In the realm of outdoor equipment, comprehending the various elements that comprise your device is essential for optimal performance and maintenance. Whether you are a professional landscaper or a weekend warrior, having a solid grasp of how each component functions can significantly enhance your experience and efficiency. A well-informed operator can not only troubleshoot issues but also ensure the longevity of their tool.

The intricate assembly of your machine involves numerous parts, each serving a specific purpose. Recognizing the roles of these elements empowers users to make informed decisions regarding repairs and upgrades. Familiarity with the design and layout of your equipment can streamline tasks, leading to safer and more effective operation.

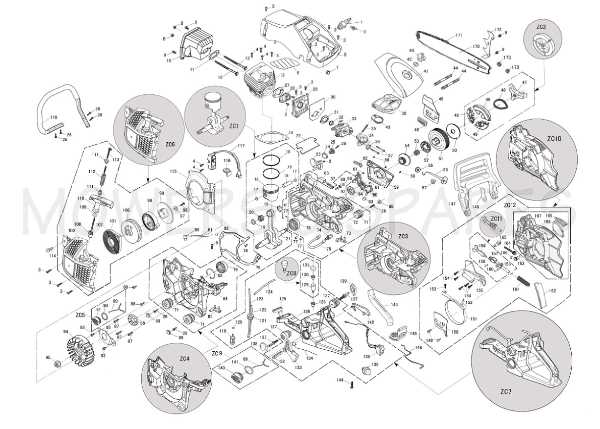

Exploring a visual representation of the tool’s assembly can demystify its inner workings. Such illustrations provide clarity, making it easier to identify components and understand their interconnections. This knowledge serves as a foundation for successful maintenance practices, ultimately leading to enhanced performance and satisfaction with your equipment.

Gaining a thorough understanding of your cutting tool’s components is crucial for effective operation and maintenance. Each element plays a significant role in the overall functionality and performance, making it essential to familiarize yourself with their individual purposes.

In this section, we will explore the primary components of a typical cutting device, highlighting their functions and interrelations. This knowledge not only aids in troubleshooting but also enhances safety during use.

- Power Source: The energy supply is fundamental to the tool’s operation, influencing performance and run time.

- Guide Bar: This component guides the cutting chain and supports it during operation, affecting the depth of the cut.

- Cutting Chain: The chain is the primary cutting element, designed to provide precision and efficiency in cutting tasks.

- Chain Tensioning Mechanism: Ensures proper tension in the cutting chain, which is vital for safety and performance.

- Safety Features: Includes mechanisms such as chain brakes and guards that protect the user during operation.

Understanding the roles of these components helps users maintain their tools effectively, ensuring longevity and optimal performance. Regular checks and knowledge of each part’s function can prevent malfunctions and enhance the overall experience.

Key Features of Greenworks 40V Model

This model is designed with a focus on delivering efficiency and ease of use for various cutting tasks. It combines innovative technology with user-friendly elements, making it suitable for both novices and experienced users.

Powerful Performance: The robust motor ensures that the tool can handle tough materials with minimal effort. This strength translates to faster cutting speeds and reduced downtime.

Lightweight Design: The ergonomic build enhances maneuverability, allowing users to operate the device comfortably for extended periods without fatigue. Its portability is a significant advantage for those working in diverse locations.

Battery Efficiency: Utilizing advanced battery technology, this model offers impressive run times, making it ideal for prolonged use. Quick charging capabilities ensure minimal interruptions during projects.

Safety Features: Equipped with essential safety mechanisms, including a chain brake and low kickback design, this tool prioritizes user protection, providing peace of mind during operation.

Maintenance Ease: Designed for simple upkeep, users can easily access components for cleaning and replacement, ensuring longevity and consistent performance without requiring specialized tools.

Importance of Regular Maintenance

Routine upkeep is essential for the longevity and efficiency of any power tool. Regular attention to these devices not only enhances performance but also ensures safety during operation. By adhering to a maintenance schedule, users can prevent potential issues that may arise from neglect, leading to a more reliable and effective experience.

Enhancing Performance and Lifespan

Consistent servicing significantly contributes to optimal functioning and extends the lifespan of the equipment. By cleaning, lubricating, and checking critical components, users can ensure that the tool operates smoothly and effectively. A well-maintained tool is less prone to breakdowns and can handle tasks more efficiently, ultimately saving time and resources.

Safety Considerations

Regular maintenance is also a crucial aspect of safety. Tools that are not properly cared for may pose hazards to users, including unexpected failures during operation. Inspecting and replacing worn or damaged components helps mitigate risks, ensuring that the device remains safe to use. Prioritizing upkeep not only protects the equipment but also safeguards the user.

How to Identify Part Issues

Understanding the signs of malfunctioning components in your equipment is essential for maintaining optimal performance. Recognizing irregularities early can prevent further damage and ensure a smooth operation. This section explores key indicators that may suggest the need for inspection and replacement of specific elements within your tool.

Common Symptoms of Malfunctions

Several telltale signs can indicate potential problems. Unusual noises during operation may signify that certain elements are worn out or misaligned. Additionally, a decrease in efficiency, such as reduced cutting capability or erratic movement, often points to internal issues. Regularly checking for leaks or visible wear can also help in identifying parts that require attention.

Visual Inspection Techniques

Conducting a thorough visual examination is crucial for pinpointing faulty components. Look for cracks, discoloration, or any physical damage on the exterior. Ensure all connections are secure and that no debris obstructs any moving parts. A detailed inspection can provide insights into which elements may need replacement or repair.

Detailed Breakdown of Major Parts

This section offers an in-depth examination of the key components found within a powerful outdoor cutting tool. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance during use.

Motor Assembly: The motor serves as the heart of the device, converting electrical energy into mechanical power. It is responsible for driving the cutting mechanism, and its efficiency significantly impacts overall functionality.

Cutting Bar: This elongated piece acts as the platform for the cutting chain. It is essential for guiding the chain during operation and comes in various lengths to suit different tasks.

Chain: The chain consists of interlinked teeth designed to efficiently slice through wood. Its sharpness and condition are vital for achieving smooth cuts and preventing jams.

Handle and Control System: The ergonomic handle provides grip and control, allowing the user to maneuver the tool comfortably. The control system, including triggers and safety features, ensures ease of use and enhances safety during operation.

Battery Pack: The power source for this tool, the battery pack, supplies energy to the motor. The capacity and voltage determine the duration of operation and the intensity of power delivered.

Each of these components plays a vital role in the operation of the tool, contributing to its efficiency, safety, and user experience. Proper understanding and care for these elements are essential for maintaining performance and longevity.

Tips for Effective Parts Replacement

When maintaining your equipment, ensuring the seamless exchange of components is essential for optimal performance. Properly managing this process can enhance the longevity and functionality of your tools. Here are several strategies to consider during component swaps.

Assess Compatibility and Quality

Before proceeding with any replacements, verify that the new components are compatible with your specific model. It’s advisable to choose high-quality options that meet manufacturer specifications. Using inferior substitutes may lead to further issues and diminish the overall efficiency of your equipment.

Follow Safety Procedures

Always prioritize safety when engaging in replacements. Wear appropriate protective gear and ensure the equipment is powered down to prevent accidental activation. This attention to safety not only protects you but also helps avoid potential damage to the equipment during the process.

By adhering to these guidelines, you can facilitate a smoother replacement process and maintain the integrity of your tools for years to come.

Safety Precautions During Repairs

When performing maintenance or repairs on power tools, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual working on the equipment but also ensure that the tool operates effectively once reassembled. Familiarizing oneself with safety measures is essential before starting any repair tasks.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is vital during any repair process. This includes safety glasses to shield the eyes from flying debris, gloves to protect hands from sharp edges, and ear protection if loud tools are involved. Proper footwear should also be worn to prevent slips or foot injuries.

Tool Safety and Maintenance

Ensure that all tools are in good working condition before use. Regularly inspect equipment for any signs of wear or damage. Always disconnect power sources before starting repairs to prevent accidental activation. Keeping the workspace organized and free from clutter also reduces the risk of accidents.

Finding Compatible Replacement Parts

When it comes to maintaining outdoor power tools, ensuring you have the right components is crucial for optimal performance. Identifying suitable substitutes can significantly extend the lifespan of your equipment and enhance its functionality. Understanding where to look for these alternatives can simplify the repair process and improve efficiency.

Understanding Compatibility

Before purchasing replacements, it is essential to grasp the specifications that dictate compatibility. Here are some key factors to consider:

- Model Specifications: Always refer to the manufacturer’s guidelines to find the appropriate model number.

- Quality Standards: Opt for components that meet or exceed original quality specifications to ensure reliability.

- Manufacturer Guidelines: Consult the official resources for detailed compatibility information.

Where to Find Alternatives

There are several avenues to explore when searching for suitable components:

- Authorized Dealers: They typically carry a comprehensive selection of genuine components.

- Online Retailers: Many websites offer a wide range of substitutes, often with customer reviews to aid decision-making.

- Local Repair Shops: Local specialists may provide insight into durable alternatives that are compatible with your equipment.

Common Troubleshooting for Chainsaw Problems

Addressing issues with power tools requires a systematic approach to identify and resolve common malfunctions. Recognizing potential symptoms can guide users toward effective solutions, enhancing both safety and performance.

Identifying Symptoms

Users may encounter various symptoms when their equipment is not functioning optimally. Understanding these signs is crucial for effective troubleshooting. Common indicators include:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Tool won’t start | Empty battery or fuel tank | Recharge battery or refill with fuel |

| Poor cutting performance | Dull or damaged blade | Sharpen or replace the cutting component |

| Excessive vibration | Loose components | Tighten all bolts and screws |

| Frequent stalling | Clogged air filter | Clean or replace the air filter |

Maintenance Tips

Regular maintenance plays a vital role in prolonging the life of the tool and preventing future issues. Here are some essential practices:

Ensure that all components are clean and free from debris. Regularly check and replace the oil as needed. Inspect the blade for wear and ensure it is properly tensioned. Following these guidelines can help maintain optimal performance and reliability.

Visual Aids for Assembly and Disassembly

Effective visual resources play a crucial role in the processes of putting together and taking apart machinery. They can enhance understanding, reduce errors, and streamline tasks, making them essential for both beginners and experienced users. Utilizing illustrations and guides can simplify complex steps, ensuring a smoother workflow and better results.

Importance of Illustrative Guides

Illustrative guides provide clear instructions that can significantly enhance the efficiency of assembly and disassembly procedures. These resources often include detailed images or diagrams that highlight specific components and their relationships. By referring to these visuals, individuals can more easily identify parts and understand the correct order of operations, which minimizes the risk of mistakes.

Utilizing Video Tutorials

In addition to printed materials, video tutorials offer dynamic visual assistance. These recordings can demonstrate techniques in real-time, allowing users to see the actual movements and procedures involved. This format can be particularly helpful for those who may struggle with written instructions alone, as it combines auditory and visual learning for a comprehensive understanding.

Resources for Further Information

For those seeking additional insights and guidance, numerous resources are available that cater to various aspects of tool maintenance and repair. Whether you’re looking for user manuals, troubleshooting guides, or community forums, these materials can enhance your understanding and improve your experience.

Online Communities and Forums

- Explore dedicated forums where enthusiasts share their experiences, tips, and solutions.

- Participate in discussions to learn from other users who may have encountered similar issues.

- Join social media groups focused on outdoor equipment to gain insights and advice.

User Manuals and Documentation

- Access official documentation for detailed information on operation and maintenance procedures.

- Download PDFs that provide step-by-step instructions for various tasks.

- Consult troubleshooting sections to address common challenges effectively.