For anyone fascinated by the world of powerful two-wheeled machines, understanding how the key components function together is a journey worth taking. The intricate connections between the different elements are what make these machines roar to life, delivering both performance and reliability. Whether you’re a mechanic, an enthusiast, or simply curious, gaining insight into these mechanical marvels can deepen your appreciation for their design.

The intricate layout of a motorbike’s core system involves a complex network of elements working in harmony. Each piece, from the smallest valve to the largest rotating unit, plays a vital role in ensuring smooth operation. Learning about the structure and placement of these essential pieces allows one to better understand how they contribute to the overall performance and durability of the machine.

By diving deeper into the specifics of these mechanical components, you can start to see the beauty in their functionality. The layout, carefully designed and tested over decades, showcases engineering at its finest, balancing power with precision. This exploration offers not only knowledge but a new perspective on how every part supports the whole, leading to a more seamless riding experience.

Exploring Harley Davidson Engine Parts Diagram

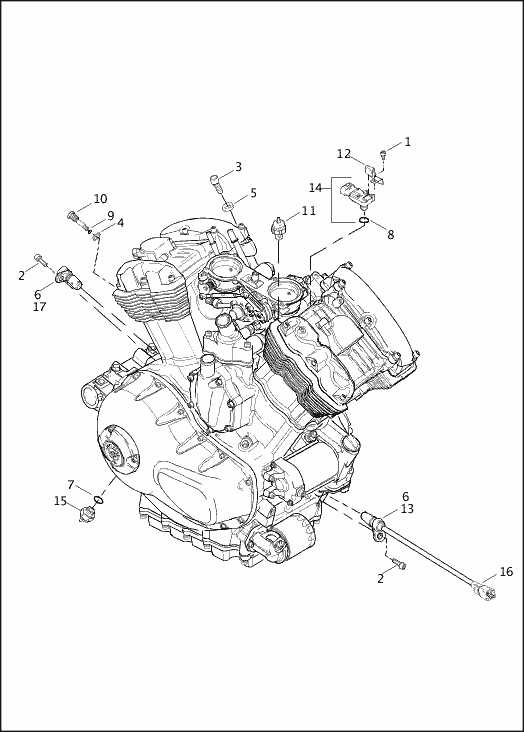

This section delves into the intricate components of the iconic motorcycle’s power unit, offering insights into their functions and interconnections. Understanding these elements is crucial for enthusiasts and mechanics alike, as they form the backbone of performance and reliability in these beloved machines.

Each component plays a vital role, contributing to the overall operation and efficiency of the motorcycle. From the ignition system to the fuel delivery mechanisms, each section of the assembly works in harmony to deliver an exhilarating riding experience. Analyzing the layout reveals the complexity of the design and the engineering prowess that goes into crafting these remarkable vehicles.

Familiarity with the structure can significantly aid in troubleshooting and maintenance. Knowledge of how each piece interacts with others allows for more informed decisions regarding upgrades or repairs. As riders deepen their understanding of the machine, they enhance not only their skills but also their appreciation for the craftsmanship that defines this legendary motorcycle.

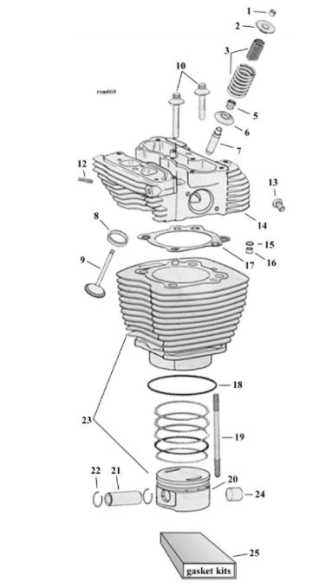

Understanding the Anatomy of a Harley Davidson Engine

Exploring the structure of a powerful motor reveals a fascinating interplay of components that work harmoniously to generate robust performance. Each element plays a crucial role in ensuring the machine operates smoothly, offering a thrilling experience to riders. This section delves into the intricate details of this mechanical marvel, highlighting the significance of various constituents that come together to create a formidable driving force.

| Component | Description |

|---|---|

| Cylinder | The chamber where combustion occurs, vital for converting fuel into energy. |

| Piston | A moving part within the cylinder that transfers the force generated during combustion to the crankshaft. |

| Crankshaft | The central shaft that converts the linear motion of the pistons into rotational motion, driving the vehicle forward. |

| Camshaft | A shaft that controls the opening and closing of valves, regulating the flow of air and fuel into the combustion chamber. |

| Valves | Critical elements that manage the intake and exhaust of gases, ensuring optimal performance. |

Key Components of a Harley Davidson Engine

The heart of any motorcycle lies in its internal machinery, which plays a vital role in delivering power and performance. Understanding these essential elements is crucial for enthusiasts and riders alike, as it provides insight into the intricate workings that make these machines so iconic.

Power Unit: At the core of the assembly, this unit is responsible for converting fuel into energy, propelling the motorcycle forward. Its design and engineering significantly influence the overall performance and responsiveness.

Combustion Chamber: This section is where the magic happens–fuel and air mix to create the explosion that drives the pistons. The efficiency of this chamber directly impacts acceleration and fuel consumption.

Pistons: These cylindrical components move up and down within the cylinders, translating the force of the combustion into mechanical energy. Their design and materials are critical for achieving optimal performance and durability.

Cylinders: These housing structures contain the pistons and are essential for maintaining the necessary pressure for effective combustion. The configuration and size of the cylinders can dramatically affect the motorcycle’s output.

Crankshaft: This component converts the linear motion of the pistons into rotational motion, ultimately driving the rear wheel. Its strength and balance are vital for smooth operation and power delivery.

Camshaft: Regulating the timing of the valves, this element ensures that the correct amount of air and fuel enters the combustion chamber. Precision in its design enhances performance and efficiency.

Fuel System: Comprising the carburetor or fuel injectors, this system manages the delivery of fuel to the combustion chamber. A well-tuned system maximizes power output and minimizes emissions.

Each of these components plays an integral role in the functionality of the machine, contributing to the overall riding experience. A deeper understanding of their interconnections can enhance maintenance and modifications, ensuring optimal performance on the road.

Detailed Breakdown of Harley Davidson Engine Parts

Understanding the intricate components of a motorcycle’s power system is essential for both enthusiasts and mechanics. This exploration delves into the various elements that contribute to the overall functionality and performance of the machine. Each component plays a vital role, working in harmony to ensure a smooth and powerful ride.

- Powerplant: The heart of the motorcycle, responsible for converting fuel into mechanical energy.

- Cylinders: These chambers house the pistons and are crucial for the combustion process.

- Pistons: Moving parts within the cylinders that compress fuel and air for ignition.

- Crankshaft: A key component that transforms the linear motion of pistons into rotational force.

- Camshaft: This regulates the opening and closing of valves, controlling the intake of air and fuel and the exhaust of gases.

Additional features enhance performance and efficiency:

- Valves: Essential for the intake of air-fuel mixture and the expulsion of exhaust gases.

- Ignition System: Responsible for initiating combustion, ensuring the engine runs smoothly.

- Fuel System: Delivers the necessary fuel to the combustion chambers for optimal performance.

- Exhaust System: Channels waste gases away from the engine, reducing emissions and enhancing efficiency.

Each of these elements is critical for maintaining the overall health and performance of the motorcycle, making knowledge of their functions invaluable for riders and technicians alike.

Functionality of Each Engine Component

The intricate system of a motor’s components works harmoniously to convert fuel into motion. Each segment plays a crucial role in ensuring optimal performance, contributing to the overall efficiency and power output of the vehicle.

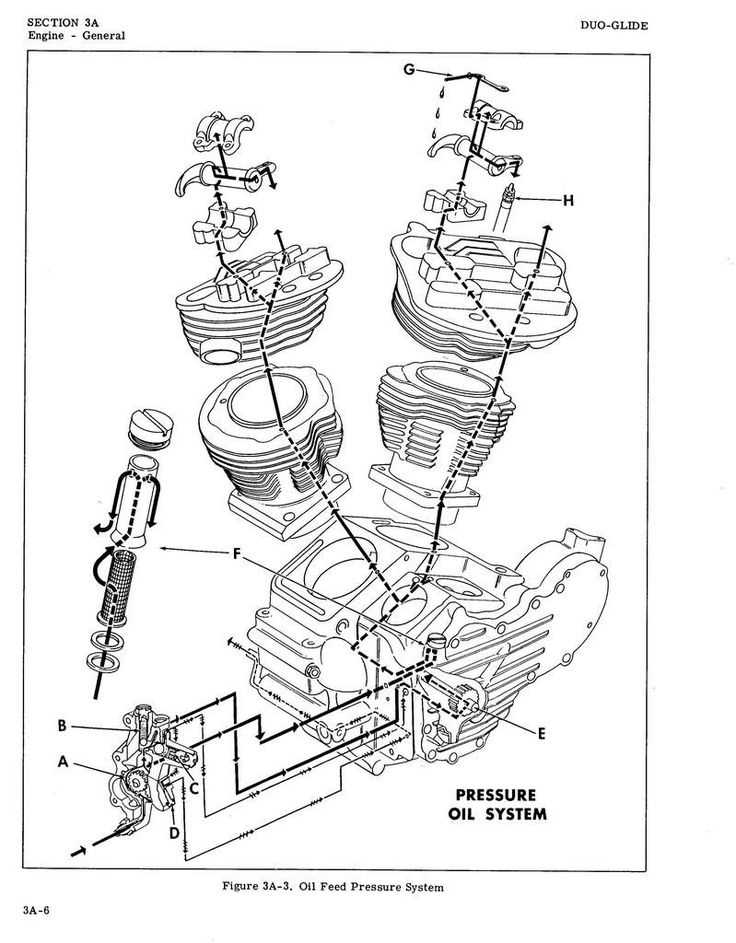

Combustion Chamber: This area is where the fuel-air mixture ignites, generating the force needed to drive the pistons. The design and configuration directly affect the engine’s power and efficiency.

Pistons: These cylindrical elements move up and down within the cylinders, translating the force from the combustion process into mechanical work. Their movement is essential for the crankshaft’s rotation.

Crankshaft: Acting as the heart of the system, this component converts the linear motion of the pistons into rotational energy, which ultimately powers the transmission.

Camshaft: Responsible for opening and closing the intake and exhaust valves, the camshaft ensures that the engine breathes properly. Its timing is critical for maintaining performance and efficiency.

Valves: These components regulate the flow of air and fuel into the combustion chamber and the exhaust gases out. Proper functioning of the valves is vital for optimal combustion and exhaust management.

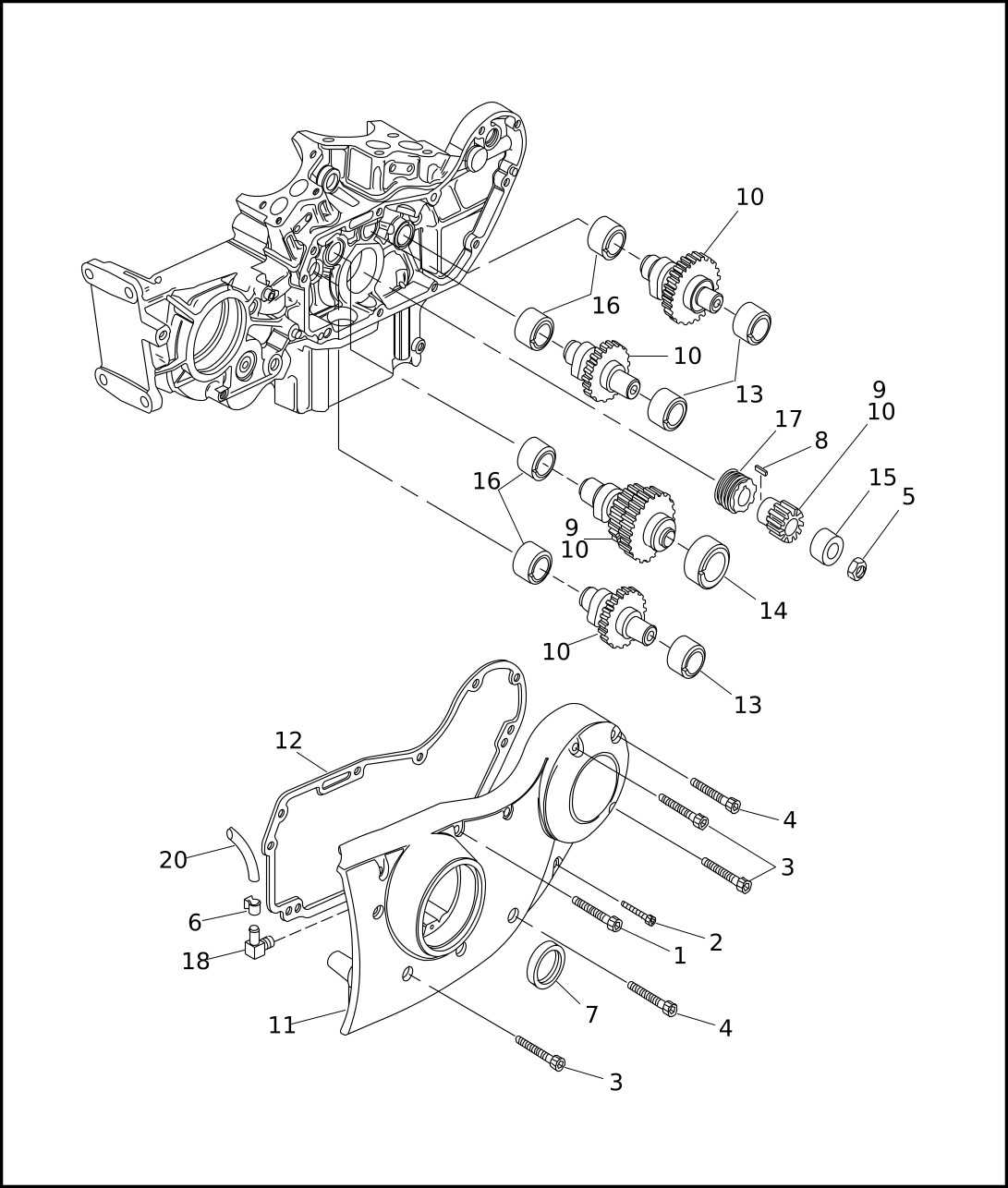

Timing Chain: This chain synchronizes the rotation of the crankshaft and camshaft, ensuring that the engine’s valves open and close at the correct intervals. Accurate timing is essential for peak performance.

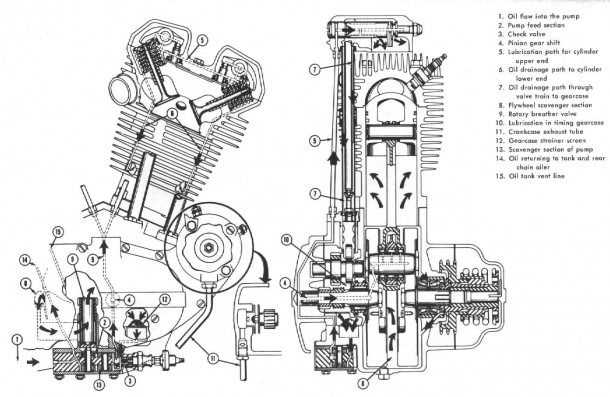

Oil Pump: This vital component circulates oil throughout the motor, lubricating moving parts and reducing friction. Efficient lubrication is crucial for the longevity and reliability of the entire system.

Cooling System: Maintaining an optimal temperature is critical for performance. The cooling system prevents overheating by dissipating excess heat, ensuring that the engine operates within safe limits.

Understanding the role of each component highlights the complexity and precision involved in automotive design. This knowledge aids in troubleshooting and maintenance, allowing for better care of the vehicle’s vital systems.

Differences Between Various Harley Davidson Engine Models

When exploring the diversity of motorcycle powertrains, it becomes evident that each model brings its own unique characteristics and performance features. The variations among these designs not only influence the riding experience but also reflect the engineering philosophies of their creators. Understanding these distinctions can significantly enhance one’s appreciation of these remarkable machines.

Performance and Configuration Variations

Different configurations can lead to notable differences in performance and handling. Some models feature a more compact layout, offering agility and ease of maneuverability, while others prioritize power output with larger displacement options. Additionally, the arrangement of cylinders, such as V-twin or parallel designs, plays a crucial role in defining the overall dynamics of each model.

Technological Advancements and Features

With the evolution of motorcycle technology, newer models often incorporate advanced features that enhance functionality and rider comfort. From electronic fuel injection systems to sophisticated braking technologies, each iteration showcases improvements that cater to the needs of contemporary riders. These innovations not only improve efficiency but also contribute to a more enjoyable riding experience.

Evolution of Engine Design Across Harley Davidson History

The journey of powertrain innovation reflects a commitment to performance, efficiency, and rider experience. Over the decades, the pursuit of technological advancement has led to significant transformations in design and functionality, catering to the evolving preferences of motorcycle enthusiasts. This section delves into the notable shifts in powertrain architecture, highlighting key milestones that have shaped the brand’s legacy.

Key Milestones in Development

- Early Designs: The initial models showcased simple configurations, emphasizing reliability and ease of maintenance.

- Introduction of V-Twin: The iconic V-twin configuration emerged, delivering distinct power characteristics and a unique auditory experience.

- Shovelhead Revolution: The 1960s brought the Shovelhead, enhancing cooling efficiency and power delivery.

- Evo Engine Launch: The 1980s introduced a robust powerplant, focusing on durability and reduced vibration.

- Modern Advancements: Recent innovations incorporate electronic fuel injection and advanced cooling systems, optimizing performance and compliance with environmental standards.

Impact on Riding Experience

The evolution of powertrains has not only influenced performance metrics but has also transformed the overall riding experience. Enthusiasts can now enjoy:

- Smoother rides with reduced vibration

- Enhanced torque for superior acceleration

- Improved fuel efficiency for longer journeys

- Increased customization options for personal preferences

Significance of Engine Parts in Harley Davidson Performance

The components that make up the heart of a motorcycle play a crucial role in its overall capability and effectiveness. Understanding how each element interacts with the others can provide insights into enhancing power, efficiency, and durability. A well-designed assembly ensures that the machine operates smoothly and reliably, translating into a thrilling riding experience.

The interplay among various elements influences not only speed and acceleration but also the responsiveness of the bike. For example, a finely tuned system can dramatically improve torque output, allowing for quicker maneuvers on the road. Additionally, proper maintenance of these components can lead to increased longevity, reducing the need for frequent repairs and replacements.

Moreover, optimizing the relationships between these essential elements contributes to better fuel efficiency. A motorcycle that runs efficiently not only conserves fuel but also minimizes emissions, making it more environmentally friendly. Ultimately, recognizing the significance of each component leads to a deeper appreciation of the artistry and engineering behind powerful two-wheelers.

Maintenance Tips for Harley Davidson Engine Parts

Proper upkeep of your motorcycle’s vital components is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances the ride quality but also prevents costly repairs down the road. Following a structured approach to care can significantly improve the reliability of your machine.

Start by routinely checking fluid levels, including oil and coolant, as these are crucial for smooth operation. Change the oil according to the manufacturer’s recommendations to keep the internal mechanisms well-lubricated. Inspecting filters for dirt and blockages is equally important to maintain efficient performance.

Additionally, it’s advisable to examine the ignition system periodically. Worn-out spark plugs can lead to misfires and reduced power. Replace them as needed to ensure optimal combustion. Keeping the air intake clean and free from debris will also enhance the overall efficiency of the vehicle.

Regularly inspect the battery for corrosion and ensure proper connections. A well-maintained battery is key to reliable starts. Don’t forget to check the drive belt or chain, adjusting tension and lubrication to guarantee smooth power transfer from the engine to the wheels.

Finally, consulting a professional technician for periodic comprehensive inspections can help catch potential issues early. Staying proactive with these maintenance tips will contribute to a smoother, safer riding experience.

Common Issues and Troubleshooting of Harley Davidson Engines

Motorcycle enthusiasts often face a variety of challenges with their two-wheeled machines. Understanding the frequent problems that can arise is crucial for maintaining optimal performance. This section delves into some typical complications and offers practical solutions to help riders keep their rides in peak condition.

One of the most prevalent concerns is related to the starting system. Riders may experience difficulties in ignition, often attributed to battery issues, faulty connections, or a worn-out starter. Regular inspections and maintenance of these components can prevent such frustrations.

Another issue that frequently arises involves the fuel delivery system. Inadequate fuel flow can lead to performance problems, resulting in stalling or sluggish acceleration. Checking for clogs in the fuel filter and ensuring the fuel pump operates correctly are essential steps in troubleshooting this problem.

Below is a table outlining common challenges and their potential solutions:

| Issue | Description | Solution |

|---|---|---|

| Ignition Failure | The vehicle does not start or has difficulty starting. | Inspect the battery, wiring, and starter; replace if necessary. |

| Poor Fuel Flow | Inconsistent acceleration or stalling. | Check for clogs in the fuel filter and ensure proper fuel pump operation. |

| Overheating | The machine runs hotter than normal, potentially causing damage. | Inspect coolant levels and ensure proper airflow; clean radiators if needed. |

| Strange Noises | Unusual sounds during operation, indicating potential mechanical issues. | Conduct a thorough inspection of mechanical components; seek professional help if necessary. |

By addressing these common challenges proactively, riders can enhance the reliability and enjoyment of their machines, ensuring a smoother and safer journey on the open road.

Upgrading Engine Parts for Improved Performance

Enhancing the components of your motor can significantly boost its efficiency and responsiveness. By focusing on key elements, you can experience a noticeable transformation in your ride’s power and handling. This process not only involves selecting high-quality replacements but also understanding the intricate balance between different systems.

First and foremost, consider the value of high-performance replacements. Upgrading to advanced options can lead to increased output and improved fuel efficiency. Many enthusiasts find that investing in superior pistons, valves, or camshafts yields rewarding results.

Moreover, it’s crucial to ensure that all upgraded components are compatible with one another. This compatibility is essential to maintain optimal performance and avoid potential mechanical issues. Consulting with experts or utilizing reputable resources can help guide your choices, ensuring a smooth integration process.

Finally, regular maintenance and adjustments after upgrades are vital to sustaining peak performance. Implementing changes without ongoing care can lead to diminished returns. By prioritizing enhancements and their upkeep, you can enjoy a more exhilarating and reliable riding experience.

Future Trends in Harley Davidson Engine Technology

The motorcycle industry is on the verge of significant transformations, driven by advancements in design and engineering. As enthusiasts look toward the horizon, innovations are set to redefine performance, efficiency, and sustainability in two-wheeled vehicles. Manufacturers are embracing cutting-edge technologies to enhance rider experiences while addressing environmental concerns.

Electrification and Hybrid Solutions

One of the most prominent shifts involves the move towards electrification. Electric powertrains are gaining traction, offering remarkable torque and minimal emissions. Additionally, hybrid systems, which combine traditional combustion with electric components, are being explored to maximize efficiency without compromising the thrill of the ride. This dual approach promises to attract a new generation of riders while retaining the loyalty of seasoned enthusiasts.

Smart Technologies and Connectivity

The integration of smart technologies is revolutionizing the way riders interact with their machines. From advanced diagnostics to real-time performance monitoring, connectivity features are enhancing the overall experience. These innovations not only improve safety but also allow for personalized riding experiences through tailored settings and remote updates. As technology continues to evolve, the relationship between rider and machine will become increasingly intuitive and responsive.