In the realm of heavy equipment, having a clear understanding of various machine elements is crucial for maintenance and repair. This section aims to provide insights into the intricate relationships and functions of different components within a specific model. By visualizing how each part interacts, operators and technicians can enhance their operational efficiency and prolong the lifespan of their machinery.

Familiarizing oneself with the intricate assembly of a machine not only aids in troubleshooting issues but also contributes to better performance. The importance of accurate representation of each element cannot be overstated, as it serves as a valuable reference for those engaged in repair work or routine checks. Grasping these relationships ultimately empowers users to make informed decisions regarding their equipment management.

By delving into the specifics of these mechanical structures, users can uncover essential information that facilitates smoother operations. Understanding the arrangement and functionality of each segment fosters a deeper connection between the operator and the machinery, leading to improved outcomes in daily tasks and projects.

This section provides a comprehensive overview of a specific agricultural machine model, highlighting its features, functionalities, and applications in various farming scenarios. Understanding the key components and their roles is essential for effective maintenance and operation, ensuring that users can maximize the machine’s efficiency and longevity.

Key Features and Specifications

The discussed machinery is equipped with advanced technology that enhances performance in agricultural tasks. The design incorporates user-friendly elements and robust construction, making it suitable for various farming environments. Below are some key specifications:

| Specification | Details |

|---|---|

| Engine Type | Turbocharged Diesel |

| Power Output | Up to 100 HP |

| Transmission | Hydrostatic Drive |

| Weight | Approximately 5,500 lbs |

| Working Width | Variable up to 80 inches |

Importance of Component Understanding

A detailed comprehension of the machine’s elements is crucial for effective troubleshooting and repair. Knowledge of each component’s function aids operators in recognizing issues early, thereby preventing costly repairs and downtime. Familiarity with the construction and arrangement of these elements fosters better handling and operation of the machinery, ensuring optimal performance during use.

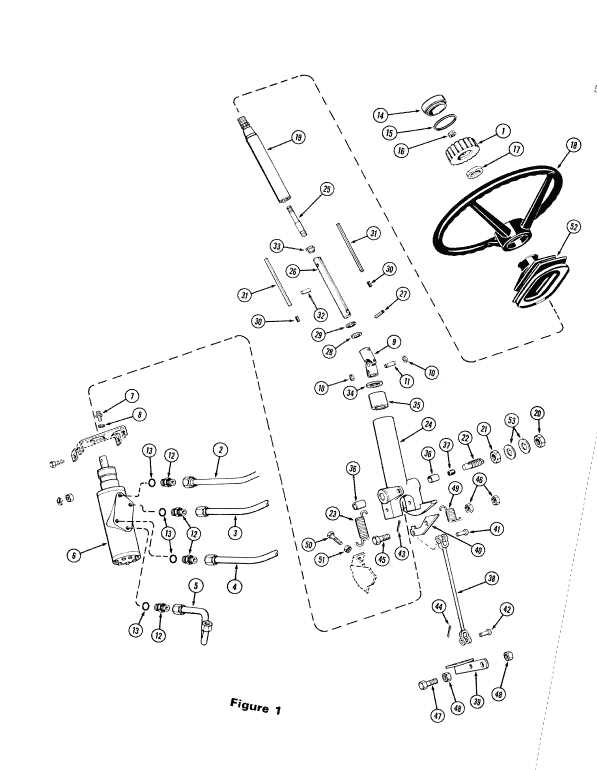

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and operation. Visual representations of individual elements serve as essential tools, allowing users to identify and comprehend the structure of their equipment. By providing clarity, these visuals aid in troubleshooting and facilitate timely repairs.

Enhanced Troubleshooting

When issues arise, having a visual reference can significantly streamline the diagnostic process. Technicians can quickly pinpoint the affected components, reducing downtime and enhancing overall efficiency. This accessibility fosters a deeper understanding of the machinery, leading to more effective resolutions.

Facilitating Maintenance

Regular upkeep is vital for the longevity of any machine. Visual guides not only highlight key elements but also offer insights into proper handling and care. By utilizing these references, operators can ensure that maintenance procedures are carried out effectively, thus prolonging the lifespan of their equipment.

Identifying Key Components

Understanding the essential elements of machinery is crucial for effective maintenance and operation. By recognizing these primary components, operators can enhance performance and ensure longevity. This section aims to clarify the most significant parts commonly found in such equipment.

Key components can typically be categorized into several groups:

- Structural Elements: These form the framework and support for the entire unit, providing stability and durability.

- Powertrain Components: This includes elements responsible for generating and transmitting power, crucial for the operation of the machinery.

- Control Systems: These components allow for the regulation and management of various functions, ensuring efficient operation.

- Safety Features: Essential for preventing accidents, these components help protect both the operator and the machinery.

When assessing the functionality of the machinery, it is vital to focus on each component’s role:

- Examine structural integrity to ensure the foundation remains solid.

- Evaluate the efficiency of power transmission mechanisms for optimal performance.

- Test control systems regularly to maintain responsive operation.

- Inspect safety features to guarantee compliance with regulations and protect personnel.

By familiarizing oneself with these essential elements, operators can effectively troubleshoot issues, perform routine checks, and implement necessary repairs, leading to a more efficient operation.

Exploring Common Repairs

Regular maintenance and timely fixes are essential for the longevity of machinery. Understanding the frequent issues that arise can help operators address problems efficiently and enhance performance. This section delves into typical repairs encountered in heavy equipment, providing insights into the most effective solutions.

Identifying Frequent Issues

Operators often face a variety of challenges that require attention. Common concerns may include:

- Engine performance problems

- Hydraulic system leaks

- Transmission malfunctions

- Electrical system failures

- Wear and tear on critical components

Effective Repair Strategies

Implementing proper strategies can greatly improve machinery functionality. Here are some recommended approaches:

- Conduct regular inspections to catch issues early.

- Utilize quality replacement components for repairs.

- Follow manufacturer guidelines for servicing.

- Train personnel on basic troubleshooting techniques.

- Keep a comprehensive maintenance log to track repairs and service intervals.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of machinery requires regular upkeep and attention to detail. Adopting effective maintenance practices can significantly extend the life of your equipment and prevent unexpected failures. This section outlines essential strategies to keep your machinery running smoothly.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Regular Inspections | Weekly | Identifies wear and potential issues early |

| Fluid Changes | Every 250 hours | Prevents contamination and maintains efficiency |

| Filter Replacements | Every 500 hours | Enhances airflow and prevents blockages |

| Greasing Moving Parts | Monthly | Reduces friction and extends component life |

| Cleaning Components | Biweekly | Removes debris and improves performance |

Implementing these practices as part of your routine will lead to increased reliability and longevity of your machinery. By staying proactive and attentive, you can avoid costly repairs and enhance productivity over time.

Safety Precautions When Working

Ensuring a safe working environment is crucial for maintaining health and preventing accidents during operations. Adopting proper safety measures can significantly reduce risks associated with machinery handling and maintenance tasks.

Proper Personal Protective Equipment (PPE) is essential. Always wear appropriate gear such as gloves, goggles, and helmets to shield yourself from potential hazards. Make sure that the equipment fits correctly and is suitable for the specific tasks being performed.

Maintain a Clean Workspace. A tidy environment minimizes distractions and helps prevent accidents. Keep tools and materials organized, and promptly clean up spills or debris to ensure safe movement around the work area.

Understand the Equipment you are working with. Familiarize yourself with its operation and potential dangers before beginning any task. Reviewing the manufacturer’s guidelines and training materials can enhance your understanding and preparedness.

Regular Inspections of tools and machinery are necessary to identify wear or defects that could lead to malfunctions. Conduct routine checks to ensure everything is in good working order and address any issues before commencing work.

Stay Focused and avoid distractions while operating machinery. Concentration is key to preventing accidents and ensuring efficient workflow. If you feel fatigued or distracted, take a break before resuming your tasks.

Implementing these precautions contributes to a safer working environment, ultimately protecting both the worker and the equipment. Prioritizing safety should always be at the forefront of any operational procedures.

Finding Replacement Parts

When it comes to maintaining machinery, sourcing suitable components is essential for ensuring optimal performance. Whether it’s for routine upkeep or necessary repairs, knowing where to find reliable replacements can save time and enhance functionality. This section outlines effective strategies to help you locate the right components for your equipment.

Online Resources

The internet offers a wealth of information for those seeking alternatives. Various websites specialize in providing detailed catalogs of components, allowing users to search by specifications or equipment type. Additionally, online forums and communities can be invaluable resources, where experienced users share insights and recommendations about trustworthy suppliers.

Local Suppliers and Distributors

Visiting local vendors can also be beneficial. Many suppliers carry a range of components suitable for different types of machinery. Establishing relationships with these distributors can lead to personalized service and expert advice, which can be crucial when identifying the correct replacements for your needs.

Understanding Assembly Process

The assembly process involves the systematic organization and integration of various components to create a functional unit. This procedure is crucial in ensuring that each element fits together seamlessly, enhancing the overall performance of the machine. A clear comprehension of this process is essential for effective maintenance and troubleshooting.

Step-by-step procedures play a vital role in guiding individuals through the assembly, detailing each stage to minimize errors. This methodical approach helps technicians understand how each segment contributes to the machine’s operation.

Additionally, visual aids can greatly enhance the assembly experience. Diagrams and charts provide a reference point, allowing for easier identification of components and their respective placements. By utilizing these tools, individuals can ensure that every part is accurately positioned, contributing to the overall integrity of the structure.

Ultimately, a thorough understanding of the assembly process fosters confidence in handling machinery, leading to improved efficiency and reliability in operations.

Troubleshooting Guide

This guide provides essential information for identifying and resolving common issues that may arise with heavy machinery. Proper maintenance and quick diagnostics can enhance the performance and longevity of the equipment.

When faced with operational difficulties, consider the following steps:

- Inspect the engine for unusual noises or vibrations.

- Check the fluid levels, including oil, coolant, and hydraulic fluids.

- Examine the electrical system for any blown fuses or faulty connections.

- Look for signs of wear or damage on belts and hoses.

For more specific concerns, the following issues are often encountered:

- Starting Problems:

- Ensure the battery is charged and connections are secure.

- Inspect the starter motor for functionality.

- Overheating:

- Verify the radiator is clean and free of obstructions.

- Check for leaks in the cooling system.

- Hydraulic Issues:

- Examine hydraulic fluid levels and refill if necessary.

- Look for leaks in hoses or fittings.

By systematically addressing these areas, you can effectively diagnose and rectify most common operational challenges. Regular maintenance is key to ensuring reliable performance.

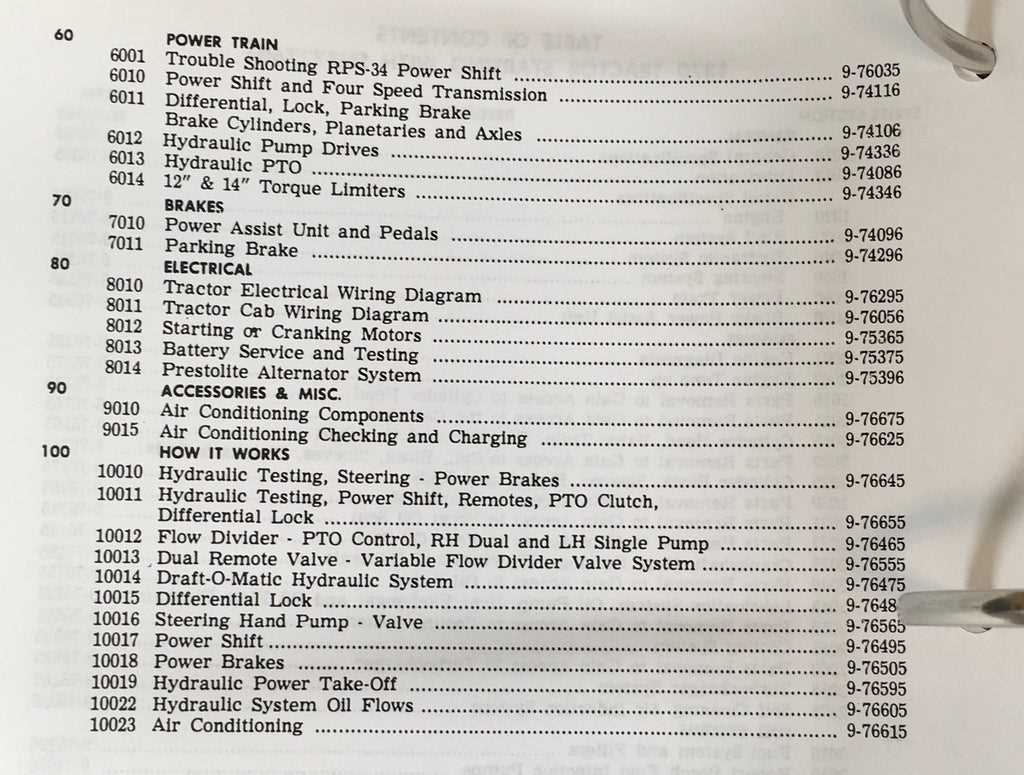

Resources for Further Learning

Gaining a deeper understanding of machinery and their components is essential for anyone involved in maintenance, repairs, or enhancements. Accessing reliable information sources can greatly enhance your knowledge and skills in this field.

One valuable resource is technical manuals, which provide detailed explanations of various systems, including operational guidelines and troubleshooting tips. Additionally, many manufacturers offer online libraries where users can download documentation, including schematics and user guides.

Engaging with online forums and communities can also be beneficial. These platforms allow users to share experiences, ask questions, and receive advice from others who have faced similar challenges. Furthermore, consider enrolling in educational courses or workshops focused on machinery maintenance, as these can provide hands-on experience and expert insights.

Finally, utilizing videos and tutorials available on various platforms can visually demonstrate complex processes, making it easier to grasp difficult concepts. By exploring these resources, you can build a solid foundation of knowledge and improve your practical skills.