For those who enjoy maintaining their own equipment, grasping the intricacies of lawn tractors is essential. A well-structured visual guide can significantly enhance your ability to identify and replace various elements of your machinery. This knowledge not only streamlines repairs but also prolongs the lifespan of your outdoor tools.

Visual aids can serve as the ultimate reference, allowing enthusiasts to delve deeper into the specific parts and their functions. Understanding how each component interconnects is vital for effective troubleshooting and maintenance. Familiarity with the structure can empower users to take control of their gardening tasks with confidence.

Whether you’re a seasoned user or a newcomer, having access to clear representations of your machine’s build can lead to more efficient management. This resource will help demystify the complexity of lawn tractor systems, ensuring you’re well-prepared for any challenge that arises in your yard work.

Understanding Craftsman YTS4500 Parts Diagram

Gaining insight into the components of a lawn tractor is essential for effective maintenance and repairs. Familiarity with the individual elements allows users to identify issues quickly and ensure the longevity of their machine. A comprehensive illustration serves as a valuable resource, detailing the various parts and their interconnections.

Importance of Component Identification

Recognizing each segment is crucial for troubleshooting and performing repairs. When a specific part malfunctions, knowing its location and function simplifies the repair process. This understanding also aids in ordering the correct replacements, ensuring the machine remains operational.

Using the Visual Guide Effectively

When utilizing the visual reference, start by familiarizing yourself with the layout. Each labeled section provides insights into the arrangement and functionality of the different components. Cross-referencing with the owner’s manual can enhance comprehension and support effective maintenance practices.

Overview of Craftsman YTS4500 Model

This section provides a comprehensive look at a popular riding machine known for its efficiency and reliability. Ideal for homeowners and landscaping professionals alike, this model showcases an array of features designed to enhance usability and performance.

- Robust engine for reliable power.

- Ergonomic design for comfortable operation.

- Advanced cutting technology for precision results.

- Durable construction for long-lasting use.

Equipped with various enhancements, this model aims to simplify yard maintenance while delivering exceptional results. Whether for mowing large lawns or navigating tight spaces, it stands out in its category.

Key Components in the Diagram

This section explores essential elements found within the schematic representation of a particular machine. Understanding these crucial parts enhances maintenance and repair efforts, ensuring optimal performance and longevity.

Engine: The power source is vital, as it drives all functions. Regular checks can prevent operational issues.

Transmission: This component transfers power from the engine to the wheels, allowing for smooth movement. Proper lubrication is key.

Chassis: The framework supports various parts, contributing to stability and durability. Inspecting for wear and tear is important.

Wheels: These are critical for mobility. Ensuring they are properly inflated and aligned is essential for efficient operation.

Control System: This includes levers and switches that enable user interaction with the machine. Regular testing can prevent malfunction.

Importance of Accurate Parts Identification

Precise identification of components is crucial for maintaining and repairing machinery effectively. Ensuring the right elements are recognized leads to enhanced performance, longevity, and safety of the equipment.

- Efficiency: Accurate identification minimizes downtime by streamlining the repair process.

- Cost-Effectiveness: Using the correct components reduces the risk of purchasing unnecessary replacements.

- Safety: Properly identified elements ensure that machinery operates within safe parameters, preventing accidents.

- Optimal Performance: The right components enhance the overall functionality and efficiency of the equipment.

In conclusion, meticulous recognition of each element leads to better outcomes in maintenance and operation.

Common Issues with YTS4500 Parts

When dealing with equipment components, certain challenges frequently arise that can hinder performance and efficiency. Understanding these typical problems can aid in troubleshooting and maintenance efforts, ensuring smooth operation.

| Issue | Description |

|---|---|

| Wear and Tear | Over time, components may degrade, leading to reduced efficiency and potential failure. |

| Improper Installation | Incorrect assembly can result in malfunctions, affecting overall functionality. |

| Corrosion | Exposure to moisture can cause rust and corrosion, weakening critical parts. |

| Compatibility Issues | Using mismatched or incorrect components can lead to performance issues. |

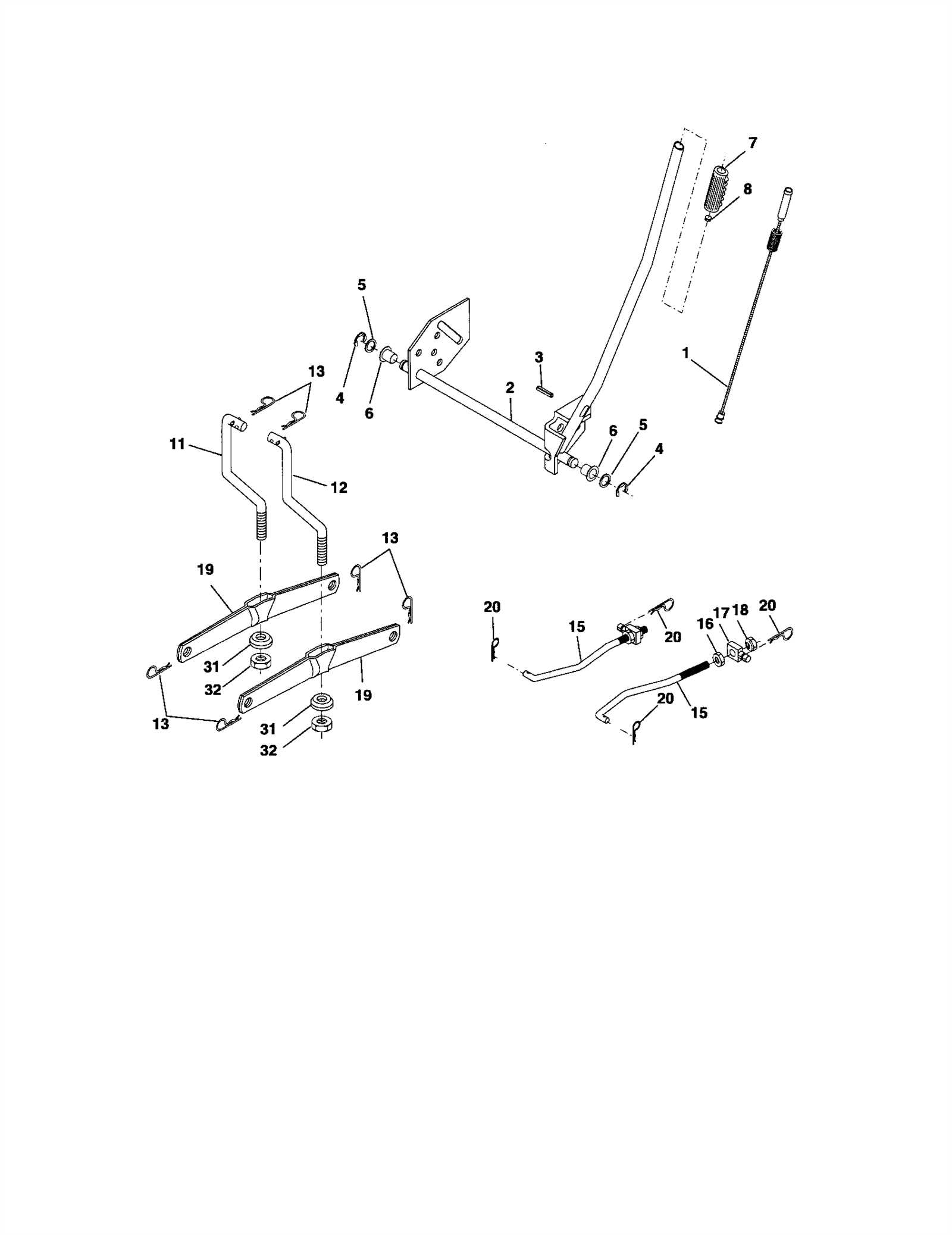

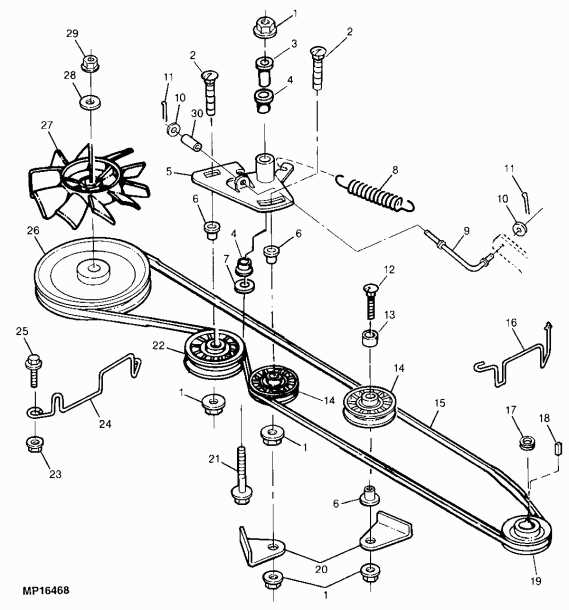

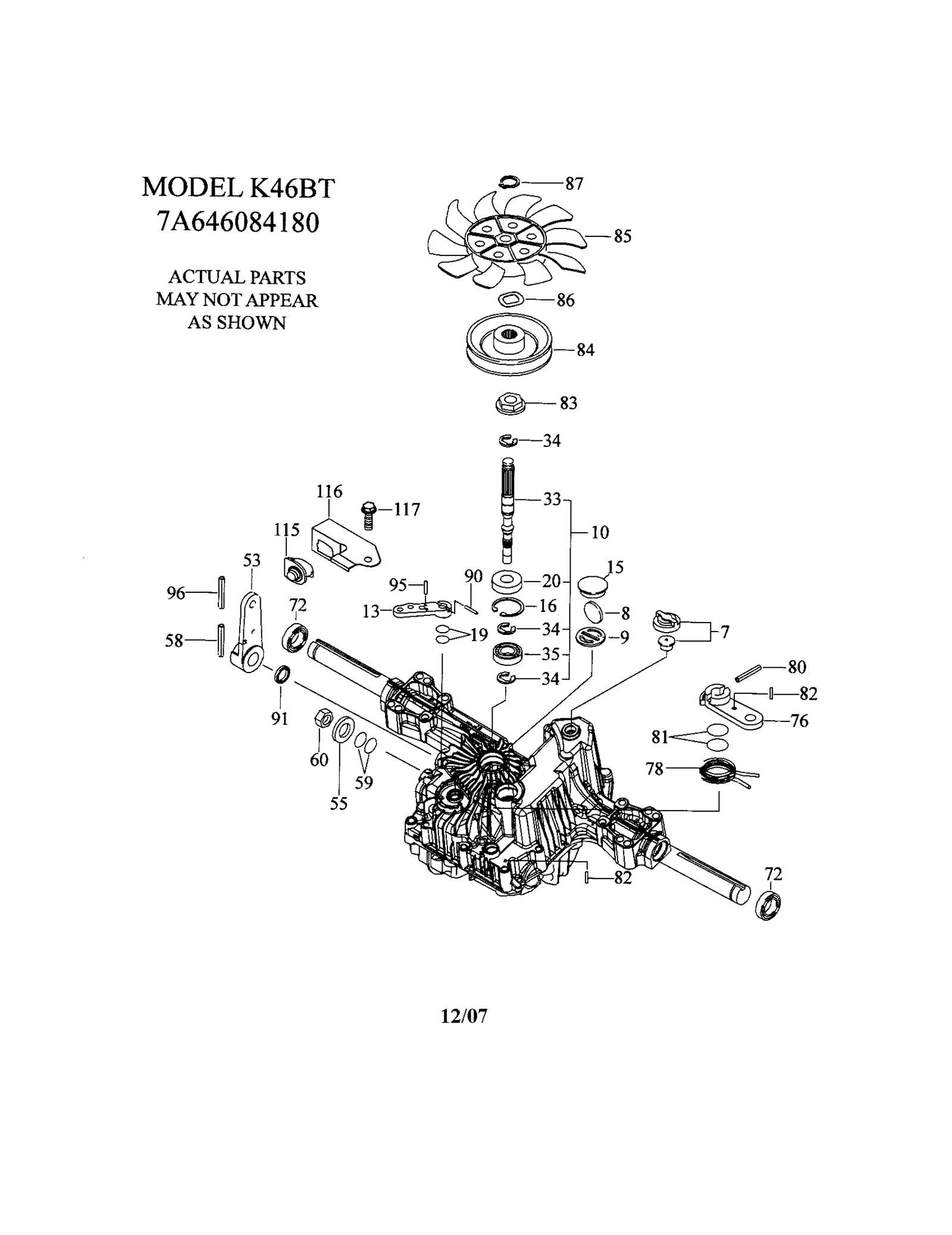

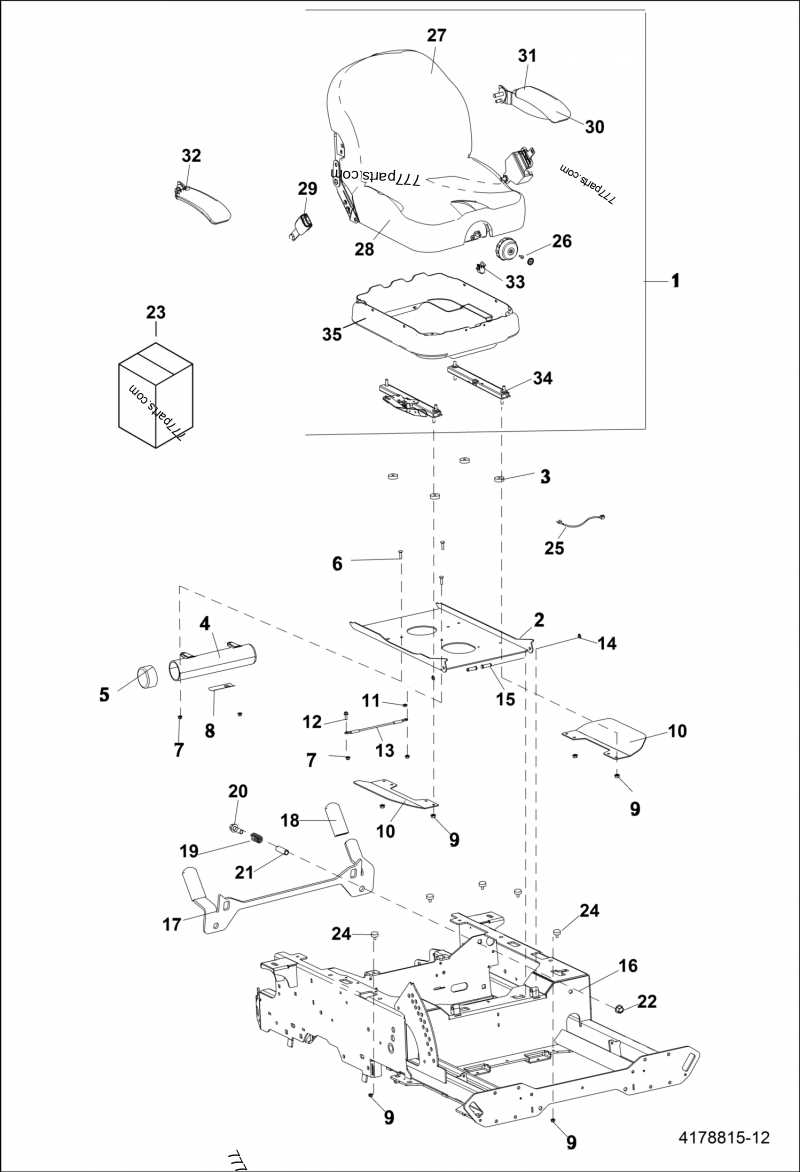

How to Read the Parts Diagram

Understanding the visual representation of components is crucial for effective maintenance and repair tasks. These illustrations provide a detailed view of various elements, helping users identify and locate each piece efficiently. Familiarizing yourself with these visuals can enhance your ability to troubleshoot and replace items accurately.

First, take note of the numbering system used in the illustration. Each component is typically assigned a unique identifier, making it easier to cross-reference with accompanying lists or manuals. This organization streamlines the process of finding the correct items needed for your project.

Next, pay attention to the labels and descriptions. Often, components will have brief annotations indicating their function or compatibility. These notes can provide valuable insights when selecting replacements or understanding how different parts interact with one another.

Additionally, observe the layout and connections shown in the illustration. Understanding how elements are arranged and linked can help you visualize the assembly and disassembly processes. This knowledge is essential for avoiding mistakes and ensuring a smooth repair experience.

Finally, consider referring to a reference guide or user manual alongside the illustration. These resources often offer further explanations and tips that can enhance your comprehension of the visual guide. With practice, reading these visuals will become a straightforward task, empowering you to tackle repairs with confidence.

Maintenance Tips for YTS4500

Regular upkeep is essential for optimal performance and longevity of your equipment. By following these simple guidelines, you can ensure that your machine runs smoothly and efficiently.

- Check and replace the air filter periodically to maintain airflow and engine efficiency.

- Keep the blades sharp to achieve a clean cut and reduce strain on the engine.

- Inspect belts for wear and tear; replace them if they show signs of damage.

- Change the oil and oil filter regularly to keep the engine lubricated and functioning properly.

Additionally, ensure that all nuts and bolts are tightened to prevent vibrations that could lead to component damage. Clean the exterior regularly to remove debris and dirt, which can affect performance.

- Refer to the owner’s manual for specific maintenance schedules.

- Use manufacturer-recommended fluids and parts for best results.

- Store the equipment in a dry place to protect it from the elements.

Following these maintenance tips will help you delve deeper into preserving the ultimate functionality of your machinery, allowing for a more enjoyable experience.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Whether you need a specific item or an entire assembly, there are numerous avenues to explore. Here’s a guide to help you identify reliable sources for obtaining these essential elements.

| Source | Description |

|---|---|

| Manufacturer Website | The official site often offers direct access to a comprehensive inventory and specifications. |

| Authorized Dealers | These retailers provide genuine components and can offer expert advice on compatibility. |

| Online Marketplaces | Platforms like eBay or Amazon feature a wide selection from various sellers, often at competitive prices. |

| Local Repair Shops | These establishments may have spare items on hand or can assist in sourcing them for you. |

| Forums and Community Groups | Online communities can offer insights on where to find specific components and share personal experiences. |

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for achieving effective results. Various instruments not only streamline the repair process but also enhance safety and precision.

Essential tools include a reliable wrench set, which allows for easy adjustments and fittings. Additionally, a comprehensive screwdriver collection is crucial for handling screws of different sizes and types.

Moreover, pliers can provide necessary grip and leverage, making them invaluable for various tasks. A sturdy utility knife also proves beneficial for cutting materials cleanly and efficiently.

Finally, don’t overlook the importance of safety gear, such as gloves and goggles, to protect yourself during repairs. Equipped with these tools, you’ll be prepared to delve into any project with confidence.

Comparing YTS4500 with Other Models

This section explores the distinctions and similarities between a specific model and its counterparts in the market. By examining features, performance, and overall value, we aim to highlight what sets this particular unit apart from others available today.

Performance: When assessing efficiency, it’s crucial to consider engine power and speed. While many alternatives may offer similar specifications, this model excels in delivering consistent output under various conditions.

Durability: The materials used in construction significantly impact longevity. This model utilizes high-quality components, ensuring it withstands rigorous use better than many of its competitors.

User Experience: Ease of use and comfort play essential roles in user satisfaction. Comparing ergonomics and accessibility features reveals that this model provides superior handling and intuitive controls, enhancing the overall experience.

Cost-Effectiveness: Analyzing the price-to-performance ratio can be enlightening. While some alternatives may be cheaper, this model’s longevity and efficiency often result in greater value over time, justifying a higher initial investment.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionality in various machinery. Understanding these elements can enhance performance and ensure longevity.

| Question | Answer |

|---|---|

| What should I consider when purchasing replacements? | Focus on compatibility, quality, and warranty options to ensure optimal performance. |

| How can I identify the right component for my equipment? | Refer to the user manual or consult an expert for guidance on specifications and models. |

| Are aftermarket options reliable? | Many aftermarket choices can offer great value, but it’s essential to research brands and reviews. |

| How often should I replace worn-out elements? | Regular inspections can help determine the need for replacements; generally, follow manufacturer recommendations. |

Benefits of Regular Maintenance

Consistent upkeep of machinery and tools offers numerous advantages that extend their lifespan and enhance performance. By investing time and effort into routine care, users can enjoy a range of positive outcomes that ensure optimal functionality.

Enhanced Efficiency

- Regular checks prevent minor issues from escalating into major problems.

- Well-maintained equipment operates smoothly, reducing energy consumption.

- Routine cleaning and lubrication ensure optimal performance during use.

Cost Savings

- Preventive care minimizes the need for costly repairs and replacements.

- Investing in maintenance can lead to lower operational costs over time.

- Extended equipment life results in better long-term value.