Maintaining equipment used for cutting wood is essential for ensuring long-term efficiency and safety. To keep everything in optimal condition, it’s important to regularly assess the functionality of each component. Knowing how various elements work together can make a significant difference in performance and longevity.

This guide will provide a detailed breakdown of the essential elements involved in keeping your tool in top shape. From the critical working mechanisms to the smaller, often overlooked details, having a clear understanding of how each part operates is crucial for anyone looking to extend the life of their equipment.

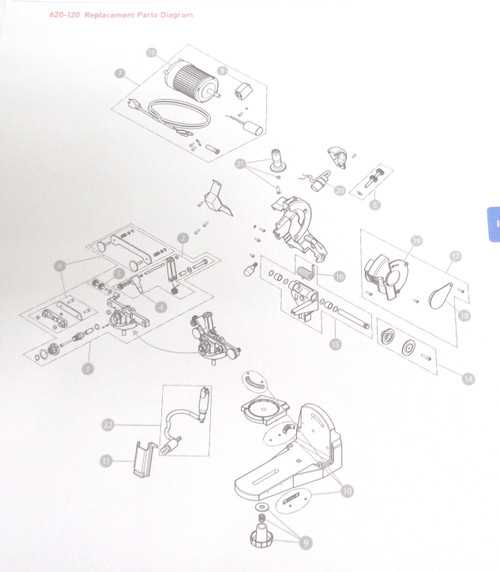

Overview of Oregon Chainsaw Sharpener Components

Understanding the key elements that make up a sharpening tool is crucial for anyone who wants to maintain their cutting equipment efficiently. This guide provides an in-depth look at the main sections, allowing you to grasp how each piece contributes to the overall functionality and precision of the sharpening process.

Main Structural Elements

The core framework is designed to ensure stability and accuracy. It typically consists of a base that anchors the entire setup and adjustable mechanisms that control the sharpening angle. These features help achieve precise results, whether you’re working with a standard or custom setup.

Functional Mechanisms

Critical to the sharpening process are the rotating grinding wheel and its accompanying motor. These components work together to grind down the metal, restoring cutting efficiency. Adjustable guides and tensioners allow you to tailor the settings for various tasks, ensuring the best performance and extended lifespan of the tool.

Key Parts of a Chainsaw Sharpener

The efficiency and durability of your cutting tool rely heavily on maintaining the precision of its cutting edge. Understanding the critical components of your sharpening device ensures optimal performance and ease of use. Below, we’ll explore the essential elements that make up this tool and their roles in keeping your equipment in top condition.

1. Grinding Wheel

The abrasive disc is the heart of any sharpening device, responsible for refining and shaping the cutting edge. Available in various sizes and materials, it caters to different blade types and sharpness requirements. The grit level determines how fine or coarse the sharpening process will be, allowing for both rough grinding and precise finishing.

2. Angle Guide

To achieve a consistent edge, the angle guide ensures the sharpening process is carried out at the correct angle. This feature helps prevent uneven wear and prolongs the life of the blade. Adjustable to various angles, it accommodates different blade designs.

- Ensures uniform sharpening

- Prevents over-grinding

- Allows customization for different tools

3. Clamping Mechanism

The clamp holds the blade securely in place during the sharpening process. This guarantees stability and precision, reducing the risk of mistakes or accidents. A well-designed clamping system is adjustable, providing flexibility for different blade sizes.

- Improves safety

- Ensures stable sharpening

- Prevents slippage

Understanding the Role of the Motor

The motor serves as the driving force behind the entire system, ensuring efficient operation by powering the movement of mechanical components. Its function is crucial for delivering the necessary energy to perform precise tasks and maintain consistent performance during extended use.

Key aspects of the motor’s function include:

- Providing rotational power to move critical components

- Maintaining speed and torque for steady operation

- Converting electrical energy into mechanical energy effectively

- Ensuring the system runs smoothly under varying workloads

The motor’s efficiency directly influences the overall performance, making it an essential element to consider when evaluating the system’s capabilities and durability. Understanding how it operates and interacts with other components allows for better maintenance and optimization.

Guide Bar Mechanics in Sharpening

The process of sharpening heavily relies on understanding the structural role of the guide bar. Its alignment and movement play a critical part in ensuring that cutting edges are restored evenly and efficiently. Proper maintenance of this component helps to achieve consistent performance and reduces wear.

Positioning and Tension are two key factors when dealing with the guide bar. If the bar is not positioned correctly, it can lead to uneven sharpening. Tension affects the stability during the sharpening process, ensuring the precision of each stroke.

The surface condition of the guide bar also influences the effectiveness of sharpening. Any debris or wear on the bar can hinder smooth movement, affecting the accuracy of the process. Regular inspection and cleaning of the guide bar improve its function and extend its lifespan.

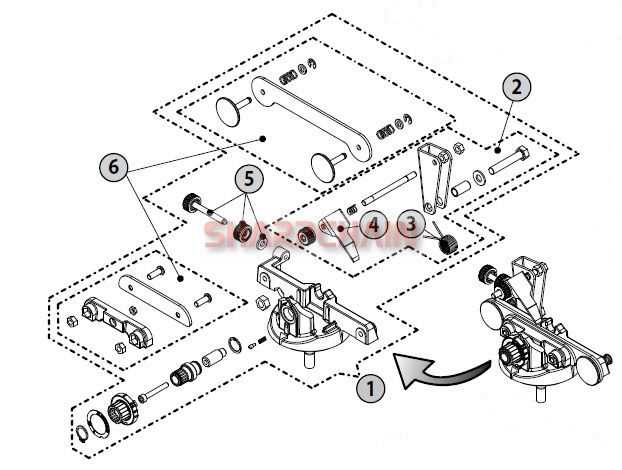

Exploring the Chain Clamp Functionality

The chain clamp plays a crucial role in ensuring precision and stability during the sharpening process. By securely holding the cutting link in place, this component allows for an accurate and consistent sharpening angle, which is essential for maintaining cutting efficiency. The effectiveness of this tool depends on its ability to prevent any unwanted movement, which could lead to uneven sharpening and reduced tool performance.

Stability and Control

One of the key features of the clamp is its ability to maintain stability throughout the operation. This functionality helps reduce vibration and enhances control, ensuring that each tooth of the cutting mechanism is sharpened uniformly. With this feature, users can achieve professional results with minimal effort, reducing the time spent on adjustments.

Adjustability and Customization

Another important aspect of the clamp is its adjustability. The ability to easily modify the clamp to accommodate different sizes or types of chains makes it versatile for various tasks. This feature not only improves efficiency but also extends the lifespan of the sharpening equipment by reducing wear and tear on both the machine and the chain.

How the Adjustment Knob Affects Precision

The adjustment knob plays a crucial role in fine-tuning the accuracy of any sharpening tool. Its primary function is to regulate the positioning and angle during sharpening, ensuring a consistent and even result. Without proper adjustments, achieving the desired sharpness and alignment can be difficult, leading to uneven wear or reduced efficiency.

- Control of Angle: The knob allows users to set the exact angle needed for optimal performance. Even slight adjustments can greatly affect the overall sharpness and edge retention.

- Depth Adjustment: Fine-tuning the depth ensures that the tool maintains uniform contact, preventing over-sharpening or inadequate grinding.

- Consistency: By locking in specific settings, the knob helps maintain consistency across multiple tasks, reducing human error and improving precision.

Understanding how to properly use the adjustment knob ensures not only precision but also extends the lifespan of your equipment, enhancing overall performance and reliability.

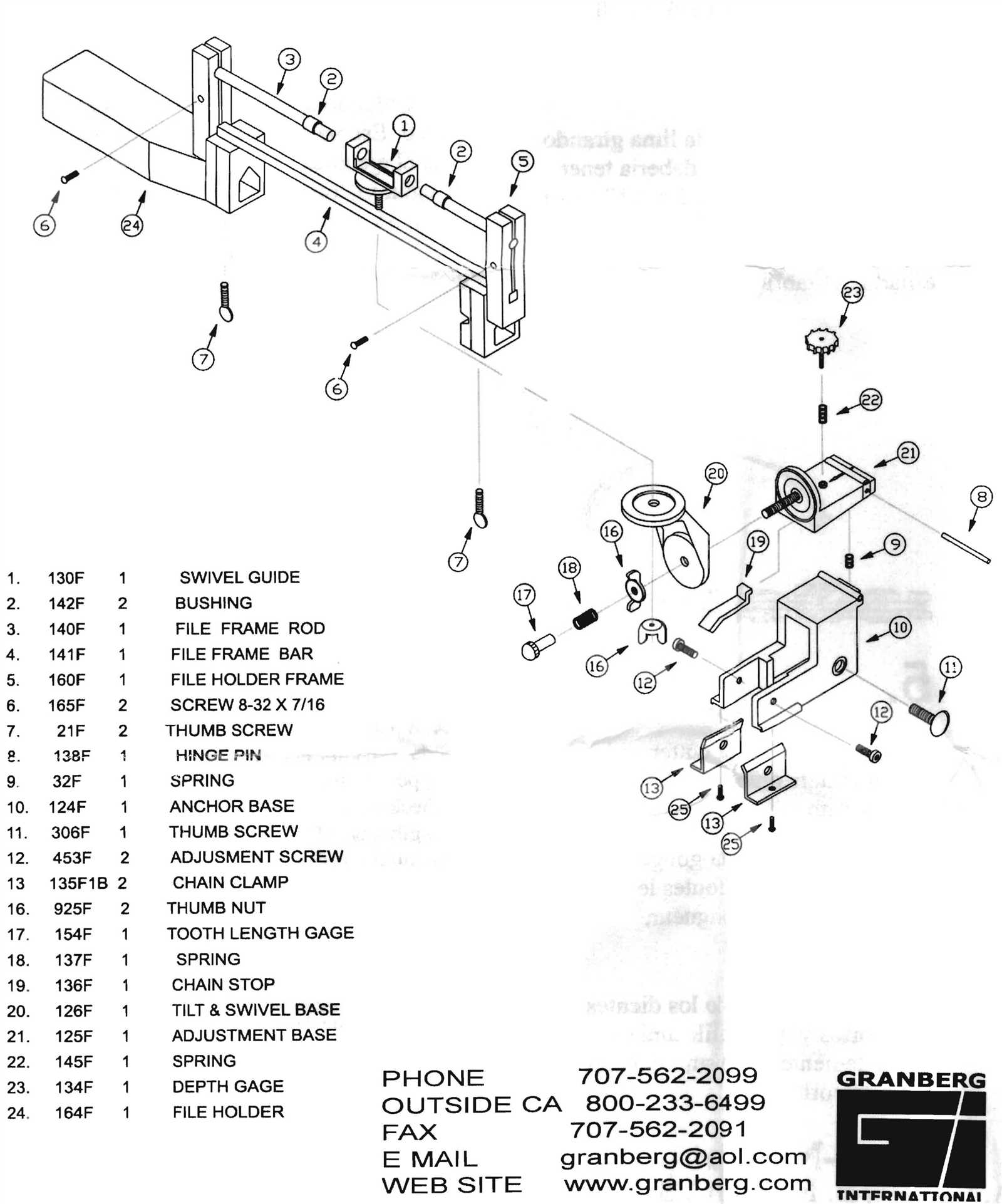

File Guide Usage in Oregon Sharpeners

A file guide is an essential tool that ensures precision and consistency when maintaining cutting edges. By holding the tool at a specific angle, it helps users achieve the correct alignment for sharpening. This section explores how to properly utilize a guide to improve efficiency and extend the life of your equipment.

Benefits of Using a File Guide

- Ensures accurate angles for consistent results.

- Reduces the risk of uneven sharpening.

- Helps maintain cutting performance over time.

- Saves time by guiding the process efficiently.

Steps for Proper Use

- Attach the guide securely to the file, aligning it with the proper angle markings.

- Position the file against the cutting edge, ensuring the guide maintains the correct angle throughout the motion.

- Apply steady pressure as you move the file across the surface.

- Check the sharpness periodically to avoid over-filing.

With practice, using a guide becomes an easy and efficient way to keep your cutting tools in peak condition.

Proper Tension Spring Maintenance Tips

Maintaining the tension spring is essential to ensuring smooth operation and extending the lifespan of your equipment. Without proper care, the spring can weaken or lose its elasticity, leading to inefficiencies or even potential damage. Regular upkeep helps avoid these issues and keeps your machine functioning at peak performance.

Regular Cleaning and Lubrication

One of the most important aspects of spring maintenance is ensuring it remains free from dirt and debris. Over time, particles can accumulate, causing friction and reducing the spring’s flexibility. Cleaning the spring with a soft brush and applying a suitable lubricant will minimize wear and maintain optimal tension.

Inspect for Wear and Damage

Periodically inspecting the tension spring is crucial for identifying signs of fatigue, such as rust, bending, or cracks. These can indicate that the spring is nearing the end of its useful life. Prompt replacement when signs of deterioration are evident helps prevent malfunction and maintains safe operation.

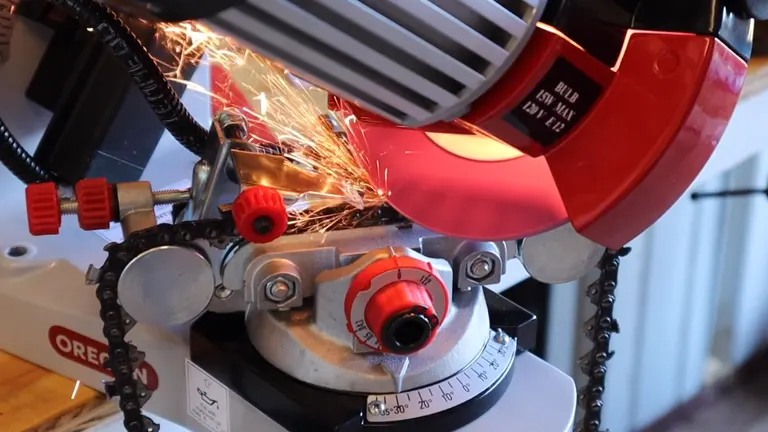

Benefits of a Sharpener Grinding Wheel

A well-maintained grinding wheel offers numerous advantages for achieving optimal cutting performance. By ensuring precision and efficiency, it significantly enhances the overall functionality of cutting tools. This device not only prolongs the lifespan of blades but also minimizes the risk of damage during the sharpening process.

Improved Cutting Efficiency: A finely honed edge results in smoother cuts and reduces the effort required for cutting tasks. When tools are sharp, they glide through materials with ease, which can lead to increased productivity.

Consistent Results: Utilizing a reliable grinding wheel ensures that each sharpening session yields uniform results. This consistency is crucial for maintaining quality, especially when working on multiple projects or using various tools.

Cost-Effective Solution: Investing in a quality grinding wheel can save money in the long run. By keeping tools in optimal condition, users can avoid frequent replacements and repairs, leading to a more economical approach to tool maintenance.

Safety Benefits: A properly sharpened edge decreases the likelihood of accidents caused by slipping or jamming. Well-maintained tools are easier to control, which enhances safety during use.

Environmental Considerations: Maintaining tools with a grinding wheel reduces waste, as it prolongs their life cycle. This practice contributes to a more sustainable approach by minimizing the need for new tools and associated manufacturing processes.

Sharpening Angle Indicators and Their Importance

Properly maintaining cutting tools is essential for ensuring optimal performance and longevity. One critical aspect of this maintenance is the angle at which the cutting edges are honed. The sharpening angle plays a significant role in the efficiency and effectiveness of the tool, influencing both the quality of the cut and the ease of operation.

Angle indicators serve as valuable guides for achieving the correct honing angle. Here are some key points highlighting their significance:

- Precision: Accurate angle indicators ensure that the cutting edges are sharpened uniformly, resulting in consistent performance.

- Efficiency: Maintaining the correct angle reduces friction, allowing for smoother operation and less wear on the tool.

- Safety: Tools sharpened at the proper angle minimize the risk of kickback and other safety hazards during use.

- Longevity: Proper honing angles extend the life of the tool, reducing the frequency of repairs and replacements.

- Quality of Cut: A correctly sharpened edge improves the quality of the cut, leading to cleaner results and better overall performance.

In summary, utilizing angle indicators when honing cutting tools is crucial for achieving optimal performance, enhancing safety, and prolonging the lifespan of the equipment. By understanding and applying the appropriate sharpening angles, users can significantly improve their cutting efficiency and effectiveness.

Replacement Options for Worn-Out Components

When the performance of your tool begins to decline, it is essential to consider viable solutions for replacing outdated or damaged elements. Maintaining optimal functionality not only enhances efficiency but also prolongs the lifespan of the equipment. Various alternatives are available, ranging from original components to aftermarket options, each with its benefits and drawbacks.

Genuine Components

Using authentic components ensures compatibility and reliability. These elements are designed specifically for your equipment, guaranteeing a perfect fit and consistent performance. Although they may come at a higher cost, investing in genuine parts can save you from potential issues that arise from using subpar replacements.

Aftermarket Alternatives

Aftermarket options provide a cost-effective solution for those seeking budget-friendly replacements. These components can vary in quality, so it is vital to research reputable manufacturers. While some aftermarket products may perform comparably to genuine ones, others might lack the durability required for prolonged use. Always consider reviews and feedback from other users to make an informed decision.

Troubleshooting Common Sharpener Part Failures

Ensuring optimal performance of your equipment requires addressing potential issues that may arise with its components. Understanding the typical failures can significantly enhance the longevity and efficiency of the device. By identifying and rectifying these problems, you can maintain peak operational standards and prevent unnecessary downtime.

One frequent issue is improper alignment of the sharpening mechanism. If the angle is not set correctly, it can lead to ineffective honing and even damage to the blade. Regularly checking the alignment and adjusting it as needed is crucial for maintaining sharpness.

Another common failure involves the motor. If you notice a decline in power or the motor stalling, it may indicate wear and tear or electrical issues. Cleaning the motor and inspecting the wiring can help identify potential problems. Additionally, ensure that the motor is receiving adequate power supply and that the connections are secure.

Wear on the grinding wheel is also a prevalent concern. A wheel that has become dull or uneven can hinder performance and affect the quality of the sharpening process. Regularly inspect the wheel for signs of wear and replace it if necessary to ensure consistent results.

Lastly, debris buildup can impede the functionality of the unit. Regular cleaning of all components, including the housing and any moving parts, is essential to avoid blockages and maintain smooth operation. Ensuring that your equipment is free of dust and shavings will contribute to its efficiency and lifespan.