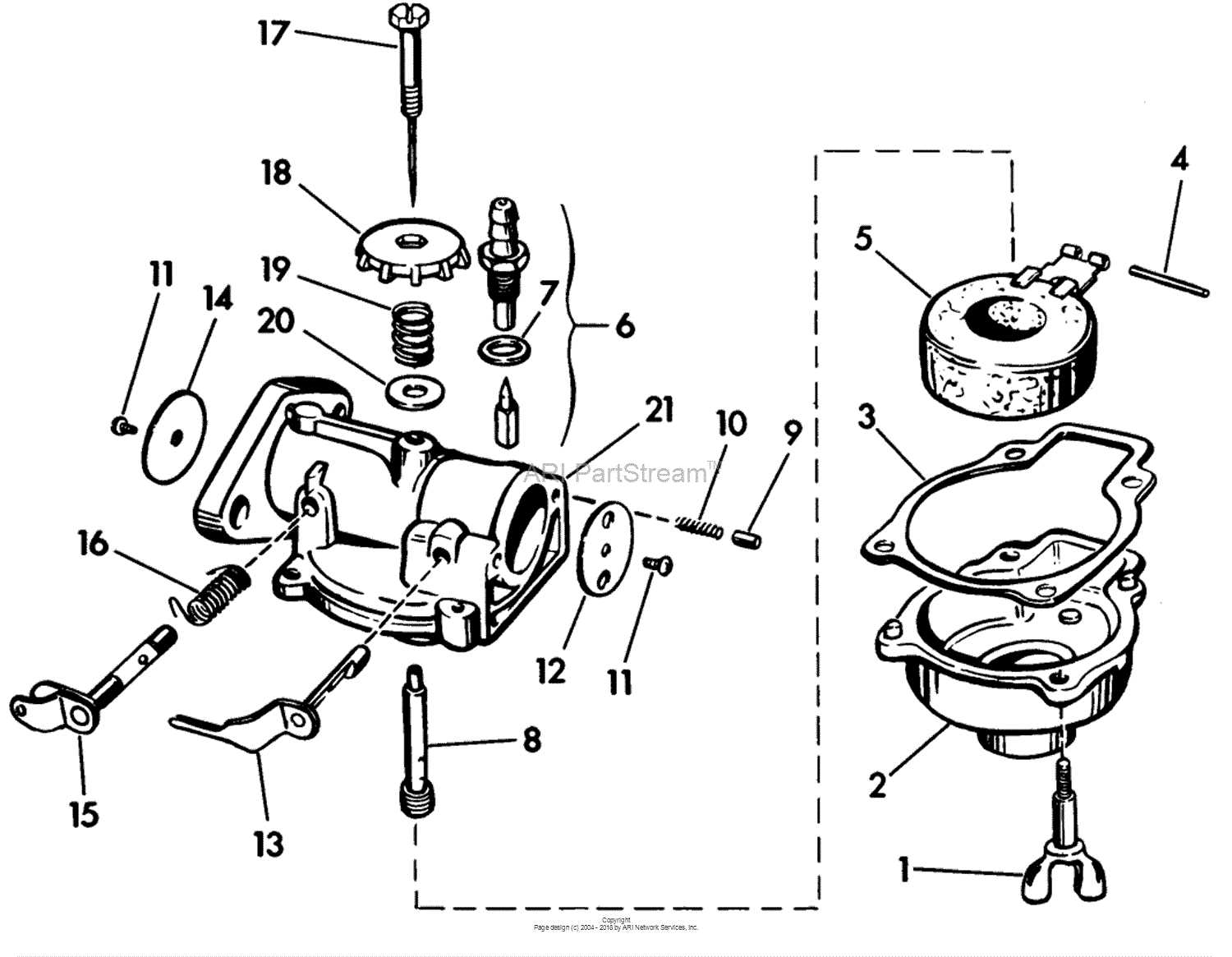

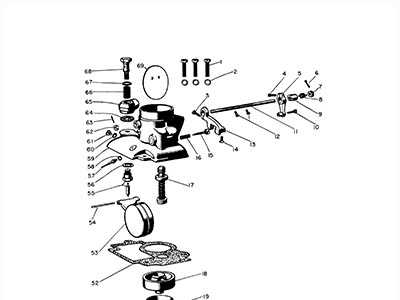

Key Components of Zenith Carburetors

This section explores the essential elements that contribute to the optimal performance of fuel delivery systems. Understanding these critical components is vital for effective maintenance and troubleshooting.

Main Elements

- Float Chamber: Regulates fuel supply to ensure consistent operation.

- Venturi: Creates a pressure difference to draw in fuel for mixing with air.

- Throttle Valve: Controls airflow and engine power output.

Supporting Features

- Needle Valve: Manages the flow of fuel into the chamber.

- Jet: Determines the amount of fuel mixed with air, affecting performance.

- Enrichment Device: Aids in cold starts by providing a richer fuel mixture.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of any mechanical system hinges on consistent and thorough upkeep. Regular attention not only prolongs the lifespan of the components involved but also enhances overall performance. Neglecting this crucial aspect can lead to a range of issues that may compromise functionality and increase repair costs.

Enhanced Performance

Routine servicing helps maintain optimal operation, allowing the system to function smoothly. Components that are well-maintained respond better, ensuring that the entire assembly works as intended. This leads to improved fuel efficiency and better responsiveness, ultimately enhancing the driving experience.

Cost Efficiency

Investing time in regular care can significantly reduce long-term expenses. By addressing minor issues before they escalate into major problems, owners can avoid costly repairs and replacements. Furthermore, well-maintained systems tend to consume less energy, resulting in savings over time.

In summary, adhering to a diligent maintenance schedule is essential for preserving the functionality and efficiency of any mechanical assembly. Prioritizing this aspect can lead to a more reliable and enjoyable experience.

Common Issues with Zenith Models

Various challenges can arise with specific fuel management systems, impacting performance and efficiency. Users often encounter a range of symptoms that may signal underlying problems requiring attention.

Fuel Delivery Problems

Inadequate fuel flow can lead to poor engine performance. Clogged passages or faulty pumps may hinder optimal operation, resulting in hesitation or stalling.

Air-Fuel Mixture Imbalance

An improper balance between air and fuel can cause rough idling and increased emissions. Adjustments to jets or the introduction of air leaks are common culprits needing resolution.

How to Identify Parts Quickly

Efficiently recognizing components in complex assemblies can save time and reduce frustration. By familiarizing yourself with certain characteristics and using helpful techniques, you can streamline the identification process and enhance your overall understanding.

Key Features to Look For

- Shape and Size: Observe the dimensions and contours, as these often indicate specific functions.

- Material Composition: Different materials can signify different uses; for instance, metals may indicate durability, while plastics could suggest lightweight applications.

- Color Coding: Many manufacturers use color as a quick reference for categorization, which can aid in faster recognition.

Techniques for Efficient Identification

- Reference Guides: Utilize manuals or online resources that provide detailed images and descriptions.

- Organized Storage: Keep components sorted in labeled containers to facilitate quick access and identification.

- Familiarization: Spend time with each item to understand its function and relation to other elements.

Tools Required for Repairs

For effective maintenance and restoration of automotive components, having the right equipment is essential. These tools not only facilitate the process but also ensure precision and safety while working.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are crucial for loosening and tightening fasteners.

- Wrenches: Both open-end and socket wrenches are necessary for various bolt sizes.

- Pliers: Needle-nose and standard pliers help in gripping and bending components.

- Cleaning Brushes: Essential for removing debris and ensuring optimal performance.

- Torque Wrench: Important for applying the correct amount of force to fasteners.

Having these tools at hand will significantly enhance the efficiency of any repair task.

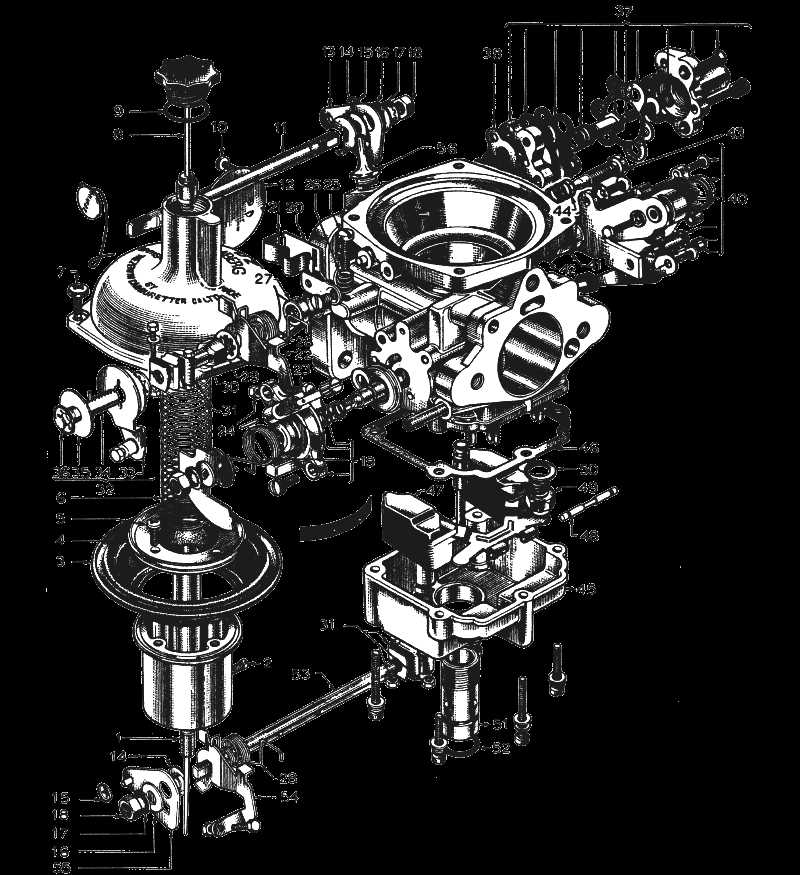

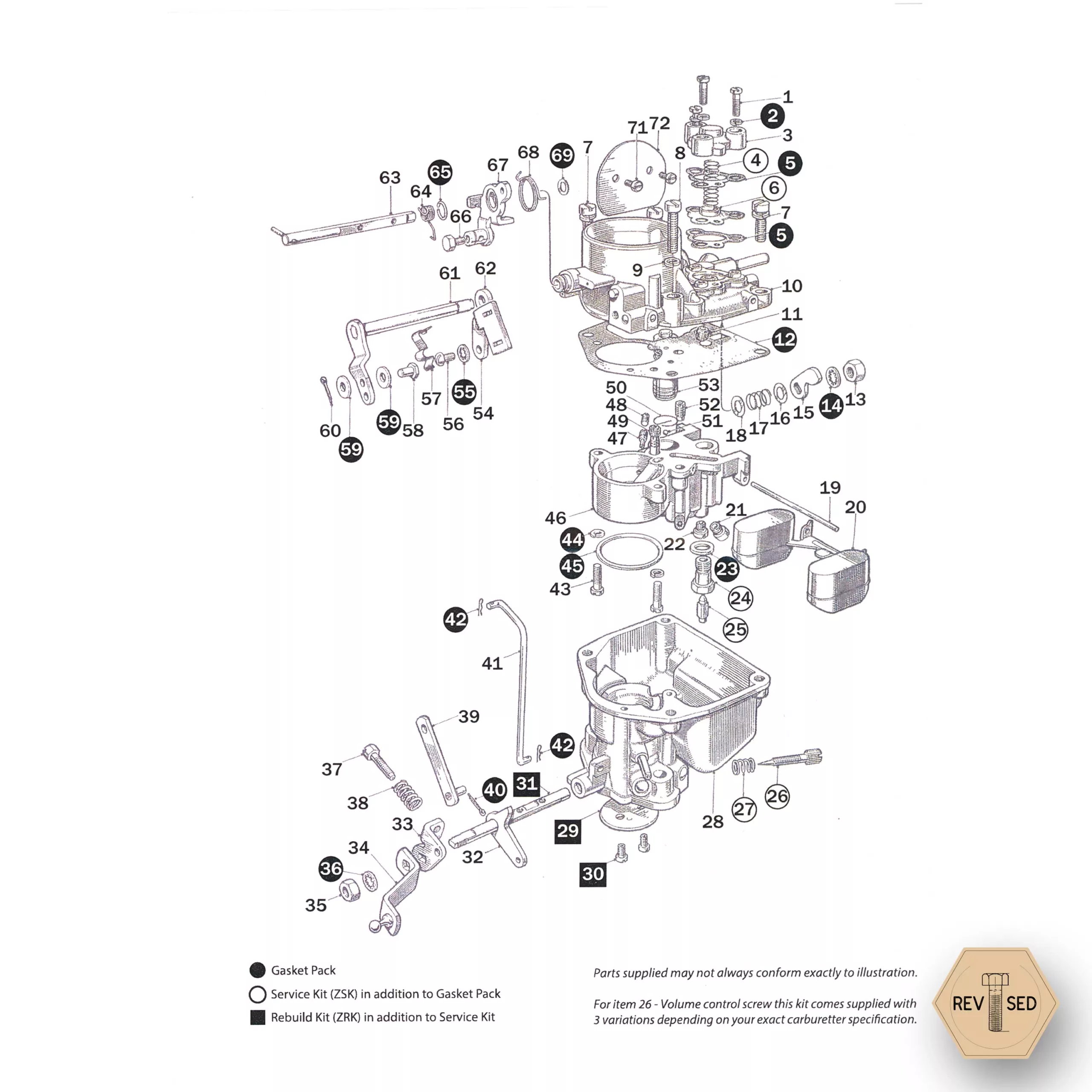

Step-by-Step Disassembly Guide

This guide will walk you through the process of taking apart a specific mechanical assembly. Understanding each step is crucial to ensure proper reassembly and optimal performance. Follow these instructions carefully to avoid any damage to components.

Preparation

- Gather necessary tools: screwdriver, pliers, and cleaning cloths.

- Find a clean, well-lit workspace to avoid losing small components.

- Ensure you have a container to organize removed items.

Disassembly Steps

- Start by removing the outer casing screws using a screwdriver.

- Carefully detach the outer casing from the main body.

- Identify and unscrew any securing bolts on the inner mechanisms.

- Gently lift out the internal assembly, taking note of its orientation.

- Remove additional components one by one, placing them in your container.

Completing these steps will help you delve deeper into the inner workings and prepare for further maintenance or cleaning. Be mindful of each piece as you go to ensure the ultimate reassembly experience.

Reassembly Tips for Efficiency

Ensuring a smooth reassembly process is essential for optimal performance and longevity of your engine components. Adopting a systematic approach can greatly enhance efficiency and minimize errors.

Preparation Steps

- Gather all necessary tools and components in one location.

- Clean each piece thoroughly to avoid contaminants.

- Organize components by type and size to streamline access.

Reassembly Process

- Refer to your reference guide or schematic for proper placement.

- Begin with the largest components and work towards the smaller ones.

- Double-check each connection and fastening to ensure security.

- Take your time; rushing can lead to mistakes.

Where to Find Replacement Parts

When seeking components for your engine’s fuel system, it’s essential to know where to look for high-quality replacements. Numerous sources provide access to both original and aftermarket options, catering to various needs and budgets.

Online Retailers: Many websites specialize in automotive supplies, offering a wide range of components. Sites like eBay or Amazon can also provide valuable choices, often at competitive prices.

Local Auto Shops: Don’t overlook nearby automotive supply stores. They can be a great resource for immediate needs, allowing you to inspect items firsthand.

Specialty Shops: Some establishments focus exclusively on vintage or specific brands. These places often stock hard-to-find components, making them ideal for enthusiasts.

Forums and Communities: Online communities and forums dedicated to automotive repair can be invaluable. Members frequently share leads on where to find elusive items and may even sell or trade their own.

Exploring these avenues will ultimately lead you to the best solutions for maintaining your vehicle’s performance.

Comparative Analysis of Carburetor Types

This section explores various fuel-air mixing devices, focusing on their design, functionality, and performance characteristics. Understanding the distinctions among these mechanisms can guide enthusiasts in selecting the ideal option for specific applications.

| Type | Advantages | Disadvantages |

|---|---|---|

| Slide Type | Smooth throttle response, easy tuning | Less efficient at low speeds |

| Butterfly Type | Good power delivery, reliable operation | Complex adjustment required |

| Variable Venturi | Adjusts to engine load, improved fuel efficiency | More expensive and complicated |

| Constant Vacuum | Consistent performance across RPM ranges | Potential for flooding |