When delving into the intricate mechanisms of a garden cultivation machine, it’s essential to comprehend the various elements that contribute to its efficient operation. Each component plays a pivotal role, ensuring that the tool functions seamlessly while enhancing soil preparation.

This section aims to provide a detailed overview of the essential components, showcasing how they interconnect and contribute to the overall performance of the machine. By exploring the functionality of each part, users can better appreciate the design and engineering that go into creating a reliable gardening implement.

Whether you’re a seasoned gardener or a newcomer to cultivation, understanding these components not only aids in maintenance and repair but also empowers you to make informed decisions regarding usage and upgrades. Knowledge of these elements enhances your gardening experience, allowing for more effective soil management and improved plant growth.

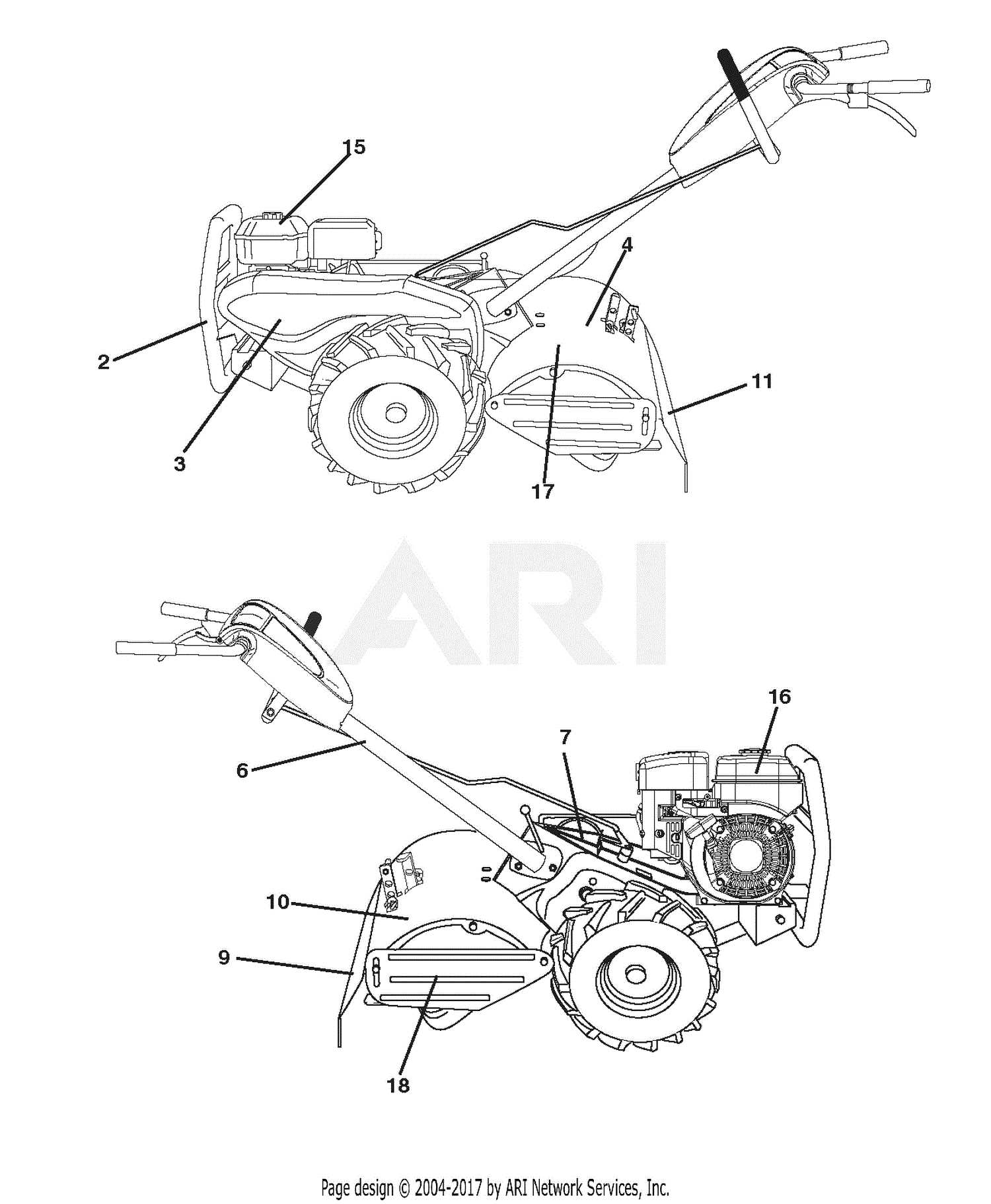

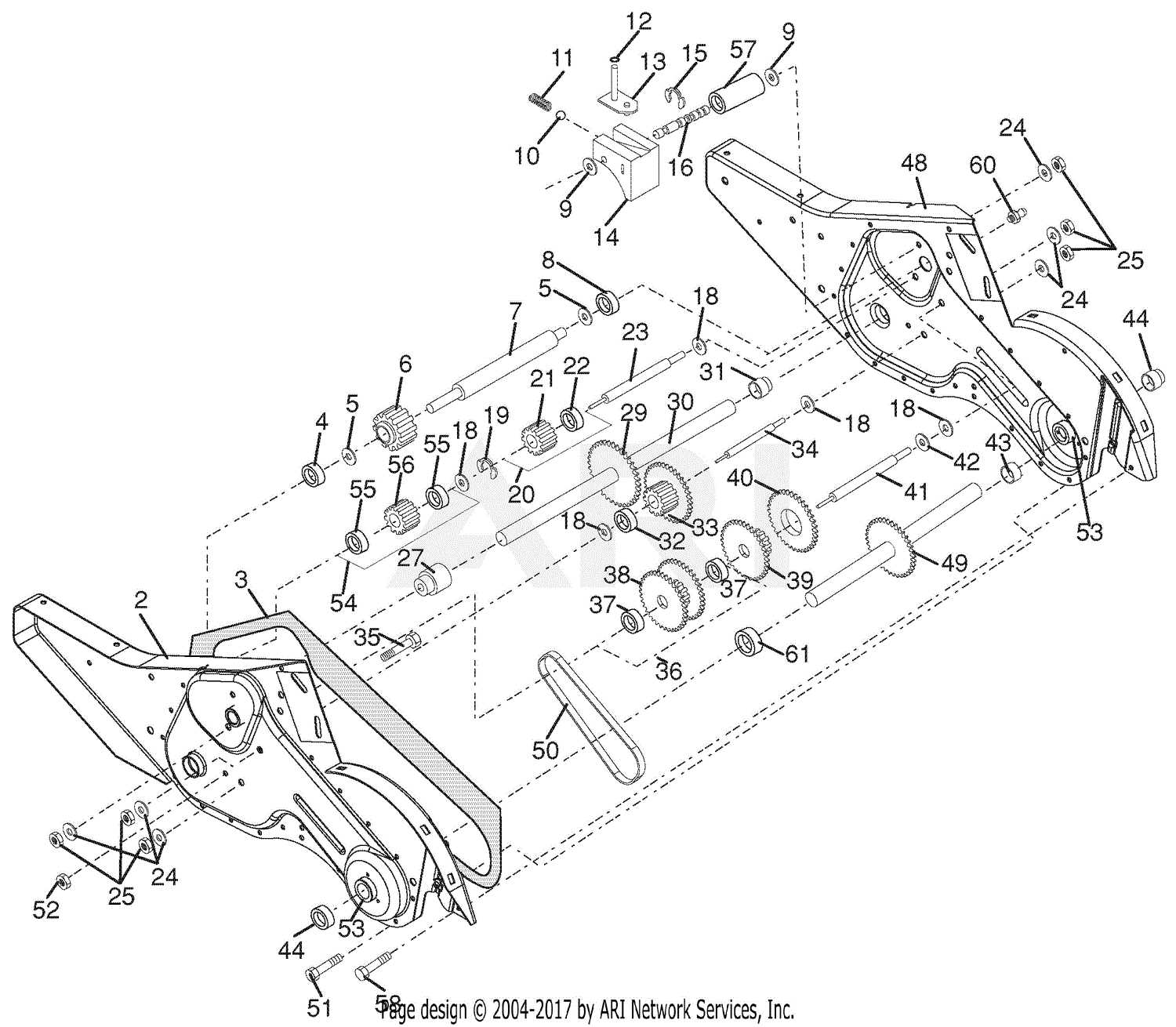

Understanding Tiller Components Overview

This section provides a comprehensive overview of the essential elements that constitute a soil cultivation machine. Each component plays a vital role in the overall functionality and efficiency of the equipment, contributing to its performance in preparing the ground for planting.

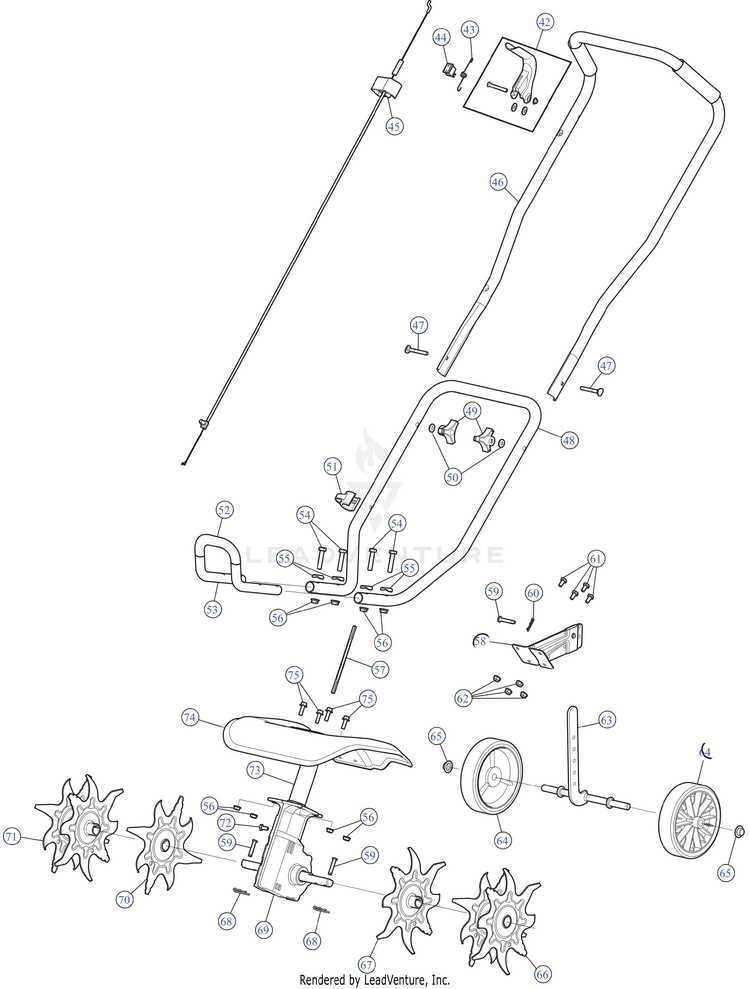

Key components include:

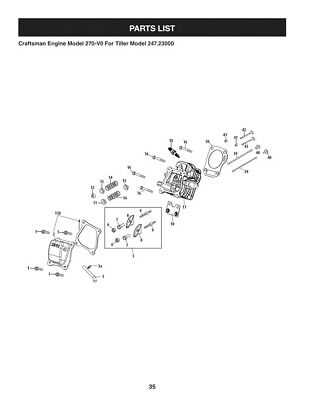

- Engine: Powers the entire machine, enabling it to perform its tasks effectively.

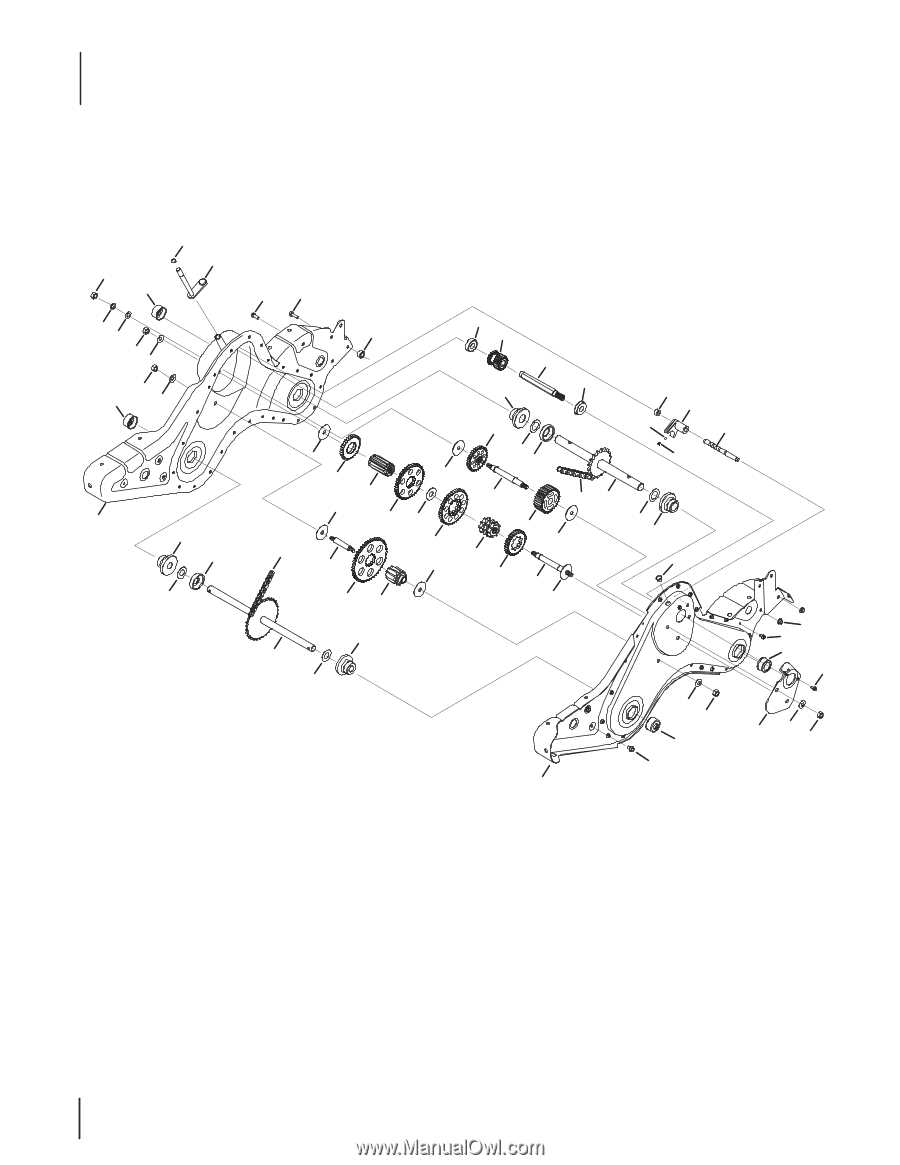

- Transmission: Transfers power from the engine to the working parts, allowing for speed adjustments.

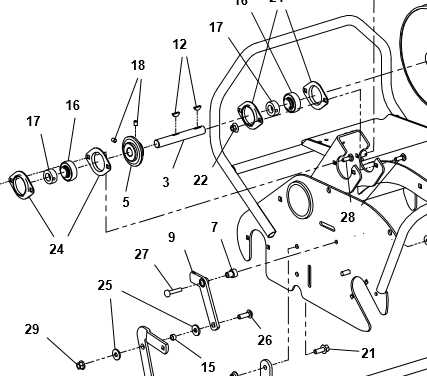

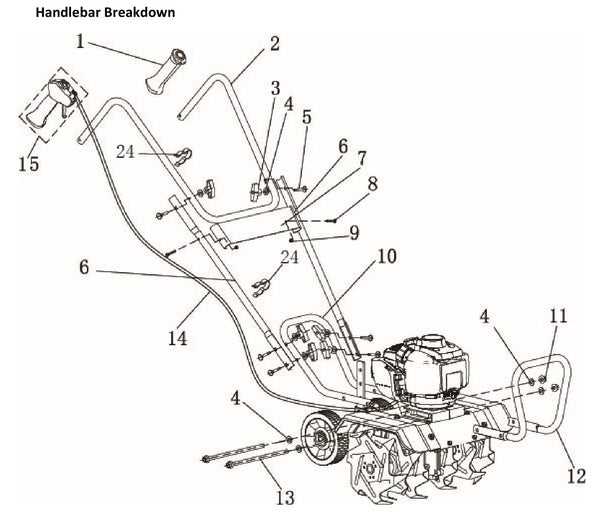

- Handlebars: Provide the operator with control and maneuverability while operating the device.

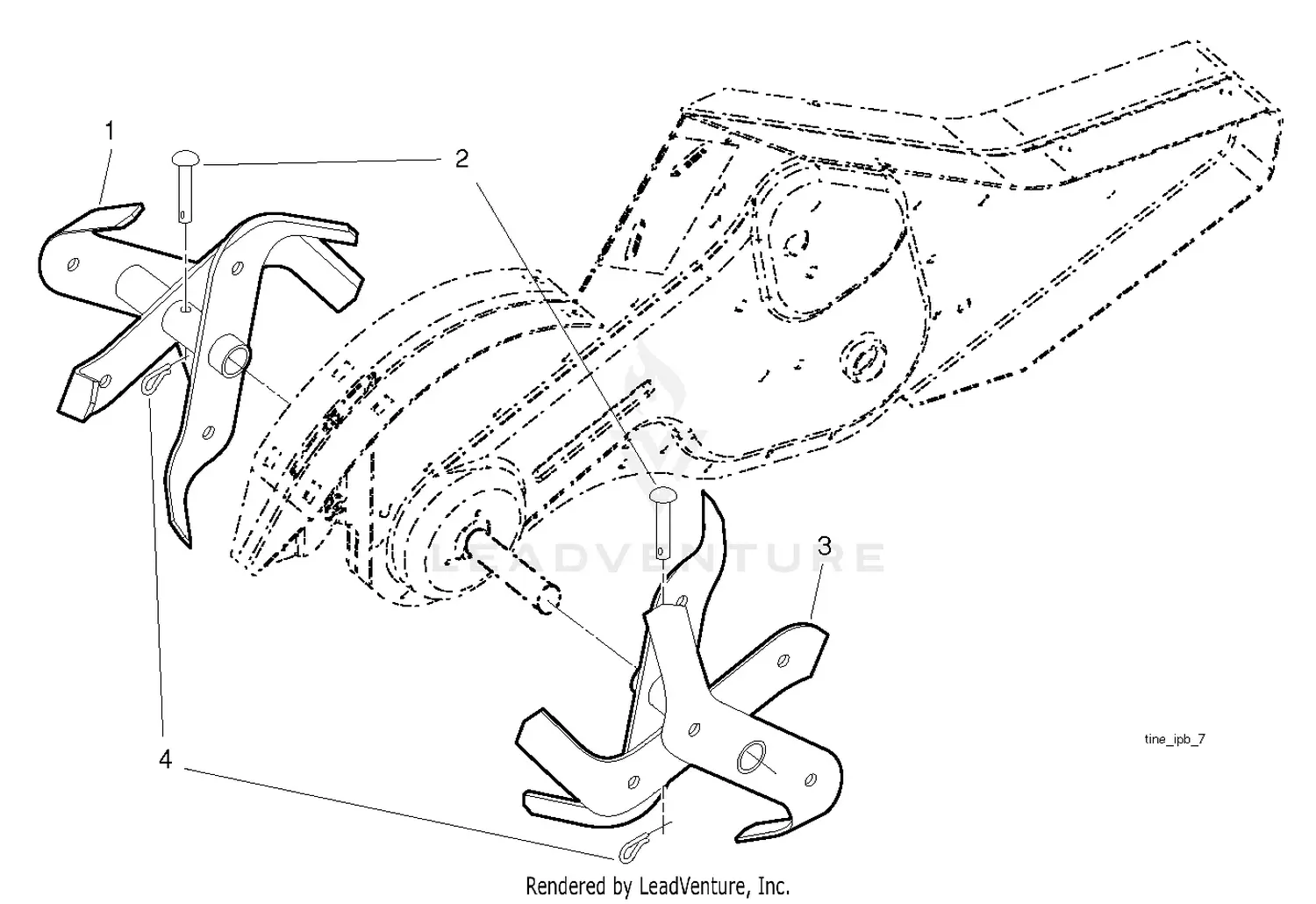

- Blades: The primary working tools that break up and aerate the soil, promoting healthy plant growth.

- Frame: The sturdy structure that houses all components, ensuring durability and stability during operation.

Understanding these fundamental parts enhances the user’s ability to maintain, repair, or replace components as needed, ensuring optimal operation throughout the equipment’s lifespan.

Essential Functions of Tiller Parts

Understanding the core functions of different components in soil cultivation equipment is crucial for effective operation and maintenance. Each element plays a specific role in enhancing performance, contributing to overall efficiency during agricultural tasks.

Key Components and Their Roles

- Blades: These sharp edges are designed to cut through the soil, breaking it apart and creating a fine texture suitable for planting.

- Drive System: This mechanism transfers power from the engine to the working elements, ensuring smooth movement and operation.

- Handlebar: Providing stability and control, the handlebar allows the operator to maneuver the equipment easily across various terrains.

Additional Functionalities

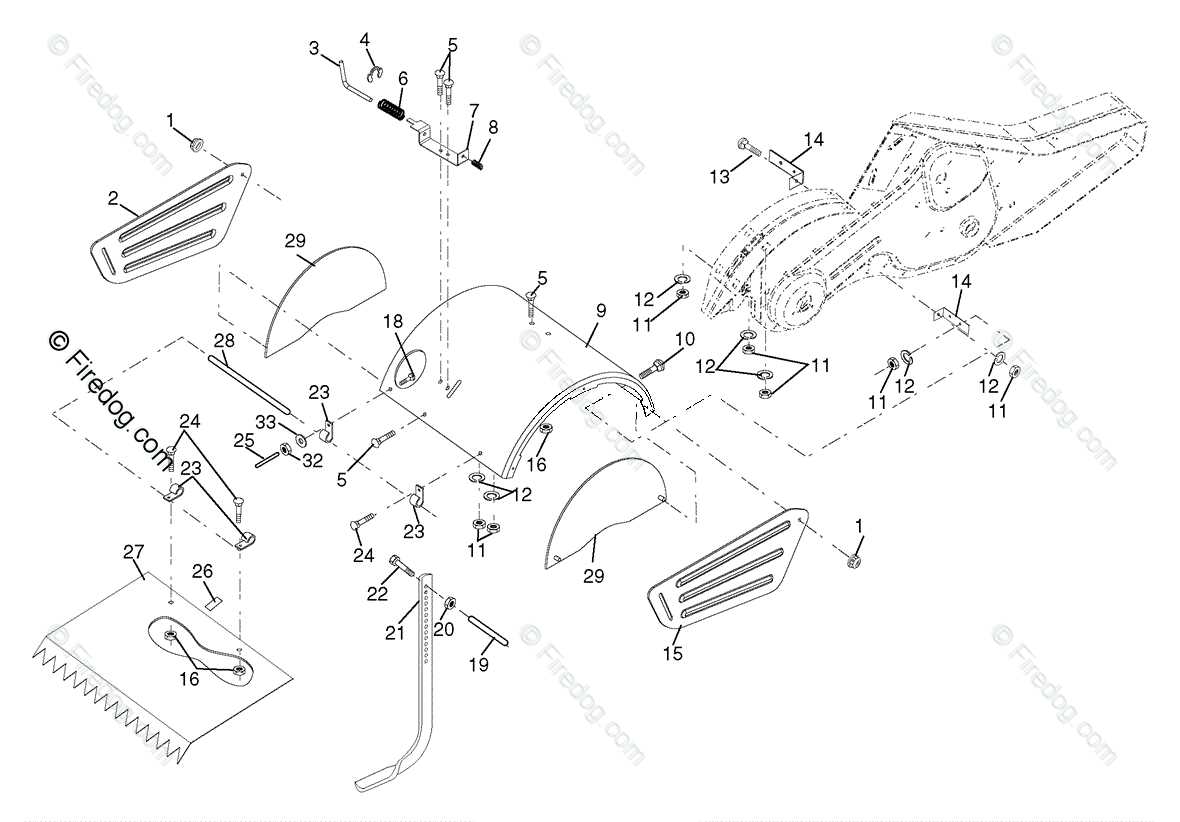

- Depth Adjustment: Many models offer mechanisms to control the working depth, allowing for customization based on soil type and crop needs.

- Weight Distribution: Properly designed components ensure balanced weight distribution, enhancing traction and minimizing operator fatigue.

Each element is integral to the equipment’s ability to cultivate soil effectively, making understanding their functions vital for any user.

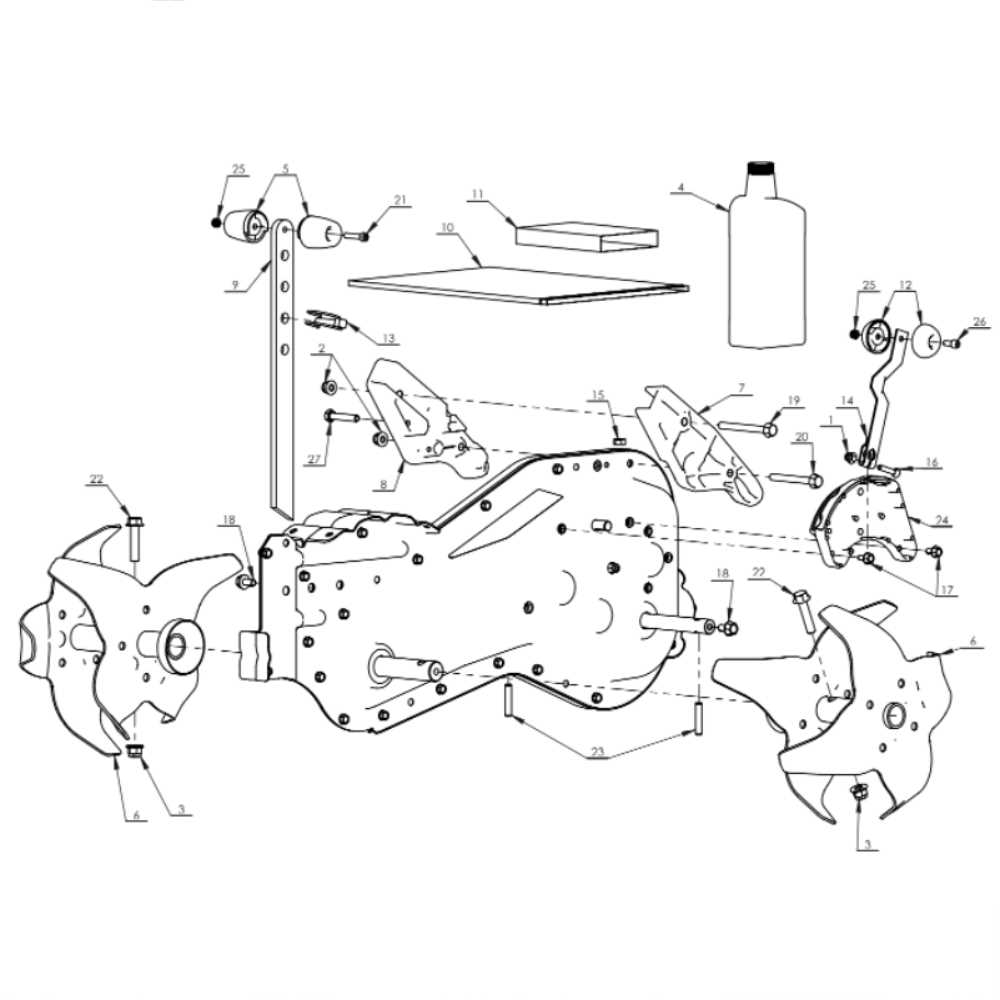

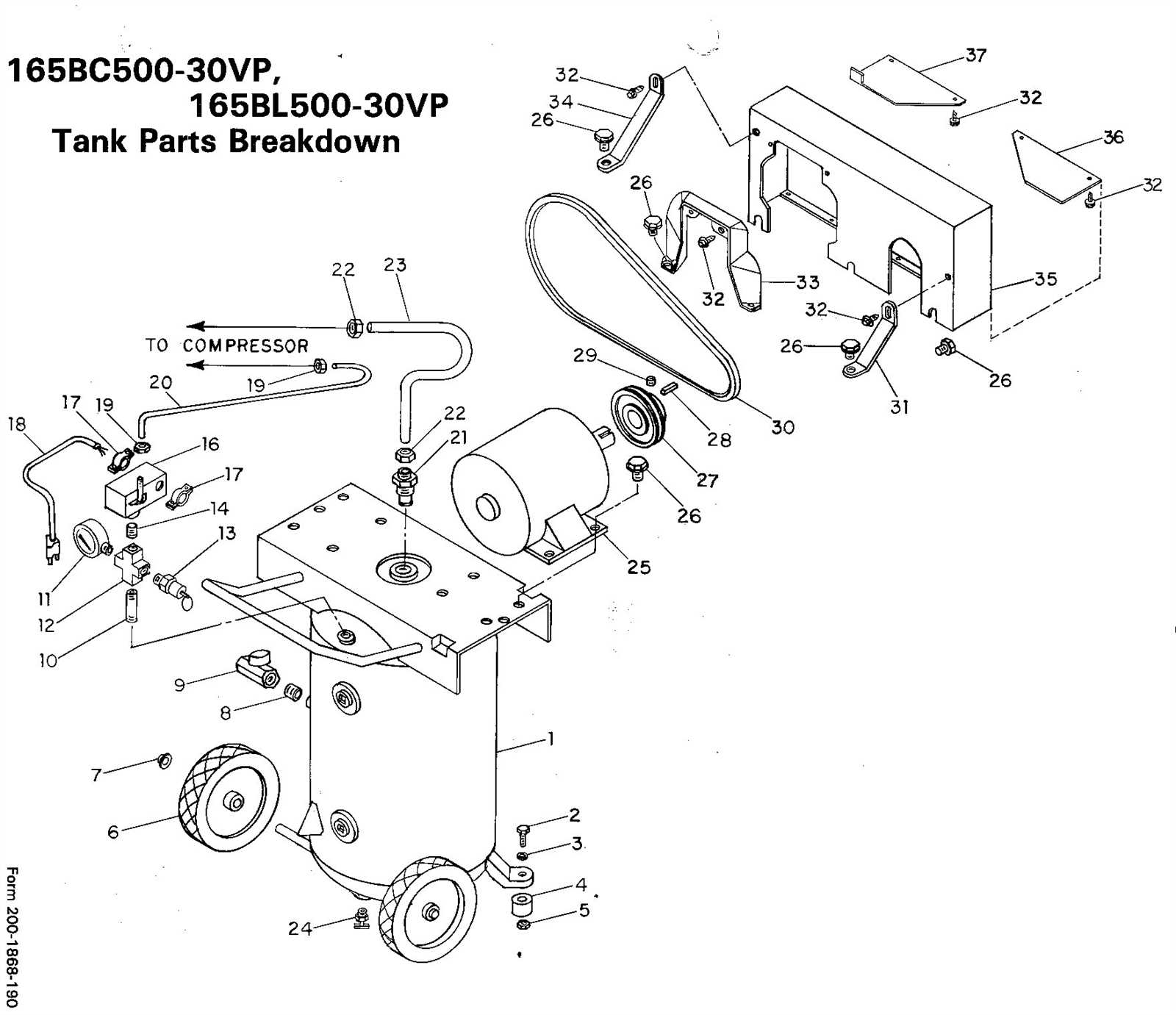

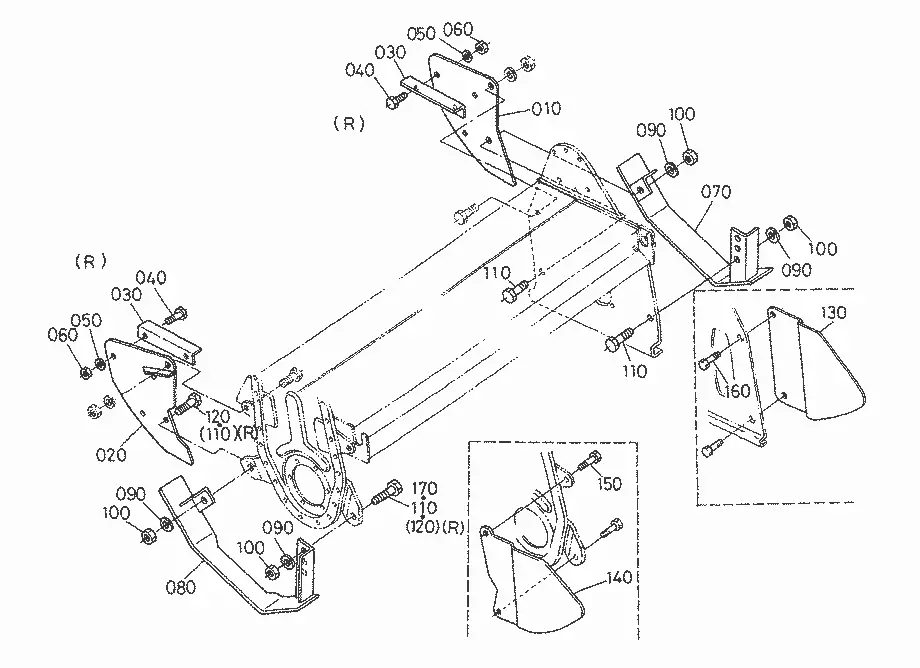

Identifying Major Mechanical Elements

Understanding the primary components of gardening machinery is essential for effective maintenance and operation. These elements play crucial roles in ensuring optimal performance, enabling users to efficiently cultivate soil and prepare it for planting.

- Engine: The heart of the equipment, responsible for generating power.

- Transmission: This system transfers power from the engine to the moving parts, allowing for adjustable speeds and maneuverability.

- Rotors: Essential for breaking up the soil, these rotating blades facilitate thorough tilling.

- Handlebars: These provide control and stability during operation, allowing for precise navigation.

- Wheels: Supporting mobility, the wheels help transport the machine across various terrains.

Each of these components works synergistically, contributing to the overall functionality and efficiency of the equipment. Familiarity with these mechanical parts not only aids in troubleshooting but also enhances the user’s ability to perform necessary repairs and adjustments.

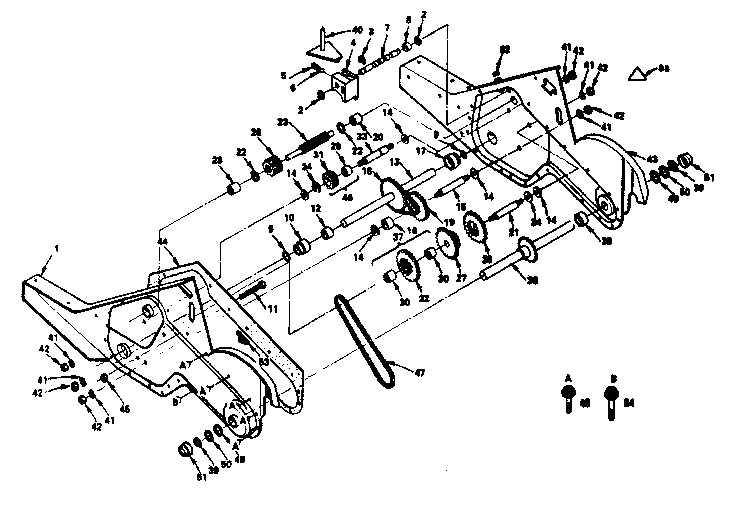

Benefits of a Rear Tine Design

The design that features a rotating mechanism positioned at the back offers several advantages for soil cultivation tasks. This configuration allows for improved maneuverability and efficient mixing of soil, making it ideal for various gardening projects.

Enhanced Soil Aeration

One of the primary benefits is the enhanced aeration of the soil. The backward rotation creates a fluffier texture, allowing air and nutrients to penetrate deeper, which is essential for healthy plant growth.

Increased Stability

The setup promotes greater stability during operation, reducing the likelihood of tipping over on uneven surfaces. This stability ensures a more consistent and thorough cultivation experience, making it easier for users to achieve their gardening goals.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any gardening equipment. Regular attention not only enhances performance but also prevents unexpected breakdowns. Implementing simple maintenance routines can make a significant difference in the durability of your machinery.

Start by routinely checking and replacing worn or damaged components. This proactive approach minimizes the risk of more extensive repairs down the line. Clean the machine after each use to remove debris and soil, which can lead to corrosion and mechanical issues.

Additionally, ensure that all moving parts are well-lubricated. Using the right lubricants will reduce friction and wear, thereby improving efficiency. It’s also wise to inspect belts and cables for signs of wear and to replace them as needed to maintain optimal functionality.

Finally, store your equipment in a dry, sheltered location to protect it from the elements. Proper storage conditions help prevent rust and damage, ensuring that your machinery remains in top shape for future gardening tasks.

Common Issues and Solutions

When operating a gardening machine, various problems may arise that can hinder performance and efficiency. Identifying these issues early and applying appropriate fixes can significantly enhance the longevity and functionality of the equipment.

-

Engine Won’t Start:

This is a frequent concern for users. Possible causes include a faulty spark plug or an empty fuel tank. Checking the spark plug for damage and ensuring there is adequate fuel can often resolve this issue.

-

Ineffective Digging:

If the machine struggles to penetrate the soil, the blades may be dull or damaged. Inspecting and sharpening or replacing the blades can restore effectiveness.

-

Excessive Vibration:

Excessive shaking can indicate loose bolts or misalignment. Regularly tightening all fasteners and ensuring proper alignment can mitigate this problem.

-

Overheating:

Machines may overheat due to blocked air vents or insufficient lubrication. Cleaning the air intake and ensuring proper oil levels are essential steps to prevent overheating.

-

Strange Noises:

Unusual sounds can signal internal issues or worn components. Conducting a thorough inspection and replacing any damaged parts can help eliminate these noises.

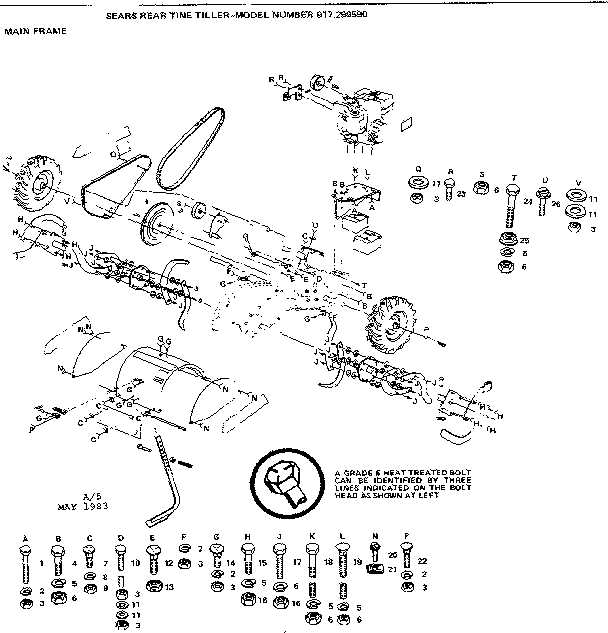

How to Replace Worn Components

Maintaining the efficiency of your gardening equipment is crucial for optimal performance. When specific elements become worn out, it’s essential to know how to replace them effectively to ensure the machinery operates smoothly. This guide will provide step-by-step instructions for identifying and substituting these components, enhancing the longevity and functionality of your tools.

Identifying Worn Parts

Before proceeding with any replacements, inspect your equipment thoroughly. Look for signs of wear, such as cracks, rust, or excessive wear on moving parts. Common areas that may require attention include belts, blades, and wheels. Regular checks can prevent more significant issues down the line.

Replacement Process

Once you’ve identified the worn components, follow these steps for a successful replacement:

| Step | Description |

|---|---|

| 1 | Disconnect the equipment from the power source to ensure safety. |

| 2 | Remove the damaged component using appropriate tools. |

| 3 | Install the new part by following the manufacturer’s instructions, ensuring a secure fit. |

| 4 | Reconnect the power source and perform a test run to verify proper operation. |

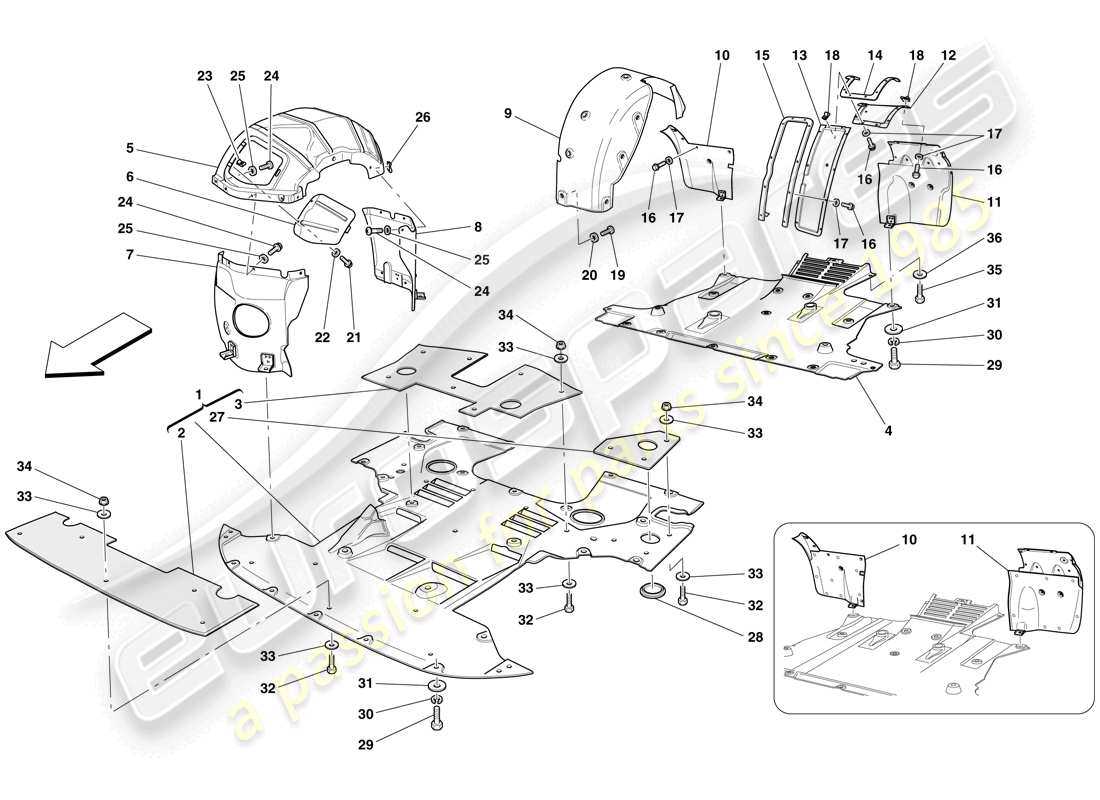

Exploring Attachment Options Available

When it comes to enhancing the functionality of your cultivation equipment, understanding the various accessories can greatly expand its versatility. Attachments can assist in a range of tasks, allowing users to tackle different gardening and landscaping challenges more efficiently.

Types of Attachments

- Plows: Ideal for breaking new ground and turning soil.

- Seeders: Perfect for planting seeds evenly and efficiently.

- Weeders: Help manage weeds while preserving the surrounding plants.

- Fertilizer Spreaders: Ensure even distribution of nutrients across the garden.

Benefits of Using Attachments

- Increased productivity by completing multiple tasks with a single machine.

- Cost-effectiveness by reducing the need for additional equipment.

- Customization to fit specific gardening needs and preferences.

Assembly Instructions for Beginners

Assembling equipment can be a rewarding experience, especially for those new to the craft. Understanding the basic components and their arrangement is essential for effective operation. This guide aims to provide clear steps to facilitate the assembly process, ensuring everything fits together seamlessly.

Essential Tools Required

Before starting the assembly, gather the necessary tools. Here is a list of items you will need:

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten bolts and screws |

| Screwdriver | For securing various components |

| Pliers | To hold or manipulate parts |

| Level | Ensures stability during assembly |

Step-by-Step Assembly Process

Follow these simple steps to ensure a successful assembly:

- Begin by laying out all components to familiarize yourself with each piece.

- Start with the base structure and secure the main frame using the appropriate hardware.

- Attach the functional elements, ensuring each piece is aligned correctly.

- Double-check all connections and tighten as necessary to ensure stability.

- Finally, perform a thorough inspection to confirm everything is securely fastened.

Safety Precautions During Operation

Ensuring safety while using garden machinery is essential to prevent accidents and injuries. Operators must adhere to specific guidelines to create a secure working environment. Understanding the equipment and its functions is a critical first step in promoting safety.

Always wear protective gear, including gloves, safety glasses, and sturdy footwear. This attire can significantly reduce the risk of injury from debris or unexpected machine movements. Additionally, long hair should be tied back to avoid entanglement with moving parts.

Before starting, inspect the area for obstacles, children, or pets. A clear workspace minimizes the chance of mishaps during operation. Ensure that all safety shields and guards are properly in place to protect from flying objects and mechanical hazards.

During operation, maintain a firm grip on the controls and stay alert to your surroundings. Avoid distractions and never operate the machinery under the influence of alcohol or drugs. Regular maintenance of the equipment is also vital to ensure its safe functionality.

Recommended Tools for Repairs

When tackling repairs on gardening machinery, having the right equipment is essential for efficiency and effectiveness. Utilizing appropriate tools not only simplifies the process but also ensures that the task is completed safely and accurately. Below are some indispensable instruments that can aid in maintenance and repairs.

Basic Hand Tools

Every repair kit should include fundamental hand tools such as wrenches, screwdrivers, and pliers. These items are crucial for loosening or tightening various components, allowing for smooth disassembly and reassembly. A set of adjustable wrenches can accommodate different sizes of fasteners, making them versatile for various tasks.

Specialized Equipment

In addition to basic tools, specialized equipment like socket sets and torque wrenches can significantly enhance repair precision. Socket sets provide the necessary reach and grip for stubborn bolts, while torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.