Maintaining a lush and healthy lawn requires not just the right techniques but also well-functioning machinery. To achieve optimal performance from your equipment, it’s essential to familiarize yourself with its components and their specific roles. This knowledge will empower you to tackle any maintenance tasks or repairs with confidence.

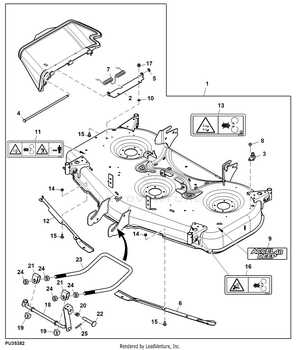

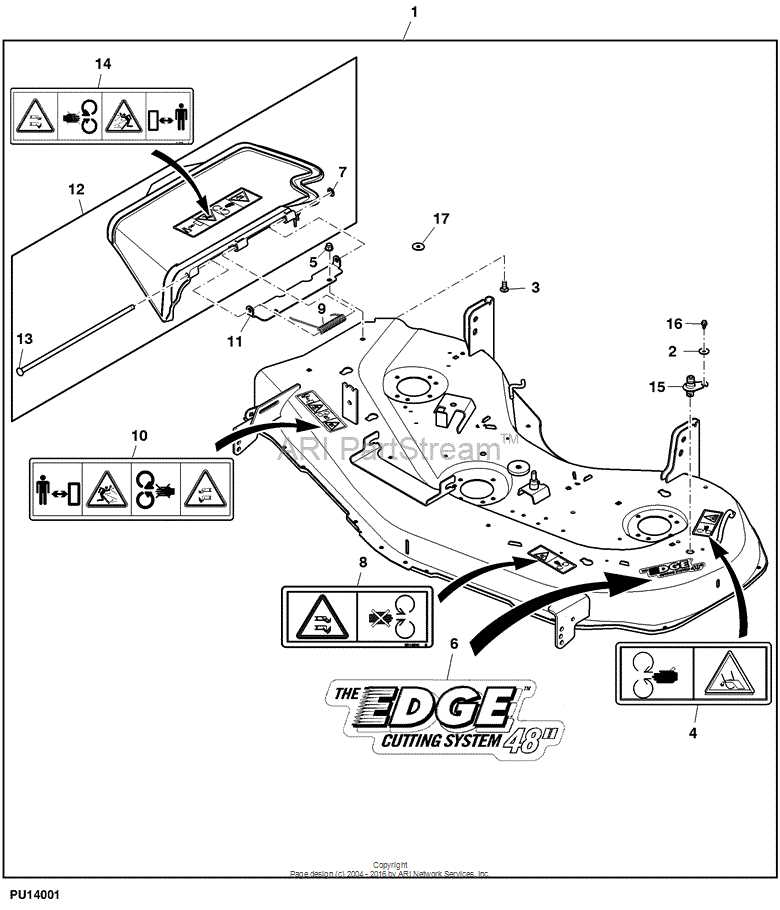

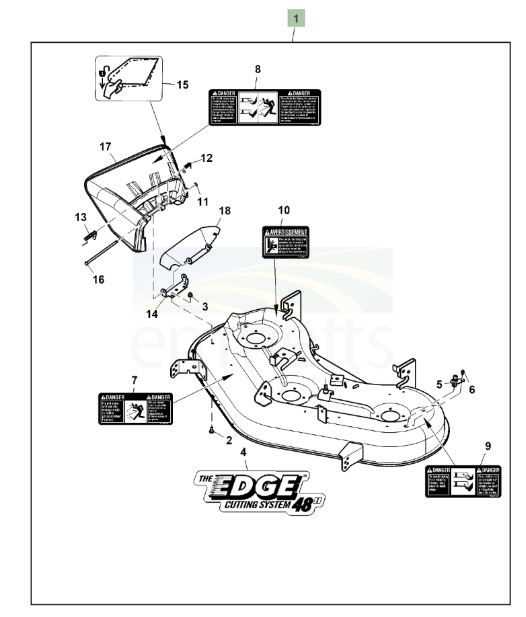

Visual aids can be invaluable in this learning process. By examining detailed illustrations that showcase the various elements of your machinery, you can easily identify what needs attention. These diagrams serve as guides, highlighting each piece’s function and how they interconnect, ensuring smooth operation and efficiency.

Whether you are a seasoned professional or a weekend warrior, understanding the intricacies of your lawn care tools can enhance your overall experience. Having access to comprehensive visual references will allow you to troubleshoot issues quickly and maintain your equipment in peak condition.

Understanding the 48C Mower Deck

This section provides an overview of a specific type of cutting apparatus designed for lawn maintenance. It is essential for users to comprehend its components and functionality to ensure efficient operation and longevity. By gaining insights into the design and parts involved, operators can achieve optimal performance and maintain their equipment effectively.

Key Components of the Cutting Apparatus

The cutting system comprises several crucial elements, each contributing to the overall efficiency. The blades, for instance, are pivotal in delivering a clean and precise cut. Additionally, the housing protects these blades while facilitating proper grass discharge. Understanding how each component interacts can greatly enhance maintenance practices.

Maintenance Tips for Longevity

Regular upkeep is vital for extending the lifespan of the equipment. Sharpening the blades ensures effective cutting, while cleaning the housing prevents buildup that can hinder performance. Additionally, periodic checks on the drive system can avert unexpected failures, allowing for smooth operation during mowing sessions.

Key Components of the 48-Inch Deck

Understanding the essential elements of a lawn cutting apparatus is crucial for maintaining efficiency and ensuring optimal performance. Each component plays a significant role in achieving precise cutting results and overall functionality. Below are the main features that contribute to the effectiveness of this equipment.

Core Elements

- Blades: The cutting blades are fundamental, determining the quality of the cut. They are designed for durability and sharpness.

- Spindles: These rotating units hold the blades in place and allow for smooth movement, facilitating effective cutting.

- Housing: The structure that encases the blades, providing protection and ensuring safety during operation.

- Lift Mechanism: This allows users to adjust the height of the cutting blades, adapting to different grass types and terrain conditions.

Additional Features

- Belts: These connect the engine to the blades, transmitting power for operation.

- Washout Port: A convenient feature that facilitates easy cleaning, helping to maintain performance over time.

- Anti-scalp Wheels: Prevent damage to the turf by allowing the unit to glide over uneven surfaces.

By familiarizing oneself with these vital components, users can ensure better maintenance practices, leading to enhanced longevity and performance of the cutting apparatus.

Common Issues with John Deere Decks

Owners of lawn maintenance equipment often encounter a range of challenges that can impact performance and efficiency. Understanding these common problems can help in diagnosing issues early and maintaining optimal functionality. This section explores frequent concerns that may arise, providing insights into potential causes and solutions.

Uneven Cutting

One prevalent issue is uneven cutting, which can result from misalignment or worn components. Factors such as blade sharpness, height adjustments, and tire pressure can contribute to this problem. Regular inspections and maintenance are crucial to ensure a consistent cut and an attractive lawn.

Excessive Vibration

Another concern is excessive vibration during operation, which can indicate underlying mechanical problems. Loose or damaged blades, unbalanced components, or worn bearings may lead to increased vibration. Addressing these issues promptly not only enhances comfort during use but also prolongs the life of the equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Proper care not only enhances performance but also minimizes the likelihood of unexpected issues. Here are some crucial practices to keep your machinery running smoothly.

Routine Inspection

Conducting periodic checks is vital for identifying wear and tear early on. Inspect all components for signs of damage or fatigue. Pay close attention to fasteners, belts, and bearings, as these areas are often prone to issues.

Cleaning and Lubrication

Maintaining cleanliness is paramount. Accumulated debris can hinder operation and lead to premature failure. Regularly clean the surfaces and ensure that moving parts are adequately lubricated to reduce friction and extend service life.

| Maintenance Task | Frequency |

|---|---|

| Inspect components | Every 25 hours |

| Clean surfaces | After each use |

| Lubricate moving parts | Every 50 hours |

| Replace worn parts | As needed |

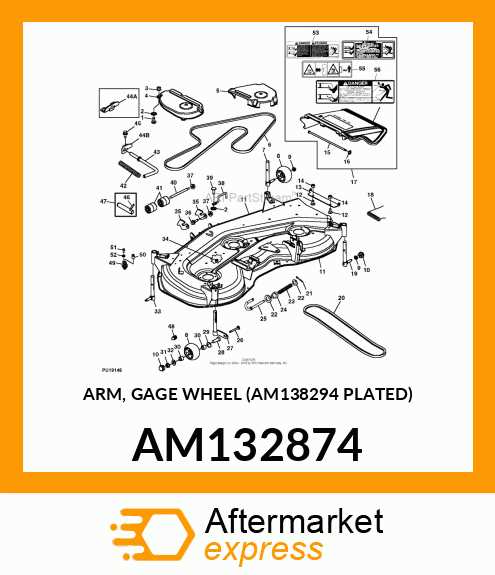

How to Identify Replacement Parts

Finding the correct components for your equipment can be a challenging task. Understanding the key elements and utilizing the right resources can simplify the process significantly. This guide outlines effective methods to help you pinpoint the necessary items for maintenance or repair, ensuring your machinery operates smoothly.

One of the most efficient ways to identify the correct components is to refer to the manufacturer’s documentation. Most brands provide detailed manuals that include diagrams and specifications. These resources can give insights into the exact models and versions compatible with your equipment.

| Method | Description |

|---|---|

| Manufacturer’s Manual | Check for diagrams and specifications in the user manual that accompany your machinery. |

| Online Resources | Utilize official websites or forums that offer parts lists and community advice on identifying components. |

| Model Number | Locate the model number on your equipment, which can assist in searching for the correct items. |

| Consulting Experts | Reach out to professionals or local dealers who specialize in your equipment for tailored guidance. |

By employing these strategies, you can effectively determine the correct components needed for your machinery, enhancing both performance and longevity.

Assembly Instructions for the 48C Deck

This section provides a comprehensive guide to the assembly process for your cutting equipment. Following these steps will ensure proper installation and optimal performance.

-

Preparation: Before starting, gather all necessary tools and components. Ensure you have a clean workspace to facilitate the assembly process.

-

Base Attachment: Begin by securing the main structure to the frame. Align the mounting points accurately.

- Use bolts and washers provided in your kit.

- Tighten bolts evenly to avoid misalignment.

-

Blades Installation: Next, attach the cutting blades. Make sure each blade is oriented correctly for efficient operation.

- Use a torque wrench to secure bolts to the recommended specifications.

- Double-check the positioning before final tightening.

-

Belts and Pulleys: Install the drive belts and pulleys. Follow the specific routing as indicated in your manual.

- Ensure belts are not twisted or excessively loose.

- Check pulley alignment for smooth operation.

-

Final Checks: Once all components are attached, conduct a thorough inspection.

- Verify all bolts and screws are tightened securely.

- Ensure there are no obstructions in the assembly.

Following these instructions will help you achieve a successful assembly. For any troubleshooting, refer to the detailed manual included with your equipment.

Comparing Mower Deck Models

Understanding the various cutting systems available can greatly enhance your lawn care experience. Different configurations and designs cater to specific needs and preferences, making it essential to explore these options for optimal performance.

When evaluating cutting units, consider the following factors:

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Cutting Width | 42 inches | 48 inches | 54 inches |

| Blade Type | Standard | High Lift | Mulching |

| Weight | 150 lbs | 180 lbs | 220 lbs |

| Compatibility | Model X | Model Y | Model Z |

Each option provides unique advantages, from cutting efficiency to adaptability with various equipment. Analyzing these characteristics allows users to select the most suitable model based on their specific landscaping requirements.

Tools Needed for Deck Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for ensuring effective and efficient repairs. A well-equipped toolkit not only saves time but also prevents potential damage during the repair process. Understanding the necessary instruments can make a significant difference in the quality of your work.

Essential Tools

Here are some key instruments you should have on hand:

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | For removing and securing screws in various components. |

| Socket Set | Provides better leverage for tight fasteners. |

| Pliers | Useful for gripping and manipulating small parts. |

| Safety Goggles | Protects eyes from debris during repairs. |

Additional Helpful Instruments

In addition to the basics, the following items can enhance your repair experience:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Grease Gun | Facilitates lubrication of moving parts. |

| Cleaning Supplies | Helps maintain a clean workspace and components. |

| Measuring Tape | Assists in ensuring correct dimensions during replacements. |

Safety Precautions When Operating Mowers

Ensuring safety while operating lawn equipment is paramount for both the user and bystanders. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Awareness of potential hazards and implementing precautionary measures are essential for a secure working environment.

Always wear appropriate personal protective equipment, including sturdy footwear, gloves, and eye protection. This reduces the chance of injury from flying debris or accidental contact with sharp components. Additionally, inspect the equipment before use to identify any signs of wear or damage, ensuring everything is functioning correctly.

Maintain a clear workspace by removing obstacles and debris that could pose risks during operation. It’s crucial to keep children and pets at a safe distance, as their presence can lead to distractions or accidents. Lastly, familiarize yourself with the specific features and controls of the equipment to ensure confident and safe handling.

Where to Purchase Replacement Parts

Finding suitable components for your lawn equipment can greatly enhance its performance and longevity. Whether you are looking for specific pieces or complete assemblies, understanding where to source these items is essential for maintaining your machinery.

Authorized Dealers are often the best starting point. They provide genuine items that ensure compatibility and quality. Many manufacturers maintain a network of certified sellers, making it easier to find what you need with reliable service.

Online Marketplaces have also become a popular choice for many users. Websites like eBay or Amazon offer a vast selection of components, often at competitive prices. Be sure to check seller ratings and reviews to ensure you are purchasing from a reputable source.

Local Hardware Stores or Garden Centers can be valuable resources as well. These establishments frequently stock common items and may even offer advice on installation and maintenance, making your shopping experience more convenient.

Lastly, consider Specialty Online Retailers that focus on lawn care equipment. These websites often have a comprehensive catalog, along with detailed descriptions and specifications, allowing you to make informed decisions.

Exploring Aftermarket Options for Decks

When it comes to maintaining your lawn care equipment, considering alternative solutions can lead to enhanced performance and extended longevity. Aftermarket offerings provide a wealth of possibilities that can meet diverse needs and preferences, often at a more competitive price than original components. This section delves into the various aftermarket selections available for enhancing your cutting apparatus.

Benefits of Aftermarket Solutions

Opting for aftermarket components can yield significant advantages. These alternatives frequently come with improved materials and designs, ensuring greater durability and efficiency. Additionally, many aftermarket manufacturers offer a wide range of customizable options, allowing you to tailor your equipment to suit specific tasks or conditions, ultimately boosting your overall productivity.

Choosing the Right Aftermarket Options

Selecting the most suitable aftermarket solutions requires careful consideration of compatibility and quality. Researching reputable suppliers and reading customer reviews can provide valuable insights. It is essential to ensure that the chosen options not only fit your machinery seamlessly but also align with your performance expectations, helping you achieve the best results possible in your lawn maintenance endeavors.