In the realm of farming machinery, comprehending the intricate assembly of essential components is crucial for optimal performance. Each element plays a significant role in ensuring that the equipment operates efficiently and effectively.

Visual aids serve as invaluable tools in grasping the layout and functionality of these mechanisms. They facilitate a deeper understanding of how various pieces interconnect, allowing users to troubleshoot and maintain their machinery with confidence.

By exploring the arrangement of these essential elements, one can delve into the intricacies of operation, identifying areas for improvement or necessary replacements. This knowledge ultimately enhances the longevity and productivity of the agricultural equipment in use.

Understanding the Case IH 496 Disc

This section delves into the essential components and functionality of a specific agricultural implement designed for soil preparation and management. Understanding its intricate design allows operators to enhance efficiency and productivity in their farming practices.

Key Features

- Robust construction for durability

- Adjustable working depth for versatility

- High-quality cutting blades for effective soil tillage

- Efficient weight distribution for stability during operation

Maintenance Tips

- Regularly inspect blades for wear and tear.

- Keep the frame clean to prevent rust and corrosion.

- Ensure all moving parts are adequately lubricated.

- Adjust settings as necessary to match soil conditions.

By familiarizing yourself with the critical aspects of this implement, you can ensure optimal performance and longevity, ultimately contributing to successful agricultural outcomes.

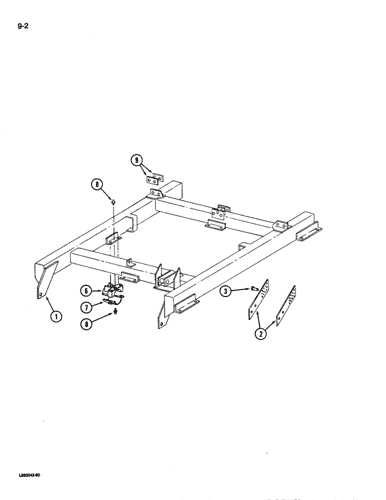

Key Components of the Disc Harrow

The effective functioning of a soil tilling implement relies on several essential elements that work harmoniously to achieve optimal results. Understanding these components is crucial for anyone involved in land preparation and agricultural practices.

- Frame: The structural backbone providing stability and support.

- Blades: Sharp, rotating elements designed to cut and mix soil.

- Hitch: The connection point to the towing vehicle, ensuring secure attachment.

- Adjustable Width: Features allowing customization based on field conditions.

- Bearings: Components ensuring smooth rotation of the blades.

- Scrapers: Devices preventing soil buildup on the blades for consistent performance.

These vital parts collectively enhance the tool’s efficiency, enabling it to prepare the ground effectively for planting and improving overall soil health.

Importance of Proper Maintenance

Benefits of Regular Maintenance

Routine care offers several advantages, including improved safety, enhanced productivity, and better fuel efficiency. Regular checks help identify wear and tear early, allowing for timely repairs and adjustments.

Key Maintenance Tasks

| Task | Frequency | Importance |

|---|---|---|

| Lubrication | Weekly | Prevents friction and wear |

| Inspection of components | Monthly | Identifies potential issues |

| Cleaning | After each use | Maintains efficiency |

| Calibration | Seasonally | Ensures accuracy |

Common Issues with Disc Parts

In agricultural machinery, certain components often face challenges that can affect performance and efficiency. Understanding these common problems is essential for maintenance and longevity of the equipment. Operators frequently encounter issues such as wear, misalignment, and damage, which can hinder optimal functionality.

Wear and Tear

One of the primary concerns is the gradual deterioration of components due to prolonged use. Factors such as soil type, moisture levels, and operating conditions can accelerate this process. Regular inspections can help identify signs of wear early, allowing for timely replacements and preventing further complications.

Misalignment and Damage

Improper alignment can lead to uneven wear and ineffective operation. This misalignment may stem from installation errors or physical impacts during use. Additionally, components may suffer from cracks or breaks due to excessive force or impact with rocks and other debris. Regular maintenance checks are crucial to ensure proper alignment and to identify any damage before it results in costly repairs.

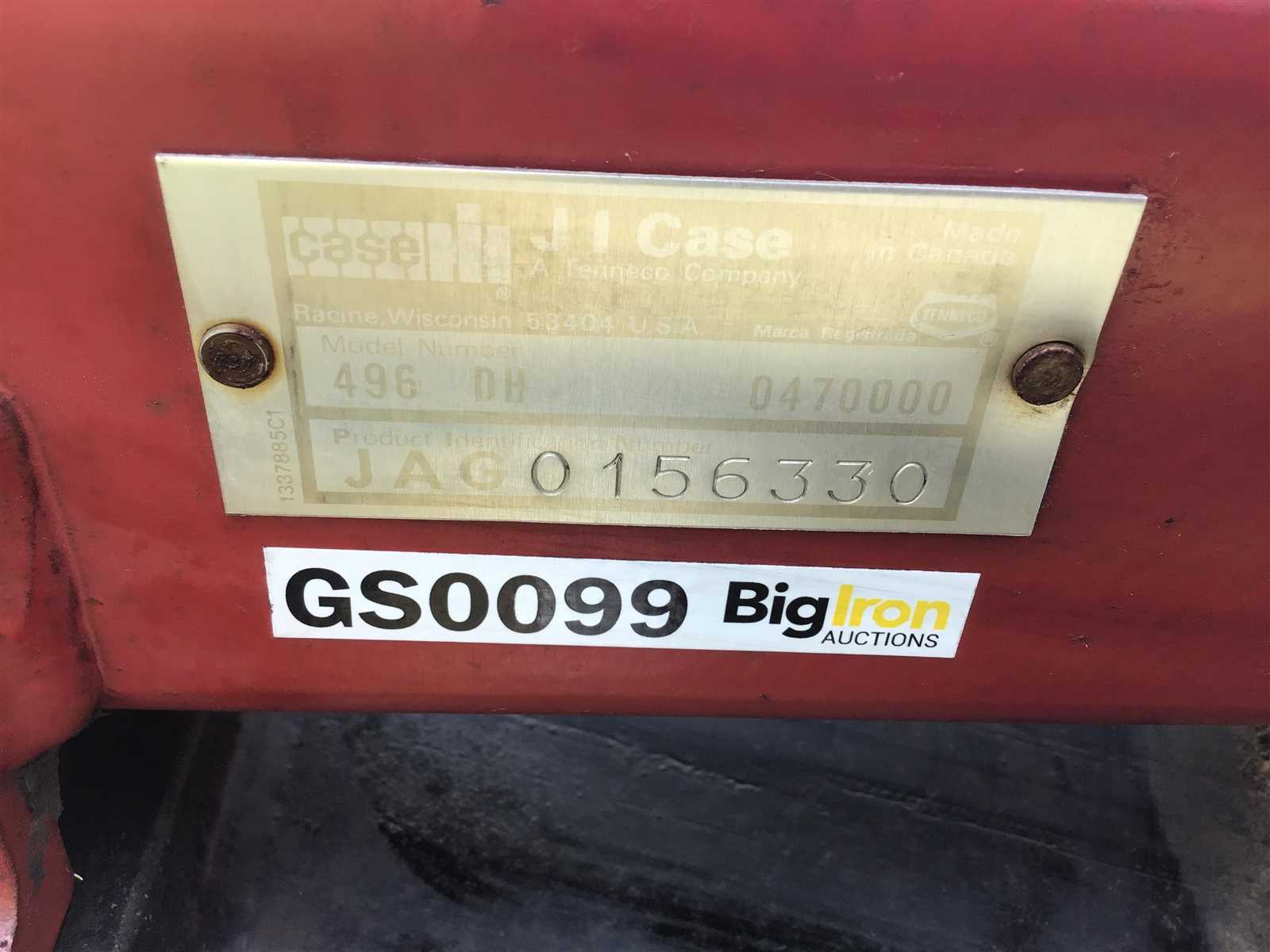

How to Identify Replacement Parts

Identifying components for machinery maintenance is crucial for ensuring optimal performance and longevity. Understanding the specific elements needed can prevent downtime and enhance efficiency. A systematic approach helps in accurately pinpointing the required pieces.

Start by consulting the manufacturer’s manual, which typically provides detailed information about each component’s specifications. This resource is invaluable for understanding compatibility and function. Additionally, make a list of any numbers or identifiers found on the original items, as these can simplify the search for suitable alternatives.

Visual aids, such as online catalogs or exploded views, can greatly assist in recognizing the various components. By cross-referencing these images with your existing equipment, you can ensure that the replacements match in size and design.

If uncertainty persists, reaching out to experts or parts suppliers can provide guidance. They can offer insights based on experience and assist in confirming that you are selecting the correct items for your needs.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These high-quality replacements are specifically designed to fit perfectly, offering reliability and enhancing the overall efficiency of equipment.

Enhanced Durability

Genuine components are manufactured to meet strict quality standards, which translates to greater resilience against wear and tear. This durability minimizes the need for frequent replacements, ultimately saving time and money.

Improved Performance

Using original components guarantees that the machinery operates at its best. Enhanced compatibility leads to smoother functionality, which can significantly boost productivity and reduce downtime during operations.

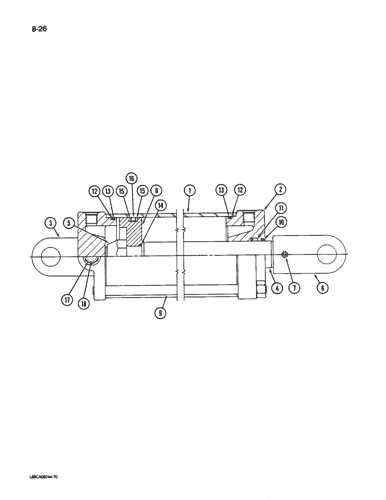

Assembly and Disassembly Guidelines

This section provides essential instructions for the proper assembly and disassembly of agricultural equipment components. Understanding these procedures ensures safety and efficiency, prolonging the lifespan of machinery while preventing unnecessary damage.

Preparation Steps

Before beginning the process, it is crucial to gather all necessary tools and components. Ensure that the work area is clean and free from obstacles to facilitate smooth operations. Additionally, reviewing the user manual can provide valuable insights into specific requirements and safety precautions.

Disassembly Procedure

Start by disconnecting any power sources to prevent accidental activation. Carefully remove any protective covers and components in a logical sequence, labeling parts as you go to aid reassembly. Take note of the orientation and positioning of each piece, as this information will be vital when putting everything back together. For larger assemblies, consider enlisting a second person to assist with handling heavy parts.

When you reach the final components, ensure that you are using appropriate techniques to minimize wear and avoid damaging any connections. Store disassembled parts in an organized manner to streamline the reassembly process.

By adhering to these guidelines, you can maintain the integrity of your machinery and ensure a successful assembly and disassembly experience.

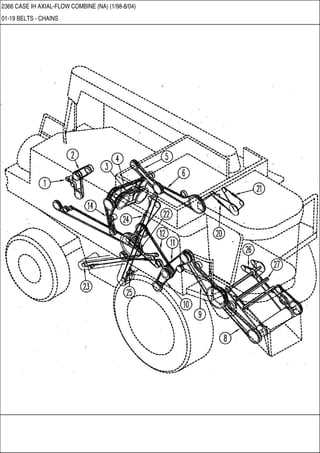

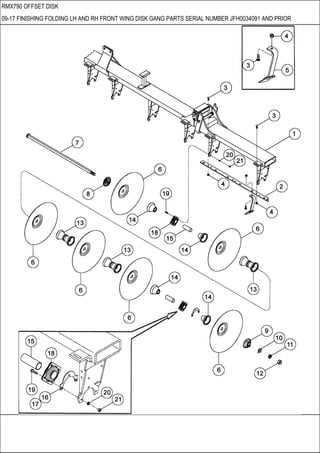

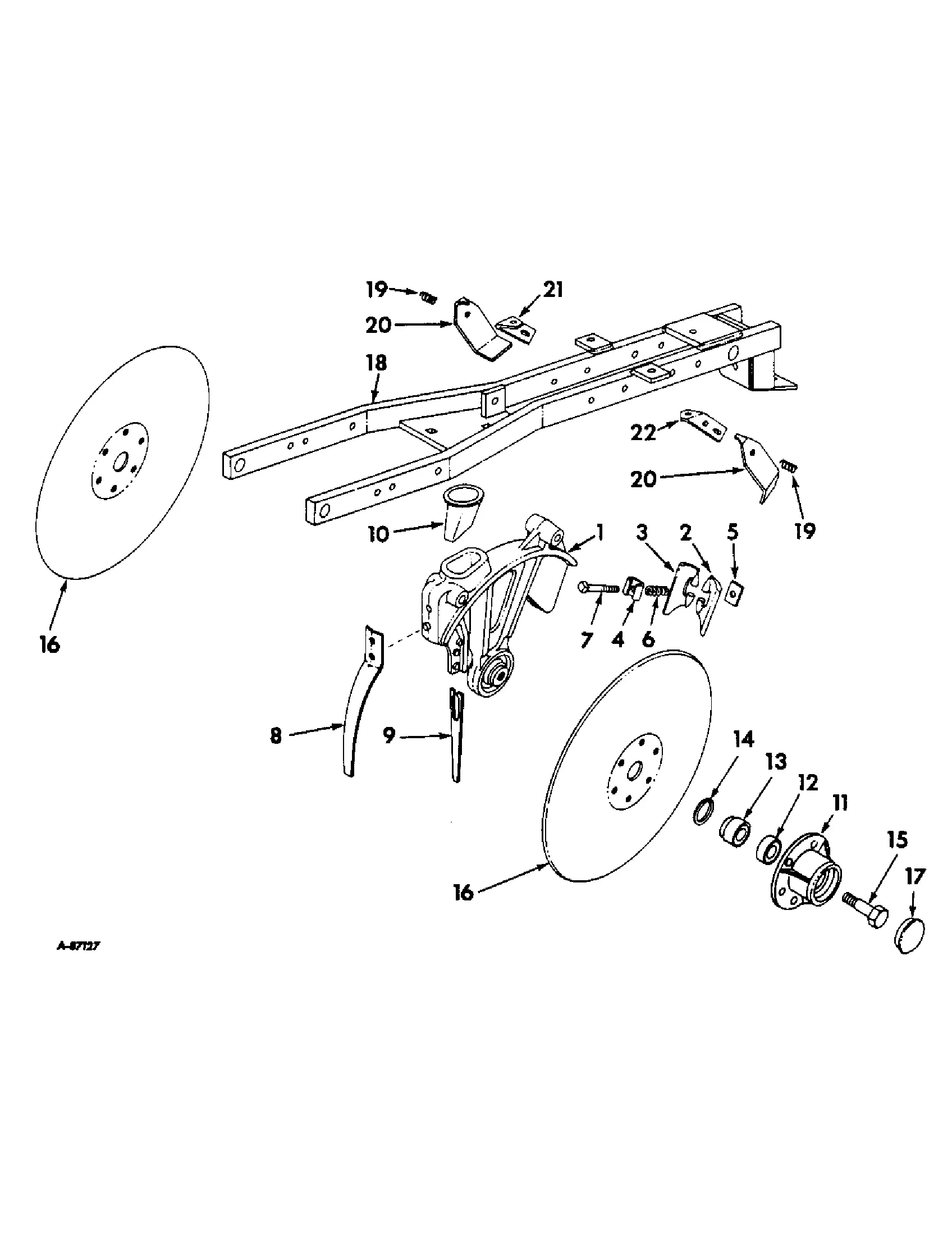

Visual Guide to Parts Diagram

This section aims to provide a comprehensive visual representation of essential components for optimal understanding and maintenance. By illustrating various elements, users can better navigate the intricate mechanisms involved.

Key features to explore include:

- Identification of critical elements

- Understanding relationships between components

- Visual cues for easier assembly and disassembly

Utilizing the visual guide effectively allows users to:

- Quickly locate specific parts

- Enhance troubleshooting efficiency

- Ensure proper maintenance practices

By delving into these visuals, users will gain the ultimate insight needed for effective operation and repair tasks.

Best Practices for Repairs

Effective maintenance and restoration of agricultural machinery can significantly enhance their lifespan and performance. Understanding the essential methods and techniques can lead to successful interventions, ensuring equipment operates at peak efficiency.

Regular Inspection

Routine evaluations are crucial in identifying potential issues before they escalate. Check for signs of wear, loose components, or leaks regularly to maintain optimal functionality.

Use Quality Components

When replacing any element, it’s vital to choose high-quality materials that meet or exceed original specifications. This approach not only improves performance but also minimizes the risk of future malfunctions.

Supplier Options for Disc Components

When seeking high-quality components for agricultural equipment, identifying reliable suppliers is crucial. Various options are available that cater to different needs, whether for replacement or enhancement of your machinery. This section highlights key suppliers and their offerings to help you make informed decisions.

Types of Suppliers

Suppliers can generally be categorized into two types: original equipment manufacturers (OEMs) and aftermarket providers. OEMs supply parts that match the specifications of the original machinery, ensuring compatibility and performance. Aftermarket suppliers, on the other hand, offer a wider range of options, often at competitive prices, but varying in quality and fit.

Supplier Comparison Table

| Supplier Type | Advantages | Considerations |

|---|---|---|

| OEM | Guaranteed compatibility, high-quality standards | Higher cost, limited customization |

| Aftermarket | Cost-effective, broader selection | Variable quality, potential compatibility issues |

When choosing a supplier, consider your specific requirements and budget. Researching reviews and testimonials can also provide insights into the reliability of different vendors.

Upgrades and Modifications Available

Enhancing agricultural equipment can significantly improve performance and efficiency. Various upgrades and modifications are available to optimize functionality, increase durability, and adapt machines for specific tasks.

Some popular options include:

- Improved cutting blades for enhanced soil penetration.

- Heavy-duty frame reinforcements to withstand rigorous use.

- Advanced hydraulic systems for better control and responsiveness.

Additionally, operators may consider:

- Adjustable leveling features to ensure uniform soil preparation.

- Wider working widths for increased productivity.

- Custom attachments for specific crop requirements.

These enhancements can lead to greater efficiency and reduced operational costs, making them worthwhile investments for serious agricultural professionals.