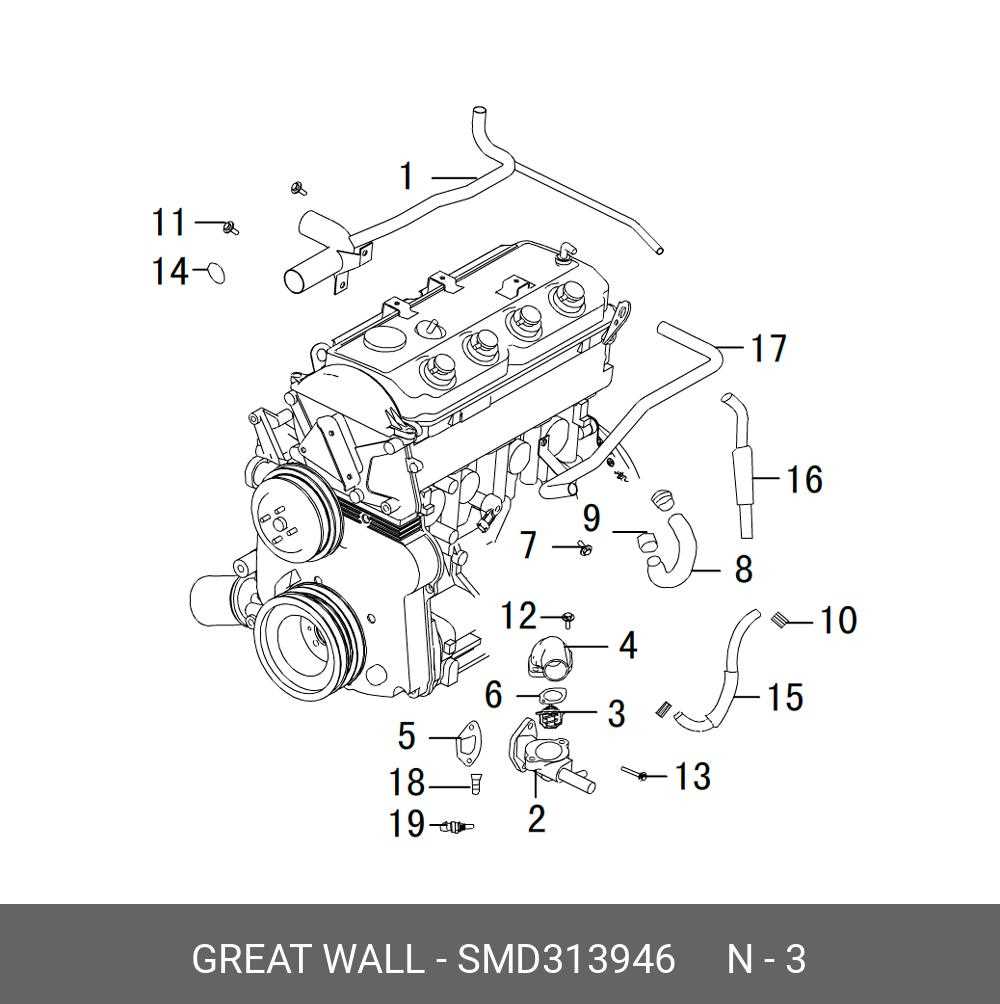

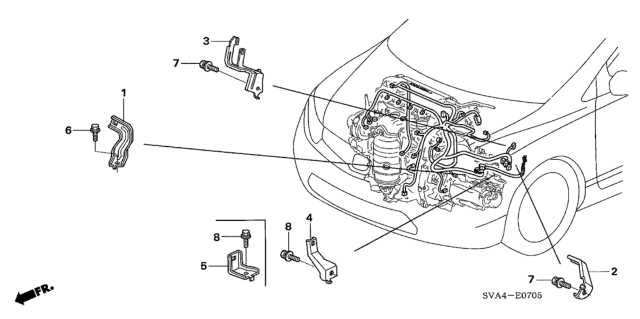

When it comes to maintaining a vehicle, it’s crucial to have a clear understanding of the essential mechanisms that contribute to its functionality. For those looking to delve deeper into the workings beneath the hood, identifying various components becomes a necessary step. Knowing the layout of these elements helps in better diagnosing issues and performing routine maintenance.

Each section of the vehicle’s internal structure plays a significant role in its overall performance. From the intricate systems that ensure smooth operation to those responsible for power generation, having a visual representation of these elements can make tasks like repairs or replacements more straightforward. It provides a comprehensive view that simplifies otherwise complex procedures.

Whether you’re a seasoned mechanic or a car owner looking to familiarize yourself with the basics, gaining insights into how everything is connected is invaluable. This guide will walk you through the primary elements, allowing you to grasp the

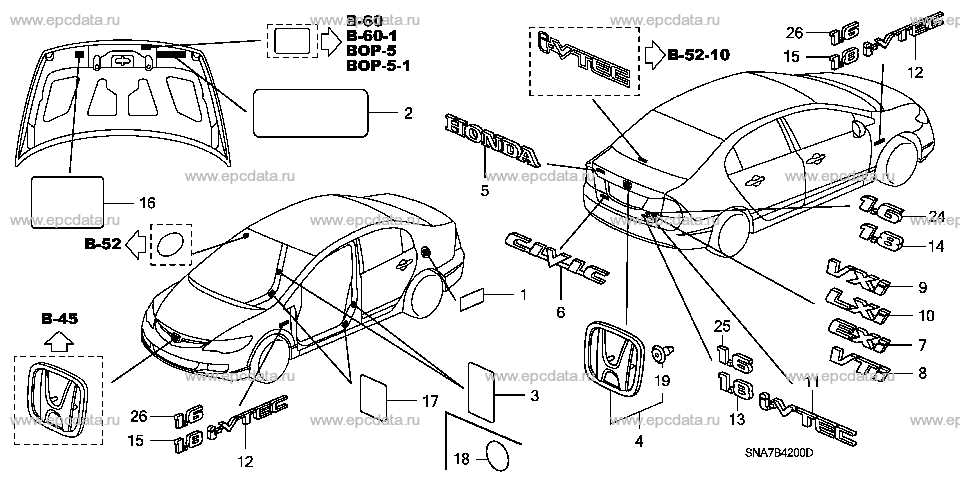

Understanding the 2006 Honda Civic Engine Layout

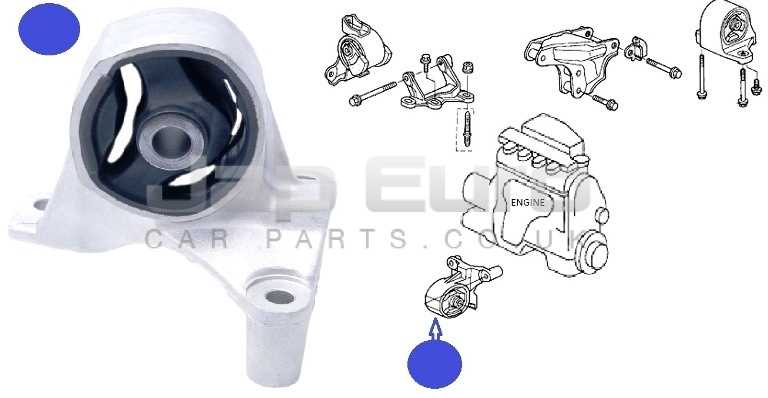

The structure of a vehicle’s power system is a complex combination of multiple components working together to ensure smooth operation and performance. In this layout, various key elements are strategically placed to optimize efficiency, cooling, and functionality. Understanding how these components are arranged can offer valuable insights into maintenance, troubleshooting, and overall system functionality.

At the heart of the setup lies the power generation unit, where energy is converted to propel the vehicle. Surrounding this core are numerous auxiliary systems, including fluid reservoirs, cooling mechanisms, and electrical wiring, all of which are interconnected to support seamless operation.

Key systems responsible for fuel management, air intake, and exhaust processing are positioned to ensure optimal performance and meet regulatory standards. Additionally, the cooling system and lubrication pathways are crucial for preventing overheating and reducing friction, both vital for maintaining longevity.

By exploring this setup, one can gain a deeper appreciation for how each part contributes to

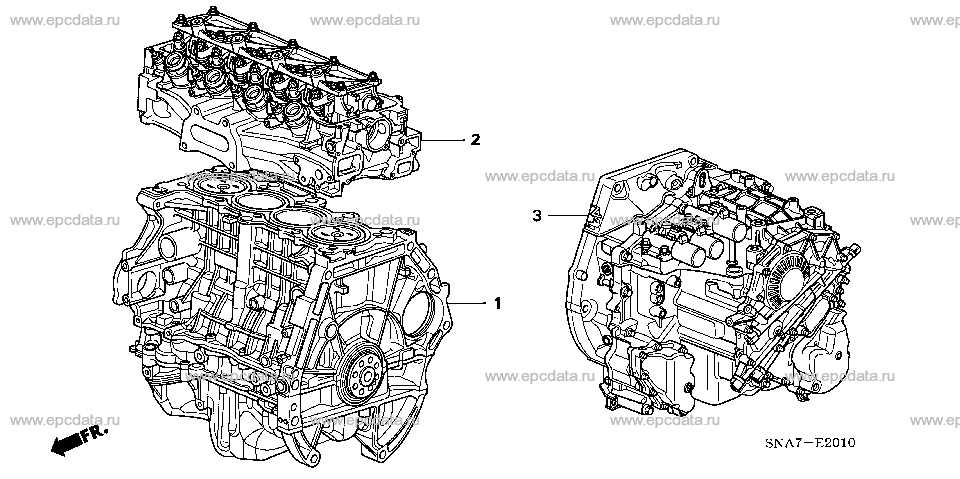

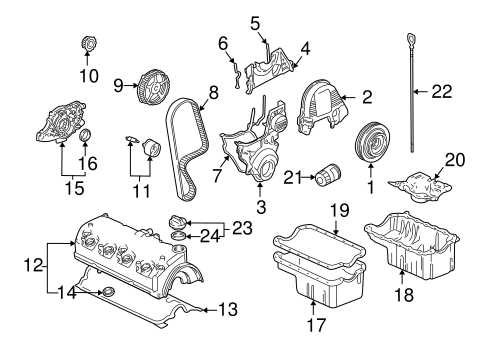

Key Components in the Civic Engine Block

The central unit responsible for power generation in many vehicles contains several vital elements that work together to ensure smooth operation. These components are crucial for converting fuel into motion and managing the mechanical processes that occur during operation.

One of the primary elements is the crankshaft, which plays a pivotal role in transforming linear energy into rotational force. Working alongside this is the piston, moving within the cylinders to create the necessary pressure for combustion. The synchronization of these two parts is fundamental for proper functionality.

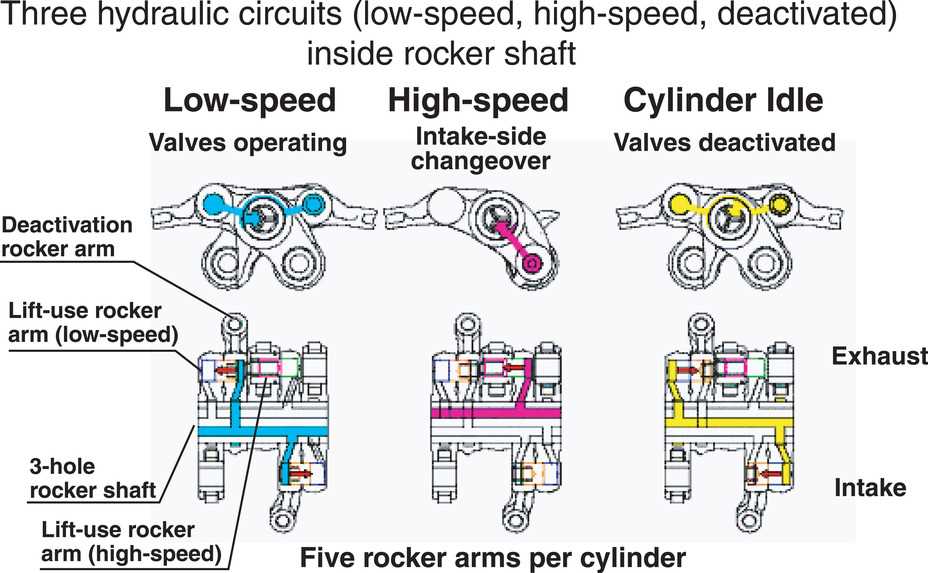

Another essential piece is the camshaft, which controls the opening and closing of valves, ensuring the right amount of air and fuel enters the chambers. Additionally, connecting rods are responsible for

How the Cylinder Head Operates in a Civic

The cylinder head is a critical component that ensures the smooth operation of the combustion process. It plays a key role in sealing the upper part of the engine’s combustion chamber, regulating airflow, and housing crucial elements necessary for fuel ignition. Understanding its functionality provides insights into how power is generated efficiently and safely within the vehicle.

Main Functions of the Cylinder Head

The primary purpose of the cylinder head is to manage air and fuel flow, allowing the proper combustion to occur. It contains several mechanisms that contribute to this process:

- Valves: These control the intake of air and fuel and the release of exhaust gases after combustion.

- Spark plugs: Positioned within the head, they ignite the fuel-air mixture, initiating the combustion process.

- Coolant passages: Built-in channels allow coolant to circulate, preventing overheating during

Overview of the Fuel System

The fuel system is a vital component responsible for efficiently delivering fuel from the tank to the combustion chamber. It ensures that the vehicle runs smoothly by regulating fuel flow and maintaining the correct fuel-to-air ratio for optimal performance. A well-functioning fuel system not only enhances the driving experience but also contributes to fuel economy and reduces emissions.

This system consists of several key elements, each playing a crucial role in the process of fuel transportation. These components work in harmony to ensure that the powertrain receives a steady supply of fuel, enabling smooth acceleration and efficient operation. Regular maintenance of this system is essential to avoid performance issues and ensure long-term reliability.

2006 Honda Civic Cooling System Explained

The cooling system in this vehicle plays a crucial role in maintaining optimal operating temperatures for various components. It is designed to regulate heat dissipation and ensure the motor runs smoothly under different conditions. Proper temperature control is essential for preventing overheating and enhancing performance longevity. Let’s take a closer look at the main elements involved in this process and how they work together to ensure efficient temperature management.

Main Components of the Cooling System

This system consists of several key elements that work together to circulate coolant and dissipate heat. The radiator is the core part responsible for transferring heat from the coolant to the outside air. The water pump ensures a continuous flow of coolant through the system, while the thermostat regulates the temperature by controlling when the coolant is allowed to flow. Additionally, hoses and fans assist in guiding the coolant and enhancing airflow to keep everything functioning as intended.

How the Cooling Process Works

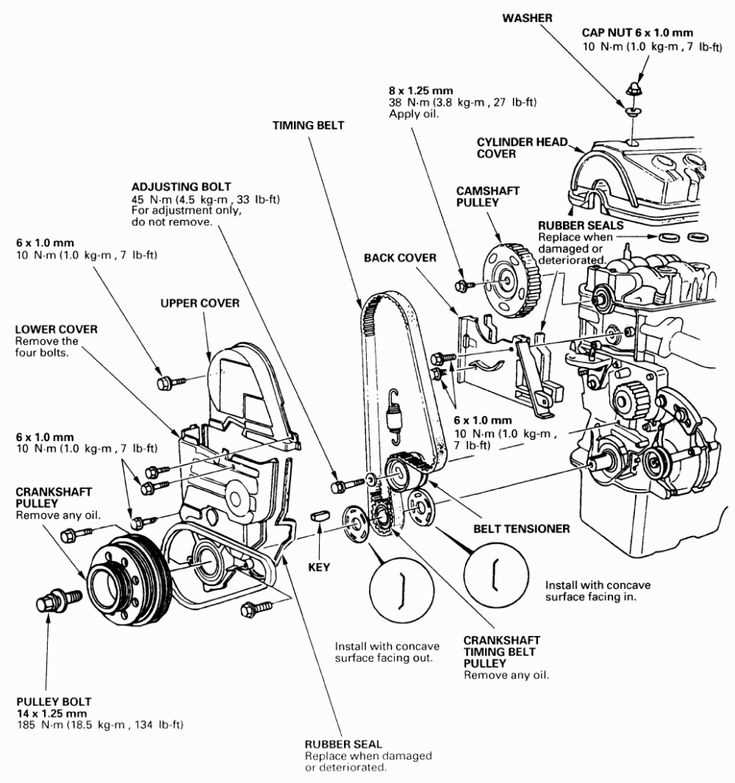

Drive Belts and Their Role in Engine Function

Drive belts are vital components within the automotive system, facilitating the transfer of power from one part to another. These flexible loops, made of durable materials, ensure that various mechanical systems operate in harmony, contributing to the overall performance of the vehicle.

The primary functions of drive belts include:

- Power Transmission: They transmit rotational energy from the crankshaft to auxiliary systems.

- Accessory Operation: Belts enable the functioning of essential accessories, such as the alternator and air conditioning compressor.

- Efficiency Improvement: By maintaining proper tension, they reduce energy losses, enhancing overall efficiency.

Understanding the significance of these components is crucial for maintaining optimal vehicle performance. Regular inspections can help detect wear and tear, preventing potential failures that could lead to extensive repairs.

In conclusion, drive belts play a crucial role in ensuring smooth operations within a vehicle. Proper maintenance and timely replacements are key to ensuring long-lasting functionality and reliability.

Identifying the Timing Chain in a 2006 Civic

Recognizing the timing chain within a vehicle’s mechanical setup is essential for maintaining optimal performance. This crucial component ensures synchronized movement between various internal mechanisms, playing a pivotal role in the overall functionality of the power unit.

Location of the Timing Chain

The timing chain is typically positioned at the front of the unit, housed within a protective cover. Accessing this assembly often requires the removal of other components, so it’s vital to consult relevant resources or guides to facilitate proper identification and maintenance.

Visual Identification Features

When inspecting the timing chain, look for the following characteristics:

Feature Description Color Usually metallic or grey, indicating robust construction. Links Composed of interconnected links that exhibit flexibility and strength. Tensioner A component that maintains proper tightness, ensuring smooth operation. Wear Indicators Look for signs of fraying or stretching, which may signal the need for replacement. Exhaust System Parts in a Honda Civic Engine

The exhaust system plays a crucial role in managing the emissions and sound produced during combustion. It is designed to efficiently route exhaust gases away from the combustion chamber, ensuring optimal performance and reducing harmful pollutants. Understanding the components that comprise this system can enhance both maintenance practices and performance tuning.

Main Components

This assembly consists of various elements that work together to facilitate the exit of exhaust gases. Key components include the manifold, which collects gases from multiple cylinders; the catalytic converter, which reduces toxic emissions; and the muffler, which minimizes noise. Each part is essential for ensuring that the vehicle operates efficiently and meets environmental standards.

Regular maintenance of the exhaust assembly is vital for preserving engine efficiency and longevity. Checking for leaks, corrosion, and blockages can prevent performance issues. Properly functioning components also contribute to fuel economy and overall driving experience, highlighting the importance of this system in vehicle operation.

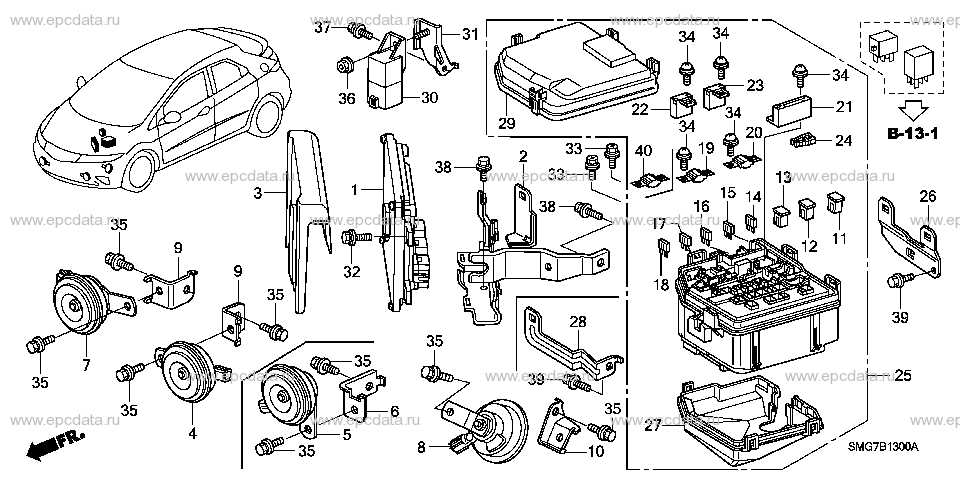

Electrical Components Critical to Engine Performance

Effective operation of a vehicle relies heavily on its electrical systems, which play a pivotal role in enhancing functionality and reliability. Various elements within these systems interact seamlessly to ensure optimal performance and efficiency.

Among the essential components are sensors, relays, and control units, each serving a unique purpose. Sensors gather vital data regarding conditions such as temperature and pressure, while relays manage electrical signals to various systems. Control units analyze this information and make real-time adjustments to maintain peak performance.

Component Function Ignition Coil Transforms battery voltage into high voltage for spark generation. Oxygen Sensor Monitors the oxygen level in the exhaust, optimizing fuel mixture. Fuel Injector Delivers precise amounts of fuel into the combustion chamber. Mass Airflow Sensor Measures the amount of air entering the intake to ensure proper fuel delivery. Battery Supplies electrical power to start the vehicle and operate systems. Understanding these components allows for better maintenance and troubleshooting, leading to improved longevity and efficiency of the vehicle.

Role of Sensors in Honda Civic Engine Efficiency

Sensors play a crucial role in enhancing the performance and efficiency of modern vehicles. They provide vital data that allows for precise control of various systems, contributing to overall functionality and environmental sustainability.

By continuously monitoring different parameters, these devices ensure that the vehicle operates optimally under various conditions. Their contributions can be categorized as follows:

- Fuel Management: Sensors help regulate the air-fuel mixture, improving combustion efficiency and reducing emissions.

- Temperature Control: By measuring engine temperature, sensors assist in preventing overheating and ensuring smooth operation.

- Emission Monitoring: These devices track exhaust gases, allowing for compliance with environmental regulations and minimizing pollutants.

- Performance Optimization: Sensors provide real-time feedback that helps adjust ignition timing and other parameters for better power output.

In summary, the integration of sensors significantly enhances vehicle efficiency, leading to improved performance and reduced environmental impact. The continuous advancement in sensor technology further supports the development of more efficient and sustainable transportation solutions.

Common Wear Parts in a 2006 Civic Engine

Vehicles consist of numerous components that undergo regular stress and strain, leading to eventual wear and tear. Understanding which elements are most susceptible to degradation can significantly enhance maintenance practices and extend the life of the vehicle. This section outlines the frequently replaced items that are critical for optimal performance.

One of the most essential components that often requires attention is the timing belt. This crucial element connects various rotating parts and ensures proper synchronization. Over time, it can fray or break, potentially causing severe damage. Regular inspection and replacement according to the manufacturer’s schedule are vital to prevent catastrophic failures.

Additionally, the ignition system, including spark plugs and wires, is prone to wear. These components play a significant role in engine efficiency and power generation. Failing plugs can lead to misfires, reduced fuel economy, and increased emissions. Timely replacement is necessary to maintain smooth operation.

Another common issue involves the cooling system. The radiator, hoses, and thermostat can develop leaks or blockages, which may lead to overheating. Regular checks and replacement of these items are essential to ensure the engine operates within the optimal temperature range, preventing costly repairs.

Lastly, oil filters and air filters are critical for maintaining cleanliness and preventing contaminants from causing damage. Clogged filters can restrict flow and reduce efficiency, highlighting the importance of routine maintenance and timely changes. By addressing these commonly worn items, vehicle owners can ensure reliable performance and longevity.