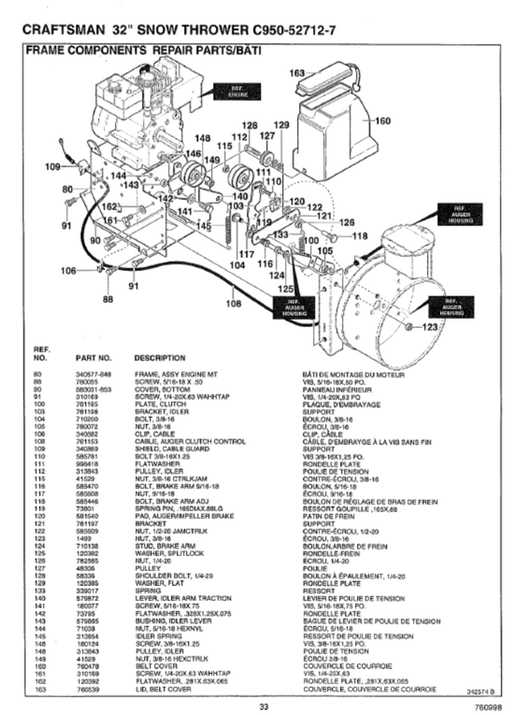

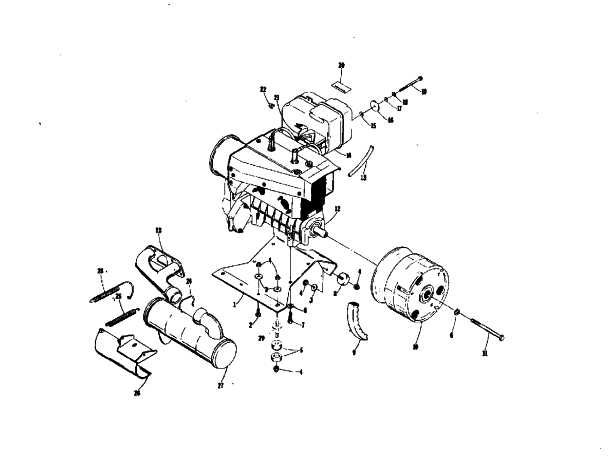

When dealing with any mechanical device, understanding its structure and layout is essential for effective maintenance and troubleshooting. Each mechanism is made up of interconnected elements that work together to perform various functions, and identifying these elements is the first step towards mastering its functionality.

By breaking down the internal arrangement of such equipment, users can better comprehend how the components interact. This overview provides a clear representation of the essential elements and their positions within the system, offering a practical guide for those looking to repair or upgrade their machinery.

Knowing the setup of each internal piece allows for a more efficient approach when dealing with potential issues. This section will guide you through the primary components, explaining their function and how they fit together to ensure optimal performance.

Understanding Key Components of an Air Compressor

To achieve optimal functionality in pneumatic systems, it’s crucial to recognize the role of each element. Understanding how different mechanisms work together will help in troubleshooting and maintenance, ensuring smooth and efficient operation.

Main Structural Elements

- Motor: This element provides the driving force needed to operate the system.

- Tank: A storage unit that holds the pressurized gas, ready for use.

- Pressure switch: A control device that regulates pressure levels and turns the system on or off when needed.

Additional Key Mechanisms

- Regulator: Adjusts the output force to match the tool requirements.

- Drain valve: Used for releasing excess moisture that collects during use.

- Safety valve: Ensures that the system operates within safe pressure limits, protecting it from potential damage.

Main Functions of the Pressure Switch

The pressure switch is a critical component in managing and regulating the operation of certain machinery. Its primary role is to control the activation and deactivation of the device based on the internal pressure levels. By automatically responding to changes, it ensures safe and efficient performance without the need for constant manual oversight.

Maintaining Optimal Performance: The switch helps maintain consistent performance by engaging the motor when pressure drops below a set threshold, and disengaging it once the upper limit is reached. This ensures the equipment runs efficiently without exceeding safe limits.

Protecting the System: Another key function is protecting the system from overpressure, which could lead to potential damage or safety concerns. By stopping the device when pressure gets too high, it prevents failures or malfunctions.

Exploring the Role of the Tank Valve

The tank valve is a critical component in various systems that rely on controlled pressure. It serves as a crucial point for managing the flow of gas or fluid within the storage unit, ensuring that the right pressure levels are maintained throughout the system. Understanding its function can greatly enhance the overall performance and safety of the equipment in which it is installed.

Key Function of the Valve

The primary purpose of the tank valve is to regulate the release and containment of stored energy. This mechanism allows the operator to control when and how much pressure is released from the tank, playing a pivotal role in maintaining efficiency. Proper usage and maintenance of the valve are essential to prevent leaks and other potential issues.

Maintenance and Safety Tips

Regular inspection of the tank valve is vital to ensure its optimal performance. Checking for wear, corrosion, or damage can help identify potential failures before they become critical. It’s important to make sure that all seals and connections are intact to prevent any unintentional pressure release, which could compromise the system’s safety. Always follow best practices when servicing or replacing this component to guarantee long-term functionality.

Importance of the Safety Relief System

Ensuring proper functioning of the safety relief mechanism is crucial for any equipment involving pressurized systems. This component serves as a critical safeguard, preventing potential hazards that can arise from overpressure situations. By automatically releasing excess pressure, it maintains balance within the system and helps avoid malfunctions.

The following points highlight why this system is essential:

- Prevents dangerous overpressure conditions

- Ensures the longevity of internal components by maintaining optimal pressure

- Reduces the risk of system failure, minimizing repair costs

- Provides an additional layer of security, ensuring safe operation under varying conditions

In summary, the safety relief mechanism is a key feature for maintaining both performance and security, making it an indispensable part of any pressurized equipment.

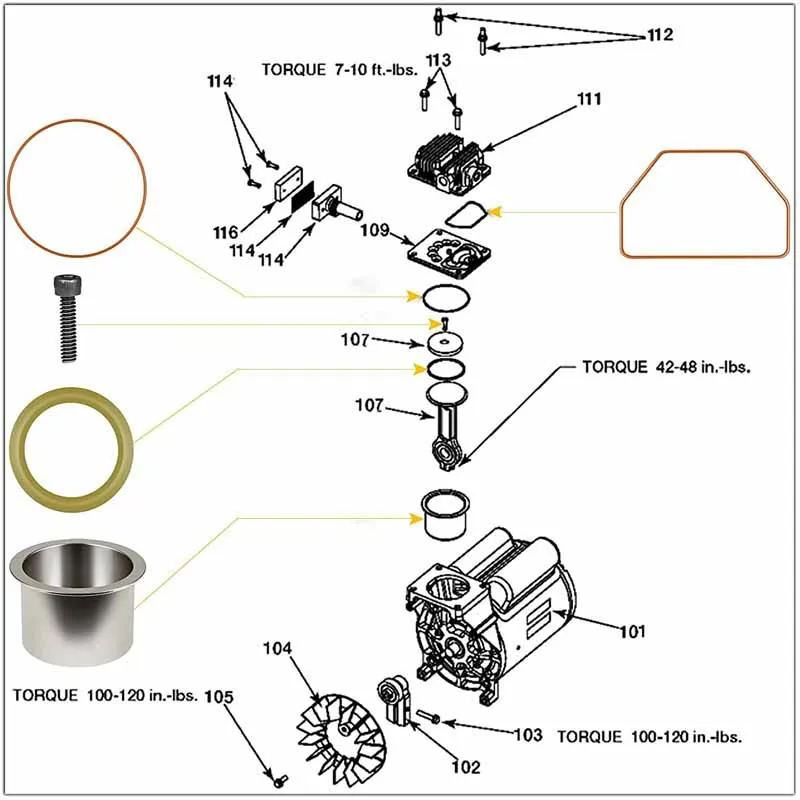

How the Motor Powers the Compressor

The motor is the central component responsible for converting electrical energy into mechanical motion. It provides the force required to drive the entire system, ensuring the pressure build-up necessary for efficient operation. By spinning the internal mechanisms, the motor allows the machine to perform its function, transforming energy into usable power for a variety of tasks.

Electrical input flows into the motor, where it is transformed into rotational energy. This rotational motion is then transferred to the core system components, ensuring that all parts work in harmony. Without the motor’s energy conversion process, the entire system would be unable to generate sufficient pressure.

The efficiency of the motor is crucial, as it directly impacts the performance of the overall system. Proper maintenance of the motor ensures smooth operation and prolongs the lifespan of the equipment, making it a key factor in reliable functionality.

Inspecting the Function of the Regulator

The regulator plays a crucial role in maintaining balanced pressure within the system. Over time, its functionality may degrade, affecting overall efficiency. Regular inspections ensure that the component performs at optimal levels, preventing malfunctions and potential damage to the entire setup. In this section, we will explore the key steps to evaluate the performance of this critical device.

Visual Examination

Start by visually inspecting the regulator for any signs of wear or damage. Look for cracks, corrosion, or signs of leakage around connections. Make sure that the adjustment knob moves smoothly and is not overly stiff or loose. This step helps identify potential problems that could impact pressure regulation.

Testing Output Levels

To test the output, you’ll need to connect the unit to a gauge and monitor the readings. Adjust the regulator knob and observe whether the pressure responds accurately. Fluctuations or failure to adjust may indicate that the regulator requires repair or replacement. Below is a simple guide to track testing results.

| Pressure Setting | Expected Output | Actual Output | Comments |

|---|---|---|---|

| Low | 5-10 PSI | ______ | ______ |

| Medium | 30-40 PSI | ______ | ______ |

| High | 60-70 PSI | ______ | ______

Air Filter Maintenance for Optimal Performance

Ensuring regular upkeep of the filtration component is crucial for maintaining peak functionality and extending the lifespan of the machinery. Over time, dust and debris can accumulate, reducing efficiency and potentially causing mechanical issues. Proper attention to this key element helps prevent blockages and ensures smooth operation, making it an essential part of the overall care routine. Inspection and CleaningFrequent checks are necessary to identify when the filter requires attention. Visible dirt or reduced airflow can be clear signs that cleaning or replacement is needed. Gently tapping or using compressed air to dislodge particles is an effective way to extend its usability. However, if there are signs of wear, replacement should be considered for optimal results. Replacement for Consistent PerformanceOver time, filters can lose their effectiveness even with regular cleaning. It’s important to replace them according to the manufacturer’s guidelines or whenever there is noticeable degradation in performance. A new filter ensures the system operates at its best, helping to maintain energy efficiency and reducing the risk of malfunctions. Understanding the Pressure Gauge MechanismThe pressure gauge is a critical component that helps monitor and regulate the system’s internal force levels. Its primary function is to ensure safe operation by providing accurate readings of the current pressure within the system. Understanding how this mechanism works can enhance efficiency and prevent potential issues. Inside the device, the gauge operates through a sensitive sensor that detects changes in pressure. As the internal pressure increases or decreases, the sensor translates these variations into readable values displayed on the dial. This process ensures precise control, allowing users to make adjustments when necessary for optimal performance. Regular inspection and maintenance of the gauge are essential for ensuring accurate readings. Over time, debris or mechanical wear can affect its accuracy. Therefore, keeping it clean and calibrated will help maintain consistent and safe operation. Compressor Pump: Core of the SystemThe pump serves as the fundamental element in the system, playing a crucial role in generating the necessary pressure for various applications. Its efficiency directly impacts the overall performance and reliability of the equipment, making it essential for users to understand its functions and maintenance requirements. Functionality and ImportanceThis component is responsible for converting mechanical energy into pneumatic energy, effectively compressing gas for storage or use. Its design and operation determine how well the system can achieve desired pressure levels while minimizing energy consumption. Regular inspection and timely servicing are vital to ensure longevity and optimal performance. Maintenance TipsTo prolong the lifespan of the pump, consider the following suggestions:

By adhering to these guidelines, users can maximize efficiency and prevent costly repairs, ensuring the smooth functioning of the entire system. The Role of the Check Valve in EfficiencyThe check valve plays a crucial part in optimizing performance by ensuring that flow is directed in a single direction. This functionality is essential in preventing backflow, which can lead to inefficiencies and loss of pressure. By maintaining a consistent direction of movement, this component significantly enhances overall operation. In systems where compression occurs, the check valve’s role is to allow the pressurized fluid to move forward while blocking any reverse flow. This mechanism not only aids in maintaining pressure levels but also contributes to energy conservation. When reverse flow is eliminated, the system can operate more effectively, reducing the need for frequent adjustments and allowing for smoother functionality. Moreover, the reliability of the check valve impacts the longevity of the entire system. By preventing potential leaks and ensuring that components remain intact, this valve helps in reducing wear and tear. As a result, users can expect improved durability and less frequent maintenance, leading to cost savings over time. Overall, the significance of the check valve cannot be understated. Its efficiency in controlling flow direction is integral to the optimal functioning of various systems, making it an indispensable component for anyone looking to enhance performance and reliability. Common Issues with the Drain ValveThe drain valve plays a crucial role in maintaining the functionality of the equipment, ensuring that moisture is effectively expelled. Over time, various complications can arise that may hinder its performance, leading to potential operational issues. Understanding these common problems can help in identifying and addressing them promptly, thereby enhancing the overall efficiency of the unit. Frequent LeaksOne of the most prevalent issues encountered with the drain valve is leaking. This can occur due to worn-out seals or improper tightening of the valve itself. Regular inspection is essential to catch leaks early and prevent moisture buildup, which can lead to more severe damage. Clogging and Blockages

Another common concern is clogging, which can happen as dirt, debris, and moisture accumulate over time. This blockage can restrict the proper drainage of condensate, resulting in increased pressure within the system. Maintaining a clean and clear valve is vital for optimal performance, as it ensures that the system operates efficiently without unnecessary strain. Maximizing Lifespan with Proper Part CareEnsuring the longevity of mechanical systems relies heavily on attentive maintenance and care. By adhering to best practices, individuals can significantly enhance the durability and efficiency of their equipment, ultimately leading to a more reliable experience. This section delves into essential strategies for maintaining components in optimal condition. Regular Inspection: Conducting frequent checks is crucial for identifying wear and tear early. By examining each element regularly, users can spot potential issues before they escalate into major problems. This proactive approach not only saves time and money but also enhances the overall performance of the machinery. Cleaning and Lubrication: Keeping components clean is vital for their functionality. Dust, debris, and moisture can cause premature failure. Regularly cleaning surfaces and applying appropriate lubricants can reduce friction and wear, ensuring smooth operation. Proper Storage: Storing machinery in a controlled environment protects it from extreme temperatures and humidity, which can adversely affect its components. Utilizing protective covers or enclosures can further shield it from dust and accidental damage. Following Manufacturer Guidelines: Adhering to the recommendations provided by the manufacturer is essential. These guidelines often include specific maintenance schedules and part replacement intervals, designed to optimize performance and lifespan. By implementing these practices, users can extend the life of their machinery, ensuring it operates at peak efficiency for years to come. |