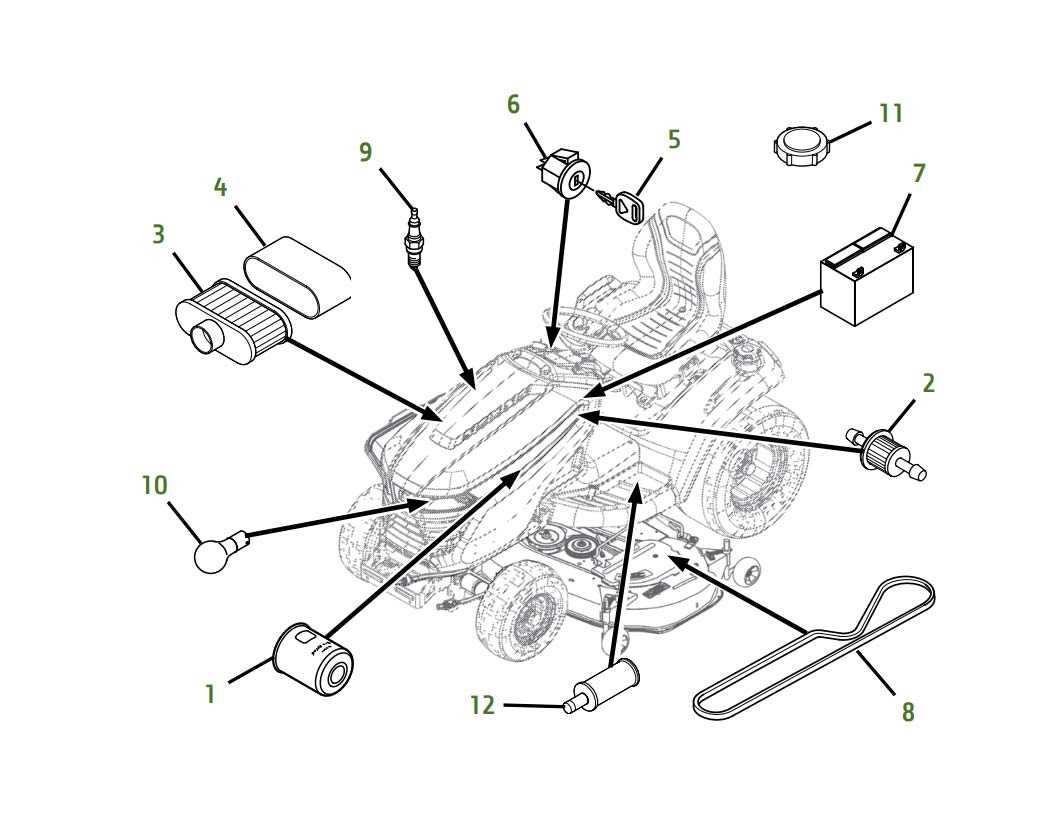

Maintaining any outdoor equipment in optimal condition requires a thorough understanding of its key elements. Knowing how various components work together allows for smoother functionality and reduces the risk of breakdowns during use. Regular inspection and knowledge of the device’s structure are crucial for long-term durability.

Every section of a mechanical setup plays an integral role in achieving seamless performance. From the smallest fasteners to the larger frame pieces, each detail ensures efficiency. Familiarity with the system’s layout helps in pinpointing potential issues and aids in the upkeep of the machinery.

Ensuring correct assembly and monitoring of these elements can prevent future complications. Understanding the intricate design of the system supports the overall maintenance, ensuring everything runs as expected during operation.

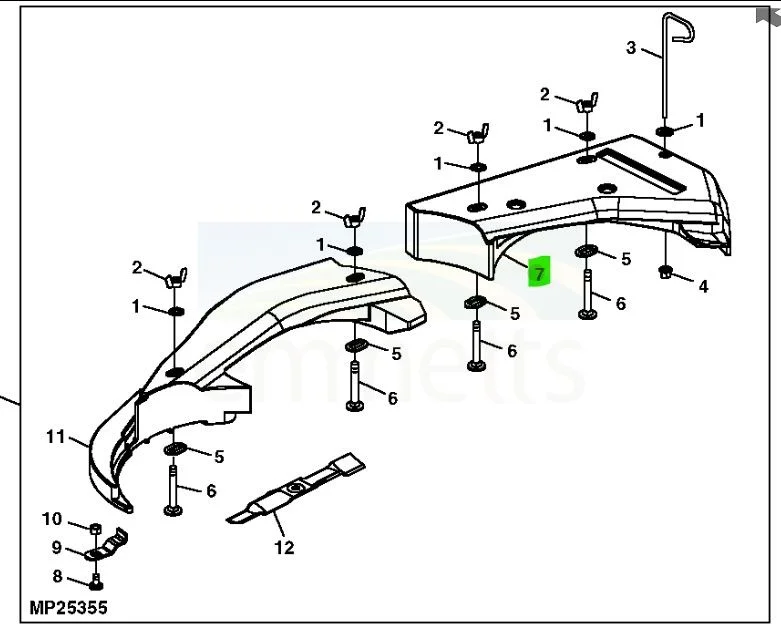

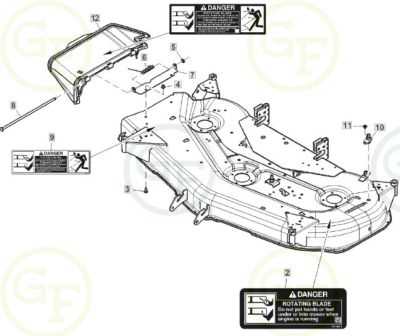

Understanding the 54c Mower Deck Components

When it comes to maintaining efficient performance, it’s crucial to familiarize yourself with the key elements that contribute to smooth operation. Each component plays a specific role in ensuring the machinery functions correctly, allowing for optimal precision and power during use.

| Component | Function | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

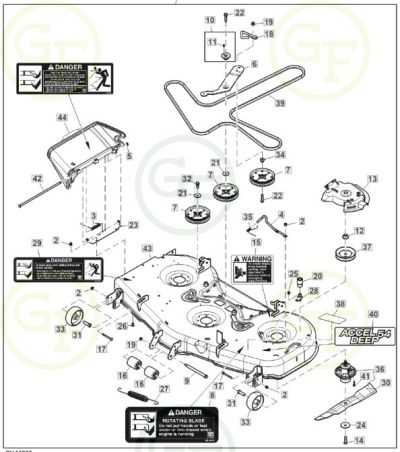

| Blades | These are responsible for cutting and slicing through vegetation, ensuring an even and clean trim. | ||||||||||||||||||||||||||||||||||||||

| Spindles | Provide the necessary rotation for the blades, translating the motor’s power into cutting action. | ||||||||||||||||||||||||||||||||||||||

| Pulleys | These manage the tension and alignment of belts, ensuring smooth and continuous movement during operation

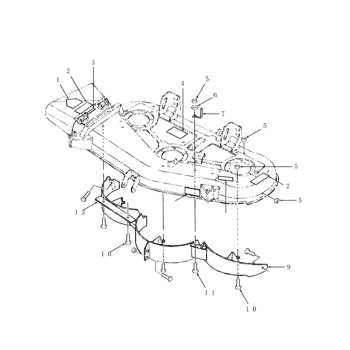

Key Functions of the Mower DeckThe cutting unit of a lawn care machine plays a vital role in ensuring effective and even trimming of grass across various terrains. Its design allows for precise handling of vegetation, adapting to different ground conditions while maintaining performance consistency. Efficient Grass ManagementOne of the primary functions is to manage the flow of grass clippings, guiding them through a carefully engineered system. This enables an even distribution of cuttings, whether they are discharged, mulched, or bagged. The structure of the cutting unit ensures minimal clumping, enhancing the overall quality of the finish. Height Adjustment and Versatility

The unit is equipped with mechanisms that allow for easy adjustment of cutting height, providing versatility in handling different types of grass and desired cutting lengths. This functionality enables users to tailor their lawn care to seasonal needs or specific landscaping requirements. Blade Design and Maintenance Tips

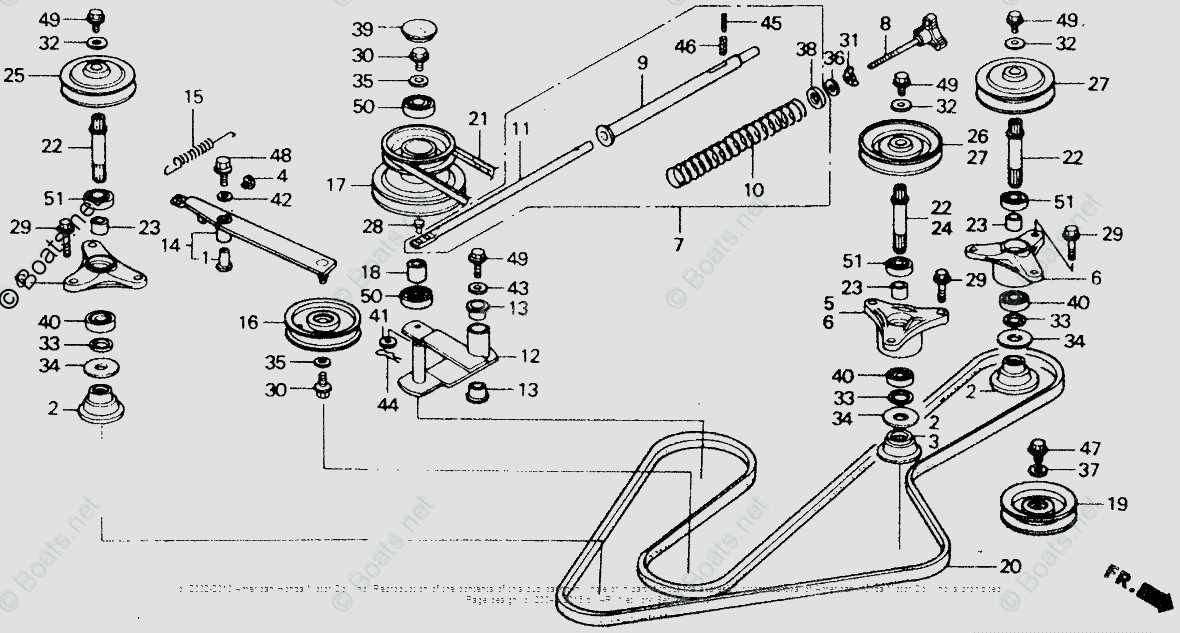

Effective cutting performance relies heavily on the design and upkeep of the cutting edges. The shape and structure of the blades are key factors in achieving a clean and even cut, contributing to the overall efficiency of the machine. Regular maintenance ensures longevity and optimal functionality, helping to prevent uneven wear and performance issues. Sharpening the blades periodically is essential for maintaining precision. Dull blades can tear rather than cut, leading to a rougher finish. Make sure to sharpen at the correct angle and avoid over-sharpening, which can weaken the edges. Balancing the blades after each sharpening is critical. Imbalanced blades can cause vibration, leading to damage to the equipment over time. It’s important to check for balance by using a specialized tool or a simple balancing method at home. Belt System for Efficient Performance

The belt system plays a crucial role in ensuring optimal functionality, transferring power seamlessly to maintain smooth operation. Its design is focused on maximizing energy efficiency, reducing wear, and enhancing overall durability. With the right tension and alignment, the system supports the engine’s output while minimizing friction and potential breakdowns. A well-maintained belt mechanism guarantees long-lasting performance, preventing unnecessary downtime. Regular inspection and adjustments ensure that the system continues to function at its peak, providing reliable service over extended periods. An efficient belt configuration contributes significantly to operational precision and energy conservation. Spindle Assembly and Its ImportanceThe spindle assembly plays a crucial role in the functioning of cutting equipment. It serves as a central component that connects the rotating blade to the rest of the machine, ensuring smooth and efficient operation. Proper maintenance and understanding of this element are essential for optimal performance and longevity of the device. Key Functions of the Spindle Assembly

Why Spindle Assembly Maintenance Matters

|