In the realm of heavy machinery, familiarity with the various elements that constitute operational efficiency is crucial. A clear understanding of these components enables operators and technicians to maintain functionality and enhance performance. This section delves into the intricate arrangement of essential elements within a specific piece of machinery, providing insights into their roles and interconnections.

Each segment of the assembly plays a vital role, contributing to the overall capability and reliability of the equipment. By examining the layout and functionality of these key components, users can make informed decisions regarding maintenance and repairs. This knowledge not only facilitates smoother operations but also extends the lifespan of the machinery.

Through detailed exploration, readers will gain a comprehensive overview of how each part interacts within the system. This understanding is essential for anyone looking to optimize their experience with heavy equipment, ensuring that every operation is executed with precision and care.

Understanding the Case 580M Backhoe

Heavy machinery designed for excavation and earth-moving tasks plays a crucial role in various construction and agricultural projects. These versatile machines are engineered to handle a range of functions, making them indispensable for operators seeking efficiency and productivity on the job site.

One of the remarkable features of such equipment is its combination of power and precision. With the ability to perform digging, lifting, and loading tasks, these machines streamline operations and reduce the need for multiple vehicles. The design incorporates several key components that work in harmony, allowing operators to navigate different terrains while maintaining optimal performance.

| Component | Description |

|---|---|

| Engine | Powers the machine, providing the necessary force for various tasks. |

| Hydraulic System | Enables smooth movement of the loader and excavator arms through fluid power. |

| Transmission | Facilitates gear shifting to adapt to different operational demands. |

| Operator’s Cabin | Designed for comfort and visibility, allowing for efficient control of functions. |

Understanding the structure and functionalities of such equipment enhances the operator’s ability to execute tasks effectively. Regular maintenance and knowledge of the machine’s components contribute significantly to its longevity and reliability on the job.

Overview of Key Components

Understanding the fundamental elements of heavy machinery is essential for both operation and maintenance. Each component plays a critical role in the overall functionality and efficiency of the equipment. This section explores the main features that contribute to the performance and reliability of such machinery.

- Engine: The powerhouse that drives the entire system, providing the necessary force for movement and operation.

- Hydraulic System: A vital mechanism that enables various movements, allowing for lifting, digging, and loading operations with precision.

- Transmission: Responsible for transferring power from the engine to the wheels, ensuring smooth mobility and control over different terrains.

- Chassis: The framework that supports all other components, providing stability and structural integrity during operation.

- Operator’s Cabin: The workspace designed for the operator, equipped with controls and visibility features for effective maneuvering.

Each of these elements is interrelated, and their optimal performance is crucial for achieving operational efficiency. Regular inspections and maintenance can enhance their longevity and functionality.

Importance of Maintenance and Repair

Regular upkeep and timely restoration are essential components of any machinery’s longevity and efficiency. Neglecting these practices can lead to significant performance issues, reduced lifespan, and costly breakdowns. Ensuring that all systems function optimally helps prevent unplanned downtime and enhances productivity.

Proactive care not only addresses minor wear and tear but also identifies potential issues before they escalate. This approach can save both time and resources, fostering a smoother operation. Moreover, maintaining equipment enhances safety for operators and surrounding personnel, reducing the risk of accidents and injuries.

Ultimately, prioritizing maintenance and repairs contributes to better performance, higher reliability, and improved overall functionality. By investing in these practices, users can secure the operational integrity of their machinery and maximize return on investment.

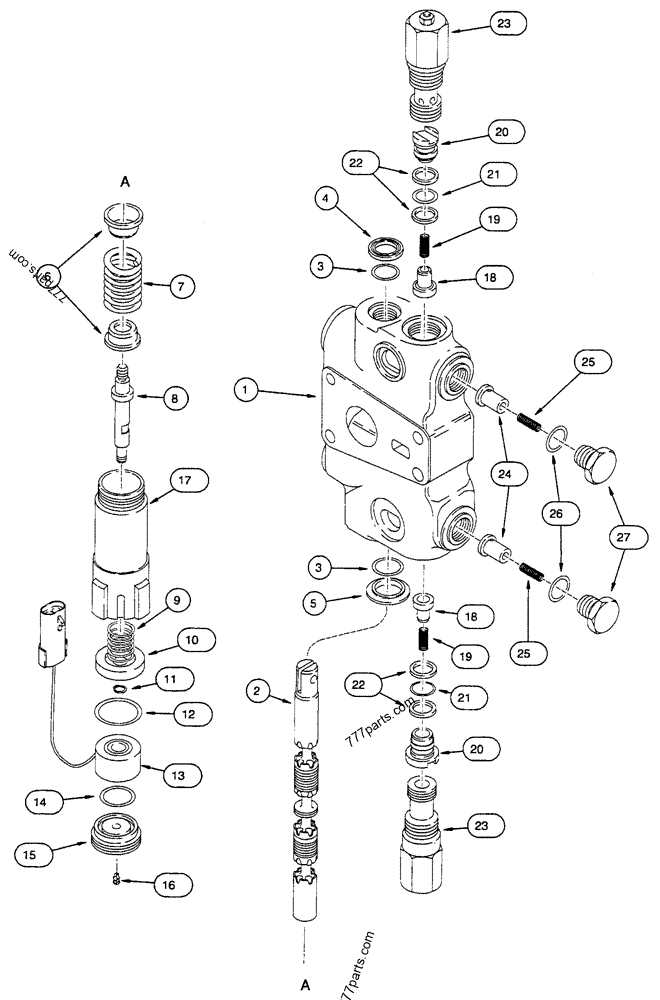

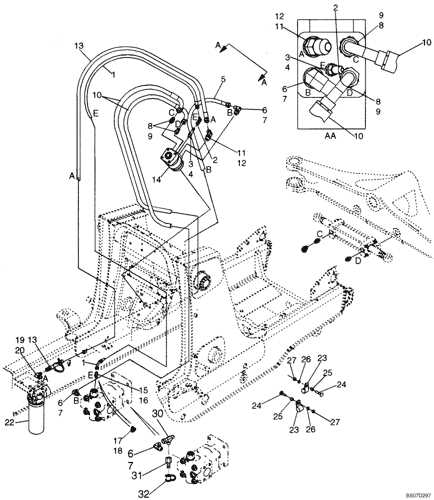

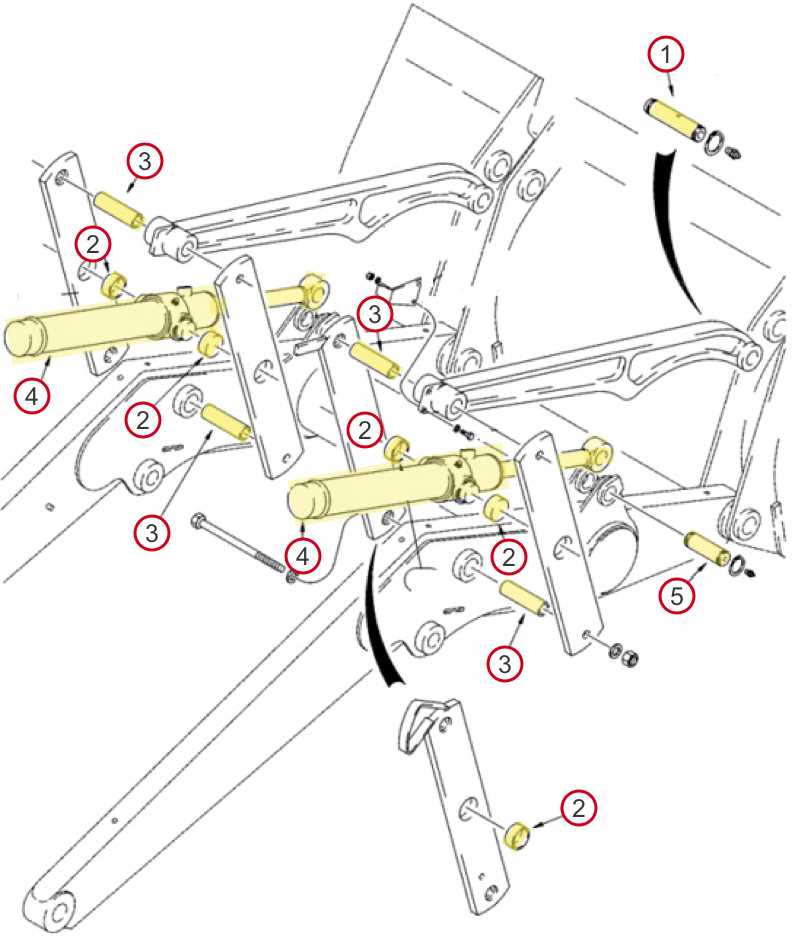

Identifying Hydraulic System Parts

The hydraulic system is essential for the effective operation of heavy machinery, enabling smooth and powerful movements. Understanding its components is crucial for maintenance and troubleshooting. This section outlines the key elements of this system, emphasizing their functions and significance in ensuring optimal performance.

| Component | Description |

|---|---|

| Hydraulic Pump | Converts mechanical energy into hydraulic energy, generating flow within the system. |

| Hydraulic Cylinder | Transforms hydraulic pressure into linear motion, enabling lifting and pushing actions. |

| Hydraulic Hoses | Transmits fluid between components, ensuring the system’s connectivity and efficiency. |

| Control Valve | Regulates the flow and direction of hydraulic fluid, allowing precise control over movements. |

| Filter | Removes contaminants from the hydraulic fluid, protecting components from damage. |

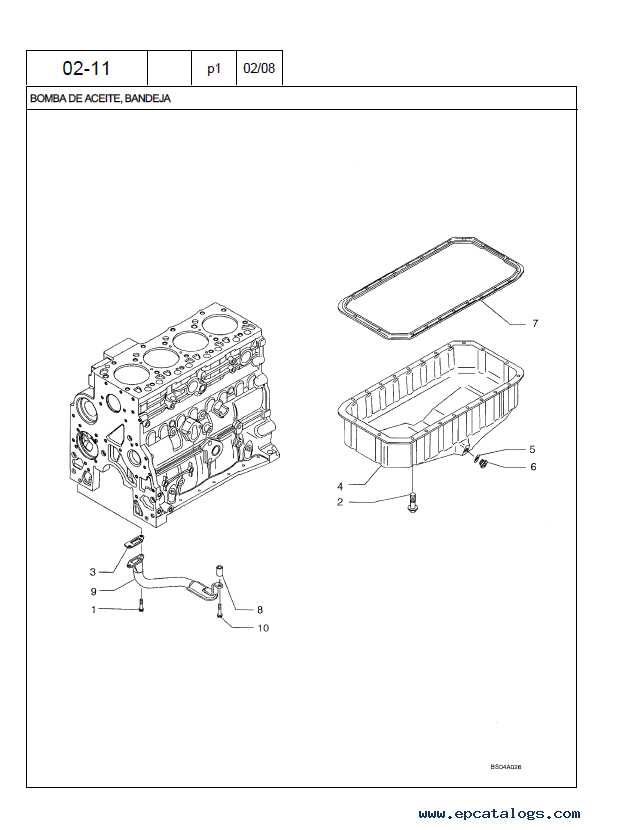

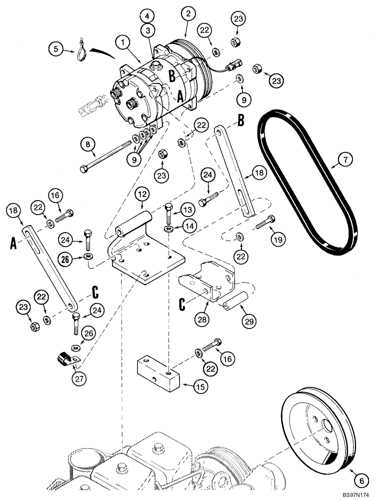

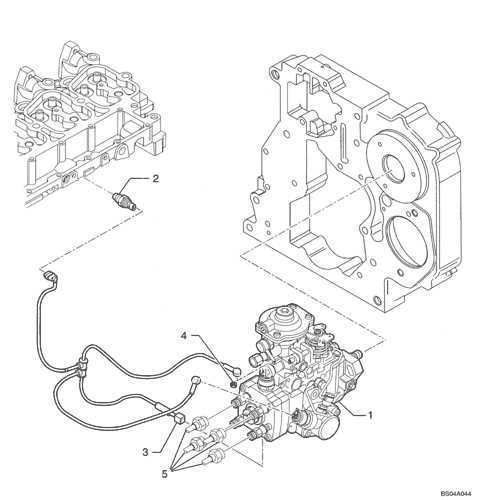

Engine Assembly and Its Functions

The engine assembly serves as the heart of any machine, transforming fuel into mechanical energy to power various operations. This intricate system comprises multiple components that work harmoniously to ensure optimal performance and efficiency. Understanding its design and functionality is essential for effective maintenance and troubleshooting.

Key Components

At the core of the engine assembly lies the cylinder block, which houses the cylinders and provides structural support. Connected to this is the crankshaft, which converts the linear motion of the pistons into rotational force. Additionally, the camshaft plays a crucial role in timing the opening and closing of the valves, ensuring that air and fuel enter the combustion chamber at the right moment.

Functionality

The primary function of the engine assembly is to facilitate the combustion process, which occurs within the cylinders. As the fuel-air mixture ignites, it creates a controlled explosion that pushes the pistons down, generating power. This process not only drives the machine forward but also powers various auxiliary systems, contributing to the overall functionality and versatility of the equipment.

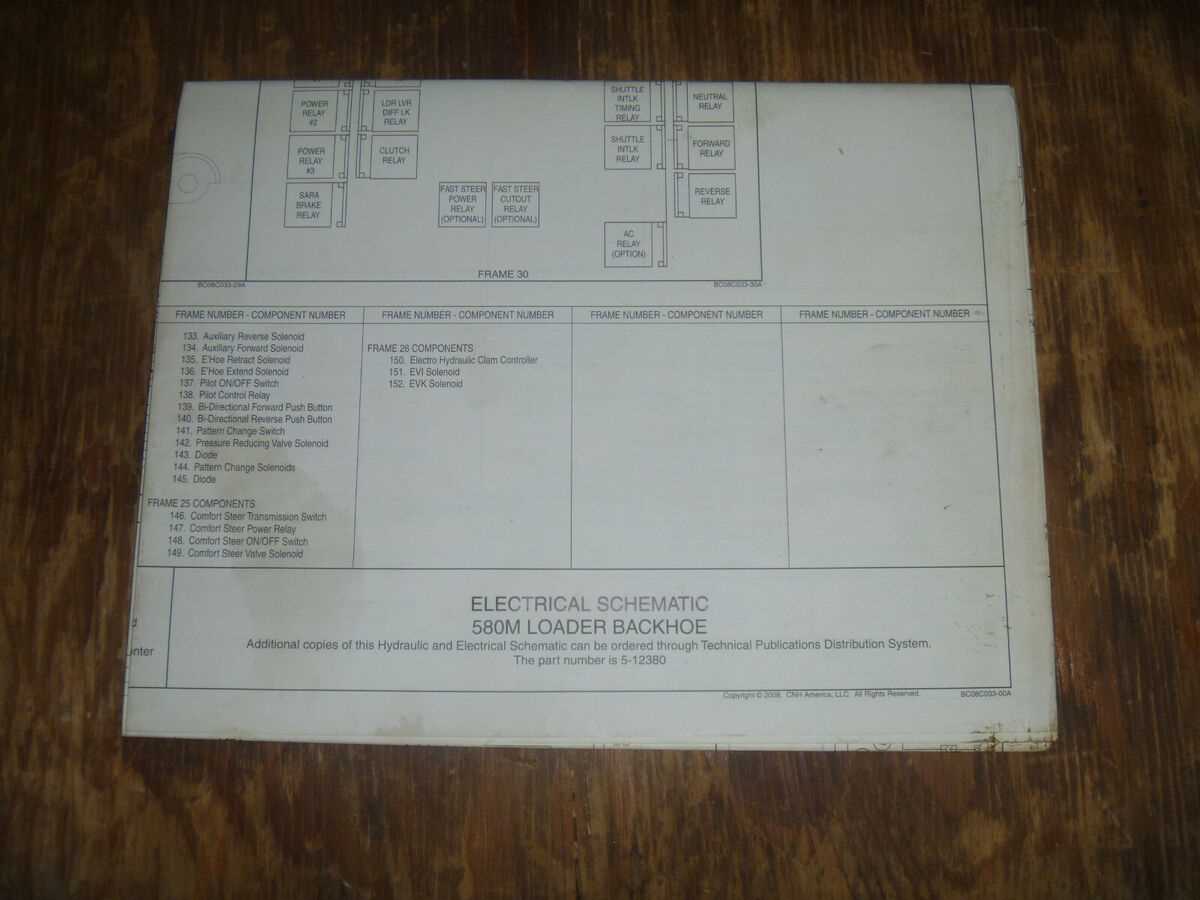

Electrical System Diagram Explained

The electrical layout of heavy machinery plays a crucial role in its functionality and performance. This section provides an overview of the intricate design and components that ensure the seamless operation of various electrical systems. Understanding this arrangement helps in diagnosing issues and performing effective maintenance.

Key Components of the Electrical Setup

- Battery: Serves as the primary power source, supplying energy to start the engine and operate electrical accessories.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery while the engine is running.

- Wiring Harness: A network of cables that connects various electrical components, allowing for communication and power distribution.

- Fuses and Relays: Protect circuits from overload and facilitate the control of electrical devices.

Understanding the Functionality

The layout typically includes various sensors and switches that monitor and control different systems. The power generated by the battery and alternator is distributed through the wiring harness to components such as lights, gauges, and hydraulic systems. Proper functioning of this network is essential for optimal performance.

Regular inspection of the electrical configuration ensures that all components operate efficiently, preventing potential breakdowns and extending the lifespan of the machinery.

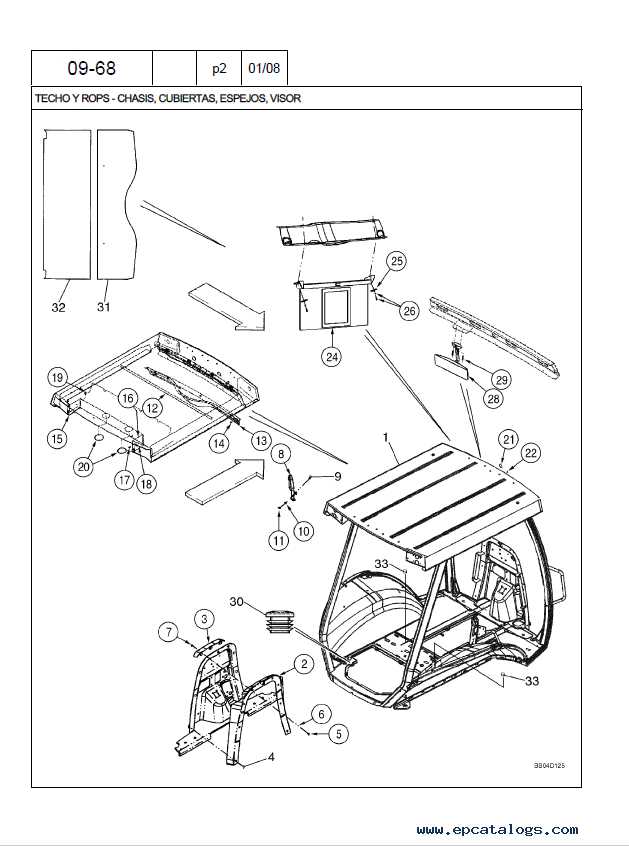

Frame and Chassis Components Breakdown

This section delves into the structural elements that form the foundation of heavy machinery. These components play a vital role in providing stability, support, and durability, enabling efficient operation across various terrains. Understanding these elements is crucial for maintenance and repair, ensuring optimal functionality.

Main Structural Elements

The primary structural components include:

- Frame: The backbone of the machine, supporting various attachments and systems.

- Chassis: Houses the essential mechanical parts and connects different sections of the equipment.

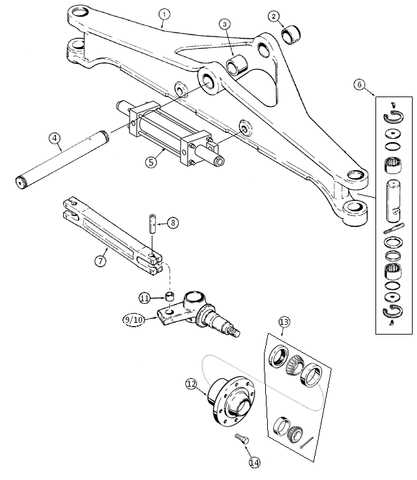

- Axles: Provide support for the wheels and facilitate movement.

- Suspension System: Enhances stability and absorbs shocks during operation.

Support and Stability Features

Additional features that contribute to the overall performance:

- Crossmembers: Reinforce the frame, adding rigidity and strength.

- Mounting Brackets: Secure various components to the frame, ensuring reliable connections.

- Stabilizers: Prevent unwanted movement, maintaining balance during use.

- Access Platforms: Allow easy maintenance and operation from various angles.

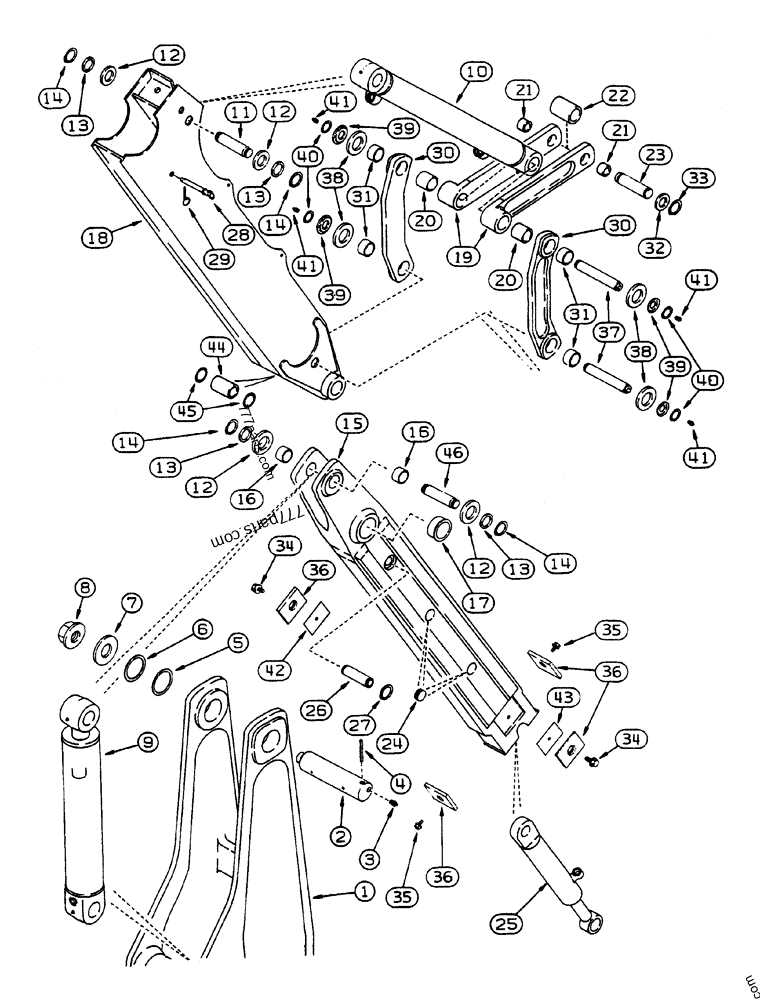

Front Loader Attachment Details

The front loader is a crucial implement designed to enhance the functionality of various heavy machinery. This tool facilitates numerous tasks, including lifting, moving, and loading materials with efficiency and precision. Understanding its components and operational aspects can significantly improve productivity on job sites.

Key Components

Essential elements of the loader include the bucket, hydraulic arms, and connecting mechanisms. The bucket is typically made of durable materials to withstand heavy loads and harsh conditions. Hydraulic arms provide the necessary lifting power, allowing for smooth operation and control during use. Connecting mechanisms ensure compatibility with the main machinery, making the attachment process straightforward.

Functionality and Usage

This implement excels in various applications, from construction and landscaping to agricultural tasks. Its versatility enables operators to tackle a range of projects efficiently. Proper maintenance and understanding of the loader’s features can lead to optimal performance, ensuring that the machine operates smoothly and effectively over time.

Bucket Specifications and Variants

In the realm of construction equipment, the attachment designed for excavation plays a crucial role in enhancing operational efficiency. Different configurations and characteristics of this implement cater to various tasks and terrain types, allowing for versatile use in diverse environments. Understanding these specifications helps operators select the most suitable option for their specific needs.

These tools come in multiple designs, each engineered to perform distinct functions. For instance, variations in width, shape, and material composition can significantly impact digging depth and soil penetration. Moreover, some models feature reinforced edges for increased durability, while others may have specialized teeth to optimize performance on challenging surfaces. The choice of attachment not only affects productivity but also influences overall equipment longevity.

When selecting an implement, it is essential to consider factors such as capacity and compatibility with the machine. Some models are designed for heavy-duty applications, while others are more suited for lighter tasks. Additionally, understanding the different mounting options and configurations can aid in achieving a seamless integration with the operating equipment, ensuring optimal functionality.

Common Replacement Parts for Efficiency

Ensuring optimal performance of heavy machinery often relies on the timely replacement of essential components. Regular maintenance and the use of quality substitutes can significantly enhance the longevity and functionality of equipment. Understanding the common elements that may require replacement is crucial for efficient operation.

- Hydraulic Filters: These elements are vital for maintaining fluid cleanliness and preventing contaminants from damaging the hydraulic system.

- Seals and Gaskets: Proper sealing is essential to avoid leaks and maintain pressure in various systems, ensuring smooth operations.

- Batteries: A reliable power source is critical for starting machinery and powering electronic components.

- Belts and Hoses: Regularly checking and replacing worn belts and hoses can prevent breakdowns and ensure the machine operates efficiently.

- Oil Filters: These filters play a significant role in keeping the engine lubricated and free from debris, which is crucial for longevity.

By focusing on these key components, operators can enhance the efficiency and reliability of their equipment, ultimately leading to improved productivity and reduced downtime.

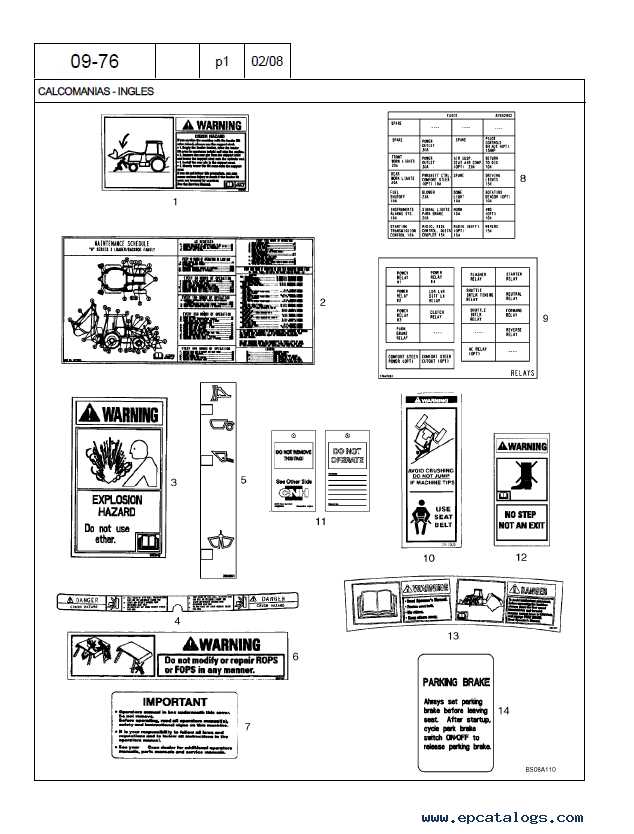

Resources for Parts and Service

When it comes to maintaining heavy machinery, having reliable resources for components and assistance is crucial. Accessing the right information ensures efficient repairs and upkeep, ultimately extending the life of your equipment.

There are several avenues you can explore to find the necessary resources:

- Authorized dealers: Local distributors often stock genuine components and offer expert advice on service options.

- Online marketplaces: Numerous websites specialize in aftermarket and original equipment manufacturer (OEM) supplies, providing a wide range of options for your machinery needs.

- Service manuals: Comprehensive guides are available, detailing specifications, installation instructions, and troubleshooting tips to assist with repairs.

- Forums and communities: Engaging with online communities allows users to share experiences, tips, and recommendations regarding components and maintenance practices.

Utilizing these resources effectively can simplify the process of sourcing components and enhance your ability to perform necessary maintenance tasks with confidence.