The intricate design of heavy machinery is a marvel of engineering, where every element plays a crucial role in ensuring optimal performance. This section delves into the various segments and assemblies that constitute a particular model, providing valuable insights into their functionality and arrangement. By exploring these components, users can better appreciate the machine’s efficiency and the interconnectedness of its parts.

When maintaining or repairing equipment, having a clear representation of its elements is essential. Such illustrations serve as valuable references, enabling operators and technicians to identify specific sections quickly. This knowledge not only streamlines maintenance processes but also enhances overall operational safety.

Additionally, understanding the layout of these components can significantly aid in troubleshooting. Recognizing how different segments interact helps diagnose issues effectively, ensuring that any necessary adjustments or replacements can be made promptly. As a result, users can achieve greater reliability and longevity from their machinery.

Importance of Parts Diagrams

The value of visual representations in machinery maintenance cannot be overstated. These illustrations provide a clear view of components and their arrangements, enabling users to understand the structure and function of various elements within equipment. This clarity is crucial for effective troubleshooting and repairs.

Understanding Components is essential for anyone involved in maintenance or repairs. Visual aids help technicians identify each element’s role, ensuring they can address issues efficiently. When a part fails, knowing its location and function allows for quicker resolution, reducing downtime and improving productivity.

Additionally, enhanced communication among team members is facilitated by these representations. By referring to a shared visual guide, workers can discuss problems and solutions more effectively, leading to better collaboration and fewer misunderstandings.

Furthermore, such illustrations can serve as educational tools for new employees or those unfamiliar with specific machinery. By studying these resources, individuals can gain a comprehensive understanding of equipment operations, which is invaluable for safety and efficiency.

In summary, these visual resources play a pivotal role in maintenance practices. They not only aid in understanding and communication but also enhance the overall effectiveness of repair efforts.

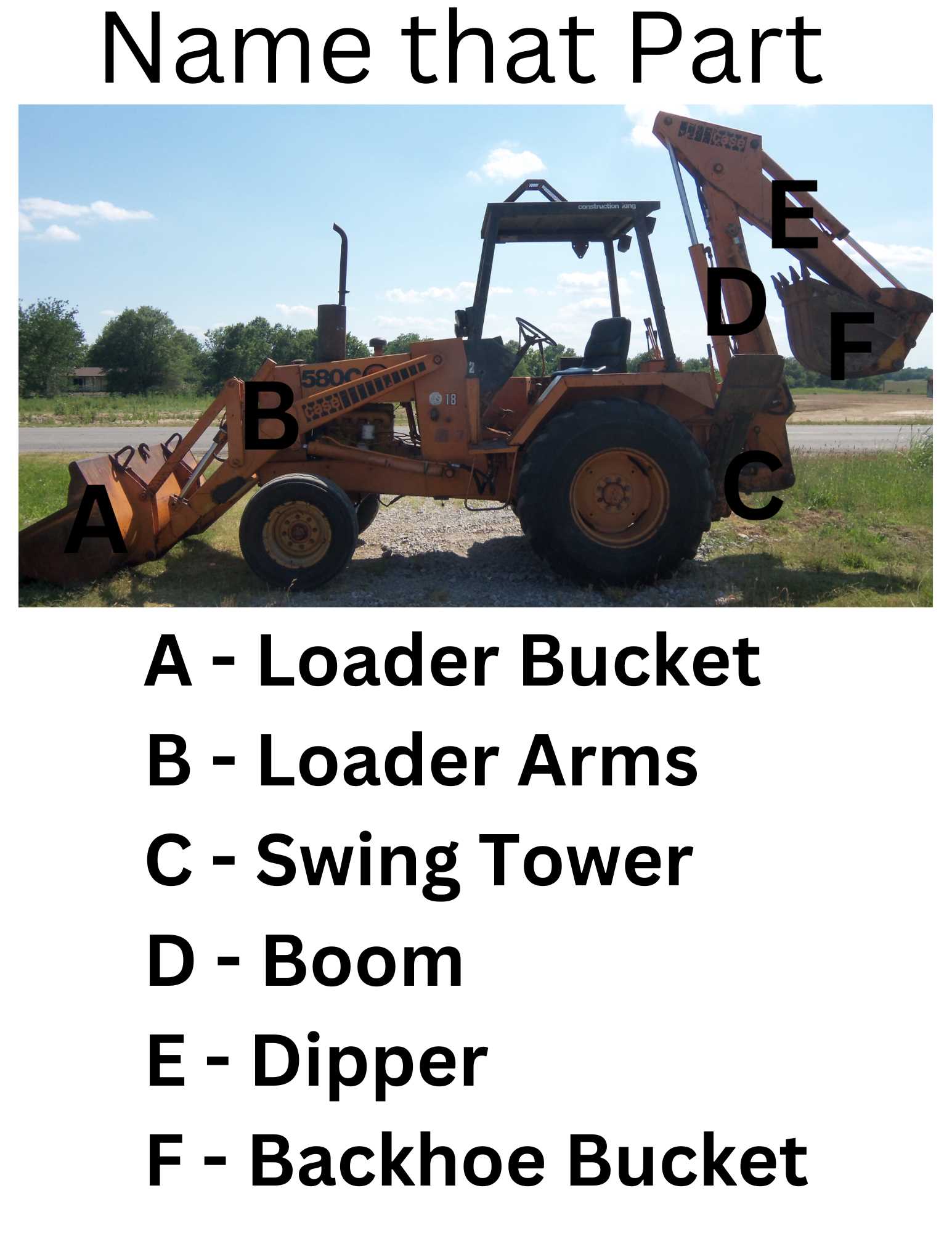

Main Components of the Case 580e

This section delves into the essential elements that contribute to the functionality and efficiency of the machine. Understanding these core components is crucial for maintenance and optimal performance.

Engine and Transmission

The heart of the machine is its engine, which provides the necessary power to drive various operations. Coupled with a robust transmission system, these components work in harmony to ensure smooth movement and operation across different terrains.

Hydraulic System

The hydraulic system is pivotal for the performance of various attachments and implements. It enables powerful lifting and digging capabilities, making the machine versatile for numerous tasks on job sites.

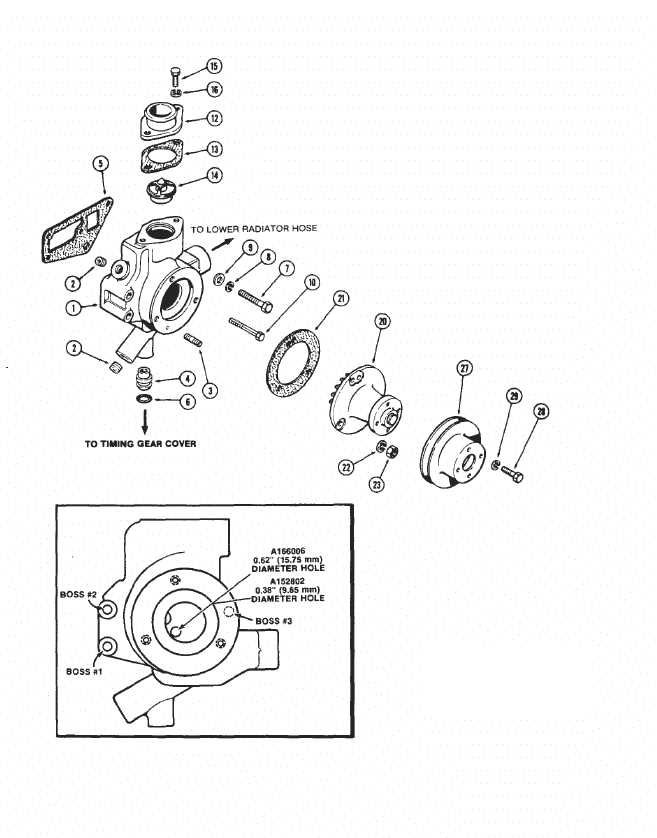

Understanding Hydraulic System Parts

Hydraulic systems play a vital role in heavy machinery, enabling the efficient transmission of power through pressurized fluid. These systems consist of various interconnected components that work together to control and direct the movement of different mechanical parts. Understanding how each element functions within this system is key to maintaining optimal performance and addressing potential issues effectively.

At the core of every hydraulic system is the pump, responsible for generating the flow of hydraulic fluid. This fluid then travels through a network of hoses and tubes, which connect to actuators such as cylinders and motors. These actuators convert the fluid’s pressure into mechanical motion, allowing for lifting, pushing, or rotating movements depending on the equipment’s function.

Valves are critical in regulating the flow and pressure within the system, ensuring that

Common Issues with Heavy Equipment Components

Heavy-duty machinery often faces a variety of issues over time, especially as different systems are exposed to challenging environments and demanding tasks. Identifying these problems early can prevent costly repairs and equipment downtime.

Hydraulic Leaks are a frequent concern in machinery, typically caused by worn-out seals, hoses, or fittings. These leaks can lead to reduced performance and potential damage to other components if not addressed promptly.

Engine Overheating is another issue that can arise, often due to clogged radiators, malfunctioning thermostats, or insufficient coolant levels. Overheating can severely impact operational efficiency and shorten the lifespan of critical parts.

Transmission Failures tend to develop

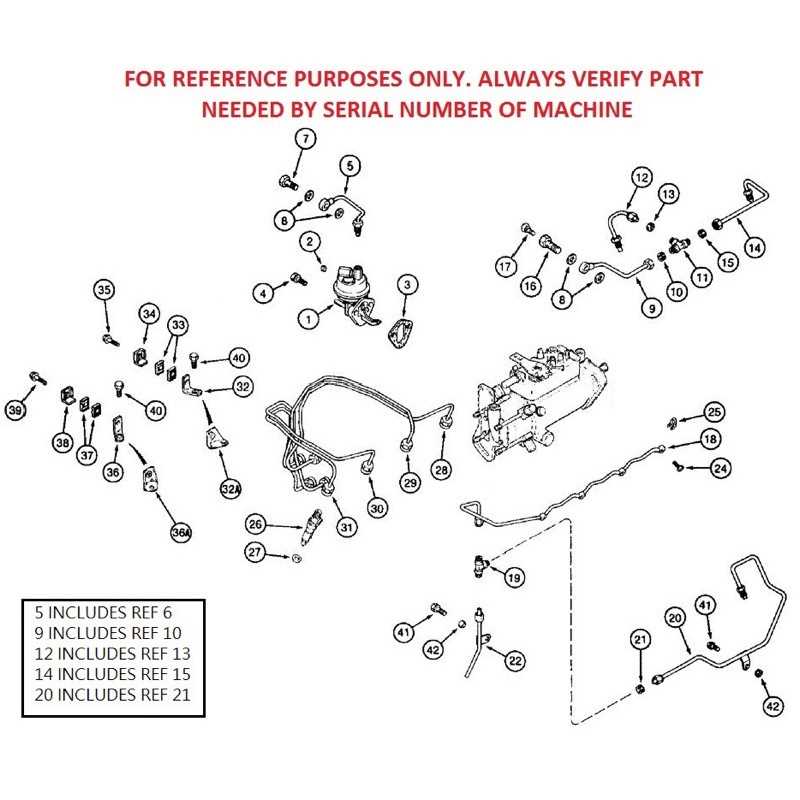

How to Read Parts Diagrams

Understanding technical schematics can significantly simplify the repair or maintenance of complex machines. These visual representations provide a clear breakdown of various system components, helping users identify and locate specific items for assembly or replacement.

To efficiently interpret these visual guides, follow these basic steps:

- Start by examining the entire illustration to get a sense of the overall structure. This will help you understand how individual elements fit together.

- Look for numbered labels or codes, which correspond to specific parts listed in an accompanying chart or index. These references make it easier to match components in the schematic.

- Use the legend or key, often provided, to interpret symbols or technical abbreviations used throughout the image.

- Check for arrows or lines that indicate connections between elements. These can help clarify how different parts interact within the

Replacement Parts for Case 580e

Maintaining and extending the lifespan of your heavy-duty machinery requires regular checks and the replacement of various essential components. When it’s time to swap out worn-out items, having a clear understanding of the necessary substitutes is key for ensuring smooth operation and long-term reliability. Below is a detailed guide on the most commonly replaced items for your equipment, ensuring that it continues to perform efficiently.

Frequently Replaced Components

Certain parts of construction machinery tend to experience more wear and tear due to daily use. These include items such as hydraulic components, brake systems, and engine components. Addressing these areas proactively can help you avoid costly downtime and maintain

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires consistent upkeep and attention to detail. Regular maintenance not only prevents costly repairs but also extends the service life of key components. A proactive approach to caring for your equipment guarantees that it will continue to operate efficiently over time.

Regular Lubrication

One of the most important aspects of maintenance is keeping all moving parts properly lubricated. Friction between components can cause excessive wear, leading to decreased functionality and premature breakdowns. Applying the appropriate grease or oil as recommended by the manufacturer ensures smooth operation and reduces the risk of mechanical failure.

Inspect and Replace Worn Components

Over time, certain elements of the equipment may show signs of wear. Regular

Identifying Wear and Tear

Recognizing signs of deterioration in machinery is crucial to maintaining efficiency and avoiding costly repairs. Regular inspections allow for timely detection of worn components, ensuring that maintenance is performed before significant failures occur.

There are several key areas where mechanical components are more prone to degradation over time. Being familiar with these can help extend the life of your equipment.

- Hydraulic systems: Check for leaks, reduced pressure, or slow response times, as these can indicate wear in seals or valves.

- Bearings and bushings: Look for excessive vibration or noise during operation, which can signal the need for replacement.

- Engine and transmission: Pay attention to unusual sounds, reduced power, or shifting issues, as these may point to worn gears or clutches.

Aftermarket vs. OEM Parts

When it comes to replacing components in machinery, there are two main options available: aftermarket and original equipment manufacturer (OEM) parts. Each option offers its own set of advantages and potential drawbacks, making the choice dependent on various factors, such as budget, performance needs, and longevity expectations. Understanding the differences between these two options can help in making a more informed decision for repairs or upgrades.

Aspect Aftermarket OEM Cost Typically more affordable Often more expensive Availability Widely available, multiple manufacturers Limited to authorized dealers or manufacturers Resources for Parts Diagrams

When it comes to finding technical schematics and breakdowns of mechanical equipment, there are several reliable platforms available online. These resources are essential for anyone seeking detailed component layouts, whether for maintenance, repair, or restoration projects. Accessible through user-friendly websites, such tools provide comprehensive guides, allowing users to navigate complex machinery structures with ease.

Official Manufacturers’ Platforms

Many manufacturers offer online catalogs that include technical blueprints for their machinery. These platforms often provide search features that allow users to locate specific equipment by model number, ensuring accuracy. In addition, some may offer downloadable files or interactive views, further aiding in identifying key components for servicing.

Aftermarket and Third-Party Resources

In addition to official sources, numerous third-party websites specialize in providing detailed diagrams for older or less common equipment. These platforms often include community-driven contributions, ensuring a wide range of