The world of outdoor power equipment is vast and varied, with numerous models designed for a multitude of tasks. Among these, a specific model stands out due to its reliability and efficiency, making it a favorite among both professionals and enthusiasts alike. This section delves into the intricate assembly of this cutting device, highlighting its various elements and how they contribute to its overall functionality.

By examining the construction of this tool, users can gain valuable insights into its operation and maintenance. Knowledge of the individual components not only aids in troubleshooting but also empowers owners to make informed decisions when it comes to repairs or upgrades. Whether you are a seasoned user or a newcomer, understanding the makeup of this essential equipment can enhance your experience and prolong its lifespan.

In this exploration, we will uncover the arrangement and significance of each component, offering a clearer view of how they interconnect to perform seamlessly. This knowledge is crucial for anyone looking to optimize their equipment’s performance and ensure it remains in peak condition.

The power tool in focus is known for its efficiency and reliability in tackling various cutting tasks. This machine is designed for both novice and experienced users, making it a versatile choice in the realm of outdoor equipment. Understanding its internal components is crucial for proper maintenance and optimal performance.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the tool, crucial for cutting efficiency. |

| Guide Bar | The elongated metal piece that directs the chain during operation, influencing the cutting accuracy. |

| Chain | A series of sharp links that rotate around the guide bar, enabling the cutting action. |

| Air Filter | Filters debris from the air entering the engine, ensuring optimal combustion and performance. |

| Fuel Tank | Holds the mixture of fuel and oil necessary for engine operation. |

Understanding the various components allows users to perform regular checks, replacements, and upgrades, thereby extending the lifespan of the equipment. A thorough grasp of each element will empower users to troubleshoot and maintain their machinery effectively.

Key Components of the Chainsaw

The efficient operation of a cutting tool relies on several essential elements that work in harmony. Understanding these critical components helps users appreciate how the device functions and enhances their ability to troubleshoot or maintain it effectively.

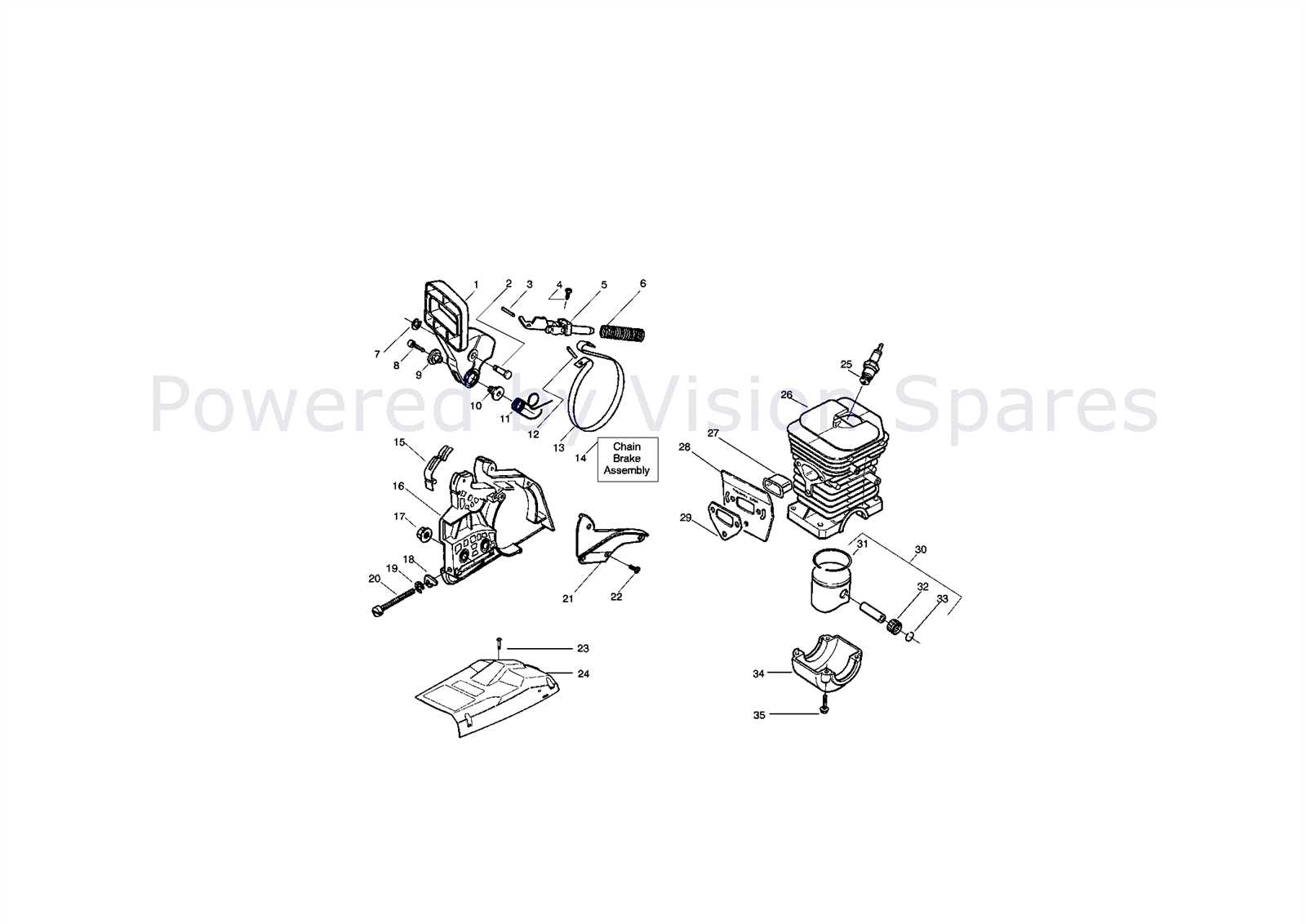

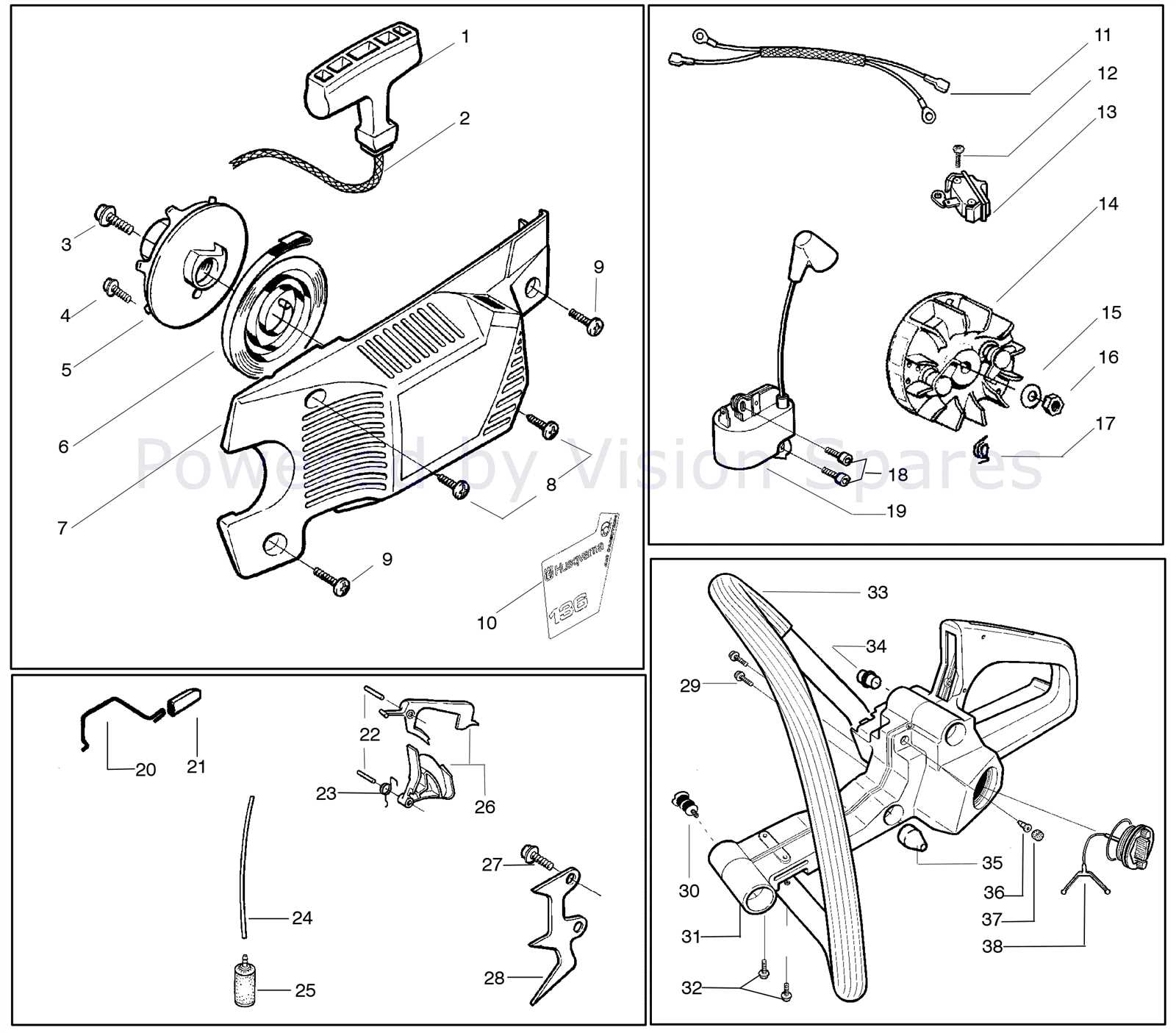

At the heart of the device is the engine, which provides the necessary power to drive the chain. This component is typically a two-stroke engine, designed for high performance and lightweight characteristics. The fuel system ensures that the engine receives the right mixture of fuel and oil, crucial for optimal operation and longevity.

The guide bar serves as the track along which the cutting chain moves, facilitating precise cutting actions. The cutting chain itself is made up of interlinked segments, each equipped with sharp teeth that slice through wood efficiently. Tensioning mechanisms are also present to ensure the chain remains securely in place and operates smoothly.

Safety features, such as the chain brake, play a vital role in protecting the user from potential accidents during operation. Additionally, ergonomic handles provide a comfortable grip, enabling better control and reducing fatigue during extended use. Each of these components contributes to the overall effectiveness and safety of the cutting instrument.

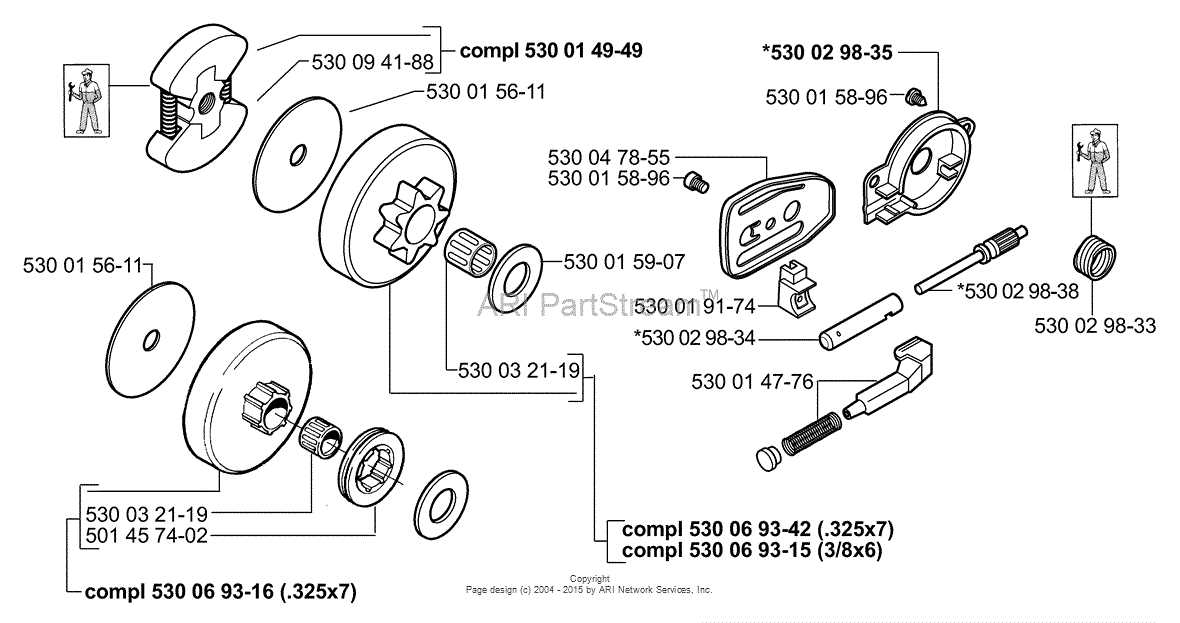

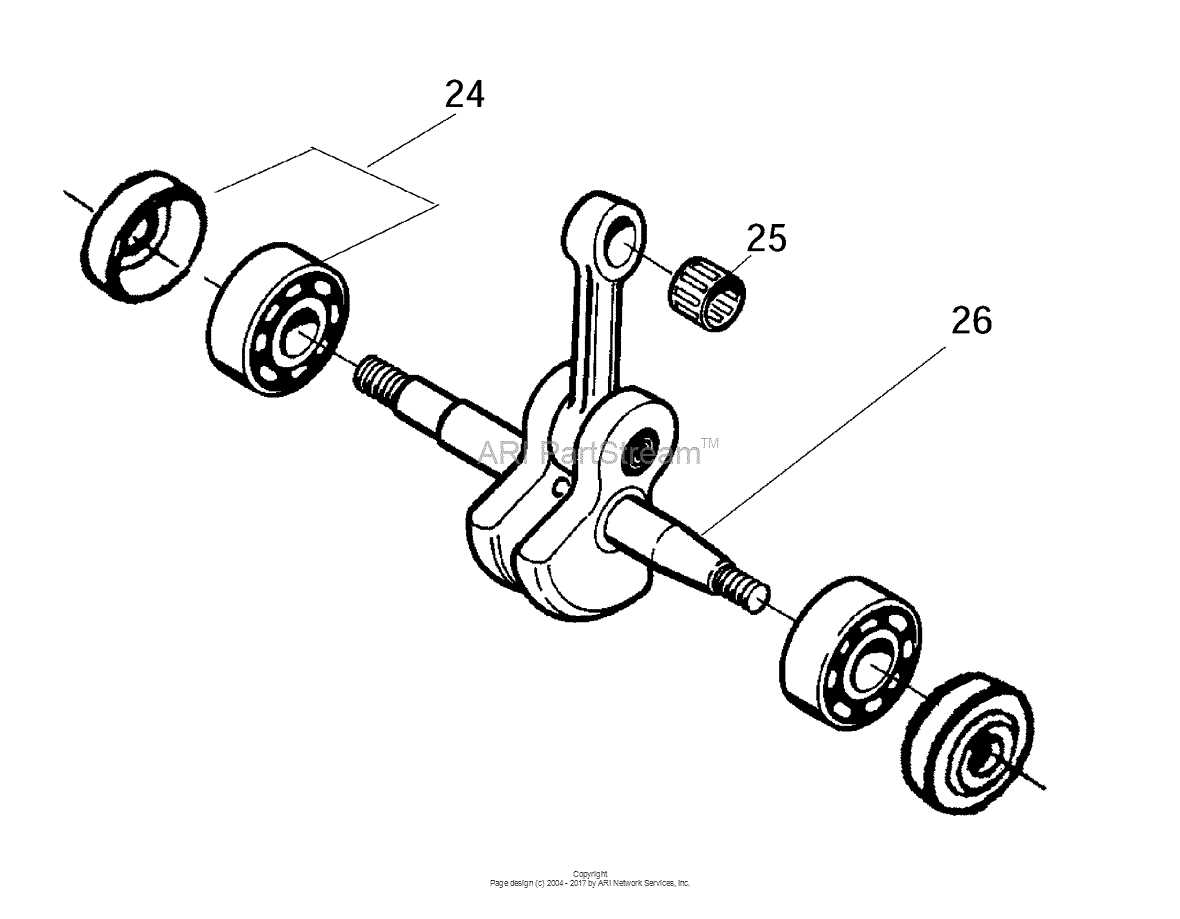

Understanding the Parts Diagram

Analyzing the assembly layout of a tool is essential for effective maintenance and repair. This layout provides a visual representation of the components involved, allowing users to identify each element’s role and function. By becoming familiar with this illustration, individuals can enhance their understanding of the tool’s operation and streamline the repair process.

Each component depicted plays a vital part in the overall functionality of the equipment. Recognizing the location and interaction of these elements is crucial for troubleshooting issues and ensuring optimal performance. Additionally, this graphical guide serves as a valuable reference when seeking replacement elements or conducting routine inspections.

Engaging with this visual reference empowers users to approach maintenance tasks with confidence. By grasping the intricacies of the tool’s assembly, individuals can make informed decisions, thereby prolonging the lifespan of the equipment and enhancing its efficiency. Overall, a thorough comprehension of the layout can significantly improve one’s hands-on experience.

Common Issues and Solutions

When operating a power cutting tool, users may encounter various challenges that can affect performance and safety. Understanding these common problems and their remedies is essential for maintaining optimal functionality and ensuring effective operation. Below are some frequently experienced issues along with potential solutions to address them.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Tool won’t start | Empty fuel tank, faulty spark plug, or clogged air filter | Refill fuel, replace spark plug, clean or replace the air filter |

| Excessive vibration | Worn or damaged components | Inspect for wear, tighten loose parts, replace damaged components |

| Poor cutting performance | Dull blade, incorrect chain tension | Sharpen blade, adjust chain tension to manufacturer’s specifications |

| Overheating | Insufficient lubrication or blocked cooling vents | Ensure proper oil level, clean cooling vents |

| Oil leaks | Damaged oil seals or loose fittings | Inspect seals and fittings, replace if necessary, tighten loose connections |

Maintenance Tips for Longevity

To ensure the extended lifespan of your outdoor power tool, regular upkeep is essential. By implementing proper care techniques, you can significantly enhance performance and reduce the likelihood of costly repairs. A few straightforward practices can keep your equipment operating smoothly and efficiently over the years.

Regular Cleaning: Keeping your tool free from debris and contaminants is crucial. After each use, make sure to wipe down surfaces and check for any build-up that may affect functionality. Pay special attention to air filters and ventilation areas to promote optimal airflow.

Lubrication: Regularly applying appropriate lubricants can prevent wear and tear on moving parts. Check the manufacturer’s recommendations for the best products and frequency of application. Proper lubrication minimizes friction and ensures seamless operation.

Inspection and Replacement: Routinely inspect components for signs of damage or wear. Replace any worn parts immediately to avoid further complications. This proactive approach will not only enhance performance but also increase the overall safety of the equipment.

Proper Storage: When not in use, store your tool in a dry and protected area. Avoid exposure to extreme temperatures or moisture, which can lead to corrosion or other issues. Using protective covers can also shield against dust and debris.

By following these straightforward maintenance practices, you can extend the life of your outdoor equipment and ensure it operates at peak efficiency whenever needed.

How to Replace Parts Efficiently

When it comes to maintaining your equipment, the process of swapping out components can significantly impact performance and longevity. Streamlining this task can save both time and effort, ensuring your tool remains in top condition. Here are some key steps to help you execute replacements effectively.

-

Gather Necessary Tools:

Before beginning, ensure you have all essential instruments at hand. This may include:

- Wrenches

- Screwdrivers

- Replacement components

- Lubricants

- Safety gear

-

Consult the Manual:

Refer to the instruction guide for specific details about the replacement procedure. This document will often outline:

- Step-by-step instructions

- Safety precautions

- Component specifications

-

Organize Your Workspace:

Ensure your work area is tidy and well-lit. A clutter-free environment will help you:

- Locate tools quickly

- Minimize risks of accidents

- Enhance focus on the task at hand

-

Follow a Systematic Approach:

Start by removing the old component carefully, taking note of how it is connected. Replace it with the new item in reverse order, ensuring:

- All connections are secure

- Parts are aligned correctly

- To check for any loose screws or fittings

-

Test the Equipment:

After the replacement, perform a thorough test to ensure everything operates smoothly. Check for:

- Unusual sounds

- Leaks or excess vibrations

- Overall functionality

By adhering to these guidelines, you can enhance your efficiency in replacing components and maintain the optimal performance of your tool.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right instruments is crucial for ensuring efficiency and longevity. The proper tools not only facilitate smooth repairs but also enhance safety during the process. This section outlines the essential equipment needed for effective servicing, providing a foundation for successful maintenance tasks.

1. Wrenches and Socket Sets: These are fundamental for loosening and tightening various components. A comprehensive set allows you to tackle different sizes and types of fasteners, ensuring you can easily access internal mechanisms.

2. Screwdrivers: A collection of flathead and Phillips screwdrivers is vital for addressing screws found in various assemblies. Having multiple sizes will help you work with precision and avoid damaging sensitive parts.

3. Pliers: Pliers are indispensable for gripping, bending, and cutting wires or components. They provide the extra leverage needed to manipulate stubborn pieces without risking damage.

4. Torque Wrench: Using a torque wrench ensures that components are secured to the manufacturer’s specifications. This tool prevents over-tightening, which can lead to mechanical failure or stripped threads.

5. Cleaning Tools: Keeping equipment free of debris is essential for optimal performance. Brushes, cloths, and specialized cleaners help maintain the equipment’s functionality and extend its lifespan.

6. Safety Gear: Never underestimate the importance of personal protective equipment. Gloves, goggles, and ear protection safeguard against potential injuries while working on machinery.

Investing in these essential tools will greatly enhance your ability to perform repairs effectively and safely, ensuring that your outdoor equipment remains in peak condition.

Safety Measures When Working

Engaging in tasks involving cutting tools requires a high level of caution and adherence to safety protocols. Understanding the potential hazards and implementing preventive measures is essential for ensuring a secure working environment. By taking these precautions seriously, one can minimize risks and enhance overall safety while operating equipment.

Protective Gear

Wearing appropriate protective equipment is crucial. Essential items include safety goggles to shield the eyes from debris, gloves for hand protection, and sturdy footwear to prevent slips and injuries. Additionally, a hard hat may be necessary in areas where falling objects could pose a threat. Investing in high-quality gear can significantly reduce the risk of accidents.

Workspace Organization

Maintaining a tidy workspace is vital for safe operations. Clear away unnecessary tools and materials to prevent tripping hazards. Ensure that the cutting equipment is properly stored when not in use, and keep the area well-lit to enhance visibility. By fostering an organized environment, individuals can focus better and respond promptly to any unforeseen situations.

Frequently Asked Questions

This section aims to address common inquiries regarding the assembly and components of outdoor cutting equipment. Understanding these elements can significantly enhance the user experience and maintenance of the machine.

- What should I do if my equipment is not starting?

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for damage or dirt.

- Verify that the ignition switch is in the correct position.

- How can I improve the longevity of my tool?

- Regularly clean and maintain all components.

- Use the recommended oil and fuel mixtures.

- Avoid overworking the machine to prevent overheating.

- Where can I find replacement components?

- Authorized dealers often carry a wide range of replacements.

- Online retailers also offer parts suitable for various models.

- Consider checking local hardware stores for commonly used items.

- What are the signs that I need to replace specific components?

- Unusual noises or vibrations can indicate wear.

- Decreased cutting performance often suggests dull or damaged blades.

- Excessive smoke or leaks may signify internal issues.

Where to Find Replacement Parts

When maintaining your equipment, it is essential to have access to reliable replacement components. Finding the right spares can sometimes feel challenging, especially if you’re unsure where to start. Thankfully, there are several options available to make this process smoother, whether you prefer shopping locally or exploring online marketplaces.

Authorized dealers are a great option for sourcing original components. They typically carry a wide selection of items that match your tool’s exact specifications, ensuring optimal performance. If you’re looking for a trusted source, these shops can provide the necessary parts, often with warranties.

For those who enjoy the convenience of online shopping, digital marketplaces offer a vast range of options. You can browse through various sellers, compare prices, and read reviews to find the best match for your needs. Many platforms also provide fast shipping options, making it easier to get your equipment back in working order quickly

Comparing Husqvarna Models and Features

When looking at different models from this popular brand, it’s important to understand how each one offers its own unique blend of qualities. Whether you’re after efficiency, durability, or specific technical capabilities, the variations between products can make a significant difference in performance for various tasks.

Here are a few key factors to consider when comparing models:

- Power output: Different tools offer various levels of engine strength, making some more suited for heavy-duty tasks, while others excel in precision work.

- Weight and handling: The overall design and balance of each model affect how comfortable it is to use over long periods.