The efficient functioning of any lawn maintenance equipment relies heavily on its internal structure and the various elements that work in harmony. Understanding these components is essential for optimal performance and longevity. This section will shed light on the intricacies of one specific model, emphasizing how each piece contributes to the overall effectiveness.

With a focus on the assembly and configuration, enthusiasts and professionals alike can benefit from a detailed overview of the crucial elements involved. This knowledge not only aids in repairs but also enhances the user experience, ensuring that the machinery operates at its peak.

As we delve into the specifics, you will find valuable insights into the arrangement and purpose of each component. Such familiarity with the assembly will empower users to tackle maintenance tasks with confidence and clarity, leading to the ultimate care of your green spaces.

Understanding John Deere 325 Mower Deck

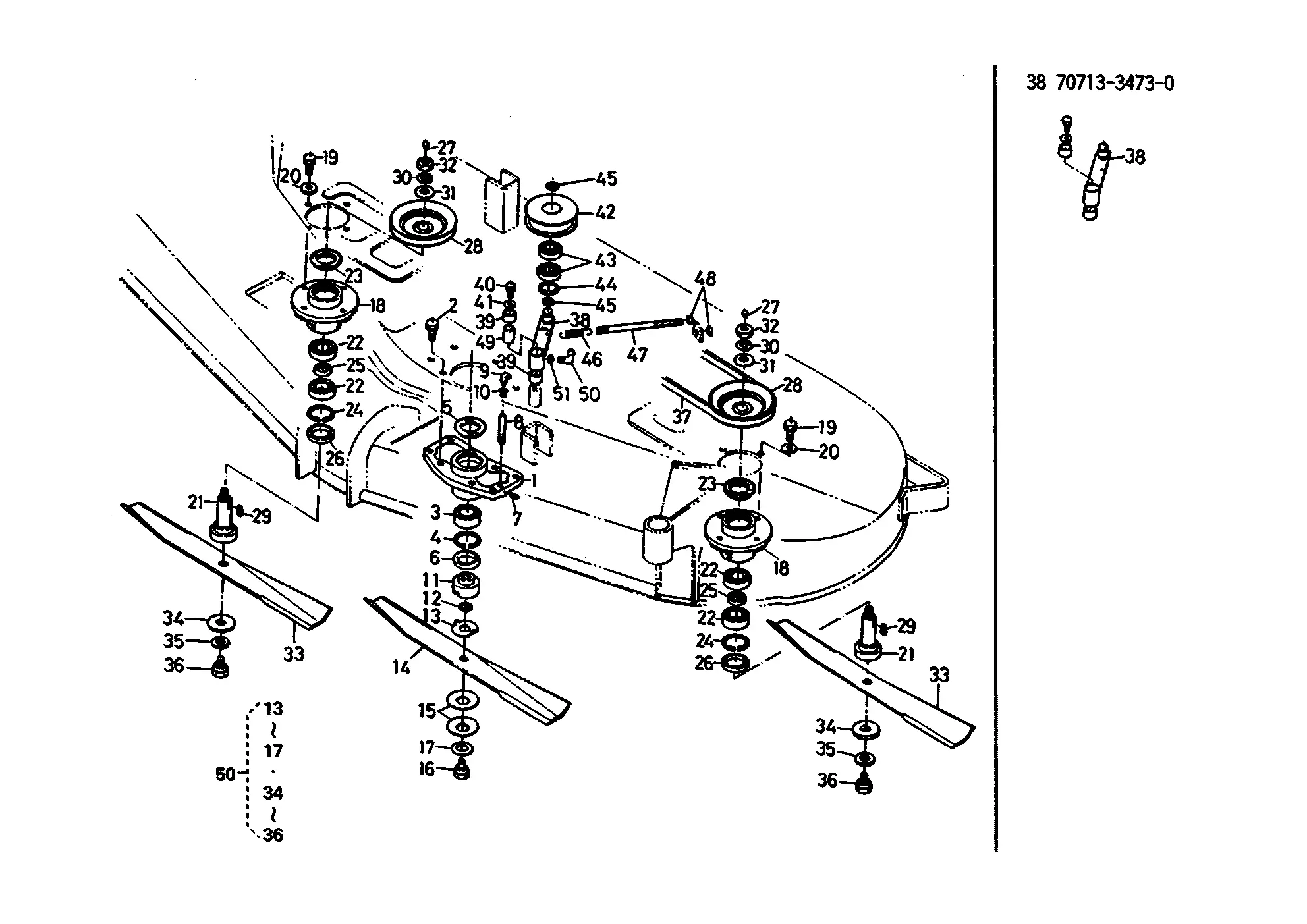

Gaining insights into the cutting mechanism of a particular grass-trimming machine is essential for optimal performance and maintenance. This section explores the various components that contribute to the efficiency of the cutting system, ensuring a smooth and effective operation. Familiarity with each element aids in troubleshooting and enhances the overall user experience.

When examining the essential components, it is beneficial to understand how they interconnect and function collectively. Below is a brief overview of key elements and their roles.

| Component | Function |

|---|---|

| Blades | Responsible for cutting grass to the desired height. |

| Spindles | Support and rotate the blades, enabling efficient cutting. |

| Belts | Transfer power from the engine to the cutting blades. |

| Deck Shell | Encloses the cutting components, providing structure and support. |

| Height Adjustment Mechanism | Allows the user to modify the cutting height for different grass types. |

By understanding these components, operators can enhance their maintenance routines and ensure a longer lifespan for their equipment. Regular checks and timely replacements are key to sustaining performance and achieving pristine results in lawn care.

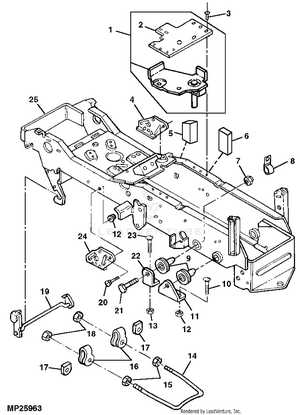

Key Components of the Mower Deck

Understanding the essential elements of a cutting platform is crucial for effective maintenance and performance. Each component plays a vital role in ensuring optimal operation, contributing to a seamless mowing experience. Below are the primary features that make up this integral assembly.

Essential Elements

- Blade Assembly: The blades are responsible for the actual cutting action, and their design impacts the quality of the cut.

- Spindle Housing: This component supports the blades and allows them to rotate efficiently, maintaining proper alignment.

- Belts: Power transmission belts connect the engine to the blade assembly, ensuring that the blades receive adequate power.

- Chassis: The frame provides stability and support for all other elements, influencing overall durability and performance.

Additional Components

- Lift Mechanism: This allows for adjusting the height of the cutting blades, accommodating various grass lengths.

- Deflector: Designed to direct clippings away from the cutting area, improving visibility and performance.

- Anti-scalp Wheels: These prevent damage to the lawn by ensuring the blades do not dig too deep into the ground.

By familiarizing yourself with these critical components, you can ensure that your cutting platform operates efficiently and effectively, leading to a well-manicured lawn.

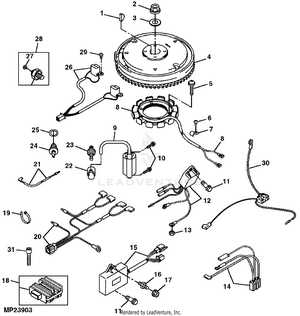

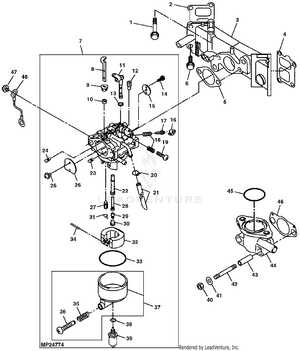

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate the schematic, allowing for quick identification and troubleshooting.

Familiarize Yourself with Symbols

Each representation has specific meanings. Recognizing these symbols can greatly enhance your comprehension:

- Shapes indicating different parts

- Lines showing connections and relationships

- Numbers corresponding to specific components

Follow the Flow of the Schematic

Start from a defined point and trace the connections:

- Identify the primary component.

- Follow the lines to see how parts interact.

- Note any annotations or numbers for reference.

Common Issues with Mower Deck Parts

Understanding the frequent challenges that arise with cutting implements can enhance maintenance and performance. These issues often stem from wear and tear, misalignment, or improper care, leading to suboptimal functionality.

- Blade Dullness: Blades can lose sharpness over time, affecting cutting efficiency.

- Rust Formation: Moisture exposure can lead to corrosion, compromising structural integrity.

- Loose Fasteners: Vibrations can cause screws and bolts to loosen, resulting in instability.

- Misalignment: Incorrect assembly can lead to uneven cutting and increased wear.

- Debris Buildup: Grass and dirt accumulation can obstruct movement and airflow.

Addressing these common concerns proactively can lead to enhanced longevity and optimal operation.

Maintenance Tips for Mower Deck

Ensuring the longevity and efficiency of your cutting equipment requires regular upkeep. By following essential maintenance practices, you can enhance performance and prolong the lifespan of your tools. Here are some key tips to keep in mind.

Regular Inspection

Conduct frequent checks for wear and tear. Look for any signs of damage or rust that could affect functionality. Addressing small issues promptly can prevent larger, costlier problems down the line.

Cleaning and Lubrication

Keep the equipment clean by removing grass clippings, dirt, and debris after each use. Regular lubrication of moving parts helps reduce friction and prevents premature wear. Use the recommended lubricants specified in your owner’s manual.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for Damage | Weekly | Look for cracks or rust. |

| Clean Thoroughly | After Each Use | Remove all debris. |

| Lubricate Moving Parts | Monthly | Use recommended oils. |

| Check Blade Sharpness | Every 10 Hours | Sharpen as needed. |

Finding Genuine John Deere Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine items ensure compatibility and reliability, providing peace of mind during operation.

Identifying Original Components involves researching authorized dealers and trusted suppliers. This guarantees that you receive quality materials designed specifically for your model.

Benefits of Using Authentic Items include enhanced durability and improved efficiency, minimizing the risk of breakdowns and costly repairs. Always prioritize quality to achieve the best results in your tasks.

Exploring online resources and forums can further aid in understanding where to find legitimate options. Engaging with fellow users can also provide valuable insights and recommendations.

Replacing Blades on the Mower Deck

Maintaining sharp cutting implements is essential for achieving a clean and efficient cut. Regular replacement not only enhances performance but also prolongs the lifespan of the machinery. This section provides guidance on the necessary steps for effective blade replacement.

Tools Required

- Wrench set

- Socket set

- Safety gloves

- Blade removal tool

Step-by-Step Process

- Ensure the equipment is turned off and cool.

- Disconnect the spark plug for safety.

- Lift the assembly using a suitable jack.

- Loosen the bolts securing the cutting implements.

- Carefully remove the old blades and replace them with new ones.

- Tighten the bolts securely to prevent movement.

- Reconnect the spark plug and lower the assembly.

Assembly Instructions for Mower Deck

This section provides essential guidance for assembling the cutting unit of your lawn care equipment. Proper installation ensures optimal performance and longevity, making it crucial to follow these instructions carefully.

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools before starting the assembly. |

| 2 | Align the housing with the support brackets, ensuring a snug fit. |

| 3 | Secure the housing using the provided fasteners, tightening them uniformly. |

| 4 | Attach the cutting blades, ensuring they are correctly oriented for efficient operation. |

| 5 | Connect the drive components, making sure all links are secure and free of obstructions. |

| 6 | Perform a final inspection to confirm all parts are correctly installed and functioning. |

Tools Needed for Mower Maintenance

Regular upkeep of your outdoor equipment ensures optimal performance and longevity. Having the right tools on hand is essential for efficient maintenance tasks, allowing for quick repairs and adjustments when needed.

Essential Hand Tools

Basic hand tools, such as wrenches, screwdrivers, and pliers, are crucial for various maintenance activities. Socket sets are particularly useful for tightening bolts and nuts, while file sets help maintain sharp edges on blades.

Cleaning and Lubrication Supplies

To keep your machine in prime condition, invest in quality cleaning agents and lubricants. Grease guns and oil cans are vital for ensuring all moving parts operate smoothly, preventing wear and tear over time.

Cost Factors for Replacement Parts

When considering the replacement of various components, several financial aspects come into play that can influence overall expenses. Understanding these factors can aid in making informed decisions and optimizing budgeting for maintenance and repairs.

- Quality of Materials: Higher-quality materials often come at a premium but can provide enhanced durability.

- Brand Reputation: Renowned brands may charge more due to their established reliability and performance standards.

- Supply and Demand: Availability can fluctuate, affecting prices based on market conditions.

- Compatibility: Specificity of parts for particular models can lead to varying price points.

- Retailer Markup: Different retailers may have distinct pricing strategies, impacting the final cost.

Being aware of these elements will ultimately help in budgeting and selecting the most suitable options for your needs.

Upgrading Your Mower Deck Setup

Enhancing your cutting system can significantly improve efficiency and performance. Whether you’re looking to boost productivity or achieve a finer finish, careful consideration of available enhancements is essential. Various components can work in harmony to elevate your experience.

Key Components for Improvement

- High-Quality Blades

- Advanced Drive Belts

- Upgraded Spindles

- Durable Roller Kits

Benefits of Upgrading

- Improved Cutting Precision

- Increased Durability

- Enhanced Maneuverability

- Lower Maintenance Costs

Investing in superior components can ultimately transform your cutting experience, making it more enjoyable and effective.