In the realm of lawn care machinery, comprehending the various components that contribute to optimal performance is essential for maintenance and repair. This section delves into the intricate elements that form the cutting assembly of a popular model, highlighting their functionality and interconnections.

By familiarizing yourself with the layout and specifications of these crucial elements, you can enhance your ability to diagnose issues effectively. Additionally, knowing the specific roles each component plays will empower you to make informed decisions regarding replacements and upgrades.

Whether you are a seasoned technician or a dedicated enthusiast, having access to a clear visual representation of the assembly can simplify your tasks and improve your overall experience with the equipment. The subsequent exploration provides a detailed overview of the key features and functionalities associated with these parts.

This section aims to provide an overview of a specific model known for its efficiency and versatility in lawn maintenance. It is essential to comprehend the various components that contribute to its functionality and performance. By familiarizing oneself with the essential elements, users can enhance their understanding and maintenance of the equipment.

Key Features of the Model

The machine boasts several features that make it a popular choice among users. Its design incorporates advanced mechanisms that ensure optimal performance during operation. Additionally, the construction materials are selected for durability, allowing for extended use even under demanding conditions.

Maintenance and Care

Regular maintenance is crucial for preserving the efficiency of the equipment. Users should pay attention to specific components that require routine checks and potential replacements. This proactive approach can prevent major issues and extend the lifespan of the unit.

| Component | Description | Maintenance Tips |

|---|---|---|

| Blades | Critical for cutting efficiency and grass health. | Sharpen regularly and check for damage. |

| Belts | Transmit power from the engine to the blades. | Inspect for wear and replace as needed. |

| Wheels | Ensure smooth movement across different terrains. | Check tire pressure and tread regularly. |

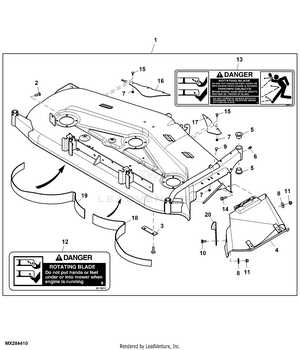

Components of the Mower Deck

The assembly of a mowing system comprises various elements that work in unison to achieve effective grass cutting and collection. Each component plays a crucial role in ensuring optimal performance and longevity of the machinery.

Housing: The outer shell of the mower protects internal components and supports structural integrity. It is designed to withstand outdoor conditions while providing accessibility for maintenance.

Blades: Sharp rotating tools responsible for cutting grass efficiently. Their design influences the quality of the cut, making regular maintenance essential for effective operation.

Spindles: These components facilitate the rotation of the blades. Proper functioning of spindles is vital for achieving the desired cutting height and blade speed.

Belt System: A series of belts transmit power from the engine to the blades. This system must be correctly adjusted and maintained to ensure effective power transfer and prevent slippage.

Wheels: The mobility features that allow the mower to navigate various terrains. Adjustable wheels can enhance cutting performance by allowing the user to set the desired cutting height.

Understanding these elements is essential for maintaining an efficient and reliable mowing system. Regular inspection and upkeep of each component will contribute to the overall effectiveness and lifespan of the equipment.

Identifying Key Parts in Diagrams

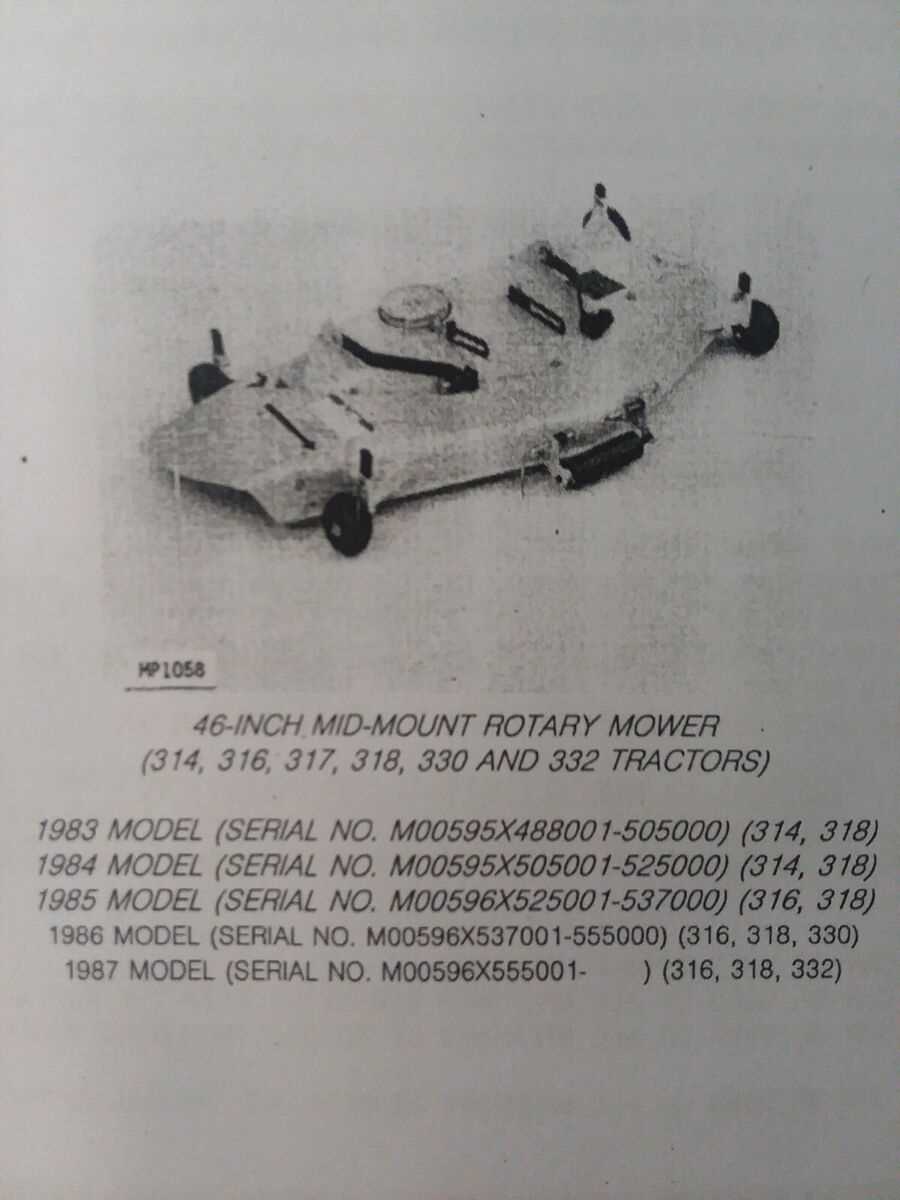

Understanding the components of machinery is crucial for effective maintenance and repairs. Visual representations serve as valuable resources, providing a clear layout of various elements involved. By analyzing these illustrations, one can easily recognize the functions and relationships of each section.

When examining these visual guides, focus on the labeled features that indicate critical components. Pay attention to the symbols and numbering, as they often correspond to detailed descriptions found in accompanying manuals. Familiarizing oneself with these elements enhances overall comprehension, making troubleshooting simpler and more efficient.

Moreover, recognizing the layout and organization of the diagram aids in locating specific areas that require attention. This knowledge not only streamlines the repair process but also contributes to a deeper understanding of the equipment’s functionality. As you engage with these resources, the ability to identify and interpret various sections will improve, leading to more effective maintenance practices.

Importance of Deck Maintenance

Proper upkeep of the cutting mechanism is essential for optimal performance and longevity of the equipment. Regular maintenance not only enhances efficiency but also contributes to a cleaner and healthier environment by ensuring a precise and even cut.

Enhanced Performance

Maintaining the cutting assembly ensures that it operates at its best. A well-maintained mechanism can significantly improve the quality of the cut, leading to better results in lawn care and landscaping tasks. Regular inspections and necessary adjustments can prevent issues that may arise from wear and tear.

Cost Savings

Investing time and effort into maintenance can result in substantial savings in the long run. By addressing minor issues before they escalate into major repairs, operators can avoid costly replacements and prolong the lifespan of their equipment. Additionally, efficient operation reduces fuel consumption, leading to lower operating costs.

Common Issues with Mower Decks

Mower components are essential for maintaining a well-kept lawn. However, various challenges may arise that affect their efficiency and performance. Understanding these typical problems can help operators diagnose and address issues promptly, ensuring the equipment operates smoothly and effectively.

One of the most prevalent issues encountered involves uneven cutting, often resulting from worn or damaged blades. This problem can lead to unsatisfactory lawn appearance and increased wear on the mower.

Another common concern is grass buildup under the cutting mechanism, which can impede performance and lead to overheating. Regular cleaning and maintenance are crucial to preventing this accumulation.

Additionally, vibration during operation can indicate misalignment or loose components, potentially causing further damage if not resolved quickly.

Finally, issues related to the discharge of clippings can also occur. If the clippings are not being expelled properly, it may lead to clumping and reduced cutting efficiency.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Uneven Cutting | Uneven grass height | Inspect and replace blades |

| Grass Buildup | Overheating, reduced efficiency | Regular cleaning |

| Vibration | Excessive shaking | Check for loose components |

| Discharge Issues | Clumping of clippings | Inspect discharge chute |

Replacing Worn-Out Components

Maintaining the functionality of your equipment involves regularly addressing any deteriorating elements. Over time, various components may experience wear and tear, which can lead to decreased performance or even complete failure. It is essential to recognize these signs early to ensure smooth operation and longevity.

Identifying worn-out parts requires careful inspection. Look for signs such as excessive noise, unusual vibrations, or reduced efficiency during use. Once you have pinpointed the problematic components, it is crucial to source high-quality replacements to restore optimal performance.

When replacing worn elements, follow the manufacturer’s guidelines to ensure a proper fit and compatibility. Using the correct tools and techniques will facilitate a smooth replacement process. After installation, perform a thorough test to confirm that the new components function as intended and improve the overall performance of your machinery.

Tools Needed for Repairs

To effectively carry out maintenance and fixes on your equipment, having the right instruments is essential. This ensures that the tasks are completed efficiently and with precision, minimizing the risk of damage or errors during the process.

Essential Tools

Several fundamental tools are necessary for successful repairs. These include wrenches for loosening or tightening bolts, screwdrivers for adjusting components, and pliers for gripping and twisting. Additionally, a jack may be required to lift the machine safely, providing easy access to various parts.

Optional Accessories

In addition to basic tools, consider using specialty equipment to facilitate specific tasks. For instance, torque wrenches can help ensure that fasteners are tightened to the correct specifications. Furthermore, having a multimeter is beneficial for diagnosing electrical issues, enabling you to troubleshoot more effectively.

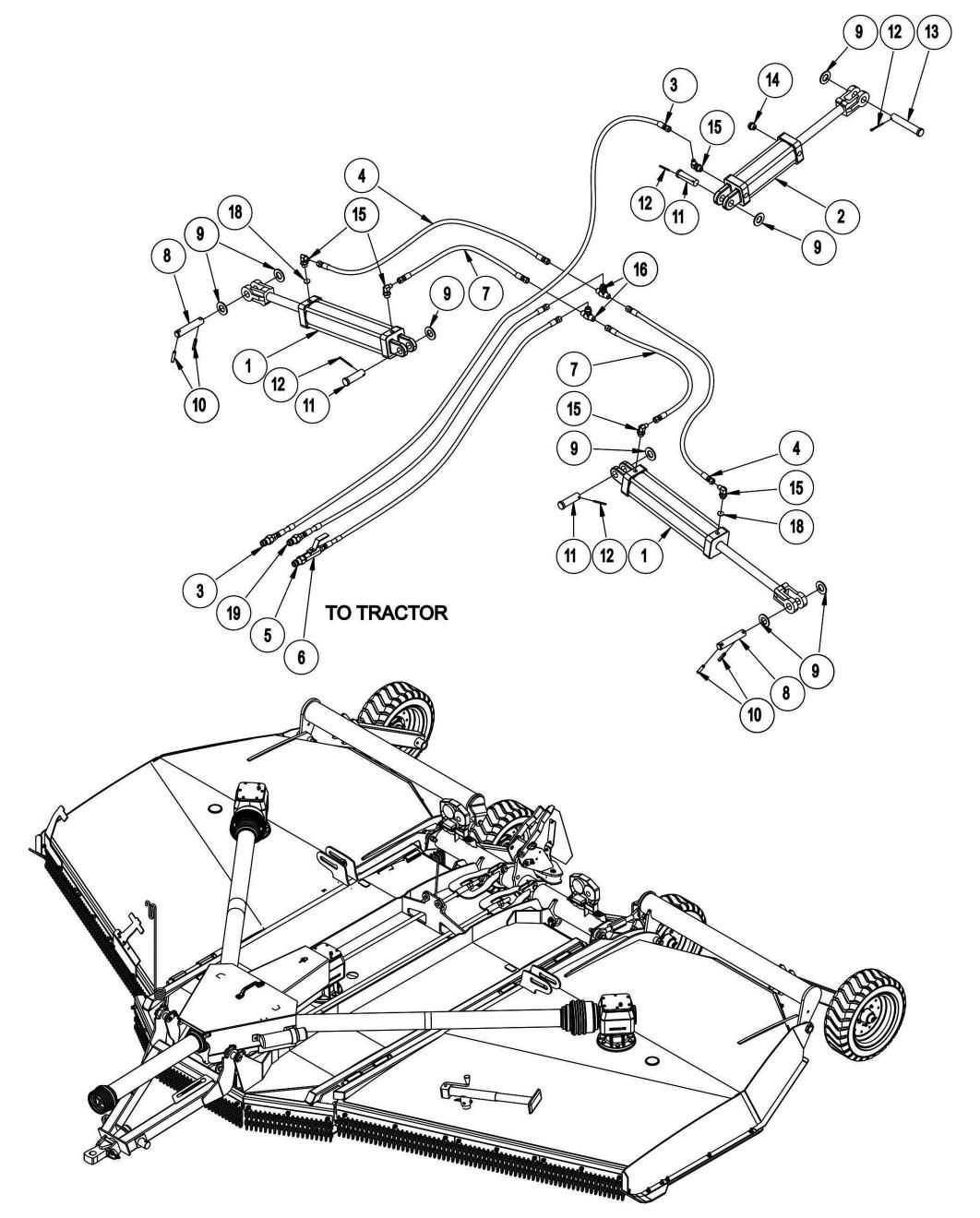

Step-by-Step Assembly Guide

This section provides a comprehensive walkthrough for the assembly process of a lawn care apparatus. Following a structured approach ensures that each component is correctly integrated, enhancing both performance and durability. This guide outlines essential steps to facilitate a seamless assembly experience.

Preparation: Begin by gathering all necessary tools and components required for the assembly. Organizing the workspace will help streamline the process and prevent any misplaced items.

Initial Assembly: Start with the main structure, ensuring all connectors are aligned. Utilize appropriate fasteners to secure each part firmly. Be sure to follow the recommended torque specifications to avoid any damage.

Integrating Additional Components: After the main frame is assembled, proceed to attach secondary parts such as the blades and pulleys. Ensure that all belts are correctly routed to maintain efficiency during operation.

Final Checks: Once the assembly is complete, conduct a thorough inspection. Verify that all connections are tight and that there are no loose components. Performing a final check can help identify any potential issues before initial use.

Conclusion: Adhering to these steps will ensure a successful assembly, promoting optimal functionality and longevity of the equipment. Proper assembly not only enhances performance but also contributes to safety during operation.

Choosing Quality Replacement Parts

When it comes to maintaining your equipment, selecting high-quality components is essential for optimal performance and longevity. Quality replacements not only enhance functionality but also ensure safety during operation. Investing in superior materials can save time and money in the long run, as they reduce the likelihood of frequent repairs or replacements.

Importance of Material Selection

The choice of materials directly affects the durability and efficiency of the components. Opting for robust materials can prevent premature wear and tear, contributing to the overall reliability of your machinery. It’s advisable to research manufacturers and their reputations to identify products that meet high industry standards.

Benefits of Genuine Components

Using authentic components often guarantees compatibility and optimal performance. These items are designed specifically for the machinery, ensuring that they fit perfectly and work efficiently. Moreover, genuine replacements may come with warranties, providing peace of mind and assurance of quality.

Adjusting the Mower Deck Height

Properly setting the height of the cutting unit is essential for achieving optimal lawn care results. Adjustments ensure that the blades operate at the desired elevation, which affects cutting efficiency and the overall health of the grass. Correct height management allows for a clean cut while minimizing damage to the turf.

Steps for Height Adjustment

To effectively modify the cutting height, follow these straightforward steps:

- Identify the current height setting using the measurement markers.

- Loosen the adjustment mechanism to allow for height changes.

- Raise or lower the unit to the preferred height, ensuring evenness.

- Tighten the mechanism to secure the new height setting.

- Test the new height by mowing a small section and assess the results.

Recommended Height Settings

The optimal height may vary depending on grass type and seasonal conditions. Below is a general guideline for ideal cutting heights:

| Grass Type | Recommended Height (inches) |

|---|---|

| Bermudagrass | 1.5 – 2.5 |

| Bluegrass | 2.5 – 3.5 |

| Fescue | 3.0 – 4.0 |

| Zoysiagrass | 1.5 – 2.5 |

Tips for Troubleshooting Problems

When faced with mechanical issues, having a systematic approach can make the resolution process much easier. Understanding potential causes and solutions is essential for effective problem-solving. Here are some practical tips to help diagnose and address common complications.

- Identify Symptoms: Start by observing the malfunctioning unit. Note any unusual sounds, movements, or behaviors that could indicate the source of the issue.

- Check for Loose Connections: Ensure that all bolts, screws, and connectors are securely fastened. Vibration during operation can lead to loosened components.

- Examine Fluid Levels: Verify that oil, fuel, and hydraulic fluid levels are adequate. Low levels can lead to performance problems.

- Inspect Belts and Cables: Look for signs of wear or damage on belts and cables, as these can impact functionality and lead to breakdowns.

- Consult the Manual: Reference the equipment manual for guidance on troubleshooting specific issues. Manuals often contain valuable information about common problems and their solutions.

By following these strategies, operators can efficiently address issues and maintain optimal performance. Regular maintenance can also help prevent future complications and prolong the lifespan of the equipment.

Safety Precautions During Maintenance

When conducting maintenance on machinery, ensuring safety is paramount. Proper precautions not only protect the individual performing the tasks but also extend the lifespan of the equipment. Here are essential guidelines to follow:

- Wear Protective Gear: Always don safety glasses, gloves, and appropriate footwear to shield against potential hazards.

- Disconnect Power Sources: Before starting any maintenance work, ensure that all power sources are disconnected to prevent accidental starts.

- Use Proper Tools: Employ the correct tools for each task to avoid damaging components or causing injury.

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety warnings prior to beginning maintenance.

Furthermore, it is advisable to work in a well-ventilated area and keep the workspace organized. This minimizes risks associated with tripping and exposure to harmful substances.

- Follow Procedures: Adhere strictly to established procedures to maintain consistency and safety during tasks.

- Seek Assistance: If uncertain about any step, do not hesitate to ask for help or consult a professional.

By prioritizing safety, individuals can perform maintenance effectively while minimizing the risk of accidents and injuries.

Where to Find Diagrams Online

Locating accurate schematics for machinery components can greatly enhance repair and maintenance efforts. Various resources are available online, catering to those seeking visual representations and detailed layouts of mechanical systems.

Manufacturer Websites

One of the most reliable sources for obtaining schematics is directly from the official websites of equipment manufacturers. These platforms often provide downloadable manuals and detailed illustrations that can assist in identifying specific components.

Online Forums and Communities

Participating in online forums and user communities can also be beneficial. Enthusiasts and experienced users frequently share valuable resources, including diagrams, tips, and advice on maintenance and repairs. Engaging with these communities allows users to exchange knowledge and access a wealth of shared information.