In the realm of agricultural machinery, a thorough comprehension of individual elements is crucial for maintaining optimal performance. Each component plays a significant role in the overall functionality of the equipment, ensuring efficiency and reliability in various tasks. Understanding these elements not only enhances operational effectiveness but also aids in timely maintenance and repairs.

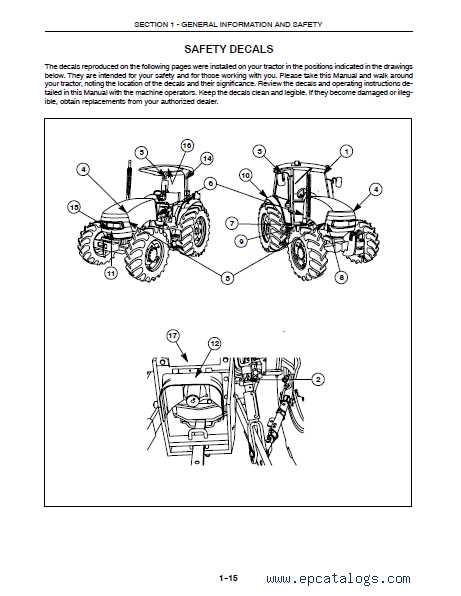

Visual representations can be incredibly beneficial when navigating the complex assembly of machinery. By analyzing these illustrations, operators and technicians can identify specific parts, streamline troubleshooting processes, and enhance their technical knowledge. This deeper insight fosters a proactive approach to equipment care, minimizing downtime and maximizing productivity.

Ultimately, a well-rounded awareness of essential components equips users with the tools needed to tackle challenges effectively. Embracing this knowledge empowers operators to engage more confidently with their machinery, contributing to smoother agricultural operations.

Overview of Farmall 95 Components

This section aims to provide a comprehensive look at the essential elements that make up a certain agricultural machine. Understanding these components is crucial for effective maintenance and operation, ensuring optimal performance in various tasks.

Key Elements

- Engine Assembly

- Transmission System

- Hydraulic Components

- Chassis and Frame

- Electrical System

Functional Aspects

- Power Generation: The engine serves as the heart of the machinery, converting fuel into mechanical energy.

- Mobility: The transmission system facilitates movement and speed adjustments across different terrains.

- Operational Control: Hydraulic components are vital for executing various tasks, from lifting to plowing.

Key Features of Farm Equipment

Agricultural machinery plays a crucial role in modern farming, enhancing efficiency and productivity. The design and functionality of these tools are tailored to meet the diverse needs of various tasks, from planting to harvesting.

One significant aspect is the durability of the machinery, built to withstand harsh environmental conditions and heavy usage. This ensures longevity and reliable performance in the field. Additionally, many devices incorporate advanced technology, allowing for precision farming techniques that optimize resource use and crop yield.

Another important feature is versatility, as equipment often comes with interchangeable components or attachments, enabling farmers to adapt to different farming practices. Ergonomics also play a role, with designs focused on operator comfort and ease of use, reducing fatigue during long working hours.

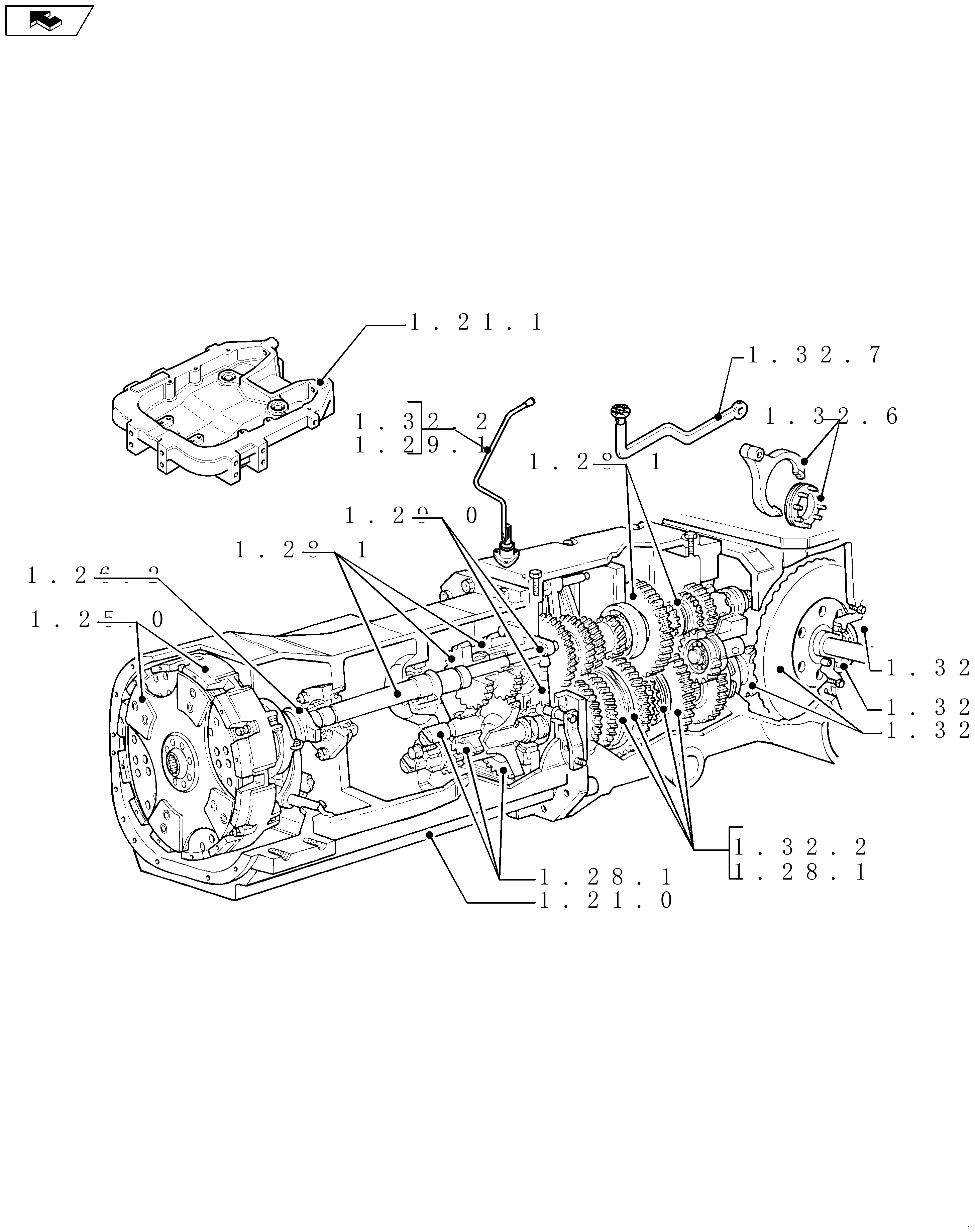

Identifying Major Assembly Groups

Understanding the primary components of agricultural machinery is essential for effective maintenance and repair. This section focuses on the key assembly categories that constitute the overall structure of these machines, providing a framework for users to navigate through their complexities.

Each assembly group plays a critical role in the machine’s functionality, ranging from the drivetrain to the hydraulic system. By familiarizing oneself with these categories, operators can enhance their knowledge and ensure smoother operations.

Drivetrain Assembly: This group includes all elements that transfer power from the engine to the wheels, ensuring optimal performance during operation.

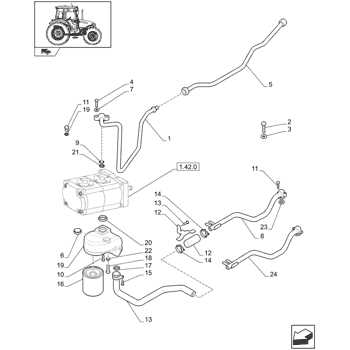

Hydraulic System Assembly: A crucial component responsible for powering various attachments and implements, this system enables efficient operation in diverse agricultural tasks.

Electrical System Assembly: This assembly encompasses the wiring, switches, and controls that govern the machine’s electrical functions, contributing to its overall reliability.

Understanding Engine Configuration

Comprehending the arrangement and function of various components within an engine is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring efficiency, power output, and overall reliability. This section delves into the essential features that define engine architecture and their implications for operation.

Key Components Overview

Fundamental elements such as the cylinder block, pistons, and crankshaft form the backbone of any engine. The interaction among these parts is vital, as they work in harmony to convert fuel into mechanical energy. Understanding their arrangement allows for better troubleshooting and enhancements.

Importance of Proper Alignment

Alignment of components is critical for preventing wear and ensuring smooth operation. Misalignment can lead to increased friction, reduced efficiency, and potential failure. Regular checks and adjustments can significantly enhance performance and extend the lifespan of the engine.

Transmission Parts and Functions

This section explores the components involved in the operation of the transmission system, emphasizing their roles and interconnections. Understanding these elements is crucial for efficient machinery operation and maintenance.

- Gears: Essential for changing speed and torque, allowing the machine to adapt to different working conditions.

- Shafts: Transmit power from the engine to the wheels, ensuring smooth movement and performance.

- Clutches: Facilitate the engagement and disengagement of gears, enabling smoother transitions during operation.

- Bearings: Reduce friction and support rotating components, contributing to overall efficiency.

- Hydraulic System: Provides the necessary pressure for shifting gears and controlling various functions within the transmission.

Each element works synergistically, ensuring that the vehicle operates seamlessly in various agricultural tasks.

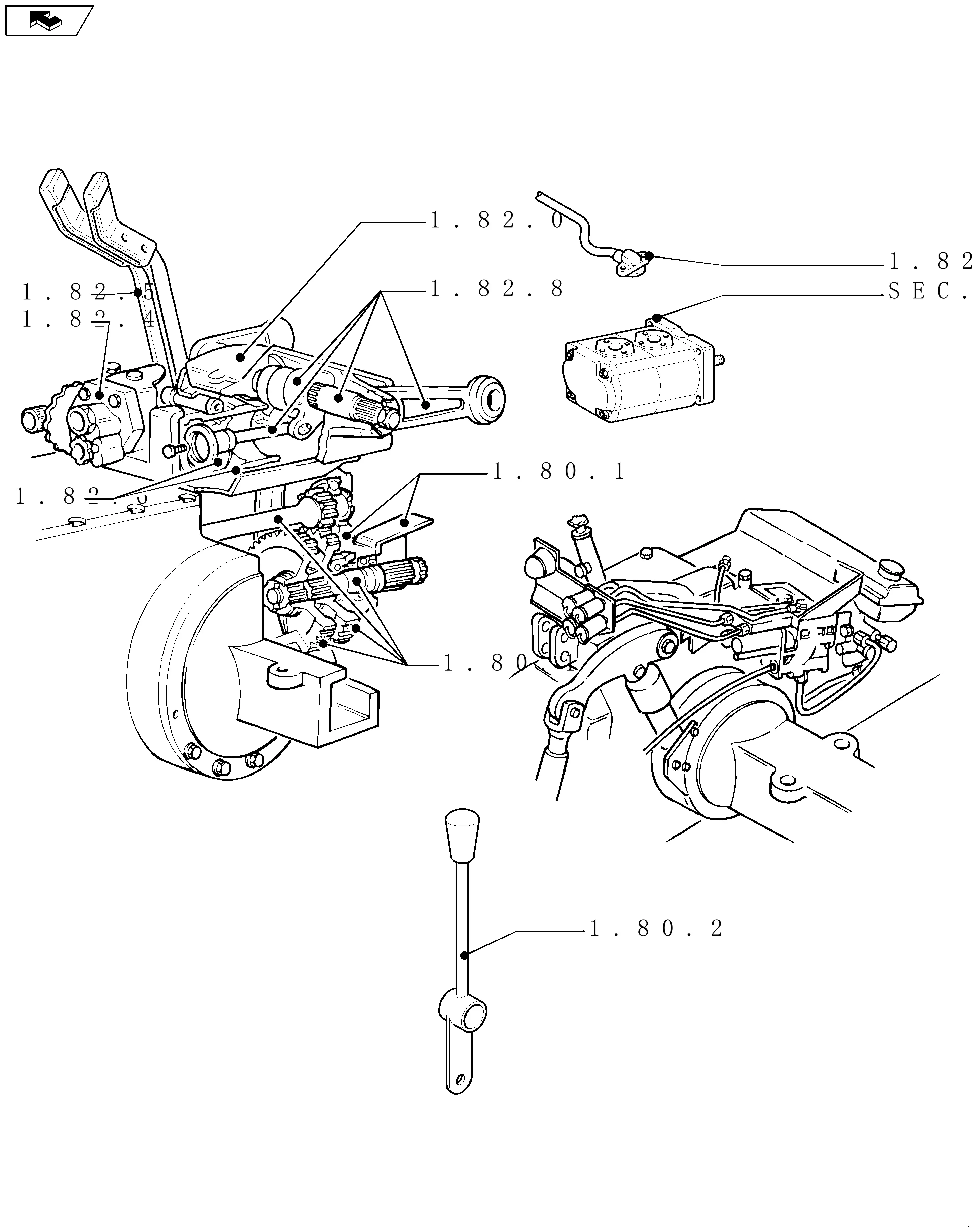

Hydraulic System Components Explained

The hydraulic mechanism in agricultural machinery plays a crucial role in enhancing operational efficiency. Understanding its various components is essential for effective maintenance and optimal performance.

Key elements of this system include:

- Pump: Responsible for generating hydraulic pressure.

- Reservoir: Stores hydraulic fluid, ensuring a continuous supply.

- Actuators: Convert hydraulic energy into mechanical movement.

- Valves: Control the flow and direction of hydraulic fluid.

- Filters: Remove contaminants from the hydraulic fluid to prolong system life.

Each component must function harmoniously to ensure the system operates efficiently, maximizing the machinery’s capabilities.

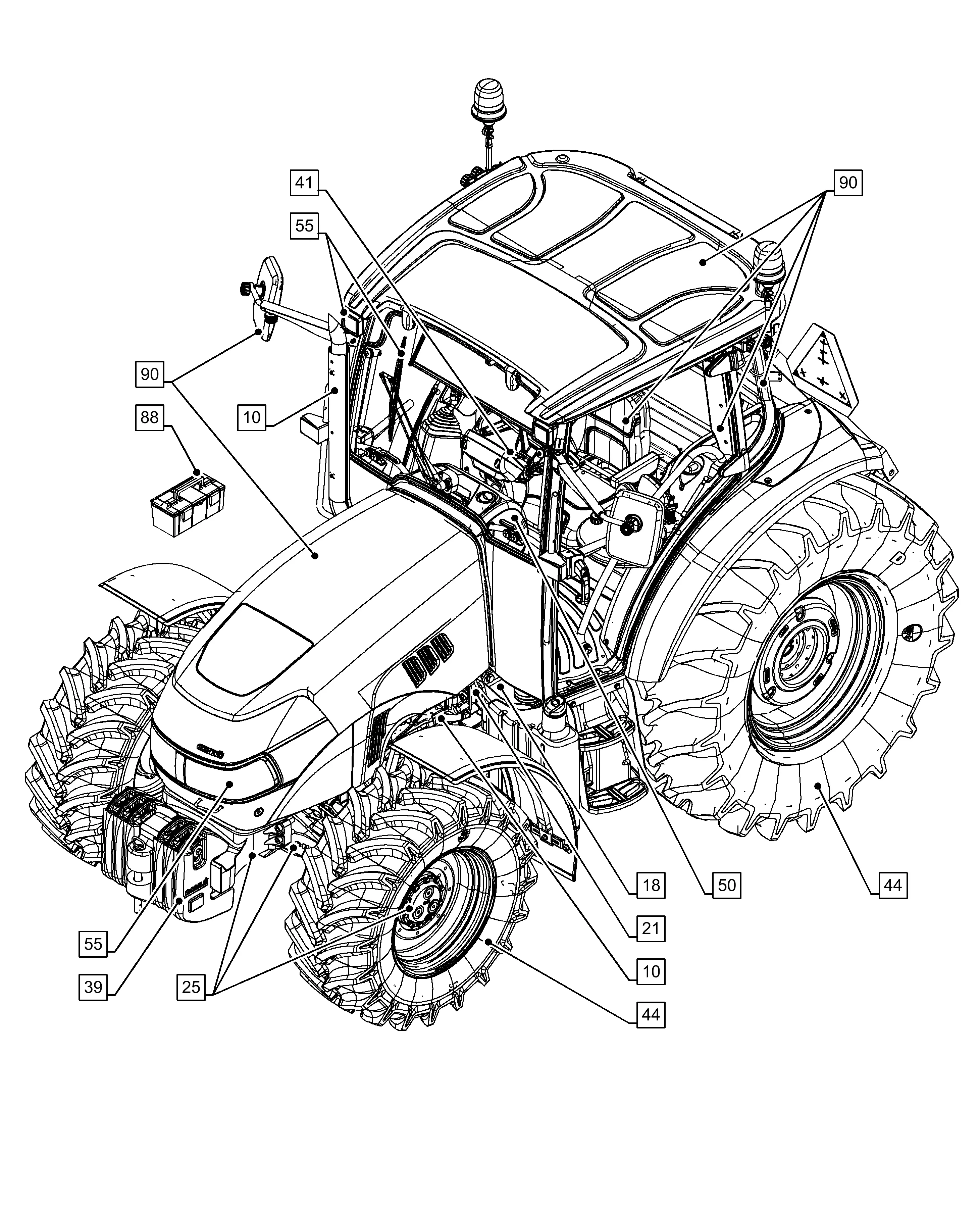

Electrical System Layout Insights

Understanding the arrangement of electrical components is essential for efficient operation and maintenance. This layout provides valuable information about the connections and functionality of various elements within the machinery, ensuring optimal performance and reliability.

| Component | Description |

|---|---|

| Battery | Stores energy and provides power to the system. |

| Alternator | Generates electricity while the engine runs. |

| Starter Motor | Initiates engine operation by cranking the motor. |

| Fuses | Protect electrical circuits from overload. |

| Relays | Control power flow to various components. |

Maintenance Tips for Key Parts

Regular upkeep of essential components is vital for ensuring optimal performance and longevity of your equipment. Implementing simple yet effective maintenance practices can prevent costly repairs and enhance operational efficiency.

Inspecting Fluid Levels

Checking the levels of various fluids is crucial. Ensure that the engine oil, coolant, and hydraulic fluids are at appropriate levels to promote smooth operation. Low fluid levels can lead to overheating or inadequate lubrication, ultimately causing significant damage. Schedule regular checks and top off fluids as necessary.

Cleaning and Lubrication

Keeping moving parts clean and well-lubricated is essential for preventing wear and tear. Remove any debris or buildup that may impede functionality. Applying appropriate lubricants can significantly reduce friction and prolong the life of components. Focus on areas such as joints, bearings, and shafts to maintain seamless operation.

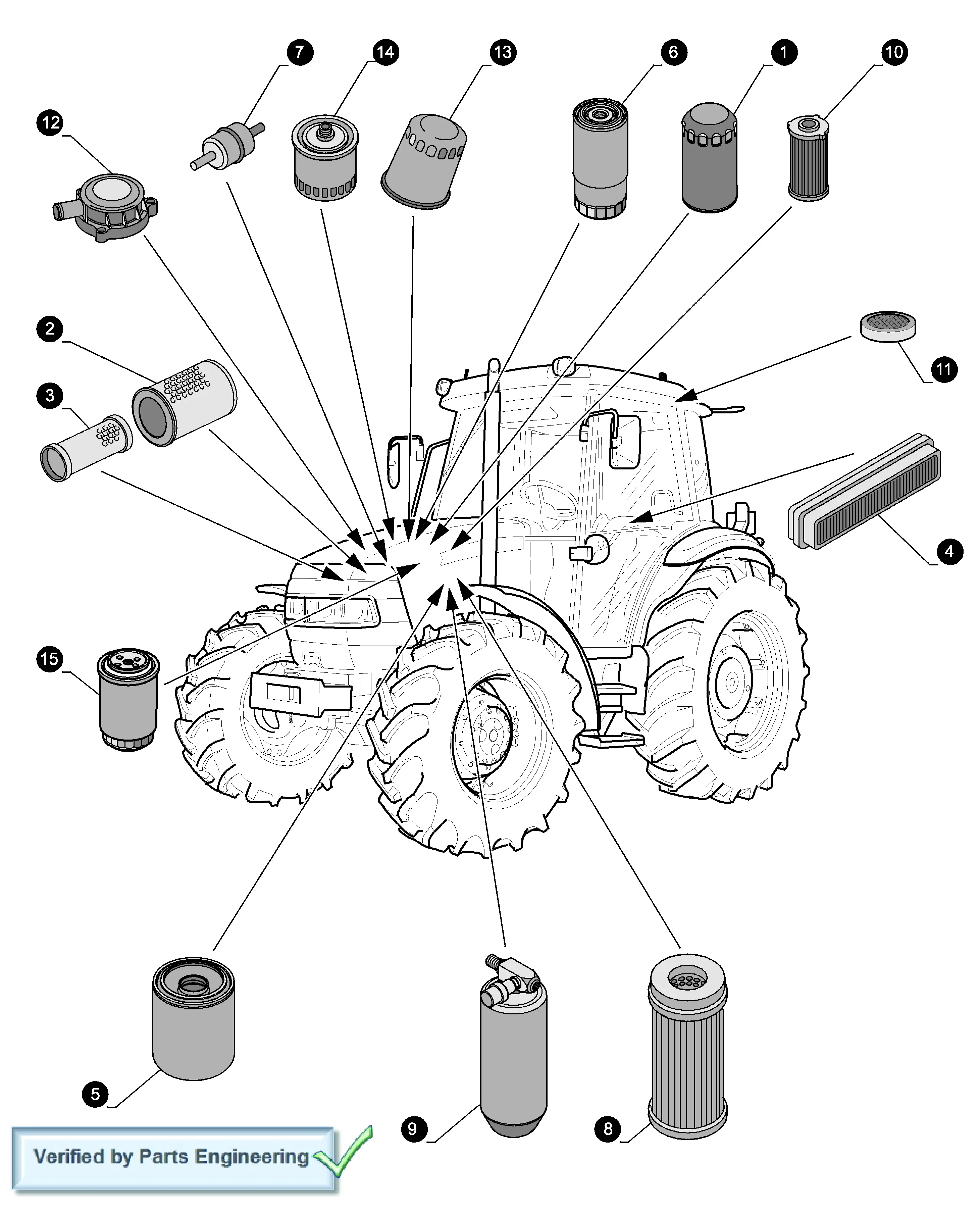

Common Replacement Parts Overview

When maintaining agricultural machinery, understanding essential components is crucial for optimal performance. Many operators encounter the need to replace various elements over time due to wear and tear or damage. Recognizing these commonly replaced items can help streamline repairs and ensure efficient operation.

Key elements often require attention, including the engine’s core components, transmission elements, and hydraulic systems. Regular inspection of these areas can prevent unexpected breakdowns and enhance the longevity of the equipment. Familiarity with replacement options not only aids in timely maintenance but also contributes to better overall functionality in the field.

Additionally, sourcing reliable alternatives for these components can significantly impact operational costs. Whether opting for original equipment or aftermarket solutions, understanding the quality and compatibility of replacements is vital. Making informed choices helps maintain machinery efficiency while reducing downtime, ultimately benefiting productivity on the farm.

Aftermarket vs. OEM Options

When it comes to selecting components for machinery, there are two primary categories to consider: original and alternative offerings. Understanding the differences between these can significantly impact performance, cost, and overall satisfaction. Each option presents unique advantages and potential drawbacks that should be carefully evaluated based on individual needs and circumstances.

Quality and Performance

Original offerings are designed specifically for particular models, ensuring compatibility and often superior performance. In contrast, alternative components can vary widely in quality, with some providing excellent value and others falling short of expectations. It’s essential to research and assess the reliability of alternative options to ensure they meet the required standards.

Cost Considerations

Typically, original offerings come with a higher price tag due to their brand recognition and assured quality. Alternative options often provide a more budget-friendly solution, appealing to those looking to save costs. However, it’s crucial to weigh the potential long-term benefits of investing in original offerings against the initial savings of alternatives, as performance and durability may affect overall expenses in the future.