When it comes to maintaining agricultural machinery, having a clear understanding of its individual elements is crucial. Each component plays a significant role in the overall performance and efficiency of the machine, impacting its longevity and productivity.

In this section, we will explore the intricate layout of various mechanisms found in a specific model of harvesting equipment. By examining the relationships and functions of these components, operators can enhance their maintenance strategies and troubleshoot issues more effectively.

With the right visual references, even complex systems can be simplified. Grasping the arrangement of these crucial elements allows for informed decision-making, ensuring that your machinery operates at its best throughout the farming season.

Understanding the Case IH 2388 Parts

Maintaining agricultural machinery is crucial for optimal performance and longevity. Familiarity with the various components of a harvesting machine allows operators to ensure smooth operation and address any issues that may arise. A thorough understanding of the different sections and their functions is essential for effective maintenance and troubleshooting.

Essential Components play a vital role in the overall efficiency of the equipment. Each element, from the engine to the harvesting mechanism, contributes to the machine’s ability to perform tasks effectively. Regular inspection of these components can prevent unexpected breakdowns and extend the lifespan of the equipment.

Moreover, accessories and attachments enhance functionality and adaptability in diverse farming conditions. Recognizing how these additional elements integrate with the primary structure is important for maximizing productivity. Proper knowledge of the assembly and disassembly processes aids in swift repairs and modifications.

In summary, gaining insight into the structure and functionality of the various elements of the machinery is essential for operators and technicians alike. This understanding not only facilitates efficient operation but also contributes to overall productivity in the field.

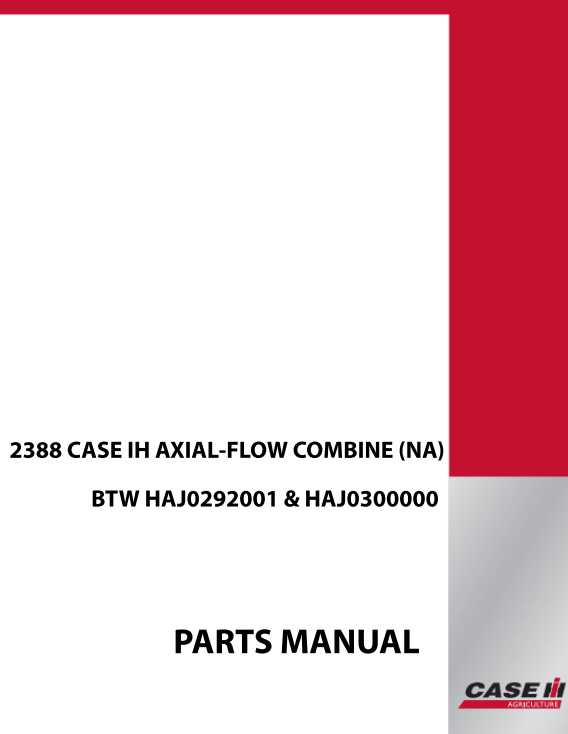

Overview of the Case IH 2388 Model

This agricultural machine represents a significant advancement in harvesting technology, designed to enhance efficiency and performance in the field. Its engineering focuses on maximizing productivity while ensuring ease of use for operators. With a robust construction and sophisticated features, it stands as a reliable choice for modern farming operations.

Key Features

Among the standout characteristics of this model are its powerful engine and innovative grain handling systems. The advanced threshing mechanism allows for optimal grain separation, resulting in higher quality yields. Additionally, the machine is equipped with intuitive controls, enabling operators to manage settings with precision.

Operational Efficiency

The design prioritizes fuel efficiency, reducing operational costs while maintaining high output levels. Coupled with its adaptability to various crops, this machine offers versatility that is essential for today’s diverse agricultural practices. As a result, it not only meets the demands of large-scale farming but also enhances the overall productivity of harvest operations.

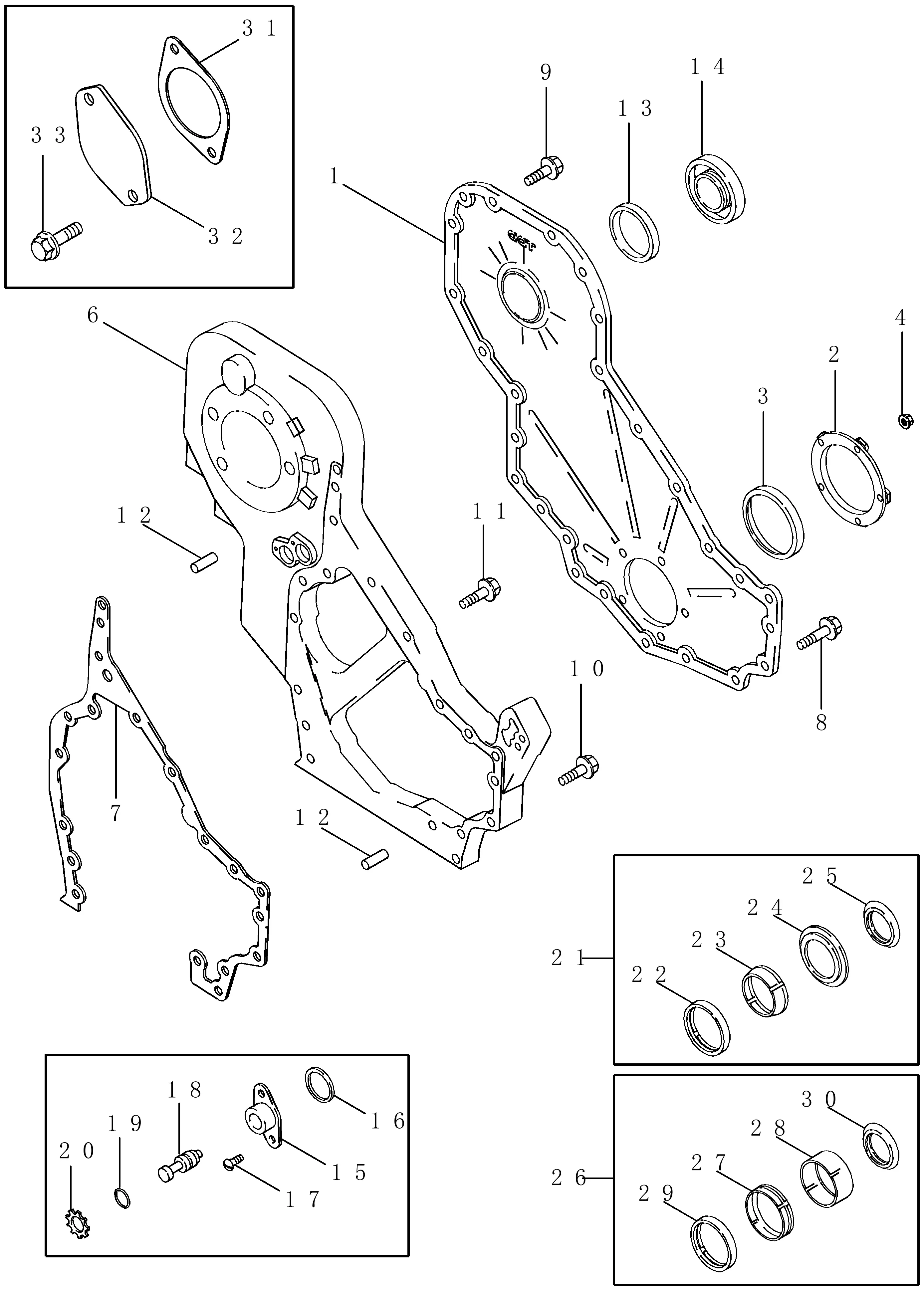

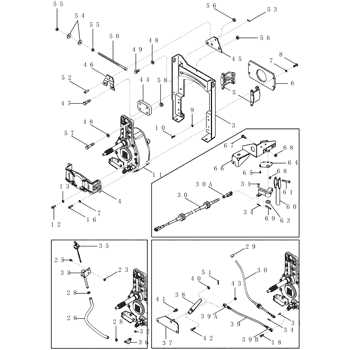

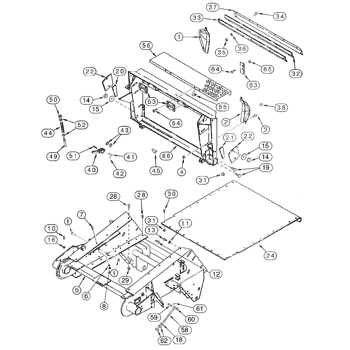

Importance of Accurate Parts Diagrams

Clear and precise schematics play a crucial role in maintaining and repairing machinery. They serve as essential tools that facilitate understanding of complex systems, ensuring efficient troubleshooting and part replacement.

Benefits of Clear Schematics

- Enhances understanding of machinery layout.

- Reduces the risk of errors during repairs.

- Saves time by providing quick reference points.

- Improves safety by outlining correct assembly procedures.

Impact on Efficiency

- Accurate visuals streamline the maintenance process.

- Proper identification of components leads to faster repairs.

- Minimizes downtime, allowing for better productivity.

How to Access Parts Diagrams Online

Finding visual references for machinery components is essential for effective maintenance and repairs. With a few steps, you can easily locate these resources online, streamlining your workflow and ensuring accurate replacements. Understanding how to navigate various platforms can greatly enhance your efficiency.

Start by searching manufacturer websites: Many brands offer digital catalogs on their official sites. Look for sections dedicated to support or resources. You can often find comprehensive manuals and illustrations there.

Utilize online forums and communities: Engaging with enthusiasts and professionals can lead to valuable insights. Members often share links or tips on where to find specific resources, making it easier to uncover necessary visuals.

Consider third-party platforms: Numerous websites specialize in machinery documentation. They can provide extensive libraries of schematics and other useful materials. Be sure to verify the credibility of these sites before relying on them.

Bookmark relevant pages: Once you find reliable sources, save them for future reference. This will save time and effort during your next maintenance session, allowing for quicker access to crucial information.

Common Replacement Parts for the 2388

When maintaining high-performance machinery, understanding essential components for replacement is crucial. Regular upkeep ensures longevity and efficiency, minimizing downtime during operations.

Key Components to Consider

- Engine Filters

- Belts and Chains

- Hydraulic Components

- Wear Plates

- Electrical Systems

Maintenance Tips

- Check fluid levels regularly to prevent overheating.

- Inspect belts for wear to avoid unexpected failures.

- Replace filters periodically to ensure clean operation.

Maintenance Tips for Case IH Equipment

Regular upkeep of agricultural machinery is essential for optimal performance and longevity. Adhering to a structured maintenance routine not only enhances efficiency but also prevents unexpected breakdowns, ensuring that your operations run smoothly throughout the season.

1. Routine Inspections: Conduct frequent checks on all vital components, including engines, hydraulic systems, and belts. Early detection of wear or damage can save time and resources.

2. Fluid Levels: Always monitor and maintain appropriate levels of oils and fluids. This includes engine oil, hydraulic fluid, and coolant. Proper lubrication reduces friction and wear, enhancing overall functionality.

3. Filter Changes: Regularly replace air, oil, and fuel filters. Clean filters improve airflow and fuel efficiency, preventing contaminants from affecting performance.

4. Tire Maintenance: Keep an eye on tire pressure and tread wear. Properly inflated tires improve traction and fuel efficiency, while worn tires can compromise safety and effectiveness.

5. Cleaning: Maintain cleanliness by removing dirt, debris, and crop residue from machinery. A clean machine not only operates better but also minimizes the risk of rust and corrosion.

6. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance schedules and procedures. Adhering to these guidelines ensures that you maintain your equipment in accordance with industry standards.

7. Professional Assistance: When in doubt, seek professional help for complex issues. Trained technicians can provide insights and repairs that ensure your equipment remains in top condition.

By implementing these maintenance strategies, you can enhance the reliability and efficiency of your agricultural machinery, ensuring successful operations year after year.

Identifying Parts Using Diagrams

Understanding complex machinery can often be daunting, yet visual representations serve as invaluable tools for deciphering their components. These illustrations provide clarity and facilitate the identification of individual elements, aiding in maintenance and repairs.

To effectively utilize these visual aids, consider the following strategies:

- Familiarize Yourself with the Layout: Start by examining the overall structure. Get a sense of where each component is located within the system.

- Focus on Labels: Many illustrations include annotations. Pay close attention to these labels as they provide essential information regarding each part’s function.

- Segment the Diagram: Break the illustration down into sections. This approach makes it easier to concentrate on smaller groups of components rather than feeling overwhelmed by the entire assembly.

- Cross-reference with Manuals: If available, consult manuals or documentation that accompany the visual aids. They often contain detailed explanations that enhance understanding.

By following these guidelines, you can efficiently navigate through technical illustrations, making the process of identifying and understanding components more straightforward and less intimidating.

Where to Buy Genuine Parts

Acquiring authentic components for your machinery is essential for optimal performance and longevity. Quality ensures that each element fits seamlessly and functions as intended, reducing the likelihood of future issues. Understanding where to source these genuine elements can significantly impact maintenance and repair efficiency.

Several reliable avenues exist for obtaining original equipment. Below are common sources where you can find the best options:

| Source | Description | Benefits |

|---|---|---|

| Authorized Dealers | Retailers recognized by manufacturers to sell original items. | Expert advice and assurance of quality. |

| Manufacturer’s Website | The official online platform providing a full range of offerings. | Direct access to the latest components and promotional deals. |

| Specialized Distributors | Businesses that focus on specific machinery and parts. | Knowledgeable staff and a tailored inventory. |

| Online Marketplaces | Platforms connecting buyers with various sellers. | Convenient shopping and price comparisons. |

Prioritizing the purchase of original elements will enhance the efficiency and reliability of your equipment. Make informed choices to ensure your investment pays off in the long run.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining machinery, the choice between original components and those made by third-party manufacturers is a crucial decision. Each option presents its own set of advantages and potential drawbacks, impacting performance, longevity, and cost. Understanding these differences can help in making informed choices that align with individual needs and operational goals.

Original components are typically produced by the same manufacturer as the equipment. They are designed to meet specific standards, ensuring compatibility and reliability. Users often appreciate the peace of mind that comes with using these parts, as they are tested to guarantee optimal performance within the intended system.

On the other hand, third-party components can offer a more cost-effective solution. These alternatives often provide a broader range of options, sometimes incorporating enhancements that can lead to improved functionality. However, the quality and compatibility can vary significantly, so it’s essential to conduct thorough research before making a purchase.

Ultimately, the decision should weigh factors such as budget constraints, the importance of reliability, and the specific requirements of the machinery in question. Striking a balance between cost and quality can lead to more efficient and effective maintenance strategies.

Impact of Parts Quality on Performance

The caliber of components utilized in machinery significantly influences its overall functionality and longevity. High-quality materials enhance efficiency, reduce the likelihood of breakdowns, and optimize operational effectiveness. Conversely, substandard elements can lead to increased wear and tear, resulting in costly repairs and downtime.

Benefits of High-Quality Components

- Improved durability and lifespan

- Enhanced efficiency and performance

- Reduced maintenance needs

- Better reliability during operations

Consequences of Poor-Quality Elements

- Increased risk of failures

- Higher operational costs due to frequent repairs

- Negative impact on productivity

- Potential safety hazards for operators

Case IH Community and Support Resources

The strength of a dedicated community enhances the experience of users, providing invaluable assistance and fostering a spirit of collaboration. Engaging with others who share similar interests can lead to solutions, shared knowledge, and an overall sense of belonging.

Online Forums and Groups

Participating in online forums allows enthusiasts to exchange insights, ask questions, and find solutions tailored to their needs. These platforms are invaluable for troubleshooting and gaining tips from experienced users.

Official Support Channels

Accessing official resources can ensure that users receive accurate information and guidance. Manufacturer websites often provide detailed documentation, FAQs, and customer support options to address various inquiries.

| Resource Type | Link |

|---|---|

| Online Forum | Visit Forum |

| Official Website | Visit Official Site |

| Community Events | Learn More |