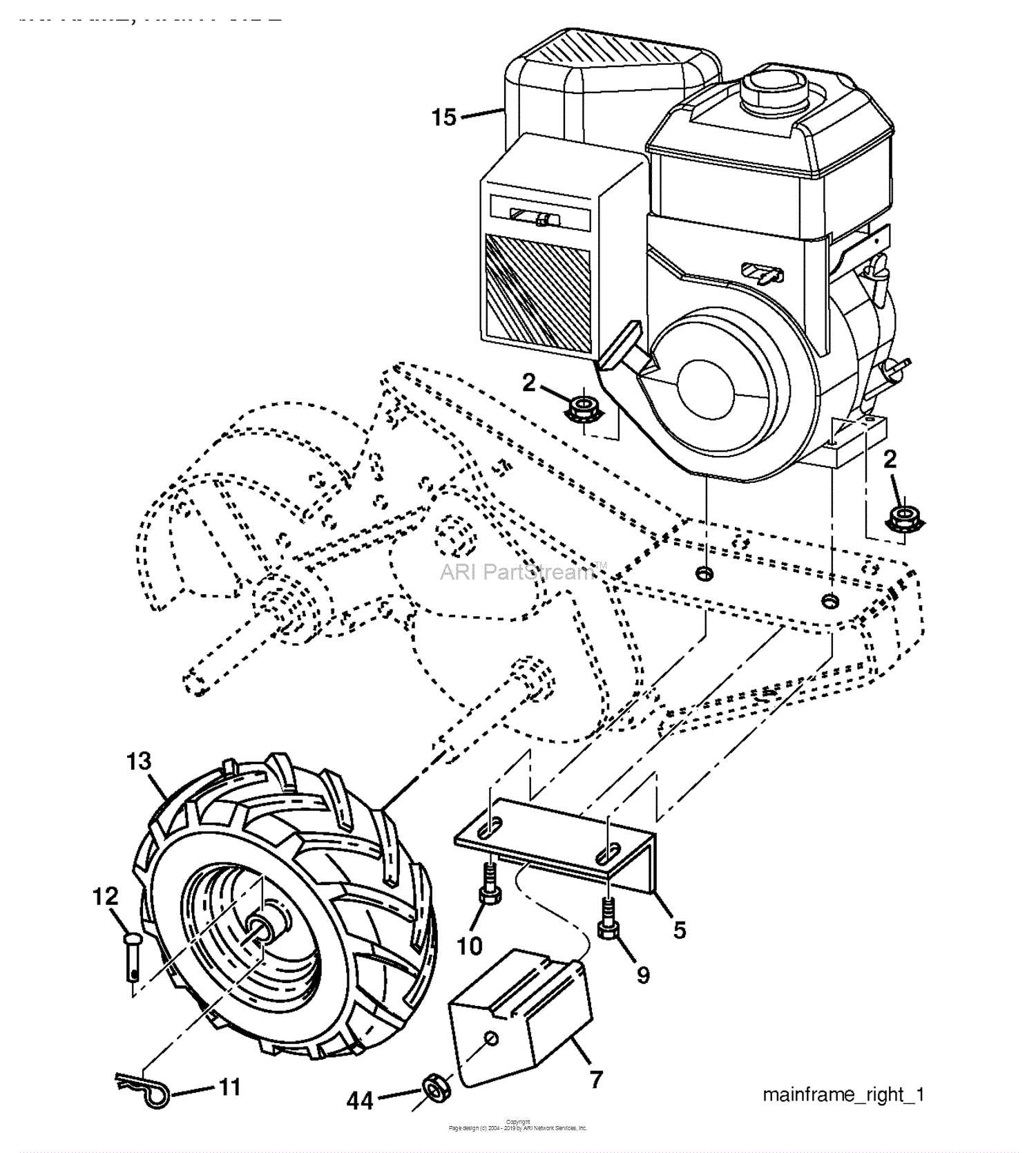

When maintaining or repairing a device, it’s crucial to understand how each element is arranged within the whole system. A clear layout of the individual elements ensures that you can easily identify, replace, or repair them without causing additional complications. Familiarity with this structure allows for more efficient troubleshooting and upkeep.

In this guide, we delve into the specifics of recognizing and interpreting visual layouts of mechanical elements. By analyzing the arrangement of key components, we provide insights that will help streamline the process of identifying necessary replacements and ensuring proper alignment.

Accurate visualization of these setups can save time and reduce the risk of errors. Whether you’re a seasoned technician or just starting, having access to well-structured layouts can make the task of repairs far more straightforward. Let’s explore how you can approach this with

Craftsman CMCST900 Parts Overview

Understanding the essential components of this versatile tool helps users maintain and operate it efficiently. The device is designed with various key elements that ensure optimal performance and longevity. This section provides a detailed look at its structure and functionality, allowing users to familiarize themselves with how each element contributes to its operation.

Main Structural Elements

The equipment is built with a durable frame that supports the motor and other critical mechanisms. These core elements include the shaft, handle, and cutting head, all of which play a significant role in its overall function. The alignment of these components ensures smooth operation, reducing wear and tear over time.

Performance Enhancing Features

In addition to its main components, the device includes several features that enhance its efficiency. These enhancements, such as the adjustable cutting head and ergonomic handle, allow for precise control and comfortable handling, making it easier to use for extended periods. Regular inspection and care of

Main Components Breakdown

In this section, we will explore the essential elements that make up the tool. Each part serves a specific purpose, working together to ensure efficient performance. Understanding how these components interact can help in maintaining the tool’s functionality and troubleshooting potential issues.

Core Elements Overview

- Motor Assembly: The heart of the tool, responsible for driving the system and powering all operations.

- Cutting Mechanism: This includes the blade or string responsible for performing the actual cutting or trimming task.

- Handle and Controls: Provides the user with control over the tool, allowing for precision and comfort during operation.

Additional Components

- Guard Shield: A protective element that prevents debris from being thrown back toward the operator.

- Power Source Connection: Whether battery-powered or corded, this component links the tool to its energy supply.

- Fastening System: Includes screws and clips that hold various parts together, ensuring stability and safety.

Detailed View of the Motor Assembly

The motor assembly plays a pivotal role in ensuring the tool’s performance and efficiency. Understanding the internal components of this mechanism helps in identifying potential issues and maintaining optimal operation over time. This section provides an overview of the key elements that make up the motor system and how they work together to drive the device effectively.

Key Components of the Motor System

- Rotor: The rotating part of the motor that interacts with the stator to generate movement.

- Stator: The stationary section that creates a magnetic field, enabling the rotor to spin.

- Brushes: Conductive parts that transfer electrical current to the motor’s moving parts.

- Bearings: These ensure smooth rotation of the rotor, reducing friction and wear.

How These Parts Work Together

-

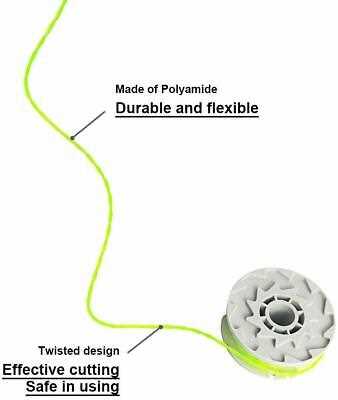

Trimmer Head and Line Spool Parts

The trimming mechanism relies on a complex combination of components designed to ensure smooth and effective cutting performance. The key element of this system is the trimming head, which works in tandem with the line spool to achieve precise results. Understanding how these parts function together can help in maintaining efficiency and extending the life of the tool.

Line Spool Assembly

The line spool holds the cutting line and is crucial for delivering a consistent trimming experience. Proper winding and feeding of the line from the spool ensure that the trimming remains even, allowing for clean and accurate cuts. Regular checks of the spool’s condition help avoid any interruptions during use.

Trimmer Head Mechanism

The trimming head secures the spool and houses the release mechanism for the line. Its design allows for easy reloading of the spool and quick adjustments during operation. Ensuring the trimmer head is properly aligned

Battery and Power System Components

The battery and power system play a crucial role in the efficiency and performance of any electric device. Understanding the key components of this system can help in maintaining and optimizing its functionality over time.

- Battery Pack: This is the main energy source that powers the entire system. It stores electrical energy and provides it when the tool is in operation.

- Charger: The charger is responsible for replenishing the battery when it runs out of power. Ensuring the proper functioning of this component is essential for prolonged use.

- Power Connector: This part links the battery to the motor or other essential components, allowing the flow of electricity through the system.

- Voltage Regulator: A regulator ensures that the appropriate amount of electrical current is distributed, preventing overloads and maintaining stable operation.

These components work together to provide a seamless power supply, ensuring the device operates efficiently for extended periods without interruptions.

Handle and Grip Assembly Details

The handle and grip components are designed to offer comfort and stability during operation. This section provides an overview of the individual parts that make up the assembly, highlighting their functions and how they work together to ensure a secure and ergonomic experience.

Main Components

- Handle Tube: The central element that connects to the shaft, offering a sturdy base for grip and control.

- Grip Cover: A soft, padded surface that enhances comfort and reduces hand fatigue during extended use.

- Control Trigger: Integrated into the grip, this allows for easy operation, giving the user immediate control over the device.

Assembly Process

- Align the handle tube with the shaft and securely fasten it into place using the provided fasteners.

- Slide the grip cover over the handle tube, ensuring it is snug and aligned properly for comfort.

- Attach the control trigger to the designated area on the grip for smooth operation.

Shaft and Coupling Parts Explanation

The shaft and coupling mechanism play a crucial role in ensuring the smooth transfer of power within mechanical systems. This section will provide an overview of how these components interact to facilitate effective energy transmission, as well as highlight their structural features and functionality. Understanding the key elements of this system helps in maintaining and optimizing the equipment’s performance over time.

Component Description Shaft The primary rod that transmits rotational force, connecting the power source to the driven part of the system. Coupling A connector that links two rotating shafts together, ensuring consistent movement and reducing the impact of misalignment. Bearing Support A structural component that provides stability to the shaft, reducing friction and wear. Joint Assembly A flexible section that allows slight angular movements between connected shafts, preventing excessive strain. Trigger and Switch Mechanism Overview

The trigger and switch system is a crucial component in various power tools, providing control over the device’s operation. This mechanism allows users to engage or disengage the tool’s functionality with ease, ensuring efficient and safe usage. Understanding the elements involved in this system is essential for proper maintenance and troubleshooting.

At the heart of this mechanism are the trigger and the switch, which work in tandem to regulate power flow to the tool. The trigger typically serves as the user interface, enabling quick activation, while the switch acts as the electrical gatekeeper, controlling the current delivered to the motor.

Component Function Trigger Initiates the tool’s operation when pressed. Switch Regulates electrical flow to the motor. Spring Returns the trigger to its resting position. Housing Protects the internal components from external damage. Maintaining the integrity of the trigger and switch mechanism is vital for optimal performance. Regular inspection for wear and tear can prevent operational failures and extend the life of the tool.

Guard and Safety Features Breakdown

Understanding the protective components and safety mechanisms of equipment is essential for ensuring user safety and optimal functionality. These features are designed to minimize the risk of accidents and injuries while enhancing the overall performance of the tool. In this section, we will explore various protective elements and safety attributes that contribute to secure operation.

Key Protective Elements

- Blade Guard: This component shields the cutting element, preventing accidental contact during operation.

- Safety Switch: A crucial feature that requires intentional engagement to activate the device, reducing the likelihood of unintended use.

- Overload Protection: This mechanism automatically shuts off the equipment if it detects excessive load, preventing potential damage or injury.

Enhanced Safety Mechanisms

- Emergency Stop: An easily accessible button that halts the operation immediately in case of an emergency.

- Vibration Dampening: Reduces hand fatigue and minimizes the risk of loss of control during prolonged use.

- Instructional Labels: Clear guidelines and warnings that provide essential information about safe operation and maintenance.

Implementing these features not only promotes user confidence but also encourages responsible usage, leading to a safer working environment.

Replacement Parts for Wear and Tear

Over time, tools can experience a decline in performance due to regular usage, leading to the need for specific components to maintain their efficiency. Identifying and replacing these elements is crucial to ensure the longevity and effectiveness of your equipment. Understanding which items are most susceptible to degradation can guide you in making informed decisions about maintenance and replacement.

Here are some common components that may require attention:

Component Symptoms of Wear Replacement Frequency Blades Dullness, reduced cutting efficiency Every 20-30 uses Batteries Decreased run time, slow charging Every 1-2 years Filters Clogs, reduced airflow Every 6 months Belts Fraying, noise during operation Every 1-3 years Casings Cracks, loose parts As needed Regular inspections and timely replacements of these key elements can help maintain optimal functionality and prevent unexpected breakdowns, ensuring your tools remain reliable for years to come.

How to Identify the Correct Parts

Determining the right components for your equipment can significantly enhance its performance and longevity. Understanding how to accurately identify and select the necessary elements ensures that you maintain the functionality of your device while avoiding potential issues that could arise from incorrect replacements. This guide provides an overview of effective strategies to recognize the required items.

Step-by-Step Identification Process

To streamline the identification process, follow these essential steps:

- Consult the user manual for specifications.

- Examine the existing components for model numbers and identifying marks.

- Utilize online resources or community forums for additional guidance.

Utilizing a Reference Table

A reference table can be a valuable tool for comparing various components and understanding their functionalities. Below is a sample table showcasing common elements and their descriptions:

Component Name Description Common Issues Blade The sharp edge used for cutting. Dullness, nicks, or bends. Handle The part that is held during operation. Cracks, breaks, or looseness. Motor The engine that powers the equipment. Overheating or unusual noises. By following these steps and utilizing reference tools, you can confidently identify the necessary components to keep your equipment running smoothly.

Maintenance Tips for Key Components

Regular upkeep of essential elements in any equipment is crucial for ensuring optimal performance and longevity. Proper maintenance can prevent unexpected failures and enhance efficiency, leading to a smoother operation. Below are some practical suggestions for keeping your equipment in top condition.

Cleaning and Inspection

Maintaining cleanliness is vital. Ensure that all parts are free from debris and residue, which can hinder functionality. Conduct regular inspections to identify wear and tear early. Look for signs of corrosion or damage, and replace any worn components promptly to avoid further issues.

Lubrication Practices

Applying the right lubricant to moving parts minimizes friction and wear. Choose a high-quality lubricant suitable for the specific materials involved. Regularly check the lubrication levels and reapply as needed, particularly in areas that experience high levels of movement.

Remember: Consistent attention to these areas will significantly improve the overall performance and lifespan of your equipment.

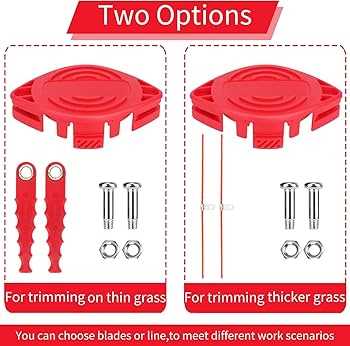

Upgrading or Modifying Your Trimmer

Enhancing your gardening tool can significantly improve its performance and efficiency. Whether you aim to boost power, increase versatility, or simply tailor it to your specific needs, various modifications can make a noticeable difference in your trimming experience. Understanding the available options allows you to make informed decisions that align with your gardening tasks.

Performance Enhancements

One popular approach to upgrade your tool is by replacing the motor with a more powerful alternative. This modification can lead to improved cutting speed and efficiency, allowing you to tackle thicker vegetation with ease. Additionally, consider upgrading the cutting head or using specialized blades that cater to different types of foliage, ensuring optimal performance for various tasks.

Ergonomic Improvements

Another aspect to consider is the comfort and usability of your equipment. Modifying the handle for better grip or adding cushioning can reduce fatigue during prolonged use. Furthermore, adjustable shafts can enhance maneuverability, making it easier to reach difficult areas without straining your body. Investing in ergonomic upgrades not only enhances your gardening experience but also contributes to your overall productivity.