When it comes to maintaining optimal performance in any modern vehicle, the proper understanding of the core mechanical systems is essential. These systems form the heart of the vehicle, ensuring smooth operation and efficient power distribution. Knowing the different components and their interactions can help with both routine maintenance and troubleshooting, leading to a more reliable and long-lasting driving experience.

Every vehicle consists of various interconnected mechanisms, each playing a crucial role in the overall performance. By understanding how these mechanisms function together, owners and technicians alike can identify issues more accurately, perform targeted repairs, and keep their vehicles running at peak efficiency. From control units to vital power distributors, each part is designed to complement the other, forming a cohesive system.

In this overview, we will explore the various elements involved in powering modern automobiles, breaking down their individual functions and how they contribute to the vehicle’s overall operation. Gaining insight into these areas can greatly enhance the knowledge needed for effective repair and maintenance.

Overview of Key Engine Components

Understanding the primary elements under the hood is crucial for grasping how the mechanical system functions as a whole. Each component plays a specific role in ensuring optimal performance, durability, and efficiency of the entire system. In this section, we will explore the most essential parts that work together to power and maintain the vehicle’s performance.

Core Power Unit Elements

- Combustion Unit: This section is responsible for generating the power that moves the vehicle. It mixes fuel with air, igniting the mixture to create energy.

- Power Transfer System: Responsible for channeling the produced energy to the wheels, ensuring smooth movement and control over speed.

- Cooling Mechanism: Prevents overheating by regulating temperature, maintaining consistent functioning and preventing damage.

Supportive Components

- Air Intake System: Allows the proper amount of oxygen to enter, aiding the energy generation process.

- Lubrication Network: Reduces friction between moving parts, minimizing wear and extending the lifespan of the entire assembly.

- Exhaust Setup: Efficiently removes waste gases, ensuring proper ventilation and emission control.

- Power generation relies heavily on the coordinated functioning of all parts mentioned above.

- Regular maintenance of these key components is essential for long-lasting performance.

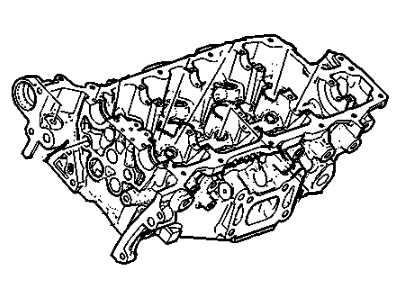

Understanding the Role of the Engine Block

The core of any vehicle’s power system plays a fundamental role in ensuring stability, efficiency, and performance. It serves as the foundation, housing crucial elements that work in tandem to convert fuel into the driving force. Its structural integrity is vital for maintaining balance under extreme conditions.

To break down its importance further, consider these key functions:

- Structural Support: It holds essential components together, ensuring they remain aligned during operation.

- Thermal Regulation: Efficient heat dissipation is crucial to prevent overheating, which could lead to severe damage.

- Lubrication Channels: Internal pathways allow oil to circulate, reducing friction and extending the lifespan of mechanical parts.

- Mounting Points: It provides secure attachment locations for other mechanical systems, keeping everything in place under pressure.

By understanding these aspects, one gains insight into why this central component is so crucial for a vehicle’s reliability and overall performance.

Exploring the Functions of Pistons and Cylinders

The intricate relationship between pistons and cylinders plays a crucial role in the operation of any internal system powered by combustion. These two components work in harmony to convert pressure into mechanical movement, enabling the vehicle to function efficiently. Understanding how this interaction takes place can help in diagnosing performance issues or maintaining the system’s overall efficiency.

The Role of Pistons

Pistons are responsible for the movement within the enclosed spaces they occupy. As a force is applied, they move up and down, transferring energy from the combustion process. This dynamic movement is critical, as it generates the power required to drive other essential components. The pistons’ precision in motion ensures the system operates smoothly and consistently under various conditions.

Cylinders and Their Importance

Cylinders house the pistons and provide the controlled environment necessary for their operation. The cylinder’s structure ensures that pressure is properly directed and maintained during combustion, allowing for efficient energy transfer. Their design and integrity are key to preventing energy loss, maintaining performance, and optimizing fuel consumption.

Crankshaft Operation and Its Importance

The crankshaft plays a vital role in ensuring the smooth transformation of linear motion into rotational movement. It acts as a bridge between the force generated by combustion and the movement needed to propel the vehicle forward. Without this component, the necessary power transfer would not occur, making it fundamental for overall mechanical efficiency.

Through a series of connected elements, the crankshaft allows for consistent, balanced motion within the system. Its functionality affects not only the energy output but also the synchronization of various moving parts, ensuring that everything runs in harmony. The precision with which it operates is key to reducing wear and maintaining longevity.

| Aspect | Function |

|---|---|

| Energy Conversion | Transforms linear energy into rotational power |

| Balance | Maintains even force distribution during operation |

| Durability | Essential for long-term reliability and minimal wear |

The Role of the Camshaft in Timing

The camshaft is a crucial element in maintaining synchronization within the internal mechanism of a motor. Its primary function is to regulate the precise opening and closing of valves, ensuring that the flow of air and fuel is timed accurately with the movements of other key components. This careful coordination allows for optimal combustion and efficient power delivery. Without proper timing, the system would lose balance, leading to reduced performance and potential mechanical failures.

How the Camshaft Controls Valve Operation

The camshaft operates by rotating in sync with other vital parts, using specially designed lobes to control the upward and downward movement of the valves. As each lobe pushes against the valve lifter, it causes the valve to open, allowing the mixture to enter or exhaust gases to exit. The shape and positioning of these lobes directly influence the timing of the valve operation, making this a delicate process that must be finely tuned.

Importance of Accurate Timing

Proper timing ensures that air intake, fuel combustion, and exhaust happen in a seamless sequence. If the camshaft timing is off by even a small margin, it can lead to issues such as misfires, loss of power, or even more severe damage to the internal system. Regular maintenance and precise adjustments are key to preserving the smooth operation and longevity of the system as a whole.

How the Timing Chain Coordinates Movement

The timing chain plays a crucial role in synchronizing the rotational movements within the machinery. By maintaining the precise timing between various components, it ensures smooth and efficient operation. This coordination is essential for achieving optimal performance and preventing potential mechanical failures.

Mechanics of Synchronization

At its core, the timing chain connects the crankshaft to the camshaft, creating a seamless link that allows for the accurate timing of valve openings and closings. As the crankshaft rotates, it drives the timing chain, which in turn moves the camshaft in perfect harmony. This synchronization is vital for ensuring that the intake and exhaust valves operate at the correct intervals, allowing for efficient air and fuel intake as well as exhaust expulsion.

Impact on Performance

A well-functioning timing chain is essential for maintaining the overall efficiency of the system. If the timing chain becomes worn or misaligned, it can lead to timing discrepancies that adversely affect performance. This may result in issues such as reduced power output, increased fuel consumption, and even potential engine damage. Regular maintenance and timely replacement of the timing chain can prevent such complications and ensure the longevity of the machinery.

Fuel Injection System in the Engine

The fuel injection mechanism plays a vital role in optimizing the performance and efficiency of a combustion chamber. This system is responsible for delivering the precise amount of fuel needed for effective combustion, ensuring that the fuel-air mixture is optimized for various operating conditions. A well-functioning injection system contributes to improved power output, reduced emissions, and enhanced overall vehicle performance.

Components of the Fuel Delivery Mechanism

At the core of the fuel delivery mechanism are several key components, each serving a distinct purpose. The fuel pump is tasked with transporting fuel from the tank to the injectors under high pressure. Once the fuel reaches the injectors, it is atomized and sprayed into the intake manifold or directly into the combustion chamber, depending on the type of system in use. This process is crucial for ensuring that the fuel mixes thoroughly with air for optimal combustion.

Importance of Precision and Timing

The timing and precision of fuel delivery are critical factors that influence performance. Modern systems utilize advanced electronics to monitor various parameters, such as throttle position and engine temperature, to adjust the fuel injection rate dynamically. This level of control enhances fuel efficiency and minimizes waste, leading to better performance and lower emissions. Additionally, regular maintenance of the fuel injection components is essential to sustain their effectiveness and prolong the lifespan of the vehicle.

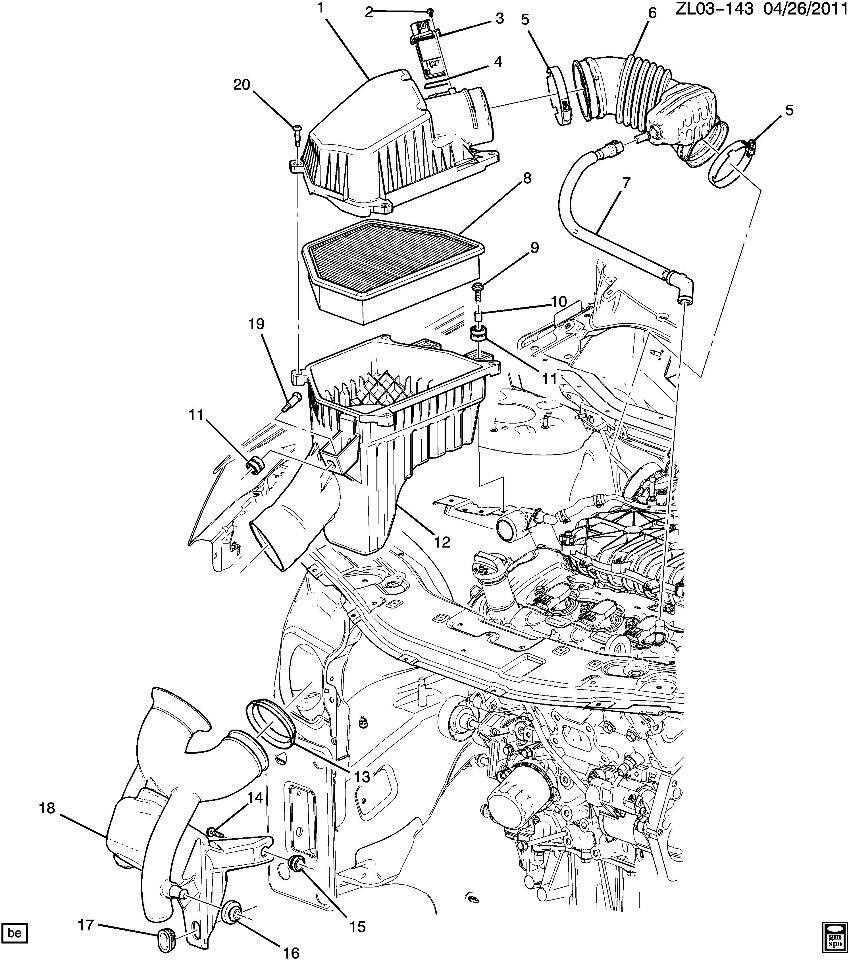

Air Intake System and Its Purpose

The air intake system plays a crucial role in the overall performance and efficiency of a vehicle. It is designed to facilitate the flow of air into the combustion chamber, ensuring that the internal processes occur smoothly and effectively. By maintaining the optimal air-to-fuel ratio, this system contributes significantly to the power output and fuel economy of the vehicle.

This assembly typically consists of various components, including filters, ducts, and manifolds, all working together to deliver clean and sufficient air to the combustion process. A well-functioning intake system helps prevent contaminants from entering the engine, thus protecting it from potential damage and wear. Additionally, the design and configuration of the system can influence the sound and character of the engine, providing a more engaging driving experience.

Furthermore, advancements in technology have led to the development of systems that enhance airflow dynamics, resulting in improved performance and responsiveness. Upgrading or maintaining the intake system can lead to noticeable benefits, including increased horsepower and torque, as well as enhanced throttle response. Overall, the air intake system is vital for achieving optimal performance and longevity of the vehicle’s mechanical components.

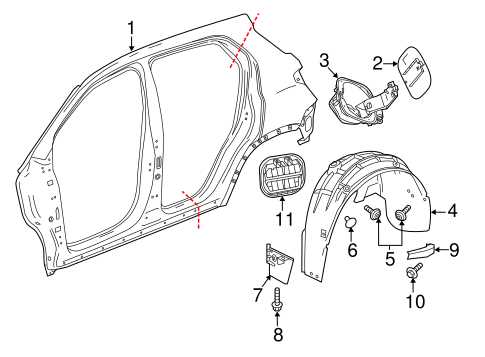

Exhaust Manifold: Functions and Maintenance

The exhaust manifold is a critical component in the vehicle’s exhaust system, responsible for directing gases away from the combustion chamber. This vital structure collects the exhaust fumes from multiple cylinders and channels them into a single outlet, ensuring efficient operation of the overall system. Understanding its functions and maintenance requirements is essential for optimal vehicle performance.

Functions of the Exhaust Manifold

The primary role of the exhaust manifold is to manage the flow of exhaust gases generated during combustion. It plays a significant part in reducing emissions and improving fuel efficiency by ensuring that gases exit the system promptly. Additionally, it aids in controlling engine temperature by dissipating heat away from the cylinders, thereby preventing overheating and maintaining proper operation.

Maintenance Tips

Regular maintenance of the exhaust manifold is crucial for sustaining its efficiency. One key aspect is to check for any signs of leaks, as these can lead to increased emissions and reduced performance. Inspecting the manifold for cracks or damage is equally important, as structural integrity is vital for proper functioning. Additionally, ensuring that all connections are secure can help prevent exhaust leaks and maintain optimal airflow.

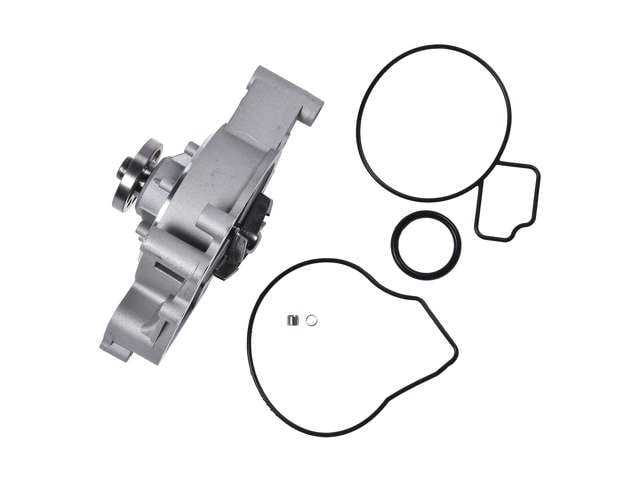

The Importance of the Engine Cooling System

The cooling mechanism is vital for maintaining optimal operating temperatures within a vehicle’s power unit. It prevents overheating, ensuring that all components function efficiently and prolonging the lifespan of the machinery.

When temperatures rise excessively, it can lead to significant damage, affecting performance and reliability. A well-functioning cooling system circulates a fluid that absorbs heat from the components and dissipates it through a radiator, helping to maintain a stable environment.

Moreover, effective temperature regulation contributes to fuel efficiency, as an overheated unit may require more energy to operate. This system not only safeguards against potential failures but also enhances overall performance by allowing the power unit to operate within its designed temperature range.

Regular maintenance of the cooling system is essential. Checking fluid levels, inspecting for leaks, and ensuring that the radiator and other components are clean can prevent future complications and maintain the integrity of the entire assembly.

Serpentine Belt and Its Components

The serpentine belt is a crucial element in the functionality of various machinery, playing a vital role in transferring power from the crankshaft to multiple accessories. This continuous loop of rubber provides the necessary torque to drive components, ensuring optimal performance of the entire system.

Key components associated with the serpentine belt include:

- Idler Pulley: This component maintains tension in the belt and guides it along its path.

- Tensioner: A spring-loaded device that adjusts the tightness of the belt, preventing slippage.

- Alternator: An accessory that generates electrical power for the vehicle’s electrical system.

- Power Steering Pump: This component provides the necessary hydraulic pressure for smooth steering.

- Water Pump: Responsible for circulating coolant throughout the system to maintain optimal operating temperatures.

- A/C Compressor: This accessory cools the air inside the cabin by compressing refrigerant gas.

Regular inspection and maintenance of the serpentine belt and its components are essential to ensure efficient operation and prevent unexpected breakdowns. Signs of wear, such as cracking or fraying, should prompt immediate replacement to avoid more significant issues in the future.

Oil Filter and Lubrication Overview

The lubrication system is vital for maintaining the smooth operation and longevity of any mechanical assembly. Proper oil circulation ensures that all moving components are adequately protected from wear and tear. This section delves into the significance of the filtration mechanism and the lubricating fluid’s role in preserving the integrity of the assembly.

At the core of this system is the filtration unit, which plays a crucial role in removing contaminants that can accumulate over time. By ensuring a clean supply of lubricant, this component contributes to optimal performance and efficiency.

| Component | Function |

|---|---|

| Lubrication Fluid | Reduces friction and wear between moving parts |

| Filtration Unit | Removes impurities from the lubrication fluid |

| Oil Pump | Circulates the lubrication fluid throughout the system |

| Drain Plug | Facilitates the removal of used fluid for replacement |

Maintaining the integrity of the lubrication system requires regular checks and timely replacement of the filtration unit and lubricating fluid. Neglecting these components can lead to reduced efficiency and potential mechanical failures.

Common Signs of Engine Wear and Tear

As vehicles age, various components may begin to show signs of deterioration, impacting overall performance and reliability. Recognizing these indicators early can help prevent more significant issues down the line, ensuring smoother operation and longevity.

Visible Symptoms

One of the most apparent signs of wear is the presence of unusual smoke coming from the exhaust. This can indicate internal damage or excessive oil consumption. Additionally, a noticeable decrease in power or acceleration may suggest that essential components are no longer functioning optimally.

Audible Indicators

Unusual noises, such as knocking or ticking sounds, often signal potential trouble within the mechanical system. These sounds may arise from worn bearings, loose parts, or other critical areas that require immediate attention.

| Signs | Potential Issues |

|---|---|

| Unusual smoke | Internal damage or oil consumption |

| Decreased power | Component inefficiency |

| Knocking noises | Worn bearings or loose parts |

| Engine overheating | Cooling system failure |

| Oil leaks | Seal or gasket failure |