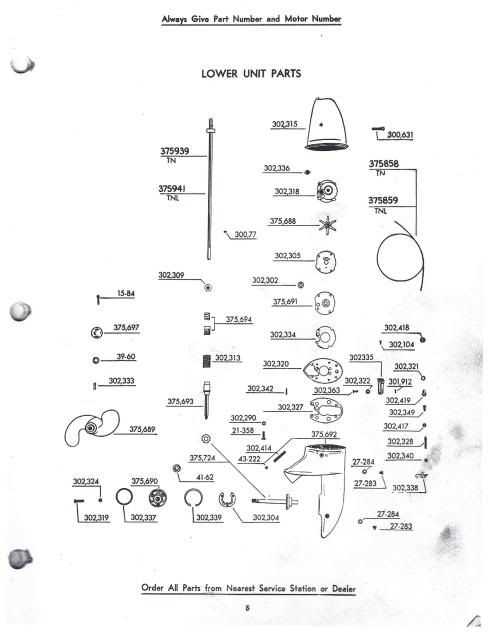

Propeller Assembly for Marine Engines

The propeller system plays a crucial role in ensuring efficient movement through the water. It consists of multiple components working together to convert engine power into thrust. A well-maintained propeller ensures smooth sailing and optimal performance.

Key elements of the assembly include the blade, hub, and related hardware, all designed to provide

Cooling System Configuration

The configuration of the cooling mechanism is crucial for maintaining optimal operating temperatures in marine engines. This system prevents overheating by circulating a coolant through various components, ensuring efficient thermal regulation and longevity of the engine.

Key Components

- Water Pump: Responsible for drawing water from the surroundings and directing it through the cooling system.

- Heat Exchanger: Facilitates the transfer of heat from the engine to the coolant.

- Thermostat: Regulates the temperature by controlling coolant flow based on temperature readings.

- Cooling Hoses: Transport the coolant to and from different parts of the engine.

Cooling Process Overview

- The water pump draws in water from the body of water.

- The coolant passes through the engine block, absorbing heat.

- The heated coolant is then directed to the heat exchanger.

- In the heat exchanger, the heat is dissipated, allowing cooler fluid to return to the engine.

- The cycle repeats, maintaining a stable operating temperature.

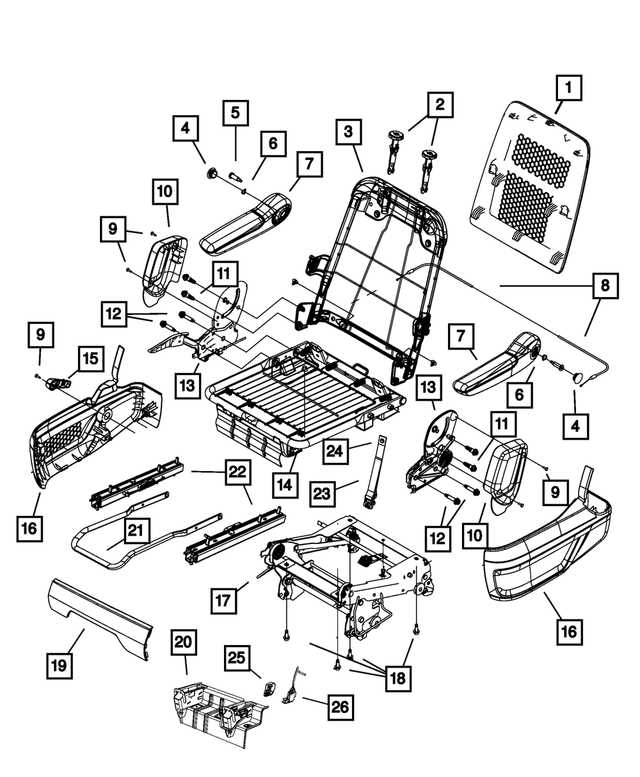

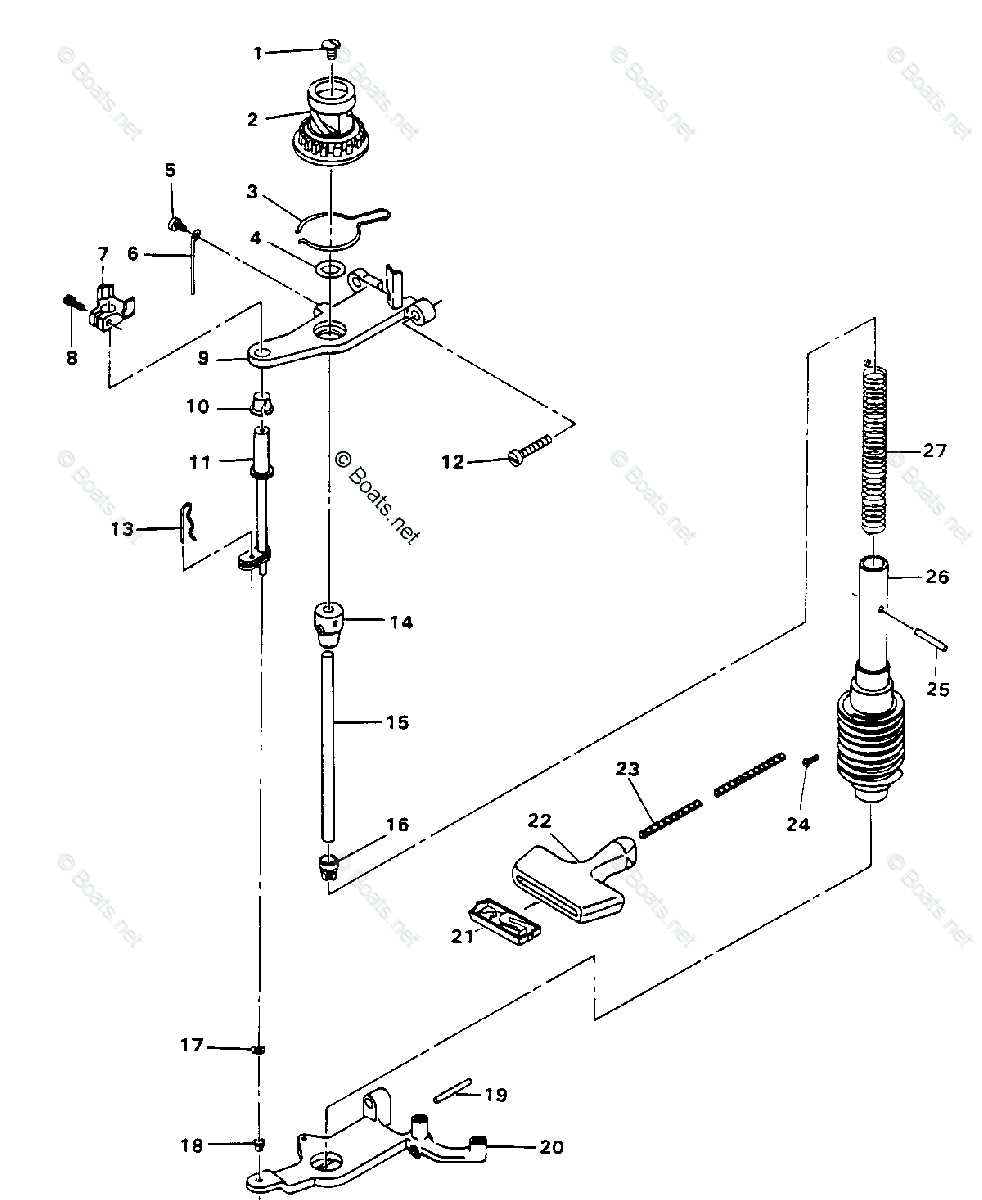

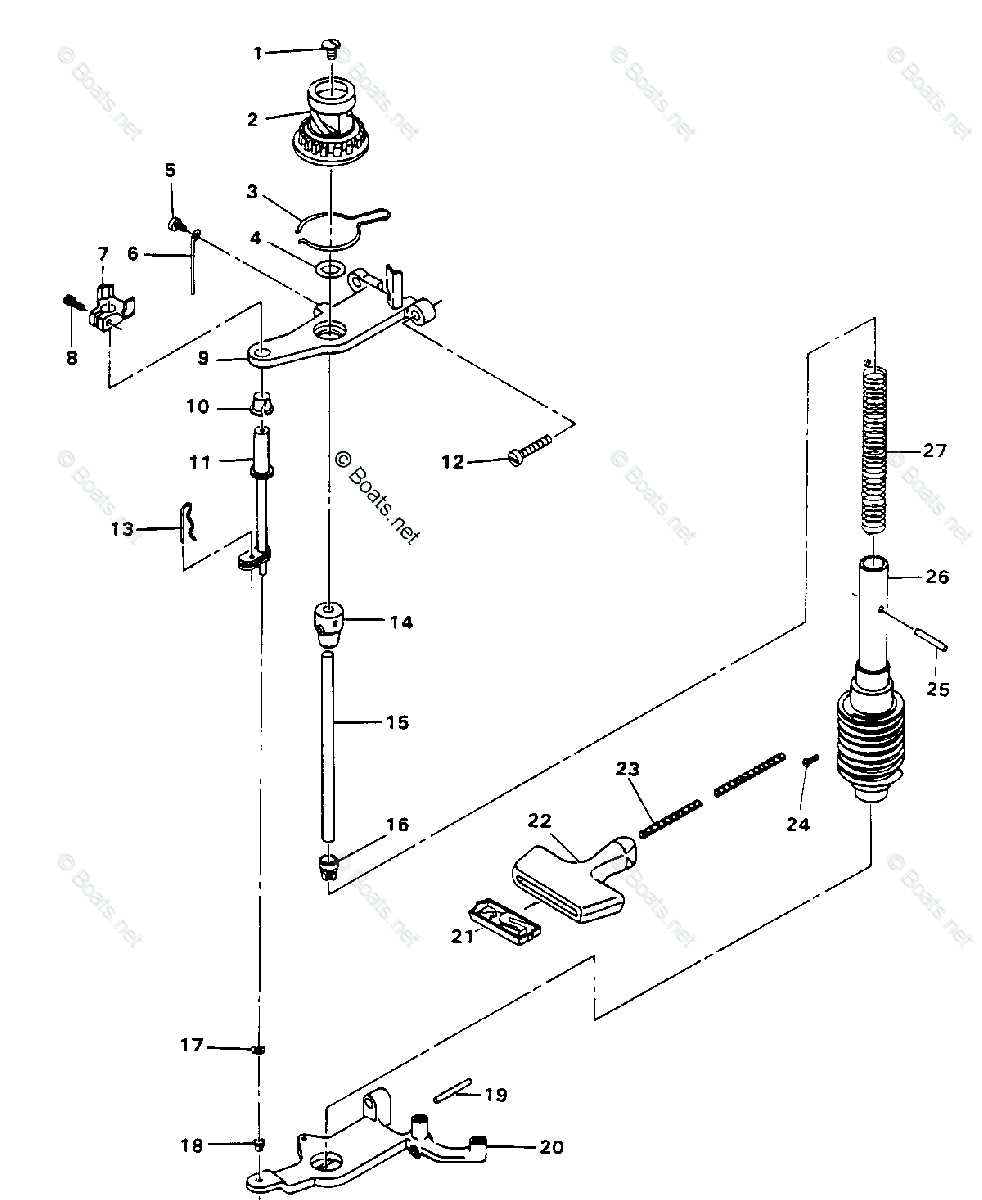

Steering Mechanism in Chrysler Models

The steering system plays a vital role in the operation of various marine engines, providing the necessary control for maneuvering and navigation. Understanding the functionality and components of this mechanism is essential for maintaining performance and ensuring safety on the water.

Key Components of the Steering System

At the heart of the steering mechanism lies a series of interconnected elements that work together to facilitate smooth handling. The primary components include the steering wheel, helm, and linkages. Each part serves a distinct purpose, contributing to the overall effectiveness of the system.

Maintenance and Troubleshooting

Regular upkeep is crucial for optimal performance. Routine inspections can help identify wear and tear on the components, ensuring that any issues are addressed promptly. Common problems include loose connections and misalignments, which can lead to difficulty in steering and reduced responsiveness. Addressing these concerns quickly can enhance the longevity and reliability of the system.

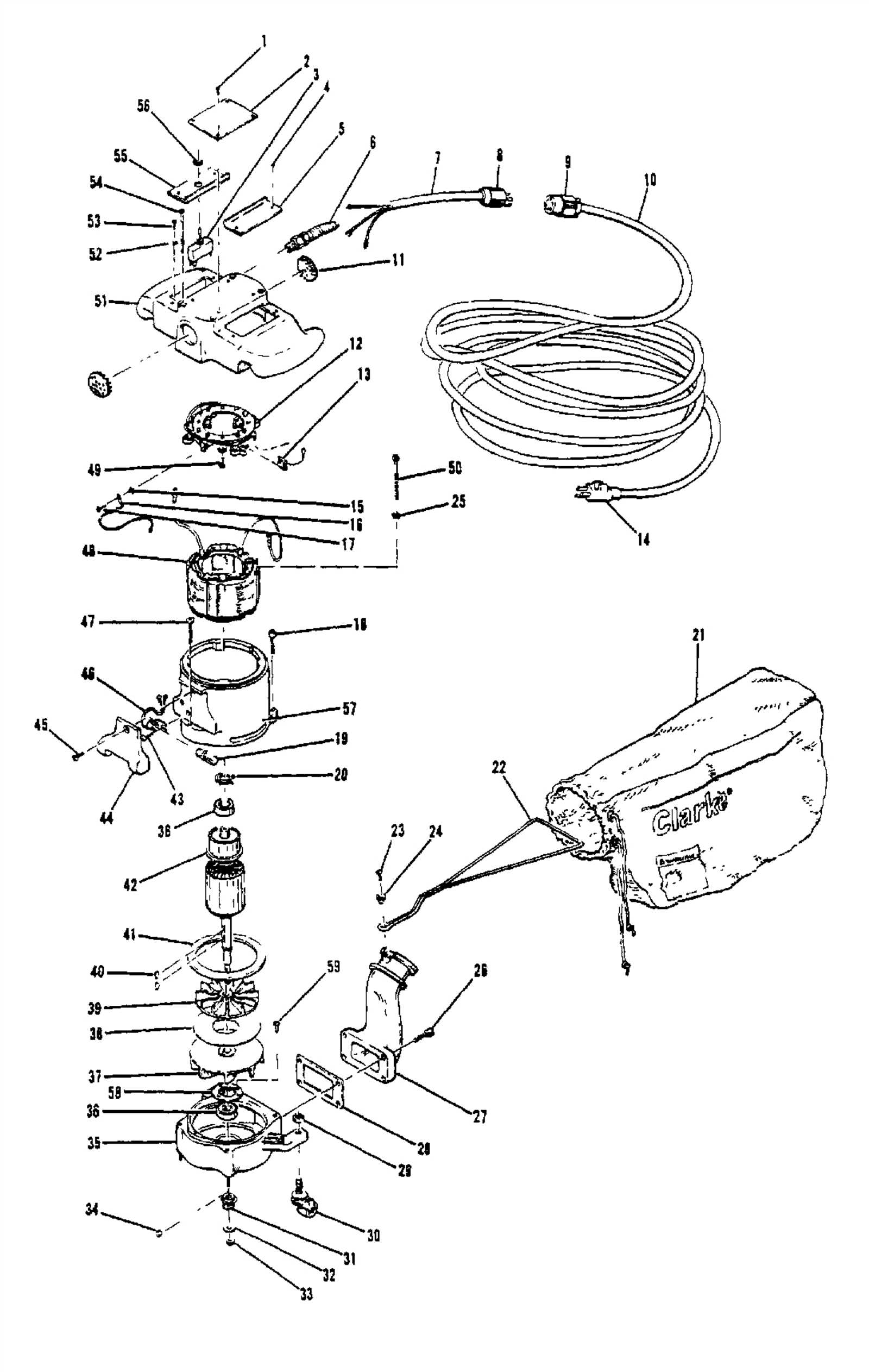

Carburetor Setup and Adjustment Guide

This section provides essential guidance on configuring and fine-tuning fuel delivery mechanisms to optimize engine performance. Proper setup is crucial for ensuring smooth operation and responsiveness, enhancing overall efficiency.

Understanding Fuel Mixture

The fuel-air mixture plays a vital role in the performance of an engine. An optimal balance ensures effective combustion, leading to improved power output and reduced emissions. It’s important to evaluate the current mixture settings and make necessary adjustments based on the specific operational requirements.

Adjustment Techniques

Begin by consulting the manufacturer’s specifications for baseline settings. Using appropriate tools, gradually adjust the mixture screws while monitoring engine response. Listening to the engine’s performance is key; a smooth and steady idle indicates a well-adjusted carburetor. If hesitation or rough running occurs, further fine-tuning may be required to achieve the desired result.

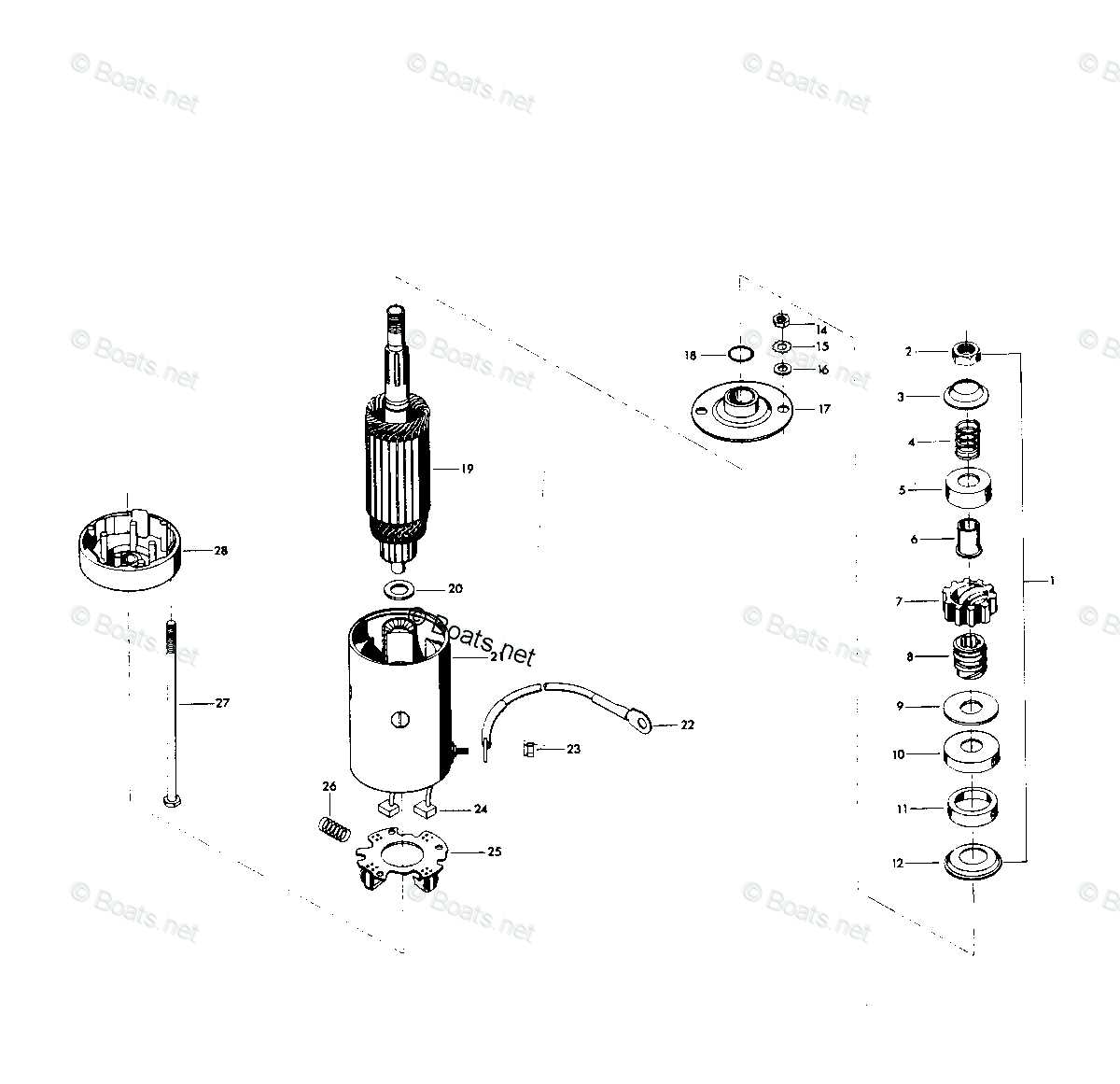

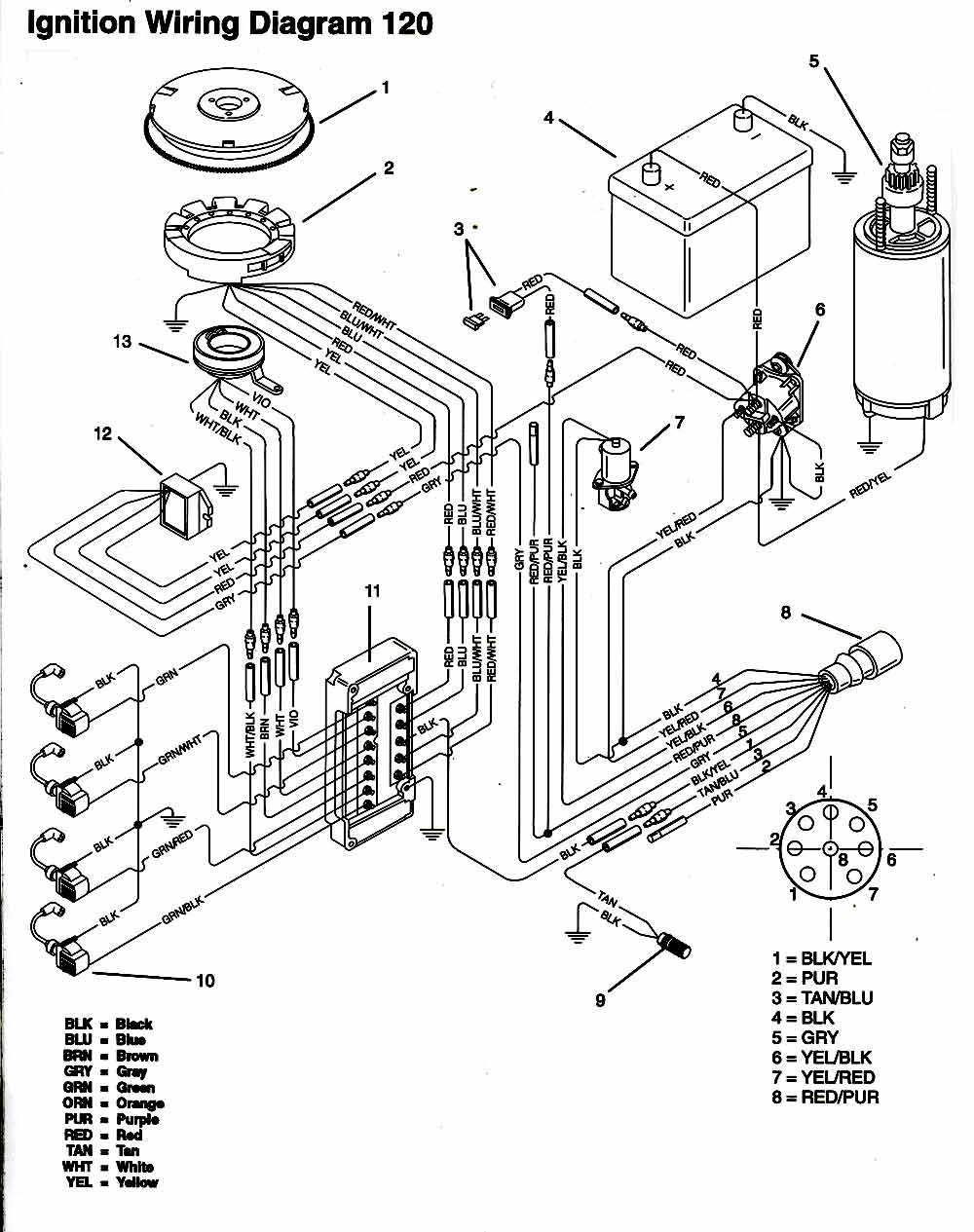

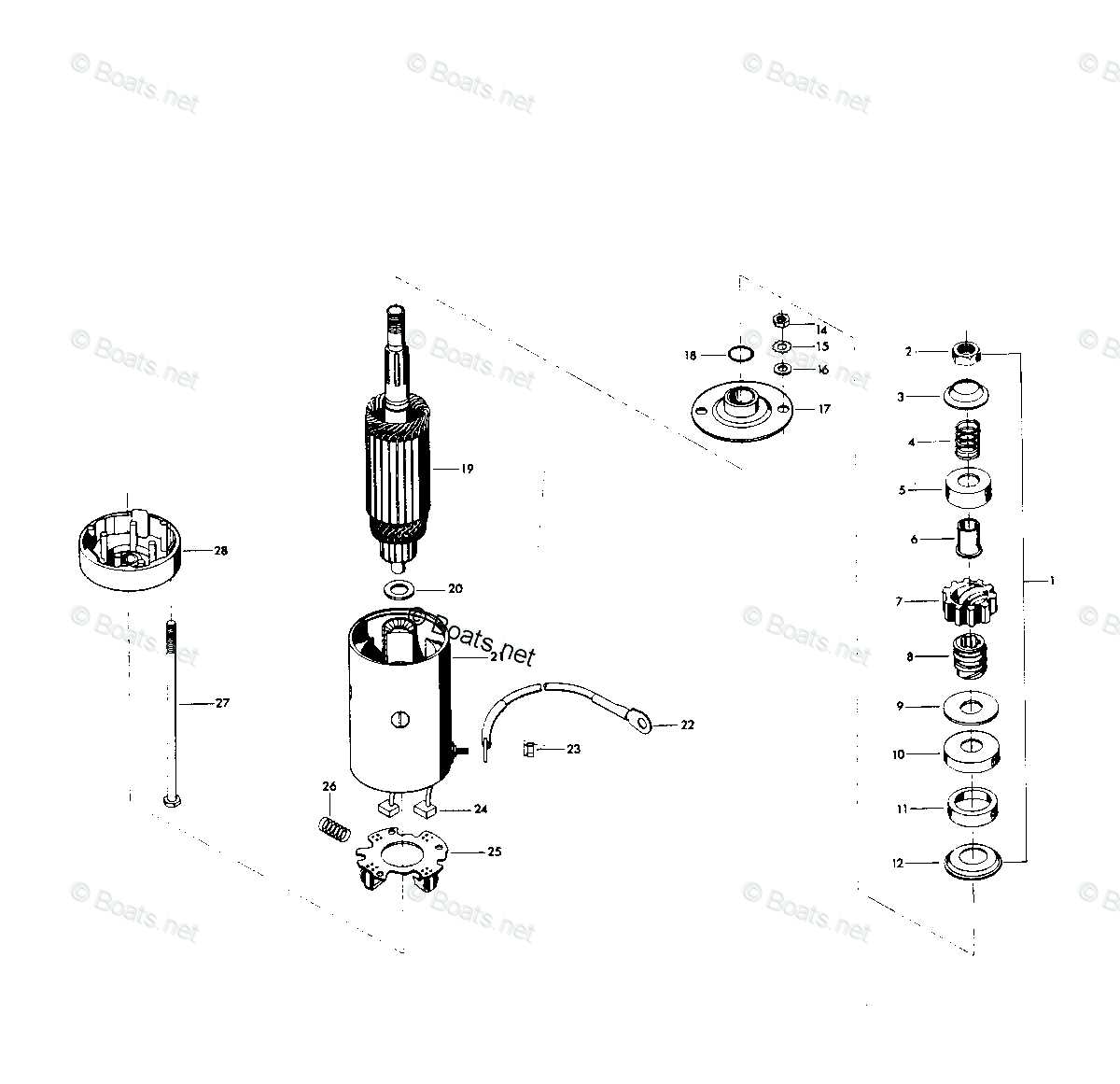

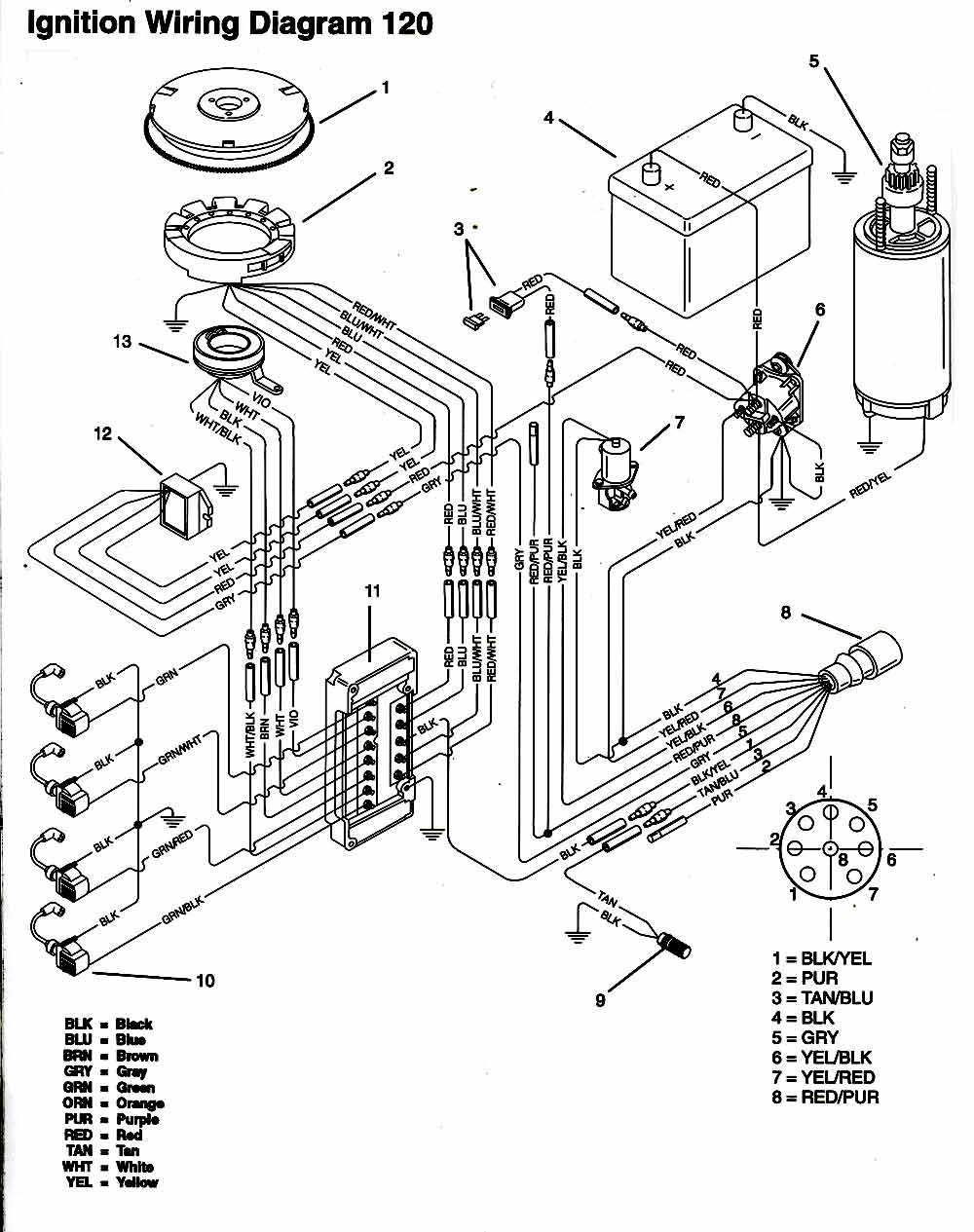

Ignition System Components Breakdown

The ignition mechanism plays a crucial role in the operation of marine engines, ensuring efficient combustion and overall performance. Understanding the various elements that comprise this system is essential for proper maintenance and troubleshooting. This section will delve into the key components involved in the ignition process and their respective functions.

1. Spark Plug: This device ignites the air-fuel mixture by producing a spark, initiating the combustion process. Regular inspection and replacement of spark plugs are vital for optimal engine performance.

2. Ignition Coil: The ignition coil transforms low battery voltage into the high voltage needed to create a spark at the spark plug. Its reliability directly affects the engine’s ability to start and run smoothly.

3. Magneto: Often found in smaller engines, the magneto generates electrical energy needed for the ignition system without relying on an external power source. It operates through the principles of electromagnetic induction.

4. CDI Unit: The Capacitor Discharge Ignition (CDI) unit stores electrical energy and releases it in a controlled manner to the ignition coil, ensuring precise timing for the spark generation.

5. Wiring Harness: This network of electrical wires connects all components of the ignition system, facilitating communication and power distribution between them. Proper maintenance of the wiring harness is essential to prevent electrical failures.

By familiarizing oneself with these components, boat owners can ensure their engines operate efficiently, enhancing both performance and reliability on the water.

Exhaust

The exhaust system is a critical component of marine engines, responsible for directing waste gases away from the engine. Proper functionality ensures optimal performance and minimizes harmful emissions. Understanding its elements is essential for maintaining efficiency and longevity in aquatic machinery.

Components of the Exhaust System

- Exhaust Manifold: Directs gases from the engine to the exhaust pipe.

- Exhaust Pipe: Channels gases away from the engine and towards the discharge point.

- Silencer: Reduces noise generated by escaping gases.

- Water Jacket: Cools exhaust gases to prevent overheating.

Common Issues and Solutions

- Corrosion: Regular inspection and replacement of rusty components.

- Blockages: Clearing debris from pipes to ensure unobstructed gas flow.

- Leaks: Tightening connections and replacing gaskets to prevent gas escape.