When it comes to maintaining and repairing a powerful cutting tool, having a clear understanding of its various elements is crucial. This section aims to provide an overview of the essential components that contribute to the functionality of this equipment. Familiarity with these elements not only aids in effective troubleshooting but also enhances the overall efficiency of the tool.

Exploring the individual elements will enable users to identify the specific areas requiring attention or replacement. This knowledge empowers individuals to carry out necessary adjustments and repairs confidently, ensuring optimal performance. Additionally, recognizing how each component interacts within the system can significantly improve the user’s experience.

In the following sections, we will delve into the intricacies of these components, offering insights that can assist in both understanding and managing the upkeep of this powerful equipment. Whether you are a seasoned user or a newcomer, this guide will serve as a valuable resource for enhancing your familiarity with the key elements involved.

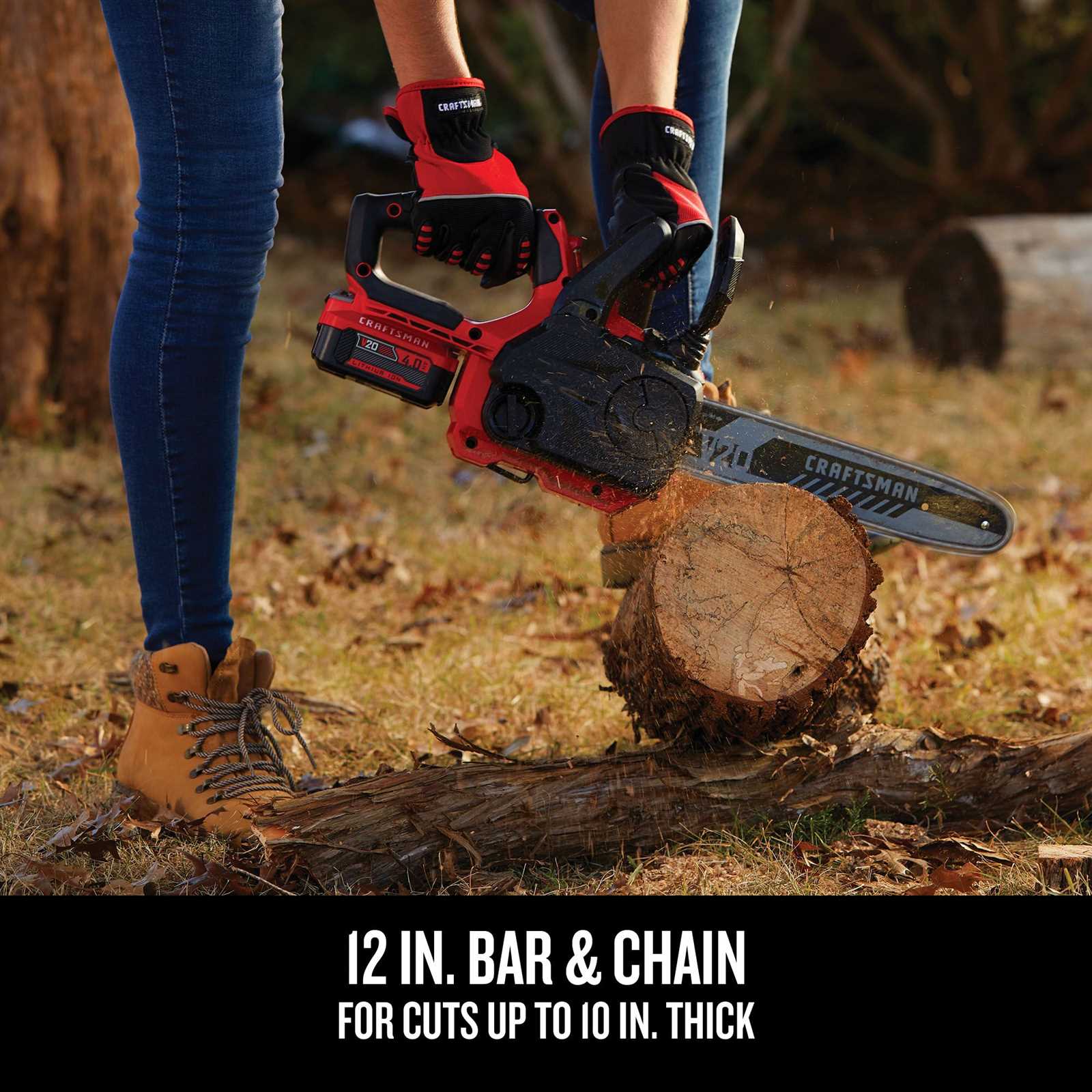

Craftsman Chainsaw Components Overview

This section provides a comprehensive look at the essential elements that make up a particular cutting tool. Understanding these components is crucial for effective maintenance and optimal performance.

1. Engine: The heart of the tool, responsible for generating power and facilitating operation. Proper care and regular checks ensure longevity and efficiency.

2. Bar: This elongated piece plays a vital role in guiding the cutting process. It is essential to keep it well-lubricated to prevent wear and tear.

3. Chain: The circular component with teeth that performs the cutting action. Regular sharpening and tension adjustments are necessary for seamless functionality.

4. Handle: Provides a grip for controlling the device during operation. Ensuring its stability and comfort can enhance safety and ease of use.

5. Safety Features: Various elements designed to protect the user, including a chain brake and safety guards. Familiarity with these features can prevent accidents and injuries.

Maintaining a clear understanding of these components can significantly improve the overall effectiveness of the tool, ensuring it operates smoothly and safely.

Understanding the 18-Inch Chainsaw Design

The structure of a cutting tool significantly influences its performance and usability. This segment delves into the fundamental elements that contribute to the functionality and efficiency of a specific model. By comprehending these components, users can better appreciate how design impacts operation and maintenance.

Key Components and Their Functions

Each element plays a vital role in the overall effectiveness of the tool. The motor serves as the powerhouse, driving the movement necessary for cutting. The cutting mechanism is designed for optimal precision, allowing for effective interaction with various materials. Additionally, the housing is crafted for durability, ensuring the longevity of the tool under challenging conditions.

Maintenance Considerations

Understanding the construction also aids in proper upkeep. Regular inspection of the key elements can prevent wear and enhance performance. Awareness of how each part functions together enables users to troubleshoot effectively and ensure the tool operates at its best.

Essential Parts of Your Chainsaw

Understanding the fundamental components of your cutting tool is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance, safety, and durability. Here, we will explore the key elements that contribute to the functionality of your equipment.

Main Components

- Power Unit: The heart of the equipment, responsible for generating the necessary energy to operate.

- Cutting Mechanism: This includes the blade and its associated mechanisms, which facilitate the cutting action.

- Guide Bar: Supports the cutting mechanism and provides stability during operation.

- Chain: The link that engages with the cutting mechanism to perform the cutting tasks.

- Safety Features: Various elements designed to protect the user during operation.

Additional Elements

- Fuel System: Supplies energy to the power unit for operation.

- Lubrication System: Ensures smooth functioning of the cutting mechanism by reducing friction.

- Handle and Controls: Provide the user with the ability to maneuver and operate the equipment safely.

- Housing: Protects internal components from external damage and provides structural integrity.

Identifying Common Replacement Components

Understanding the essential elements of a cutting tool is crucial for maintaining its performance and longevity. Recognizing frequently needed components helps users ensure their equipment operates efficiently and reliably.

Below are some commonly encountered elements that may require replacement:

- Guide Bar: This component provides a track for the cutting chain, influencing the precision of cuts.

- Cutting Chain: The chain itself is responsible for the cutting action and may wear out over time due to regular use.

- Chain Tensioner: This part allows the user to adjust the tightness of the chain, ensuring optimal performance during operation.

- Fuel Filter: A critical component that helps keep the fuel system clean and free of debris.

- Air Filter: This element prevents dirt and contaminants from entering the engine, contributing to its longevity.

Regular inspection of these components is advisable to prevent potential issues and ensure efficient operation. By staying informed about these essential parts, users can easily identify when replacements are necessary.

Maintenance Tips for Your Chainsaw

Regular upkeep is essential for ensuring the longevity and optimal performance of your cutting tool. By following a few key practices, you can enhance efficiency and minimize potential issues. Consistent care not only maintains functionality but also promotes safety during use.

Essential Maintenance Practices

To keep your equipment in excellent condition, consider the following practices:

- Check and sharpen the blade frequently to ensure clean cuts.

- Inspect the fuel mixture and replace it if necessary for better combustion.

- Clean the air filter regularly to improve airflow and engine performance.

- Examine the spark plug for wear and replace it if needed to maintain ignition efficiency.

Maintenance Schedule

Adopting a routine maintenance schedule can greatly benefit your tool. Here’s a simple table to guide your upkeep:

| Task | Frequency |

|---|---|

| Inspect blade condition | After each use |

| Sharpen blade | Every 5-10 uses |

| Check fuel mixture | Before each use |

| Clean air filter | Every month |

| Replace spark plug | Every 25 uses |

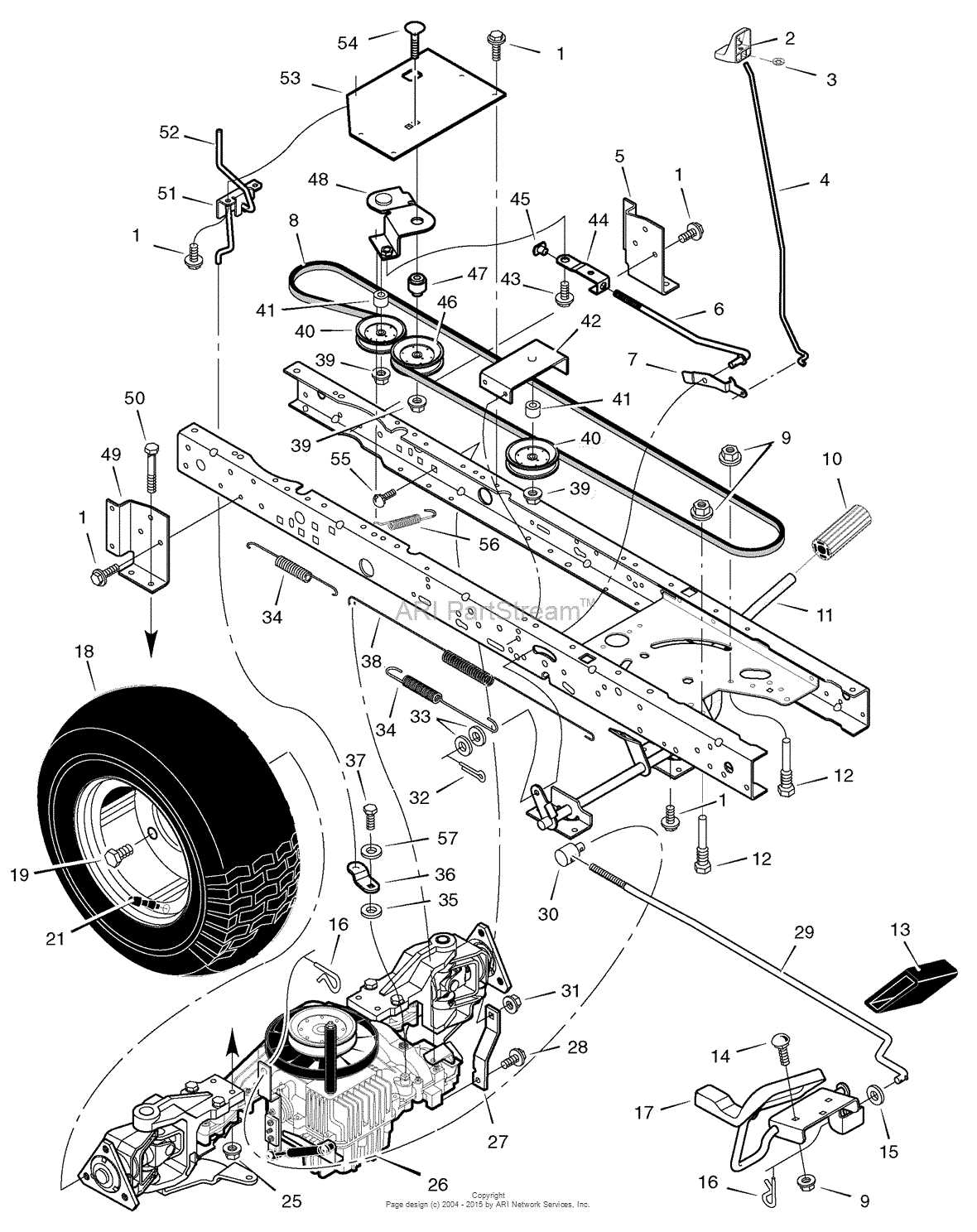

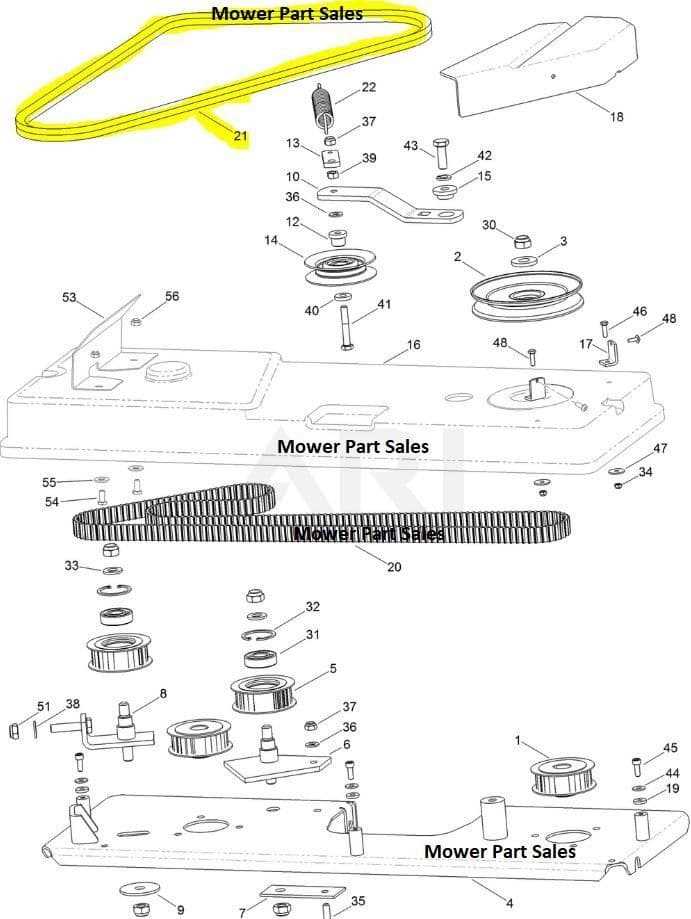

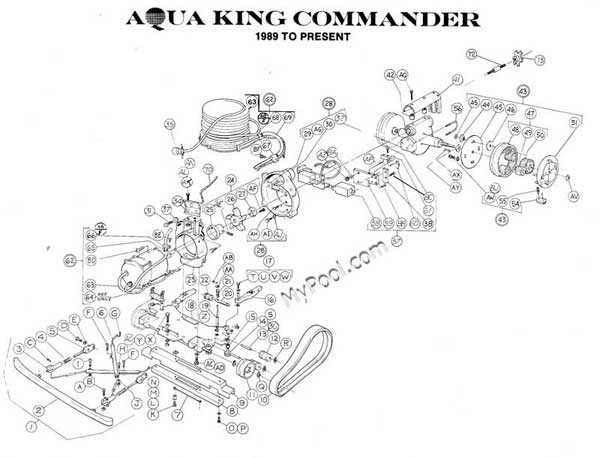

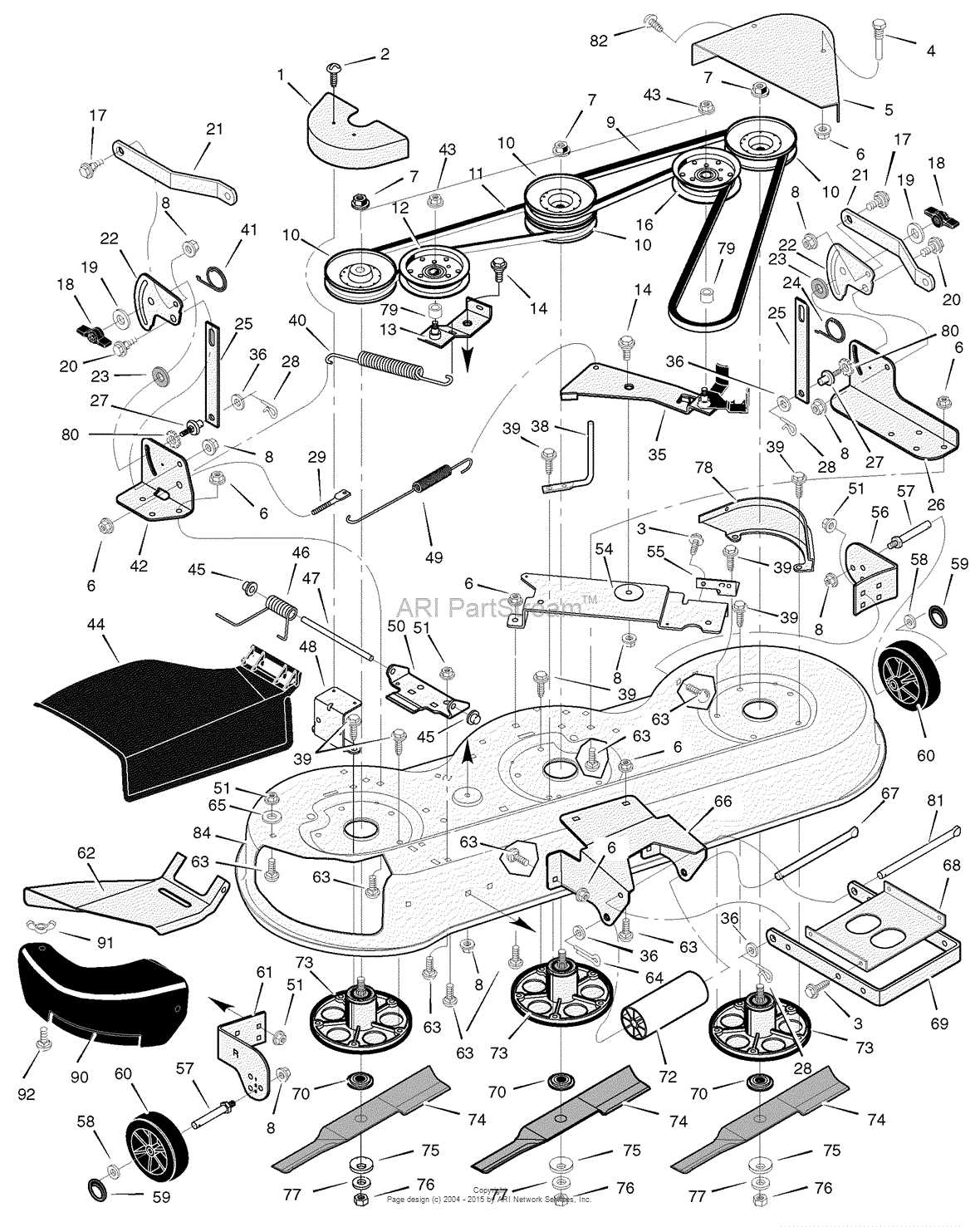

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides, highlighting the arrangement and relationship between various elements. Familiarity with these visuals can significantly enhance your ability to identify and source necessary items for repairs.

Key Elements of Visual Representations

When examining these illustrations, pay attention to the following aspects:

- Labels: Clearly defined markings that indicate specific items.

- Lines: Connecting lines that illustrate how components fit together.

- Numbers: Sequential indicators that correspond to a list of items.

Using the Information Effectively

To make the most of these visuals, follow these steps:

- Identify the components you need by cross-referencing labels.

- Take note of the numbering system for easy lookup in parts lists.

- Utilize the arrangement to visualize the assembly process.

| Component | Description |

|---|---|

| Label | Identifies the specific item in the visual. |

| Line | Shows how components connect or interact. |

| Number | Reference point for detailed descriptions in a list. |

Tools Needed for Chainsaw Repairs

To effectively carry out maintenance and repairs on a cutting device, it’s essential to have the right tools at your disposal. Having the appropriate instruments ensures that the work can be done efficiently and safely, reducing the risk of damage to the equipment and enhancing its longevity.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening nuts and bolts. |

| Screwdriver Set | Essential for removing and installing screws in various components. |

| File | Useful for sharpening the cutting edges and maintaining optimal performance. |

| Chain Breaker | Allows for the removal and installation of the cutting chain with ease. |

| Measuring Tape | Helps in measuring components to ensure proper fit and alignment. |

| Safety Gear | Includes gloves, goggles, and hearing protection to ensure personal safety during repairs. |

Ordering Replacement Parts Online

Finding suitable components for your equipment can be a straightforward process when utilizing online resources. Numerous platforms provide access to a wide array of options, allowing users to select the items that best fit their needs. This guide outlines essential steps for effectively sourcing these items through the internet.

Here are some tips to consider when placing an order:

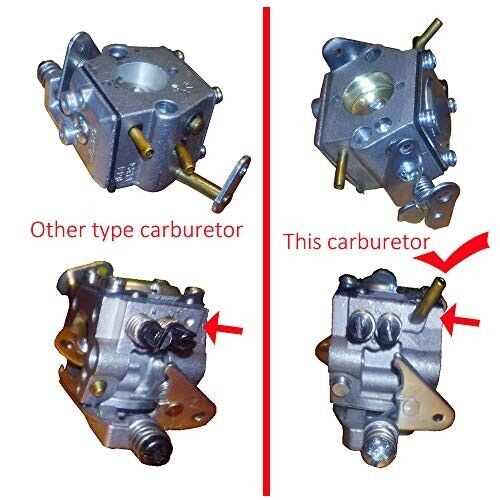

- Identify Your Requirements: Before making a purchase, ensure you know the specific components needed for your device. This may include model numbers or specifications.

- Research Reputable Retailers: Look for online stores with positive reviews and reliable customer service. Websites that specialize in equipment supplies often have extensive selections.

- Compare Prices: Take the time to compare prices across various websites to find the best deal. Be cautious of prices that seem too low, as they may indicate inferior quality.

- Check Return Policies: Always review the return policy of the retailer. In case the item does not meet your expectations, it is essential to know how to return it.

- Secure Payment Methods: Use secure payment options when making transactions online. Look for sites that offer encryption to protect your financial information.

By following these guidelines, you can confidently order the necessary components for your equipment, ensuring it remains in optimal condition for your tasks.

Assembling Your Chainsaw Correctly

Proper assembly is essential for optimal performance and safety when putting together your cutting tool. This process involves carefully aligning components and ensuring each part fits snugly to function effectively. Understanding the configuration of various elements will help you achieve a reliable and efficient setup.

Begin by reviewing the manual or guide that outlines the arrangement of components. Start with the base unit, attaching it to the motor section. Ensure that any necessary screws or fasteners are tightened securely. Pay attention to the orientation of parts, as improper alignment can lead to malfunctions.

Next, incorporate additional elements such as the handle and safety features, which are vital for user protection. Ensure that all attachments are firm and stable. It’s advisable to double-check connections to avoid any issues during operation.

Once everything is assembled, conduct a thorough inspection. Verify that there are no loose fittings or misplaced parts. Following these steps will not only enhance the effectiveness of your tool but also ensure your safety while using it.

Safety Features in Chainsaw Design

In the realm of cutting tools, safety elements play a crucial role in ensuring user protection and efficient operation. The integration of various safety mechanisms is paramount for reducing the risk of accidents and enhancing overall functionality. These features are designed to provide users with greater control and confidence while engaging in cutting tasks.

| Safety Feature | Description |

|---|---|

| Chain Brake | Stops the chain’s movement in case of kickback, minimizing potential injuries. |

| Throttle Lock | Prevents accidental acceleration by locking the throttle in a controlled position. |

| Hand Guards | Protects hands from debris and accidental contact with the cutting chain. |

| Low Kickback Chain | Reduces the risk of kickback incidents, providing a safer cutting experience. |

| Ergonomic Design | Ensures comfortable handling, reducing fatigue and enhancing user control. |

Common Troubleshooting for Chainsaws

When dealing with motorized cutting tools, encountering issues is not uncommon. Addressing these problems often requires a systematic approach to identify the underlying causes and implement effective solutions. Understanding the common difficulties can help users maintain their equipment and enhance its performance.

Common Issues and Solutions

- Engine Won’t Start:

- Check the fuel level and ensure the mixture is appropriate.

- Inspect the ignition system for any faults.

- Examine the air filter for clogs and clean if necessary.

- Poor Cutting Performance:

- Ensure the cutting blade is sharp and properly tensioned.

- Inspect the guide bar for wear and replace if needed.

- Verify that the chain is correctly lubricated.

- Excessive Vibration:

- Check for loose screws or bolts in the assembly.

- Inspect the condition of the cutting chain and bar for damage.

- Ensure that the motor is securely mounted.

Preventative Maintenance Tips

- Regularly clean air filters and cooling fins to prevent overheating.

- Sharpen the blade frequently to maintain cutting efficiency.

- Inspect the tool for wear and tear before each use.