Exploring the intricacies of a robust cutting instrument reveals a world of precision engineering and functionality. This section will illuminate the various elements that contribute to the overall performance and efficiency of such machinery. By breaking down the individual components, users can gain insight into how each piece works in harmony to achieve optimal results.

Identifying the critical segments is essential for anyone looking to enhance their understanding or perform maintenance. An overview of these elements not only aids in troubleshooting but also facilitates better handling and longevity of the device. Awareness of each part’s role and interrelation can empower users to make informed decisions during repairs or upgrades.

In essence, grasping the layout and function of these crucial components serves as a foundation for mastery. Whether you’re a novice or a seasoned operator, delving into the specifics will ultimately lead to improved efficiency and satisfaction in using the tool.

Understanding the Husqvarna 455 Rancher

This section aims to explore the intricacies of a popular outdoor power tool known for its robust performance and reliability. Designed for both professionals and enthusiasts, this equipment is engineered to handle various cutting tasks efficiently. Understanding its components and functionality is essential for effective usage and maintenance.

Key Features

- Powerful engine designed for heavy-duty applications

- Ergonomic design for enhanced comfort during prolonged use

- Advanced cutting technology for precision and speed

- Durable construction to withstand challenging conditions

Common Applications

- Tree felling and limbing

- Wood cutting for firewood preparation

- Landscaping and yard maintenance

- Emergency response and cleanup

Familiarity with this tool can significantly enhance performance and extend its lifespan, ensuring it remains a reliable companion for all outdoor projects.

Key Features of the Chainsaw

This section explores the essential characteristics that define a high-performance cutting tool, highlighting its design and functionality.

- Powerful Engine: A robust motor provides the necessary strength for demanding tasks.

- Ergonomic Design: Comfort-focused construction ensures ease of use during prolonged operation.

- Efficient Cutting System: Advanced blade technology enhances cutting precision and speed.

- Safety Features: Integrated safeguards minimize risks during operation, promoting user security.

- Fuel Efficiency: Designed to optimize fuel consumption while maintaining performance levels.

These attributes contribute significantly to the overall effectiveness and reliability of the equipment in various cutting applications.

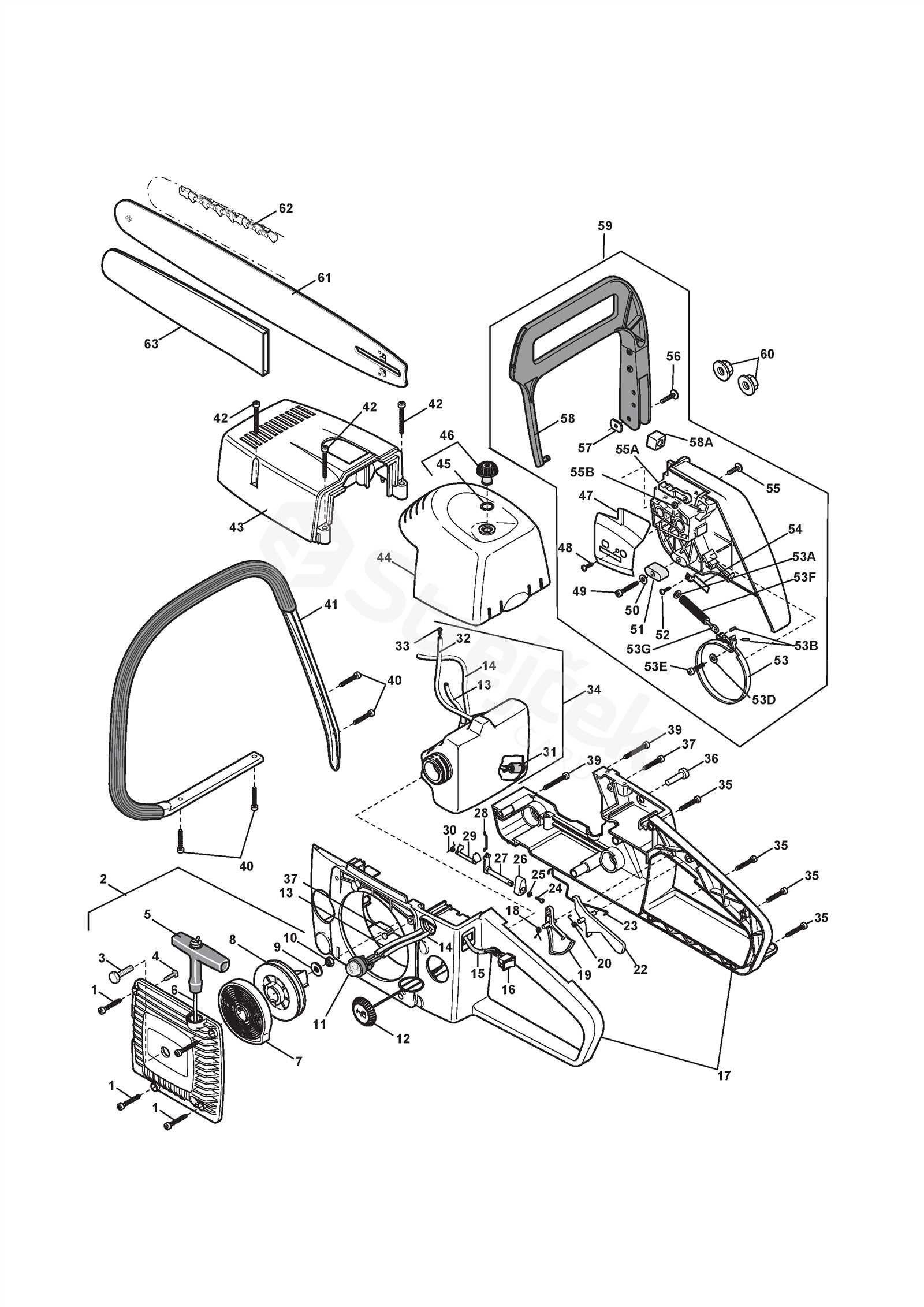

Components Overview for Easy Repair

Understanding the various elements of your cutting tool can significantly simplify the maintenance and repair process. Each component plays a crucial role in the overall functionality, and knowing how they fit together is essential for effective troubleshooting.

- Engine: The powerhouse that drives the entire unit.

- Bar: The long, flat part where the cutting takes place.

- Chain: The rotating loop that performs the cutting action.

- Clutch: Engages and disengages the chain movement.

- Handle: Provides grip and control during operation.

- Fuel System: Supplies the necessary energy to the engine.

By familiarizing yourself with these key components, you can delve into repairs with confidence, ensuring your tool remains in peak condition.

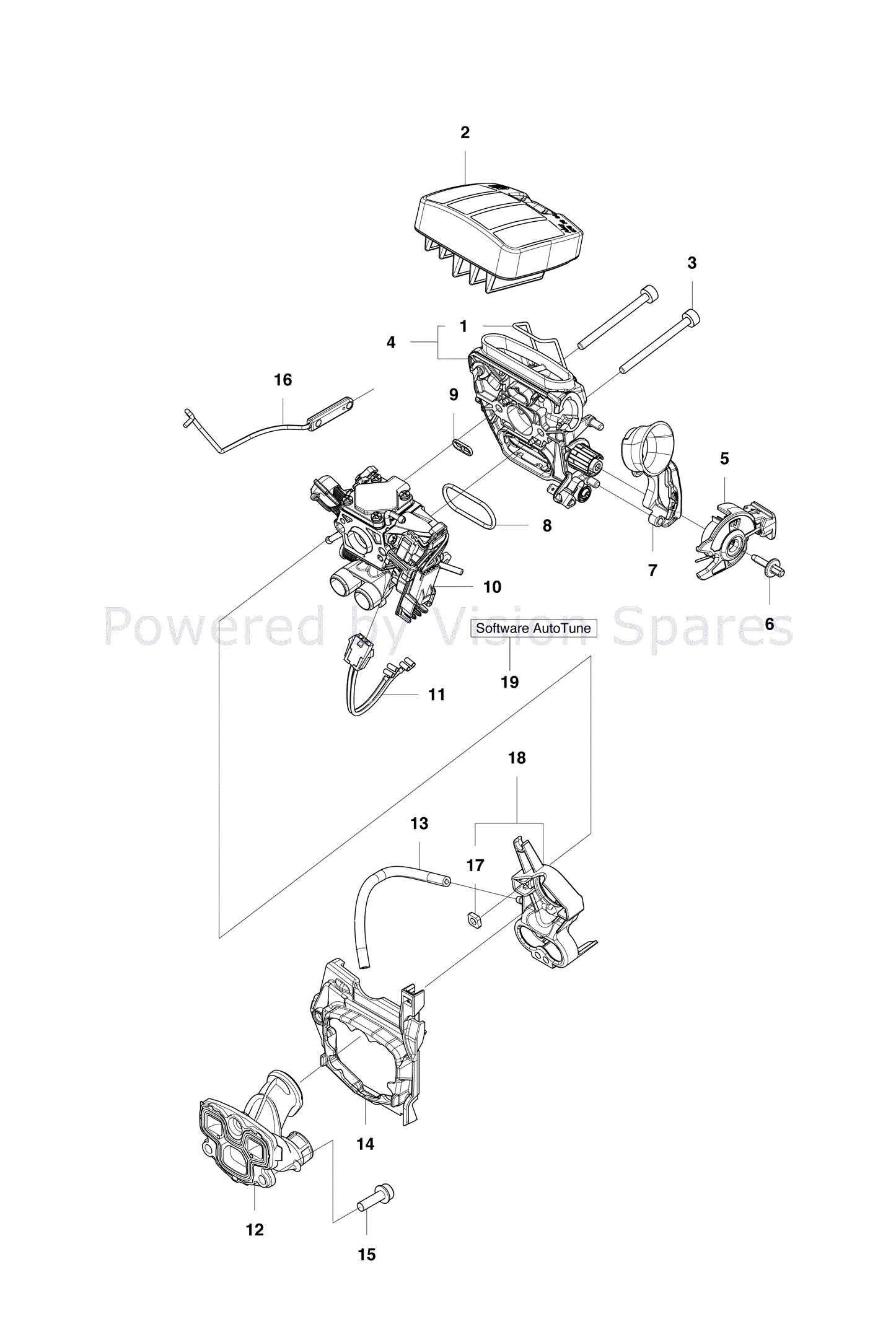

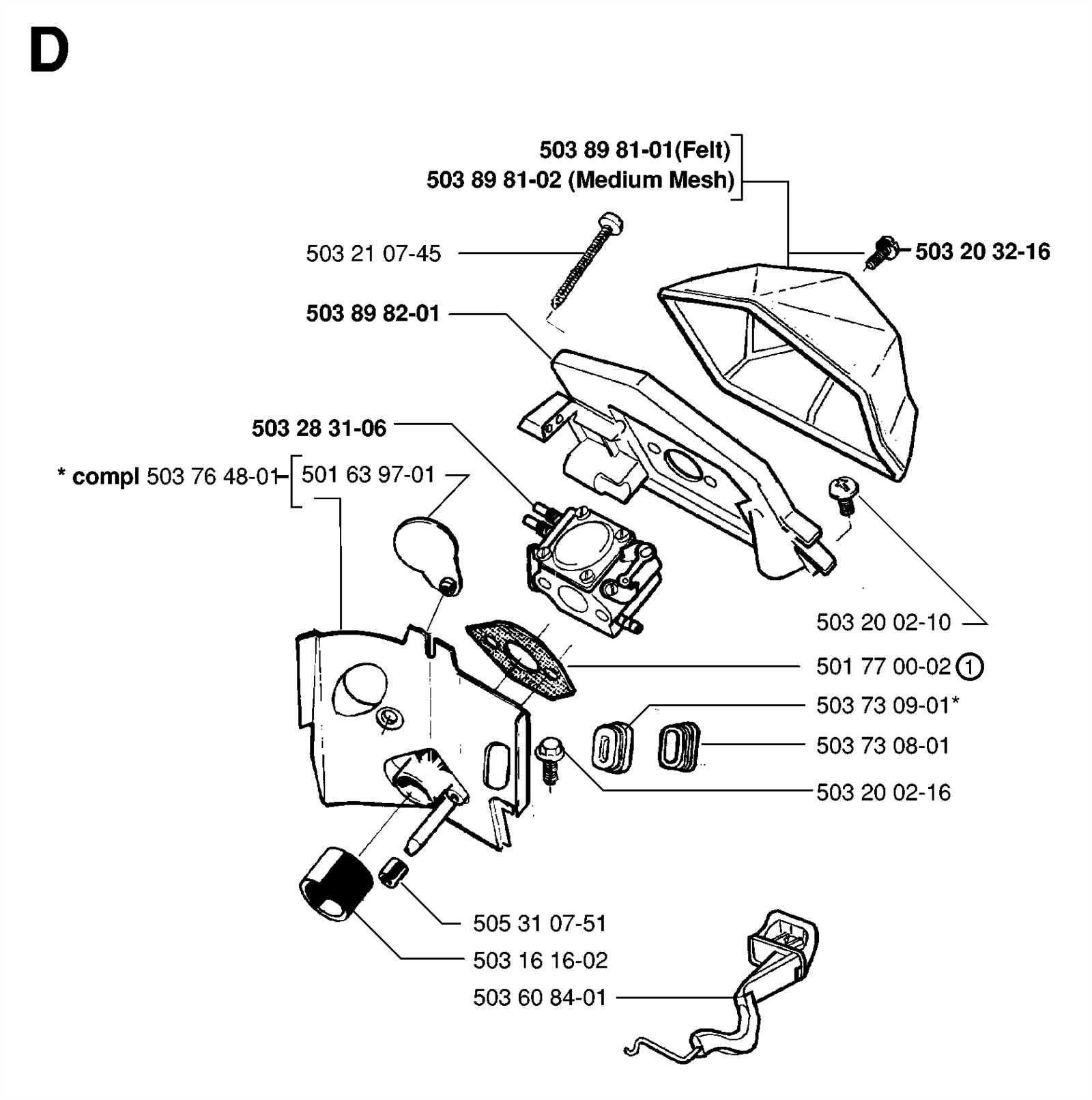

Importance of a Parts Diagram

A detailed visual representation of components is essential for anyone involved in maintenance and repairs. Such illustrations facilitate a clearer understanding of how each piece fits into the overall system, enabling efficient troubleshooting and reassembly.

Having access to these visual guides not only streamlines the repair process but also enhances safety by ensuring that every element is correctly identified and installed. This can prevent potential hazards that might arise from improper handling or assembly.

Furthermore, these representations serve as invaluable references for ordering replacements. They provide clarity on which components are needed, reducing the risk of purchasing incorrect items and saving both time and money.

Overall, a comprehensive visual breakdown is an indispensable tool for both novice and experienced users, promoting a smoother and more effective repair experience.

Common Issues and Solutions

In the realm of power equipment, users often encounter a range of challenges that can hinder performance. Understanding these common problems and their resolutions is essential for maintaining optimal functionality and extending the lifespan of your device.

Fuel-Related Problems

One frequent issue is related to fuel quality. Old or contaminated fuel can lead to starting difficulties or poor performance. To resolve this, ensure that you use fresh fuel and consider adding a stabilizer to prolong its life. Additionally, cleaning the fuel filter can enhance fuel flow and efficiency.

Starting Difficulties

Users may also face challenges when attempting to start their equipment. This could be due to a faulty spark plug or improper starting technique. Regularly checking the spark plug for wear and ensuring correct priming and choke settings can significantly improve starting reliability. If issues persist, inspecting the ignition system may be necessary.

How to Interpret the Diagram

Understanding a technical illustration is essential for effective maintenance and repair of your equipment. This visual representation organizes components systematically, allowing users to identify and locate parts easily. Familiarity with the symbols and layout is key to navigating the information effectively.

Here are some tips to help you interpret the illustration:

- Familiarize Yourself with the Legend:

- Look for a legend or key that explains the symbols used.

- Understand what each symbol represents to avoid confusion.

- Identify Major Sections:

- Components are typically grouped by function or location.

- Recognize sections such as the engine, body, and control mechanisms.

- Pay Attention to Numbering:

- Parts may be numbered sequentially, indicating assembly order or importance.

- Use these numbers to find corresponding parts in a parts list.

- Study Connection Points:

- Note where components attach to one another.

- Understanding these connections is crucial for disassembly and reassembly.

By mastering these elements, you will enhance your ability to work with the equipment effectively, ensuring longevity and optimal performance.

Essential Tools for Maintenance

Proper upkeep of outdoor power equipment requires a selection of vital instruments to ensure optimal performance and longevity. Having the right tools on hand can streamline the maintenance process, making it easier to address issues before they escalate.

A reliable wrench set is crucial for adjusting and tightening various components, while screwdrivers of different sizes facilitate easy access to screws in tight spaces. Additionally, a fuel stabilizer can enhance engine performance by preventing fuel degradation, ensuring smooth operation during each use.

Keeping a quality sharpening tool is essential for maintaining cutting efficiency, while protective gear, such as gloves and goggles, promotes safety during any maintenance task. Finally, a cleaning brush helps remove debris and prevent buildup, further extending the life of your equipment.

Identifying Replacement Parts Easily

Understanding how to locate specific components for your outdoor power equipment can significantly enhance maintenance efficiency. By familiarizing yourself with the essential elements, you can streamline the replacement process and ensure optimal performance.

To assist in this endeavor, it’s beneficial to refer to visual guides that clearly illustrate the various sections and their corresponding items. These resources often provide a comprehensive overview, making it easier to pinpoint what you need.

| Component | Description |

|---|---|

| Air Filter | Ensures clean air intake for optimal engine performance. |

| Bar and Chain | Essential for cutting; various lengths available for different tasks. |

| Sprocket | Connects the chain to the motor, enabling movement. |

| Fuel Tank | Holds fuel for the engine, vital for operation. |

Where to Find Authentic Parts

Finding genuine components for your outdoor equipment is essential for maintaining optimal performance and longevity. Reliable sources ensure that the replacements meet quality standards, providing peace of mind during operation.

Authorized Dealers

One of the best avenues to explore is contacting authorized retailers. These establishments are recognized for selling legitimate products, often backed by warranties. Checking their inventory can lead you to the exact items you need.

Online Marketplaces

In addition, reputable online platforms specialize in outdoor machinery. When shopping online, always look for customer reviews and ratings to verify authenticity. Ensure that the seller has a solid return policy, in case the items do not meet your expectations.

Safety Tips for Using Chainsaws

When operating power tools designed for cutting wood, prioritizing safety is essential. Understanding the potential hazards and taking preventative measures can significantly reduce the risk of accidents. By adhering to best practices, users can ensure a safer experience while maximizing efficiency.

Personal Protective Equipment

Wearing the right gear is crucial. This includes helmets, eye protection, hearing protection, gloves, and cut-resistant clothing. Each piece of equipment serves to shield you from specific dangers associated with cutting tasks.

Operational Guidelines

Always follow manufacturer instructions and maintain your tool in good condition. Before starting, inspect the equipment for any damage, ensure the chain is sharp, and keep your workspace clear of obstacles. Pay attention to your surroundings and be mindful of potential fall hazards.

| Safety Gear | Purpose |

|---|---|

| Helmet | Protects against falling debris |

| Eye Protection | Prevents eye injuries from flying particles |

| Hearing Protection | Reduces noise exposure |

| Gloves | Improves grip and protects hands |

| Cut-Resistant Clothing | Minimizes injury risk from accidental contact |

Upgrading Components for Better Performance

Enhancing the efficiency of your cutting tool involves a thoughtful approach to upgrading its elements. By selecting superior components, you can significantly improve performance, increase durability, and achieve smoother operation. This guide explores key upgrades that can lead to ultimate results in productivity.

Essential Upgrades for Efficiency

One of the primary areas to focus on is the engine system. Upgrading to a high-performance air filter can ensure optimal airflow, resulting in better combustion and increased power. Additionally, consider investing in a premium spark plug, which can enhance ignition efficiency and improve overall engine responsiveness.

Enhancing Cutting Precision

To achieve better cutting accuracy, replace the existing blade with a specialized one designed for your specific tasks. A sharper, more durable blade reduces effort and increases cutting speed. Furthermore, adjusting the tension and alignment of the guide bar can also lead to improved performance and longevity.

Maintenance Schedule for Longevity

To ensure optimal performance and extend the lifespan of your cutting tool, adhering to a regular maintenance schedule is essential. This involves routine checks and timely interventions to keep all components functioning smoothly. Proper upkeep not only enhances efficiency but also prevents costly repairs and replacements down the line.

Daily Maintenance: Before each use, inspect the device for any visible wear or damage. Check the chain tension and lubrication levels, ensuring they meet the manufacturer’s specifications. Clean any debris from the air filter and cooling fins to prevent overheating.

Weekly Maintenance: Conduct a more thorough examination of the machine. Clean the spark plug and replace it if necessary. Inspect the guide bar for signs of wear and replace it if any irregularities are observed. Ensure that all fasteners are tight and secure.

Monthly Maintenance: Perform a deep cleaning of the entire unit. Remove the chain and bar, cleaning them thoroughly. Check the oil system for clogs and replace any worn or damaged parts. Lubricate all moving parts to prevent rust and ensure smooth operation.

Seasonal Maintenance: At the beginning of each season, give the device a comprehensive inspection. Replace the air filter and fuel filter, and ensure that the fuel used is fresh and of high quality. Store the equipment in a dry place and consider using a protective cover to shield it from dust and moisture.

By following this structured maintenance schedule, users can significantly enhance the reliability and durability of their tools, ensuring they remain in peak condition for many years to come.

Expert Recommendations and Resources

For anyone looking to enhance their knowledge and skills regarding equipment maintenance and repair, leveraging expert insights can be invaluable. By tapping into reputable sources and experienced professionals, users can find essential information to ensure longevity and optimal performance of their tools.

Trusted Sources for Information

Consulting manuals and guides from reliable manufacturers provides a solid foundation. Websites dedicated to outdoor equipment often feature forums and user reviews that can offer practical advice and troubleshooting tips. Additionally, instructional videos can visually demonstrate complex procedures.

Professional Advice

Engaging with specialists or joining local workshops can deepen understanding and foster community connections. Experts can provide hands-on demonstrations and tailored recommendations based on individual needs. Utilizing these resources ultimately leads to better maintenance practices and improved outcomes.