In the realm of forestry and landscaping, having a clear grasp of the essential components of your cutting equipment is crucial. Whether you’re tackling a weekend project or working in a professional setting, familiarity with the various elements can significantly enhance efficiency and safety. This section will provide insight into the intricate assembly that makes up this powerful tool.

By exploring the various segments involved, users can better appreciate how each part contributes to overall performance. An informed operator can anticipate maintenance needs and troubleshoot issues more effectively, ensuring that the tool operates at its ultimate capacity.

Delving into the specifics of the internal mechanisms and external features allows for a deeper understanding of functionality and design. This knowledge empowers users to make informed decisions about repairs, upgrades, and best practices in operation, leading to improved longevity and performance of their equipment.

Understanding Solo Chainsaw Components

Gaining insight into the essential elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, contributing to performance and safety.

- Engine: The powerhouse that drives the entire mechanism.

- Guide Bar: The elongated metal piece that directs the cutting action.

- Chain: A series of interconnected links that perform the cutting.

- Handle: Provides control and stability during use.

- Safety Features: Mechanisms designed to protect the user from accidents.

By understanding these key components, users can enhance their skills and ensure the longevity of their equipment.

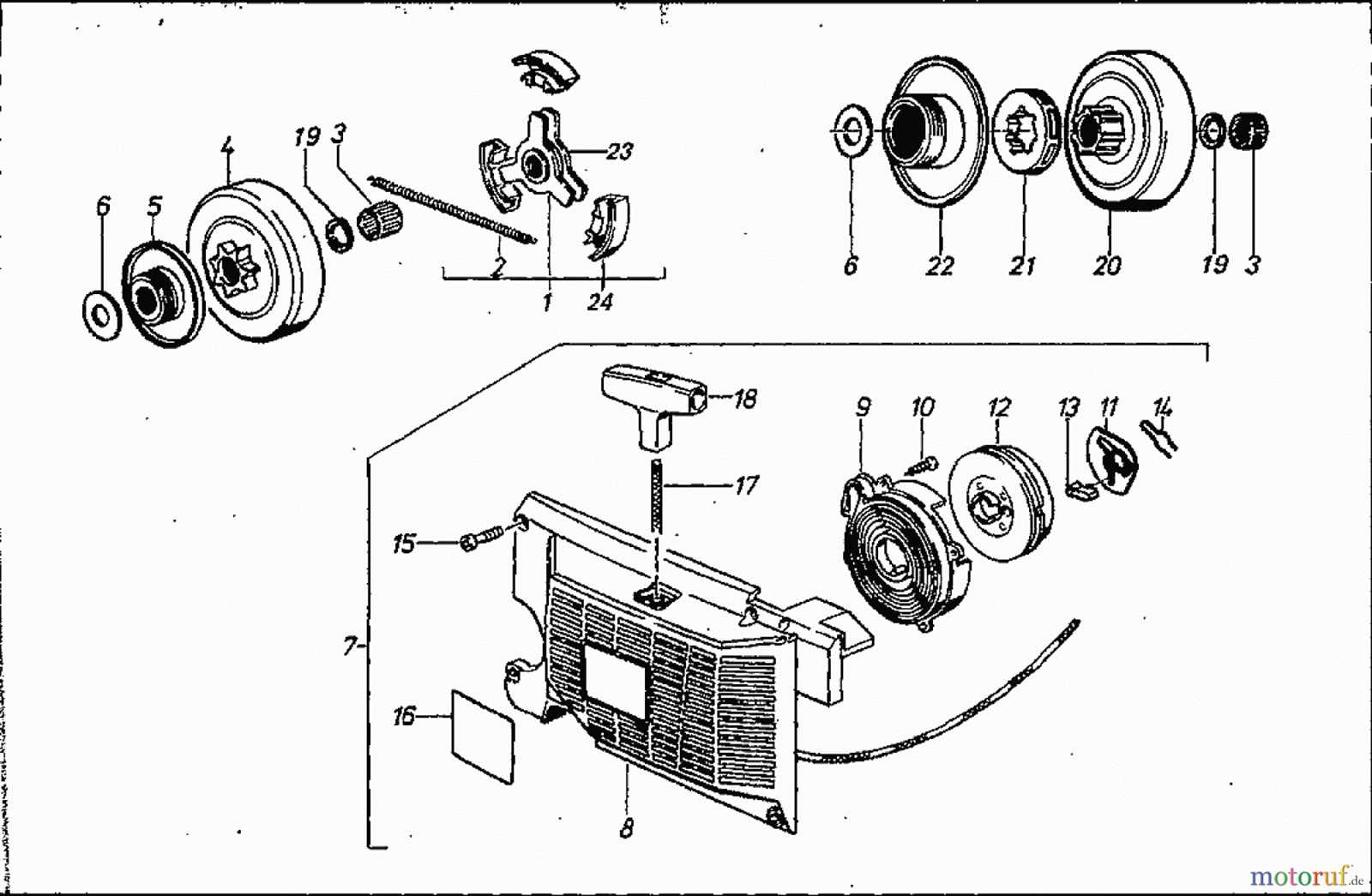

Key Parts of a Chainsaw

Understanding the essential components of this powerful tool is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance, contributing to its functionality and longevity.

Main Components

Here are some of the primary elements that make up this equipment:

| Component | Description |

|---|---|

| Engine | The heart of the tool, providing the necessary power. |

| Guide Bar | The elongated metal piece that guides the cutting chain. |

| Cutting Chain | The loop of sharp teeth that performs the cutting action. |

| Handle | Enables the operator to control and maneuver the device. |

Additional Features

Other notable attributes include safety mechanisms and the fuel system, which are integral to ensuring secure and efficient operation.

Function of Each Component

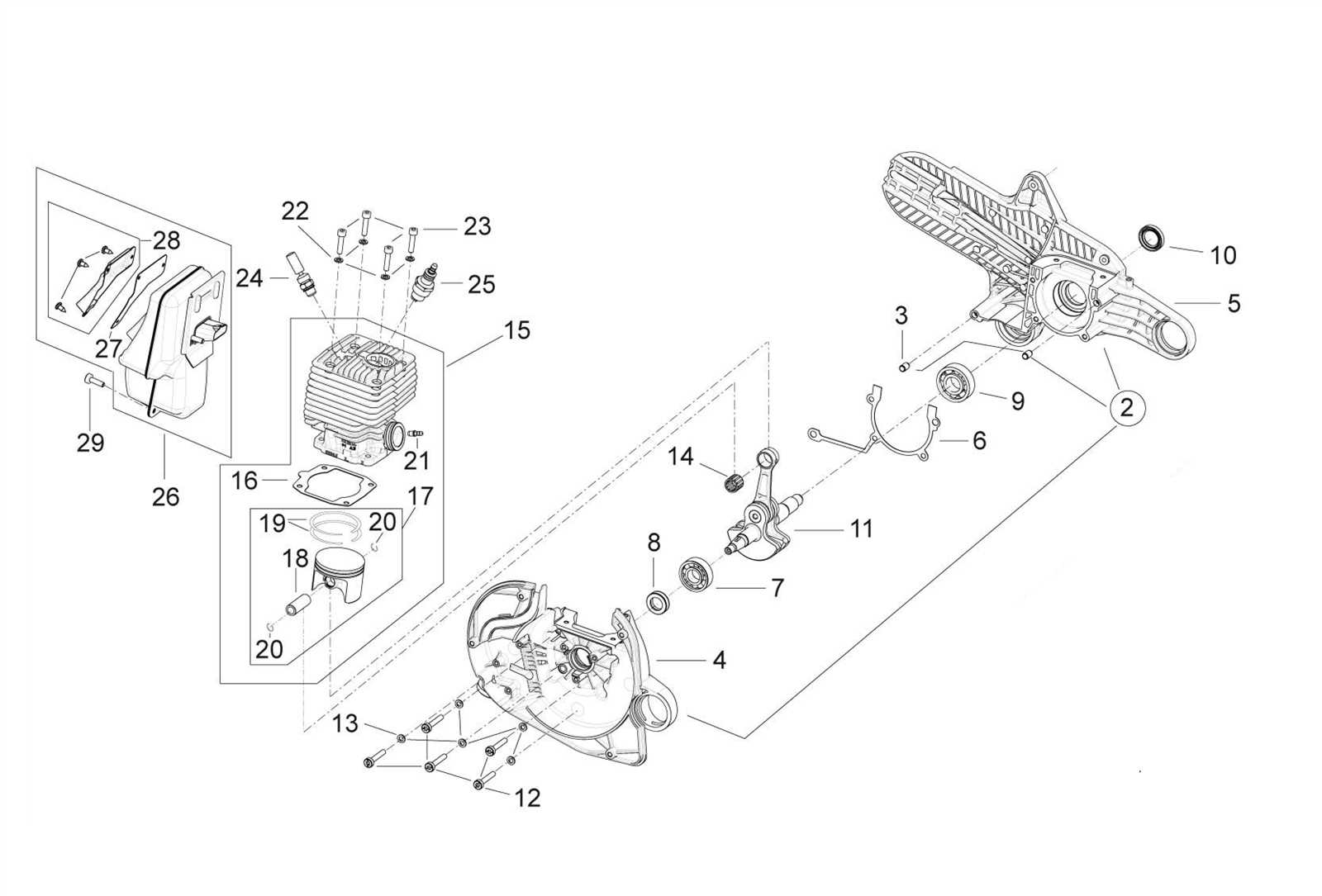

Understanding the various elements of a cutting tool is essential for effective operation and maintenance. Each part plays a critical role in ensuring the overall functionality and efficiency of the device. By exploring the specific duties of these components, users can gain insight into how they interact and contribute to performance.

The power unit serves as the heart of the machinery, generating the necessary energy for operation. Coupled with the fuel system, it ensures a continuous supply of energy for prolonged usage. The ignition system ignites the fuel-air mixture, initiating the combustion process and enabling the tool to function effectively.

The cutting mechanism, including the blade and its associated attachments, is designed to perform precise cuts with minimal effort. These elements work together to deliver optimal cutting performance, allowing users to tackle a variety of materials. The tensioning system maintains the proper tightness of the blade, ensuring safety and efficiency during use.

Additionally, the housing provides structural integrity and protection to internal components. Ergonomic features enhance user comfort, reducing fatigue during extended operation. Finally, the safety mechanisms, such as the chain brake and throttle control, are vital for minimizing risks and ensuring safe handling of the equipment.

Chainsaw Parts Identification Guide

Understanding the various components of a cutting tool is essential for effective maintenance and operation. Each element plays a critical role in ensuring optimal performance and safety. This guide aims to simplify the identification of these crucial elements, making it easier for users to familiarize themselves with their equipment.

Main Components

- Engine: The powerhouse that drives the tool.

- Bar: The long metal piece that guides the cutting chain.

- Chain: The loop that performs the cutting action.

- Handle: The part that provides grip and control.

- Fuel Tank: Holds the mixture of fuel required for operation.

Support Elements

- Air Filter: Prevents dirt from entering the engine.

- Clutch: Engages and disengages the chain from the engine.

- Chain Brake: A safety feature that stops the chain immediately.

- Starter Rope: Used to initiate the engine.

- Oil Reservoir: Contains lubrication for the chain and bar.

Importance of Regular Maintenance

Routine care is crucial to ensure the longevity and optimal performance of any mechanical equipment. Without consistent upkeep, even the most reliable tools can degrade over time, leading to inefficiency and potential failure. By investing time in preventive measures, users can avoid costly repairs and extend the life of their machinery.

- Prevents unexpected breakdowns and costly repairs

- Ensures the equipment operates at peak efficiency

- Minimizes wear and tear on critical components

- Improves safety during operation

- Maximizes the overall lifespan of the device

By adhering to a regular schedule of inspections, cleaning, and part replacements, users can enjoy smooth and reliable functionality, reducing the risk of malfunctions and improving the overall performance of their equipment.

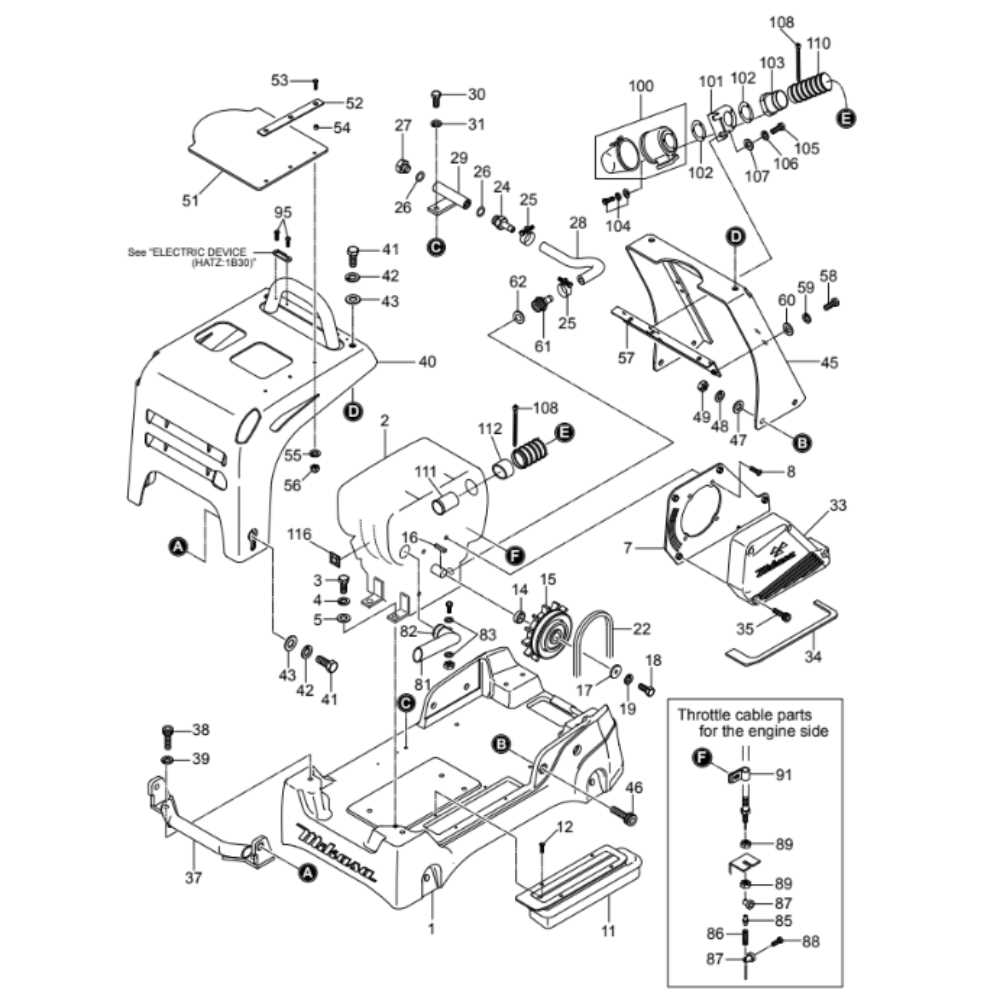

Common Issues with Chainsaw Components

Power cutting tools often experience wear and malfunction due to regular usage. This can lead to various problems, reducing both the tool’s efficiency and lifespan. Recognizing typical challenges with these essential mechanisms helps maintain optimal performance and prevent unexpected downtime during tasks.

Frequent Mechanical Problems

Many mechanical tools, especially those subjected to heavy use, encounter issues such as dull blades or engine stalling. Regular sharpening of the cutting mechanism and maintenance of fuel delivery systems are critical to prevent malfunction. Moreover, tensioning problems can lead to poor cutting performance, making proper adjustment essential for smooth operation.

Wear and Tear on Key Components

Over time, key elements like the drive system, guide bars, and filters are prone to wear. If not addressed, this can result in reduced efficiency or complete failure of the tool. Ensuring regular inspection of these components can mitigate more serious damage.

| Issue | Cause | Solution |

|---|---|---|

| Blunt Cutting Edge | Frequent use without sharpening | Regularly sharpen cutting mechanism |

| Engine Stalling | Fuel system blockage or air filter clogging | Clean or replace fuel filter and air filter |

Loose Tensioning

Choosing Replacement Components WiselyWhen selecting substitute elements for any mechanical system, it is essential to prioritize both quality and compatibility. The wrong selection can not only reduce the overall efficiency but may also lead to premature wear or unexpected malfunctions. To ensure optimal performance, always take into account the specific requirements of the system, such as load capacity, material durability, and operating conditions. Understanding CompatibilityThe first step in making a wise choice is understanding the compatibility between the original and the new component. Factors like size, material composition, and functional role within the system should match or exceed the original specifications. Additionally, carefully checking manufacturer guidelines or consulting experts can help avoid mismatches that could compromise safety and functionality. Balancing Quality and Cost

While cost is always a consideration, prioritizing low-cost alternatives may result in frequent replacements or even more costly repairs. High-quality materials and precise manufacturing standards ensure longevity and reliability. It’s crucial to strike a balance between the price of the replacement and the quality required for the specific function to avoid unnecessary expenses in the long run. Tools Needed for RepairsWhen it comes to restoring or maintaining various equipment, having the correct set of instruments is essential for efficient and safe work. The right tools not only ensure that the task is completed correctly but also reduce the chances of causing further damage. Here is a list of the most common tools you will need for repair tasks:

In addition to these hand tools, consider having these supplementary items:

|