Maintaining outdoor equipment can often require a deep understanding of its internal structure. Whether you’re conducting routine upkeep or looking to address a specific issue, having a clear visual guide to the machinery’s internal layout can make the process significantly smoother. This section delves into how understanding the configuration of essential elements contributes to seamless maintenance.

By familiarizing yourself with the placement of key elements within your lawn care tool, you ensure that each repair or replacement task is approached with confidence. This guide provides clarity on how the various elements of the equipment are connected, making it easier to diagnose and address any mechanical issues.

Knowing the positioning of different components aids in prolonging the life of your machine, ensuring that every part functions as intended. With the right approach, you can keep your equipment in optimal condition, leading to more efficient and reliable performance.

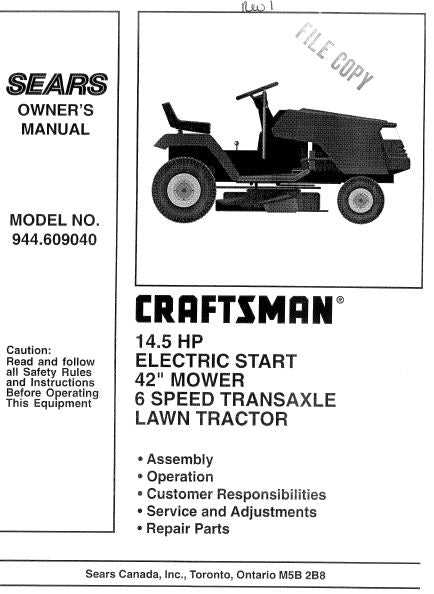

Craftsman 917 Parts Overview

The following section provides a detailed look at the essential components required for efficient functionality and maintenance. This overview highlights the core mechanisms that play a significant role in ensuring proper operation and durability.

Key Components

In this category, we will explore the most vital elements, focusing on the moving parts and structural elements that contribute to the smooth operation of the machine. These components include power transmission elements and critical connectors that ensure consistent performance.

Maintenance Essentials

Regular upkeep of these items is crucial for extending the lifespan and enhancing overall reliability. This includes monitoring and replacing wearable items as needed, ensuring all key sections remain in optimal condition.

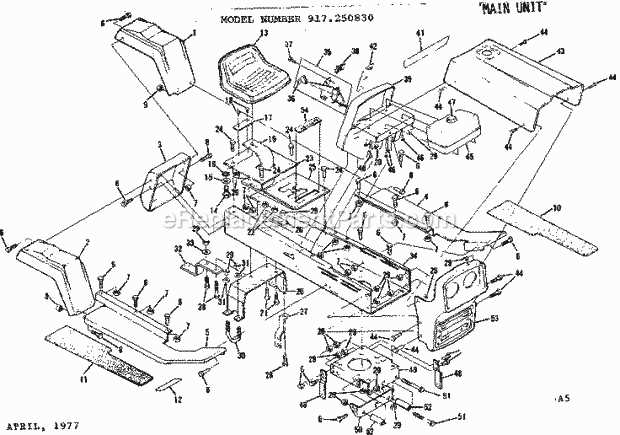

Main Components of the Craftsman 917

The structure of this equipment is made up of several key elements, each playing a vital role in ensuring its performance and durability. These essential units work together to deliver efficiency, from the core mechanisms to the peripheral elements. Understanding these components can help maintain the machine’s longevity and optimize its operation.

Engine System: The central power source drives all functions, providing the necessary energy for operation. Its design ensures reliable and continuous performance, capable of handling various tasks.

Drive Mechanism: This crucial element transfers energy from the core to the wheels or other moving parts, enabling smooth motion and control. It is designed to ensure consistent and efficient movement across different surfaces.

Cutting Assembly: Responsible for the main task, this part allows for precise and effective cutting. It is equipped with durable materials that ensure sharpness and durability over extended use.

Steering and Control: The control system allows the user

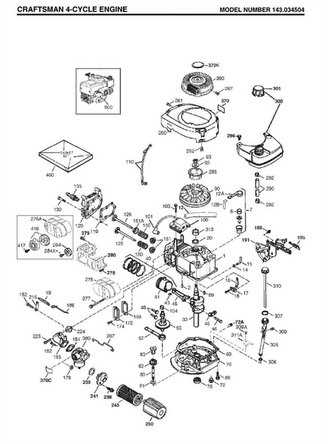

Engine Assembly Breakdown

The disassembly and analysis of the engine structure provides insight into the key components that ensure smooth operation. This section focuses on the various elements that form the core of the motor, detailing how each part interacts to deliver efficient power and performance. Understanding the internal configuration can help identify potential areas for maintenance or improvement.

Cylinder and Piston System – The core of the engine, where fuel combustion takes place, generating the necessary force to drive the machinery. The alignment and condition of these components are critical for optimal engine performance.

Crankshaft and Connecting Rods – These elements convert the linear motion from the pistons into rotational energy, which is then transferred to other mechanical systems. Proper lubrication and regular inspection of these parts are vital for preventing wear and ensuring long-term functionality.

Valve Mechanism – Responsible for regulating the intake of air and fuel, as well as the exhaust of gases. The timing and condition of the valve system are crucial for maintaining engine efficiency and avoiding operational issues.

Regular upkeep of these key components can extend the engine’s lifespan and ensure it operates at peak capacity.

Transmission and Drive System

The transmission and drive system play a crucial role in ensuring the smooth operation of any mechanical equipment. This section will focus on the core functions of these components, which are responsible for transferring power from the engine to the wheels, allowing the machine to move efficiently. Understanding the interaction between the transmission and drive mechanisms is key to maintaining optimal performance.

Main Components

The system consists of several key elements that work together to control speed and direction. The transmission adjusts the torque and speed ratios, while the drive system manages the distribution of power to the wheels. Proper functioning of each part ensures that the machine can operate under various conditions without strain or failure.

Maintenance Tips

Regular maintenance of the transmission and drive system is essential for longevity. Check the fluid levels frequently and ensure there are no leaks, as proper lubrication is vital to prevent wear. Additionally, inspect belts and pulleys for any signs of damage to avoid sudden breakdowns.

Cutting Deck Structure and Blades

The design of the cutting deck and the arrangement of blades play a crucial role in the overall efficiency and performance of lawn mowers. A well-engineered deck ensures an even cut, while the blades are responsible for smooth and precise grass trimming. Understanding the structure of these components can help in maintaining and improving the mower’s functionality.

Deck Construction

The cutting deck is typically built from durable materials to withstand the wear and tear of frequent use. Its main function is to house the blades and provide a protective barrier between the spinning blades and external objects. The deck also helps direct airflow, which is essential for efficient grass cutting and discharge. The shape and size of the deck can influence cutting width and the mower’s maneuverability in various terrains.

Blade Mechanism

The blades, mounted beneath the deck, are sharpened to slice through grass with minimal resistance. Depending on the model, the mower may use either a single blade or a set of multiple blades, which are designed to rotate at high speeds. Properly maintained blades ensure a clean cut, reducing the risk of damage to the lawn and improving the mower’s overall efficiency.

Steering and Control Mechanisms

The steering and control systems play a crucial role in ensuring smooth operation and maneuverability of various machinery. These components work together to facilitate precise movements and adjustments, enhancing the overall functionality of the equipment. Understanding their design and interaction is essential for maintaining optimal performance.

Types of Steering Systems

Different types of steering systems can be found in various machines, each offering unique advantages. For instance, some systems utilize a traditional mechanical linkage, allowing for direct control and feedback. Others may employ more advanced technologies, such as hydraulic or electronic systems, which provide enhanced responsiveness and ease of use. The choice of steering mechanism often depends on the specific application and user preferences.

Control Mechanisms and Their Functions

Control mechanisms encompass a range of components that allow operators to manipulate the direction and speed of the equipment. This includes elements such as levers, pedals, and knobs, each designed to provide a user-friendly interface. Understanding how these controls interact with the steering system is vital for effective operation, as they contribute significantly to the machine’s responsiveness and handling capabilities.

Electrical System Layout

The electrical system layout is crucial for understanding the overall functionality and performance of the equipment. This section provides an overview of the components and their arrangement, which ensures proper operation and efficiency. A well-organized electrical framework is essential for troubleshooting and maintenance, as it facilitates easy access to various parts and connections.

| Component | Description | Function |

|---|---|---|

| Battery | Stores electrical energy for starting the engine. | Provides power to the starter motor and other electrical components. |

| Starter Motor | An electric motor that initiates engine operation. | Turns the engine over to start it. |

| Ignition Switch | Controls the electrical power to the engine. | Enables the starting system and accessory power. |

| Fuses | Safety devices that protect electrical circuits. | Prevent overload and short circuits by breaking the connection when current exceeds a safe level. |

| Wiring Harness | A network of wires connecting various electrical components. | Facilitates the flow of electricity throughout the system. |

Fuel System and Carburetor Details

The fuel system and carburetor are essential components of any small engine, playing a crucial role in delivering the right mixture of air and fuel for optimal performance. Understanding these parts helps ensure efficient operation and maintenance.

The fuel system consists of several key elements:

- Fuel Tank: Stores the fuel necessary for engine operation.

- Fuel Lines: Transport fuel from the tank to the carburetor.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

The carburetor is a vital component that mixes air with fuel in the correct proportions. Key features of the carburetor include:

- Float Chamber: Maintains a consistent fuel level for optimal mixing.

- Jet System: Controls the fuel flow based on engine demand.

- Throttle Plate: Regulates the amount of air entering the carburetor, affecting engine speed and power.

Proper maintenance of these components is essential for peak performance. Regular checks and adjustments can prevent common issues, such as fuel leaks or poor engine performance.

Wheels, Axles, and Tires Components

The essential elements of a vehicle’s mobility system include the circular supports, connecting shafts, and rubber coverings. These components play a crucial role in ensuring smooth movement and stability while navigating various terrains. Understanding the intricacies of these parts is vital for effective maintenance and optimal performance.

Types of Wheels

The circular supports come in various shapes and sizes, designed to accommodate different weight capacities and driving conditions. Each type serves a specific purpose, contributing to the overall efficiency of the vehicle. Selecting the appropriate wheel type is essential for enhancing traction and maneuverability.

Axles and Their Functions

Connecting shafts serve as the backbone of the mobility system, facilitating the transfer of power from the engine to the wheels. They support the weight of the vehicle and ensure that the wheels rotate in unison. Regular inspection of these components is crucial to prevent any operational issues that could compromise safety.

Brake System Overview

The brake system is a crucial component of any machinery, ensuring safe operation by effectively reducing speed or bringing the equipment to a complete stop. Understanding its function and components is essential for proper maintenance and troubleshooting.

This system typically includes various elements such as brake pads, discs, and hydraulic components that work in unison to provide reliable stopping power. Regular inspection and timely replacement of worn parts are vital for maintaining optimal performance and safety.

Moreover, understanding the mechanisms involved in braking can enhance the user’s ability to respond to potential issues, ensuring a longer lifespan for the equipment. By familiarizing oneself with the system’s layout and functionality, operators can take proactive measures to avoid malfunctions.

Chassis and Frame Construction

The chassis and frame are essential components of any machinery, serving as the structural backbone that supports various elements and ensures stability during operation. The design and materials used in these parts significantly influence the overall performance, durability, and handling of the equipment. A robust framework is crucial for withstanding operational stresses and enhancing longevity.

Material Selection

Choosing the right materials is vital in constructing a durable chassis. Commonly used materials include high-strength steel and aluminum, which offer a balance between weight and resilience. Steel provides excellent strength, while aluminum is lightweight, contributing to improved maneuverability without sacrificing structural integrity.

Assembly Techniques

The assembly process of the frame often involves welding, bolting, or riveting components together. Each technique has its advantages, with welding typically offering greater strength and rigidity, whereas bolting allows for easier disassembly and repairs. Proper alignment and secure fastening are essential to maintain the structural integrity and overall performance of the assembly.

Maintenance Tips for Craftsman 917 Parts

Proper upkeep of equipment components is essential for ensuring longevity and optimal performance. Regular maintenance not only extends the lifespan of various parts but also enhances efficiency and safety during operation. By following a few simple practices, users can keep their machinery in top condition and reduce the likelihood of unexpected breakdowns.

First, always consult the user manual for specific maintenance guidelines tailored to your equipment model. Regularly checking fluid levels and replacing them as necessary is crucial. This includes engine oil, coolant, and any other lubricants that keep moving parts functioning smoothly.

Additionally, clean all components thoroughly to remove dirt and debris that can hinder performance. Pay special attention to filters, as clogged filters can restrict airflow and affect overall functionality. Replacing these filters periodically can prevent significant issues down the line.

Inspect belts and hoses for signs of wear, such as cracks or fraying. Addressing these issues promptly can prevent more extensive damage and costly repairs. Moreover, sharpening blades or tools regularly ensures that they operate efficiently and effectively, reducing strain on the machinery.

Lastly, store the equipment properly when not in use. Protecting it from harsh weather conditions and securing it in a dry location can significantly prolong its life. By implementing these maintenance tips, users can enjoy reliable performance and enhance the durability of their equipment.