When it comes to maintaining and optimizing your high-performance cutting equipment, a thorough comprehension of its individual elements is essential. Each component plays a crucial role in ensuring efficient operation and longevity, making it vital for users to familiarize themselves with the intricate details of their machinery. This knowledge not only enhances performance but also aids in troubleshooting and repairs.

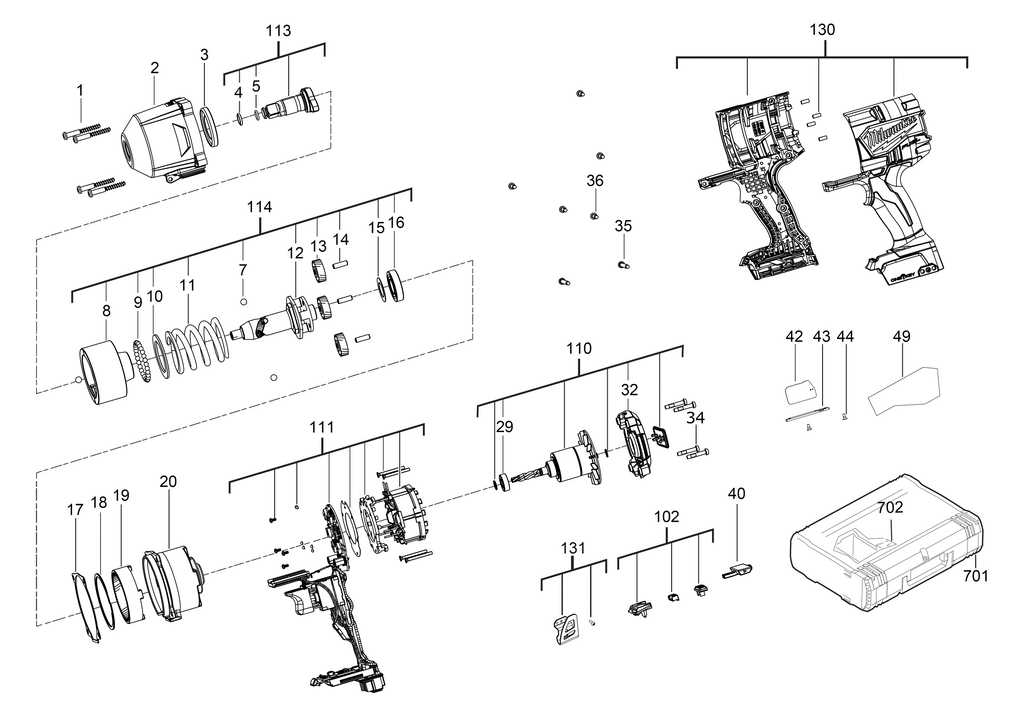

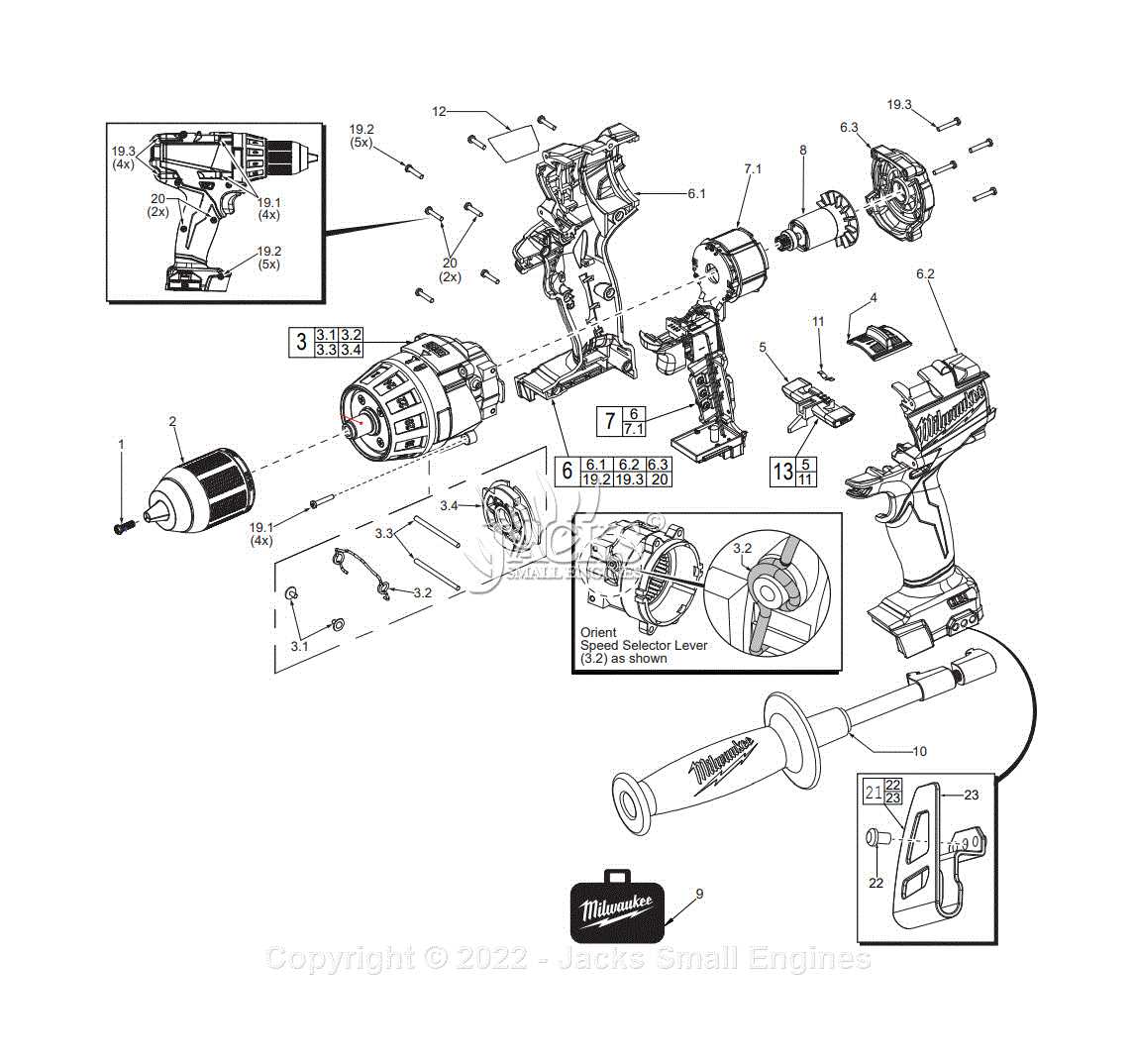

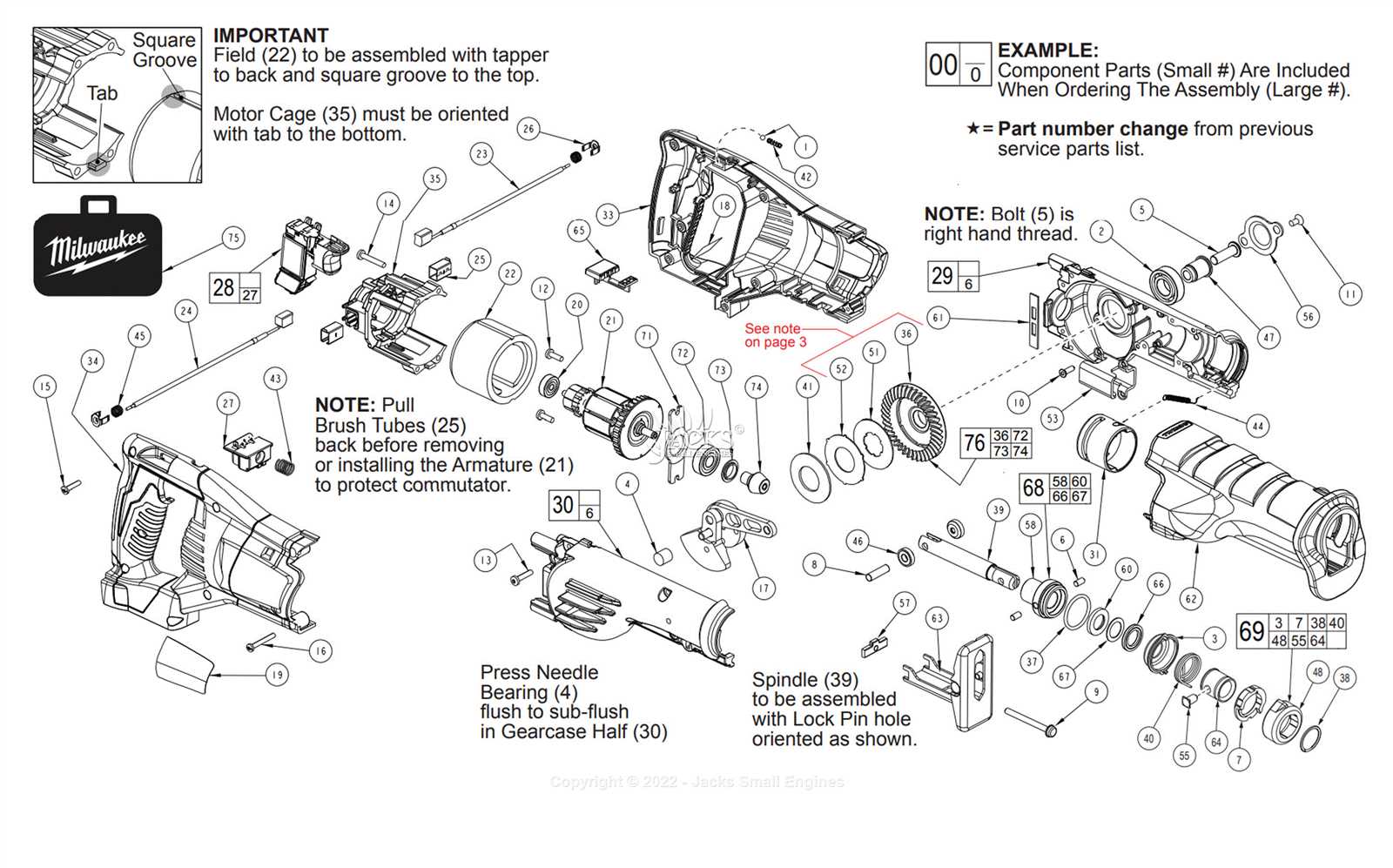

Visualizing the intricate layout of a tool’s mechanisms can significantly improve your ability to handle repairs or upgrades. By examining a detailed representation of the components, users can easily identify the various sections and understand how they interconnect. Such familiarity empowers operators to make informed decisions about maintenance and potential enhancements.

Additionally, a well-structured overview allows for easier identification of any malfunctioning parts, ensuring timely interventions. Whether you are an avid DIY enthusiast or a professional in the field, mastering the configuration of your equipment is a fundamental step towards maximizing its potential and ensuring safety during operation.

Understanding Milwaukee M18 Chainsaw

This section explores the essential features and components of a powerful, battery-operated cutting tool designed for both professionals and enthusiasts. A deep understanding of its structure enhances the user experience and ensures optimal performance, making it easier to tackle various outdoor tasks.

Key Components

Familiarity with the primary elements of this tool is crucial. The engine, guide bar, and cutting chain work together seamlessly, delivering efficiency and reliability. Each component has a specific function, and knowing their roles helps users maintain the equipment effectively.

Maintenance and Care

Regular upkeep is vital for longevity and effectiveness. Ensuring that the cutting mechanism is sharp, lubricated, and free of debris can significantly improve performance. Additionally, periodic inspections of the battery and electrical systems can prevent unexpected issues and enhance safety during use.

Key Features of M18 Chainsaw

This section explores the essential characteristics of a high-performance cutting tool designed for efficiency and ease of use. The features not only enhance productivity but also ensure safety and comfort during operation.

| Feature | Description |

|---|---|

| Lightweight Design | Offers portability and reduces user fatigue during extended use. |

| Brushless Motor | Provides greater power and longer runtime compared to traditional motors. |

| Tool-less Chain Tensioning | Allows for quick adjustments, making it easier to maintain optimal performance. |

| High-Performance Battery | Delivers sustained energy, ensuring consistent cutting speed and efficiency. |

| Safety Features | Includes automatic brake and guard mechanisms to enhance user safety. |

Importance of Replacement Parts

Ensuring the longevity and efficiency of any power tool relies heavily on the availability of high-quality components. Over time, certain elements may wear out or become damaged, necessitating their replacement to maintain optimal performance. Ignoring these crucial upgrades can lead to diminished functionality and increased risk of malfunction.

Quality replacement components are essential for sustaining the reliability of equipment. They not only restore lost capabilities but also enhance safety during operation. When parts are compromised, the risk of accidents rises significantly, which can lead to serious injuries or equipment failure.

Moreover, using authentic or high-standard substitutes often results in better performance and extends the lifespan of the entire device. Investing in replacement components is a proactive approach that minimizes downtime and ensures that your tool remains efficient and dependable for various tasks. Regular maintenance, coupled with timely updates of essential elements, promotes smooth operation and maximizes productivity.

Components of M18 Chainsaw Explained

This section delves into the various elements that make up a cutting tool, highlighting their functions and importance. Understanding these components is crucial for effective operation and maintenance.

Motor: The heart of the device, providing the necessary power to perform cutting tasks efficiently.

Guide Bar: A critical part that supports the cutting chain, allowing for precision and control during operation.

Chain: The actual cutting element that features sharp teeth designed to slice through wood effectively.

Chain Brake: An essential safety feature that halts the chain’s movement instantly in case of kickback or other emergencies.

Oil Reservoir: Maintains lubrication for the chain and bar, ensuring smooth operation and prolonging the life of the tool.

Handle: Provides grip and control, allowing the user to maneuver the tool comfortably and safely.

Trigger: The mechanism that activates the motor, giving users the ability to start and stop the device as needed.

Understanding these key components can significantly enhance the user experience and ensure safe and efficient use of the tool.

Visual Parts Diagram Overview

This section provides a comprehensive look at the components that make up a specific type of cutting tool. Understanding the layout and function of each element is essential for maintenance, troubleshooting, and repair. A clear visual representation allows users to identify various sections and their interconnections effectively.

Here, you will find a detailed table illustrating the critical elements of the tool, along with brief descriptions of their roles. This overview aims to enhance your familiarity with the structure, ensuring efficient operation and care.

| Component | Description |

|---|---|

| Motor | Drives the entire mechanism, providing the necessary power for operation. |

| Guide Bar | Acts as a support for the cutting chain, directing its movement. |

| Chain | The primary element for cutting, featuring sharp teeth designed for efficiency. |

| Handle | Provides grip and control, ensuring safe and comfortable usage. |

| Chain Tensioner | Allows for adjustments to the chain’s tightness, optimizing performance. |

| Safety Guard | Protects the user from debris and enhances overall safety during operation. |

Common Issues with Chainsaw Parts

Understanding the frequent problems associated with the components of cutting tools can greatly enhance their performance and longevity. Recognizing these issues early on can help users maintain efficiency and prevent potential breakdowns. Common challenges often arise from wear and tear, improper maintenance, or environmental factors that impact the functionality of the machine.

Wear and Tear

Over time, components can experience deterioration due to regular use. Factors such as friction, exposure to elements, and the overall load placed on each piece can lead to diminished performance. Regular inspection is essential to identify any signs of wear, such as cracking or dullness, that may require replacement.

Improper Maintenance

Neglecting routine care can result in significant issues. Failing to clean and lubricate moving parts, or not adjusting settings according to specifications, can lead to malfunctions. Proper maintenance routines, including timely replacements and cleaning, are crucial to ensuring optimal functionality and extending the lifespan of the equipment.

How to Identify Genuine Parts

When it comes to maintaining your tools, ensuring the use of authentic components is crucial for optimal performance and safety. Identifying genuine items can save you from future complications and enhance the longevity of your equipment.

Here are key tips to help you recognize original components:

- Check the Packaging: Authentic items typically come in high-quality packaging with clear branding and details.

- Look for Serial Numbers: Genuine components often feature unique serial numbers that can be verified through official channels.

- Inspect the Quality: Original items are made with superior materials and craftsmanship. Look for signs of durability.

- Research Authorized Dealers: Purchase from recognized retailers or websites to ensure authenticity.

Additionally, be aware of pricing; if a deal seems too good to be true, it probably is. Trust your instincts and prioritize quality over cost.

By following these guidelines, you can confidently select authentic components that ensure your equipment operates at its best.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. By following a few straightforward practices, you can significantly extend the lifespan of your tool and maintain its peak performance.

Regular Cleaning: After each use, make it a habit to clean the exterior thoroughly. Debris and residue can accumulate, leading to potential issues. Use a soft brush or cloth to remove dirt and chips, ensuring all vents are clear to promote airflow.

Sharp Blades: Keeping the cutting edges sharp is crucial for effective operation. Dull blades require more power and can cause unnecessary wear on the motor. Regularly inspect and sharpen the edges as needed, or replace them if they are beyond repair.

Lubrication: Ensure that moving parts are adequately lubricated to minimize friction. Use the recommended oil and follow the manufacturer’s guidelines for application. This simple step can prevent overheating and excessive wear.

Check Components: Regularly inspect all components for signs of wear or damage. Look for cracks, loose fittings, or frayed cords. Addressing these issues promptly can prevent more significant problems down the line.

Proper Storage: Store your tool in a dry, cool place away from direct sunlight. Use a protective cover to shield it from dust and moisture. This practice helps maintain the integrity of both the exterior and internal mechanisms.

By implementing these maintenance strategies, you can ensure that your equipment remains in optimal condition, ready to tackle any task effectively.

Tools Needed for Repairs

To effectively perform maintenance and fix issues with your equipment, having the right tools at your disposal is essential. A well-equipped workspace not only facilitates smoother repairs but also enhances safety and efficiency during the process.

Essential Tools: Start by gathering basic hand tools such as screwdrivers, wrenches, and pliers. These are fundamental for loosening or tightening components, making adjustments, and ensuring everything is securely in place.

Power Tools: Depending on the nature of the repairs, you may require power tools such as drills or saws. These can expedite tasks that involve cutting or drilling into materials.

Safety Equipment: Don’t overlook the importance of safety gear. Gloves, goggles, and protective clothing are crucial to safeguard against potential injuries during repairs.

Specialized Instruments: In some cases, having specialized equipment, like torque wrenches or feeler gauges, may be necessary to achieve precise adjustments or to assess the condition of certain components accurately.

Overall, being well-prepared with the appropriate tools ensures that repair tasks can be carried out effectively, promoting longevity and optimal performance of your equipment.

Step-by-Step Assembly Guide

Assembling your equipment can seem daunting, but with a clear, methodical approach, it becomes a manageable task. This guide will walk you through the necessary steps to put together your tool efficiently, ensuring that each component is correctly positioned for optimal performance.

Step 1: Gather Your Components

Before starting, ensure you have all the necessary components at hand. Check the list of items included with your equipment to avoid missing any essential parts during assembly.

Step 2: Read the Instructions

Familiarize yourself with the provided manual. It contains crucial information regarding assembly order and specific details about each component, which can significantly aid the process.

Step 3: Prepare Your Workspace

Choose a clean, well-lit area to work in. Having sufficient space will make it easier to organize the components and tools, preventing confusion during assembly.

Step 4: Start with the Base

Begin by assembling the base structure. Align the necessary parts according to the instructions, ensuring that they fit snugly together. Secure them properly to form a stable foundation.

Step 5: Attach the Mechanism

Next, proceed to attach the operational mechanism. Carefully connect each part as indicated in the manual, making sure that all screws and fittings are tightened without overtightening.

Step 6: Add the Additional Components

Once the main structure is complete, add any additional components such as safety features and guards. These are vital for safe operation, so ensure they are installed correctly.

Step 7: Final Checks

After assembly, conduct a thorough inspection. Verify that all parts are secured and functioning as intended. This step is crucial for both performance and safety during use.

Step 8: Power Up and Test

Once you are confident in your assembly, power up the equipment. Perform a test run to ensure everything operates smoothly and make any necessary adjustments before full usage.

Where to Buy Replacement Parts

Finding the right components for your outdoor power tools can significantly enhance their performance and longevity. It’s essential to source these items from reliable vendors to ensure compatibility and quality.

Here are some recommended options for purchasing essential components:

- Authorized Dealers: Check with local authorized retailers who specialize in outdoor equipment. They often carry genuine components that guarantee optimal performance.

- Online Marketplaces: Websites like Amazon and eBay provide a vast selection of items. Make sure to read reviews and verify the seller’s reputation before making a purchase.

- Manufacturer’s Website: Visiting the official site can offer direct access to a variety of original components, along with detailed specifications and compatibility information.

- Specialty Stores: Look for stores that focus on outdoor tools and equipment. These shops often have knowledgeable staff who can assist you in finding the right components.

- Local Repair Shops: These establishments often stock or can order the necessary components for your equipment, and they can also provide professional advice.

By exploring these avenues, you can ensure that your tools remain in excellent working condition, ready to tackle any task efficiently.

Warranty Information for M18 Chainsaw

This section provides essential details regarding the protection plans available for your equipment, ensuring peace of mind during usage. Understanding the terms and conditions associated with these guarantees can enhance your ownership experience and safeguard your investment.

Coverage Details

- Standard warranty duration typically spans from the date of purchase.

- Protection includes manufacturing defects and component failures under normal use.

- Exclusions may apply for misuse or unauthorized modifications.

Claim Process

- Gather proof of purchase, such as a receipt or invoice.

- Contact customer service to initiate a claim.

- Provide necessary information and follow instructions for submission.

User Reviews and Feedback

This section explores the experiences and insights of users regarding their recent purchases. Understanding real-world applications can help potential buyers make informed decisions.

- Performance: Many users highlight efficiency and power, noting the effectiveness in various cutting tasks.

- Ease of Use: Reviews frequently mention user-friendly features, making it accessible for both novices and seasoned individuals.

- Durability: Feedback indicates satisfaction with the product’s longevity, even under challenging conditions.

- Maintenance: Some users appreciate the straightforward maintenance procedures, while others suggest improvements.

- Value for Money: A common theme is the balance between cost and performance, with many feeling it offers great value.

Overall, customer insights provide a comprehensive understanding of strengths and areas for improvement, guiding future users in their choices.