In the realm of machinery maintenance, comprehending the intricate details of individual elements is crucial for optimal performance. This section aims to illuminate the various sections that constitute your device, enabling a deeper appreciation of its functionality.

Identifying each component not only enhances the efficiency of repairs but also ensures longevity. Familiarity with these intricate parts can ultimately lead to more informed decisions during maintenance procedures.

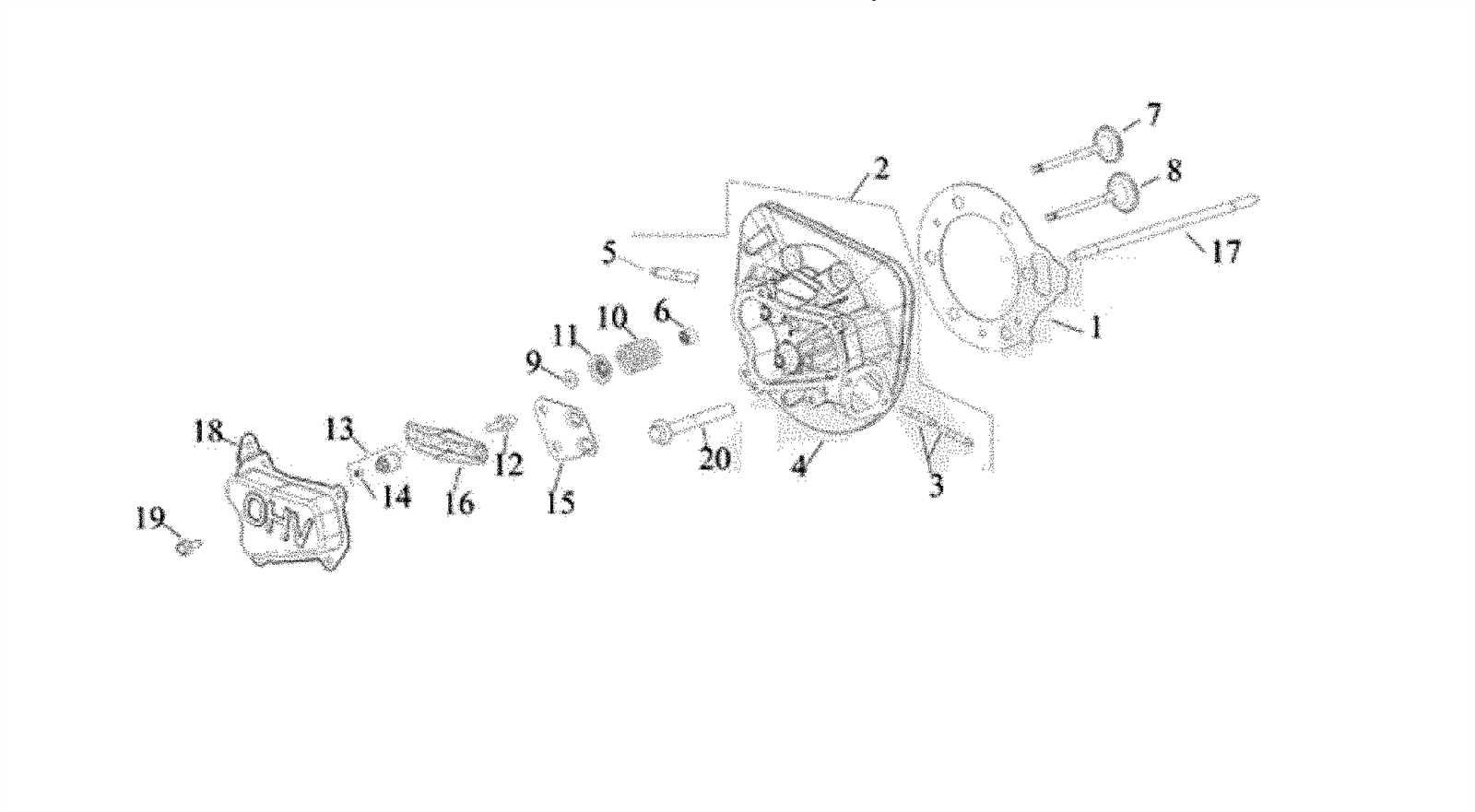

Furthermore, having a visual representation of these components fosters a clear understanding of their interrelations. This knowledge empowers users to delve into troubleshooting with confidence, making the process smoother and more effective.

Understanding Craftsman T210 Overview

This section provides an insightful look into a specific type of machinery known for its durability and functionality. Exploring its features, design, and components offers a comprehensive understanding of its capabilities and advantages in various applications.

Key Features

- Robust construction for enhanced longevity

- Efficient performance suited for a range of tasks

- User-friendly design promoting ease of operation

Benefits of Usage

- Reliable outcomes in diverse projects

- Reduced maintenance requirements

- Cost-effectiveness over time due to durability

Importance of Parts Diagrams

Understanding the intricate layout of components in any machinery is crucial for effective maintenance and repair. These visual representations serve as invaluable resources, allowing users to identify and locate essential elements quickly. This clarity not only facilitates smoother troubleshooting but also enhances the overall efficiency of any restoration efforts.

Moreover, having access to these illustrations significantly reduces the risk of errors during assembly or disassembly. Users can delve into the specifics of each segment, ensuring that all pieces are correctly positioned and functional. This attention to detail ultimately leads to a longer lifespan for the equipment and fewer costly mistakes.

In addition, these resources promote better understanding among technicians and hobbyists alike. By providing a clear visual guide, they foster a deeper comprehension of how various elements interact. This knowledge empowers individuals to tackle repairs with confidence, ultimately enhancing their skills and expertise.

Key Components of Craftsman T210

Understanding the essential elements of this machine is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, ensuring that it operates smoothly and efficiently.

Engine and Transmission

The engine serves as the powerhouse, delivering the necessary energy to propel the device. Coupled with a reliable transmission, it ensures seamless movement and speed control, making tasks easier and more effective.

Chassis and Wheels

The robust chassis provides structural integrity, supporting various components while enhancing durability. Complemented by sturdy wheels, this design enables superior maneuverability on different terrains, ensuring a smooth operation during use.

How to Interpret Diagrams

Understanding visual representations of complex structures is essential for effective assembly and repair. These illustrations serve as guides, detailing components and their relationships, helping users to navigate through intricate processes with clarity. By familiarizing oneself with the symbols and notations used, one can significantly enhance their proficiency in interpreting these visuals.

Familiarizing with Symbols

Every illustration employs specific symbols to denote various elements. Learning what each symbol represents is crucial. For instance, circles may indicate connection points, while arrows often show movement or direction. By mastering these representations, individuals can more easily follow the intended assembly sequence and troubleshoot issues that may arise.

Understanding Connections and Relationships

Beyond individual symbols, recognizing how components interact is vital. Lines and arrows often depict the connections between parts, indicating how they fit together or function in relation to one another. Analyzing these relationships allows for a deeper comprehension of the entire system, enabling more effective repairs or modifications.

Common Issues with T210 Parts

When it comes to equipment maintenance, several common problems can arise with specific components. These issues often stem from wear and tear, improper installation, or lack of routine care. Understanding these challenges is crucial for ensuring longevity and optimal performance.

One frequent concern involves the deterioration of mechanical elements, which may lead to reduced efficiency or functionality. Users often encounter difficulties with alignment and fit, resulting in operational setbacks. Additionally, neglecting regular inspections can exacerbate these problems, making timely identification essential.

Another prevalent issue is the accumulation of debris and residue, which can hinder smooth operation. Proper cleaning and maintenance practices can mitigate this risk, promoting better performance and extending the lifespan of the equipment. Addressing these challenges proactively can ultimately save time and resources.

Replacement Parts Availability

When maintaining outdoor equipment, ensuring access to suitable components is essential for optimal performance. Availability of these items can significantly affect the longevity and efficiency of your machinery. Understanding where to find quality replacements can streamline repairs and reduce downtime.

Local Retailers: Many physical stores stock essential items, allowing for quick purchases. Checking with nearby hardware or specialty shops can yield immediate results.

Online Marketplaces: The internet offers a vast array of options. Numerous e-commerce platforms specialize in supplying a wide variety of components, often with user-friendly search tools to help locate the desired items.

Manufacturer’s Website: Official manufacturer sites frequently provide detailed catalogs of available components. Utilizing these resources ensures compatibility and quality assurance.

Second-Hand Options: For those looking for budget-friendly alternatives, exploring second-hand markets can be beneficial. Many users sell gently used items that can still perform effectively.

Overall, knowing where to locate quality replacements will enhance the maintenance process and extend the life of your equipment.

Tools Needed for Maintenance

Proper upkeep of your equipment requires a selection of essential implements. These tools not only facilitate repairs but also enhance performance, ensuring longevity and reliability. Being equipped with the right items can make maintenance tasks more efficient and less daunting.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for various tasks. Wrenches are crucial for loosening or tightening bolts, while screwdrivers assist in securing screws. Pliers are versatile, aiding in gripping and bending tasks.

Safety Equipment

Safety should never be overlooked. Items like gloves and safety goggles protect against injuries while performing maintenance. Additionally, having a first aid kit nearby is a wise precaution for any unforeseen incidents.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring equipment efficiently. Following a systematic process ensures that all components are examined and replaced if necessary, leading to optimal performance. Here, we will outline a clear method that can be applied to various types of machinery.

Preparation

Before starting any repair work, gather the necessary tools and materials. Make sure to disconnect the equipment from its power source to ensure safety during the process. A clean, well-lit workspace is essential for effective repairs.

Inspection and Replacement

Begin by examining the unit closely for any signs of wear or damage. Identify components that require replacement. For clarity, refer to the following table which lists common issues and their corresponding replacement parts.

| Issue | Recommended Action |

|---|---|

| Worn belt | Replace with a new one |

| Faulty spark plug | Install a new spark plug |

| Clogged air filter | Clean or replace |

| Damaged blade | Sharpen or replace |

Once the necessary parts are acquired, proceed with the installation, ensuring that each component is secured properly. After completing the repairs, reconnect the power source and test the machinery to confirm that it operates smoothly.

Tips for Ordering Parts

When it comes to acquiring components for your equipment, ensuring a smooth ordering process can save you time and effort. By following a few simple guidelines, you can make certain that you receive the correct items promptly and efficiently. Here are some helpful suggestions to streamline your ordering experience.

Identify the Specific Component Needed

Before placing an order, it’s crucial to pinpoint the exact piece you require. Take the time to consult any available documentation or resources that outline the specifications and functionalities of the item. This will help you avoid purchasing the wrong piece and ensure that it fits seamlessly into your system.

Check Availability and Pricing

Once you know what you need, explore various suppliers to compare availability and costs. Consider checking both local stores and online retailers. Look for reviews and ratings to gauge the reliability of each vendor. Additionally, be on the lookout for any promotions or discounts that could reduce your overall expenditure.

Remember: Patience and diligence during the ordering process can lead to a successful outcome and prolong the life of your equipment.

Preventive Maintenance Strategies

Implementing effective strategies for maintenance is crucial for enhancing the longevity and performance of tools and equipment. By adopting a proactive approach, users can minimize downtime and reduce the likelihood of unexpected failures. These strategies encompass regular inspections, timely replacements, and adherence to operational guidelines, all aimed at preserving functionality and efficiency.

Routine checks allow for the early identification of wear and tear, facilitating necessary adjustments before issues escalate. Keeping a detailed maintenance log aids in tracking performance trends, enabling informed decisions about repairs and replacements. Additionally, following manufacturer recommendations for service intervals ensures that each component remains in optimal condition.

Utilizing quality replacement parts is essential, as inferior components can lead to further complications. Moreover, fostering a culture of care and attention among users promotes responsible handling and usage, contributing to overall equipment health. By delving into these preventive measures, one can achieve the ultimate reliability and effectiveness from their tools.

Resources for Further Assistance

When undertaking repairs or maintenance on your equipment, accessing the right resources can significantly streamline the process. Whether you are seeking specific components, instructional guides, or expert advice, a variety of platforms and tools are available to help you navigate your project successfully.

Here are some recommended resources to enhance your understanding and assist you in finding the necessary information:

| Resource Type | Description | Website/Contact |

|---|---|---|

| Online Forums | Communities where enthusiasts share insights, tips, and troubleshooting advice. | www.forumexample.com |

| Manufacturer’s Website | Official site providing manuals, specifications, and support options. | www.manufacturerexample.com |

| Video Tutorials | Step-by-step guides available on platforms like YouTube to assist with various tasks. | www.youtube.com |

| Local Repair Shops | Professionals offering repair services and advice tailored to specific equipment. | (123) 456-7890 |

| DIY Blogs | Personal blogs featuring detailed projects and personal experiences related to equipment maintenance. | www.diyblogexample.com |

Utilizing these resources can help you gain a deeper understanding of your equipment and ensure you have the right support when you need it most.

User Community Insights

The collective experiences and knowledge shared by enthusiasts create a valuable resource for those looking to enhance their understanding and improve their skills. Engaging with fellow users fosters a sense of community and encourages the exchange of tips, tricks, and best practices.

Key Topics of Discussion

- Maintenance Techniques

- Common Issues and Solutions

- Upgrades and Customizations

- Sharing Projects and Experiences

Community Benefits

- Access to a wealth of knowledge.

- Support from experienced users.

- Opportunities for collaboration.

- Enhanced learning through shared resources.