The intricate assembly of a grass-cutting accessory plays a vital role in maintaining an immaculate landscape. Recognizing each element and its function enhances operational efficiency and prolongs the lifespan of the equipment. This section will provide an overview of the essential components involved in this popular tool.

By exploring the configuration of these elements, users can gain insights into optimal maintenance practices. An in-depth understanding of how these parts interrelate can lead to more effective troubleshooting and repairs. Furthermore, familiarity with this equipment’s design will empower operators to achieve the ultimate results in their lawn care endeavors.

Whether you are a seasoned professional or a casual user, knowledge of this accessory’s architecture is invaluable. This guide aims to delve into the various components, illustrating their significance and offering practical advice for enhancement and upkeep.

Understanding the 54D Mower Deck

The innovative cutting system is designed for efficiency and precision, providing a superior experience for users. This apparatus enhances the functionality of lawn maintenance equipment, ensuring optimal performance and ease of use.

Key Features

- Robust construction for durability

- Advanced cutting technology for a clean finish

- Compatibility with various lawn tractors

- Effortless height adjustment options

Maintenance Tips

- Regularly check and sharpen blades for optimal performance.

- Inspect for wear and tear on components periodically.

- Clean the surface after each use to prevent buildup.

- Store in a dry place to protect against rust.

Key Features of John Deere 54D

This section highlights the essential characteristics of a renowned cutting tool, focusing on its design and functionality. These features contribute to its efficiency and effectiveness in lawn maintenance tasks, making it a popular choice among homeowners and professionals alike.

- Innovative Cutting Technology: The equipment is equipped with advanced cutting mechanisms that ensure a clean and precise trim.

- User-Friendly Design: Ergonomically designed for ease of use, allowing operators to maneuver with comfort and control.

- Durable Construction: Built from high-quality materials, this tool is designed to withstand rigorous use and harsh conditions.

- Adjustable Height Settings: Features multiple height options to cater to different types of grass and desired finish.

- Efficient Grass Discharge: Engineered for optimal grass flow, minimizing clumping and ensuring an even cut.

These attributes make the equipment a top choice for those seeking reliable performance and exceptional results in lawn care.

Auto Connect Mechanism Explained

The innovative mechanism designed for quick attachment and detachment of cutting equipment enhances efficiency and ease of use. This system allows operators to seamlessly engage and disengage their tools, significantly reducing the time and effort typically associated with traditional methods.

How It Works

This mechanism operates through a series of thoughtfully engineered components that interact smoothly. The primary elements include:

- Attachment Points: Strategic locations where tools align for secure connection.

- Lever Systems: Simple levers that enable quick locking and unlocking.

- Alignment Guides: Features that ensure precise positioning during engagement.

Benefits of the Mechanism

The advantages of this system are numerous, offering substantial improvements in workflow:

- Time-Saving: Rapid setup and removal processes.

- User-Friendly: Minimal physical effort required, suitable for all operators.

- Enhanced Safety: Reduced risk of injury due to easier handling.

Overall, this mechanism represents a significant advancement in the design of agricultural and landscaping equipment, making operations more accessible and efficient for users. Its engineering underscores the importance of innovation in modern machinery.

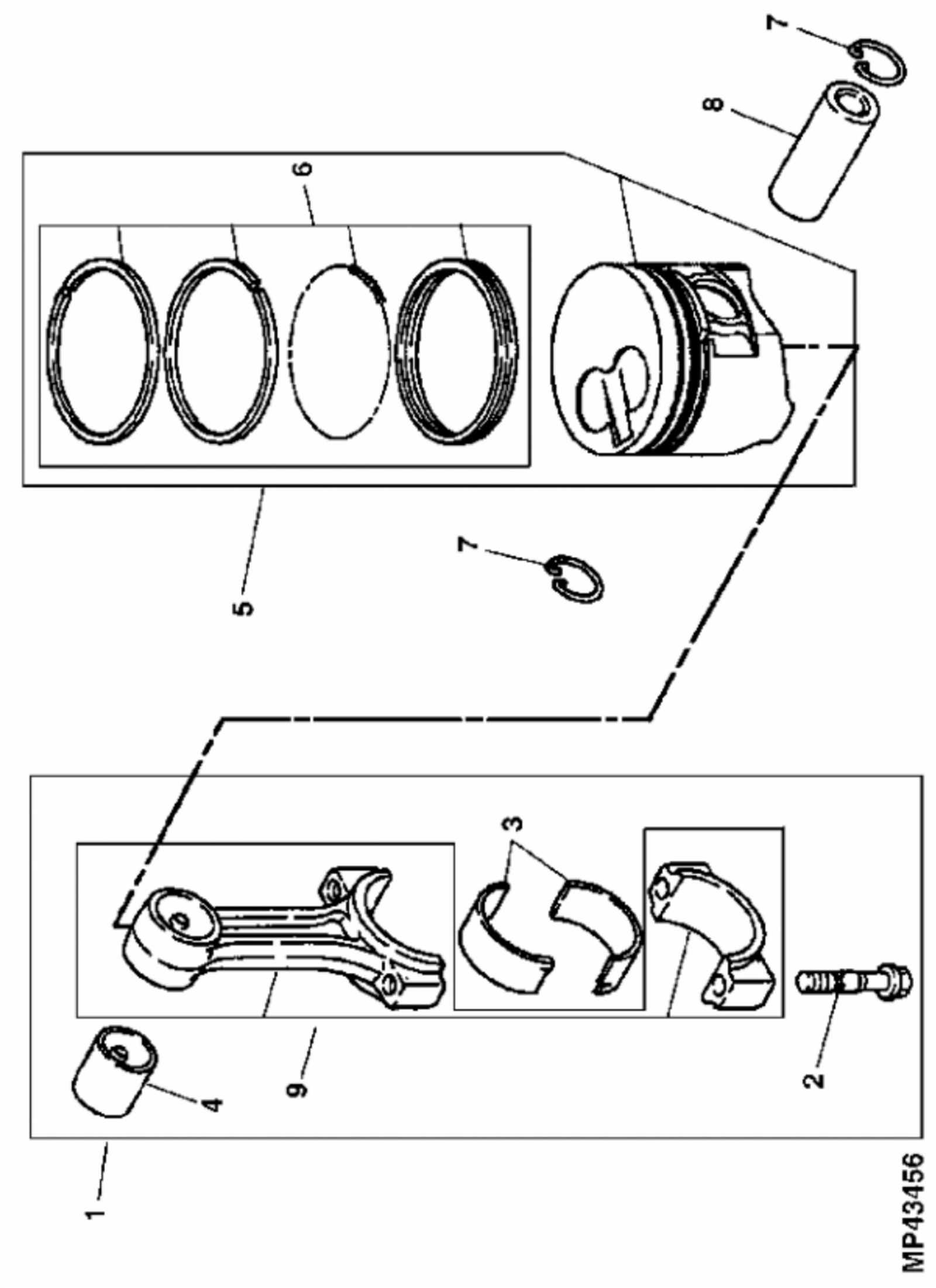

Essential Parts for Maintenance

Proper upkeep of your cutting equipment requires familiarity with the critical components that ensure optimal performance. Regular inspection and replacement of these elements not only enhance functionality but also prolong the lifespan of your machinery. Understanding these essential pieces is key to efficient operation and maintenance.

Key components include blades, which are vital for achieving a clean cut. Regular sharpening or replacement is necessary to maintain cutting efficiency. Additionally, belts play a crucial role in transferring power; checking for wear and ensuring proper tension can prevent breakdowns. Lubrication points should also be monitored to minimize friction and wear on moving parts.

Moreover, keeping an eye on the wheel assembly is important for smooth maneuverability. Ensuring that wheels are properly inflated and in good condition can significantly impact performance. Lastly, filters should be regularly cleaned or replaced to maintain airflow and engine efficiency.

Common Issues and Troubleshooting Tips

Maintaining equipment can present various challenges that may hinder performance. Understanding common problems and their solutions is essential for ensuring efficient operation.

- Unusual Noises: Check for loose components or debris that may interfere with movement.

- Poor Cutting Performance: Inspect blades for dullness and ensure proper height adjustment.

- Difficulty in Engagement: Verify that all connections are secure and free of obstructions.

Addressing these issues promptly can enhance the lifespan of the equipment and improve overall functionality.

How to Replace Mower Deck Parts

Maintaining the cutting equipment is essential for optimal performance. This guide will provide an overview of the process involved in substituting components, ensuring a smooth and efficient operation.

Gathering Necessary Tools

Before starting the replacement, ensure you have the right tools at hand. Commonly required items include wrenches, screwdrivers, and safety gloves. Having everything ready will streamline the process and enhance safety.

Step-by-Step Replacement Process

Begin by disconnecting the power source to prevent any accidents. Next, remove the damaged component by following the manufacturer’s instructions. Once the old part is removed, align the new component correctly and secure it in place. Finally, reconnect the power and test the equipment to confirm everything is functioning smoothly.

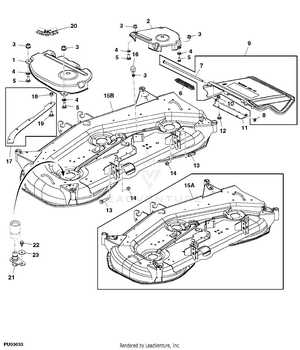

Diagram Overview: Parts Identification

This section aims to provide a comprehensive understanding of the essential components associated with the equipment, facilitating easier recognition and maintenance. Familiarity with these elements can enhance operational efficiency and prolong the lifespan of your machinery.

Key Components

- Cutting Blade Assembly

- Drive Mechanism

- Support Frame

- Adjustable Lift Link

- Mounting Brackets

Identification Tips

- Refer to the user manual for specific illustrations.

- Label each component during disassembly for easy reassembly.

- Utilize online resources for visual guides.

- Consult with a professional for unfamiliar parts.

Benefits of Using Original Parts

Utilizing authentic components for your machinery ensures optimal performance and longevity. These original items are specifically designed to work seamlessly with your equipment, providing a range of advantages that aftermarket alternatives may not match.

Quality Assurance

One of the primary benefits of opting for genuine components is the assurance of quality. Here are some key points to consider:

- Manufactured to strict standards, ensuring reliability.

- Durability that withstands wear and tear over time.

- Consistent performance that meets or exceeds expectations.

Compatibility and Support

Choosing original components also guarantees compatibility with your machine, enhancing its efficiency. Consider the following:

- Designed to fit perfectly, reducing installation issues.

- Backed by manufacturer support for troubleshooting and assistance.

- Potential for extended warranties that cover your investment.

Compatibility with John Deere Models

The adaptability of equipment is crucial for ensuring optimal performance across various machines. This section explores how certain attachments can seamlessly integrate with a range of models, enhancing functionality and user experience. Understanding these relationships helps owners maximize the potential of their machinery.

Compatibility often hinges on specific features, including connection types and design specifications. It is essential to refer to manufacturer guidelines to identify which models are supported and to ensure a proper fit.

Furthermore, compatibility can vary based on production years and model variations. Always verify the details to avoid mismatches that could lead to inefficiencies or operational issues.

Installation Guide for Mower Deck

This section provides a comprehensive overview of the steps necessary for attaching the cutting apparatus to your equipment. A proper installation ensures optimal performance and longevity, allowing for a seamless mowing experience. Following the outlined instructions carefully is essential for achieving the best results.

Preparation: Before beginning the installation, ensure you have all necessary tools and components readily available. Refer to the manufacturer’s manual for a complete list of items required. It is advisable to work on a flat, stable surface to facilitate the process.

Steps to Install:

1. Positioning: Start by aligning the assembly with the designated mounting points on the chassis. Ensure that all brackets and supports are clean and free from debris.

2. Securing: Attach the unit using the specified fasteners. Tighten them according to the recommended torque specifications to prevent any loosening during operation.

3. Adjustments: After securing, make any necessary adjustments to achieve the desired cutting height. This step is crucial for maintaining an even lawn finish.

Final Checks: Once the assembly is complete, double-check all connections and ensure that moving parts operate smoothly. Conduct a brief test run to verify that everything functions as intended.

By adhering to these guidelines, you can ensure a successful installation that enhances the efficiency and effectiveness of your equipment.

Cleaning and Care for Longevity

Maintaining your equipment in optimal condition is essential for its performance and lifespan. Regular cleaning and proper care can prevent buildup of debris, enhance functionality, and ensure that your investment serves you well over the years. Establishing a routine for maintenance is key to achieving the best results.

Routine Cleaning Practices

After each use, it’s important to remove any grass clippings and dirt. Utilize a brush or a garden hose to clear away residues, ensuring all components remain free from obstructions. This simple task can significantly reduce wear and tear, promoting smoother operation.

Storage and Maintenance Tips

When not in use, store your equipment in a dry and sheltered area to prevent rust and deterioration. Regularly check for loose bolts and perform any necessary lubrication on moving parts. Adhering to these practices will ultimately enhance performance and longevity, allowing you to enjoy efficient operation season after season.

Safety Tips for Mower Use

Operating a cutting machine requires attention to safety to prevent accidents and injuries. Understanding the potential hazards and adhering to best practices can ensure a safer experience while maintaining your landscape.

Essential Precautions

Before starting the equipment, always inspect it for any damage or wear. Ensure that the area is clear of obstacles, debris, and bystanders. Wearing appropriate protective gear is vital to safeguard against flying objects and noise.

Maintenance and Care

Regular maintenance is crucial for safe operation. Check the blades frequently for sharpness and integrity, and perform routine cleaning to avoid buildup. Follow the manufacturer’s guidelines for servicing and storage to enhance longevity and reliability.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always wear safety glasses, gloves, and ear protection. |

| Inspect Equipment | Check for any damages or loose parts before use. |

| Clear Area | Remove debris and ensure no one is in the vicinity. |

| Maintain Blades | Keep blades sharp and in good condition for optimal performance. |

Where to Find Replacement Parts

Finding suitable components for lawn equipment is essential for maintaining optimal performance. Several reliable sources can help you locate the necessary items to ensure your machinery operates smoothly.

- Authorized Dealers: Check with certified retailers who specialize in outdoor equipment. They often have a comprehensive selection of genuine components.

- Online Marketplaces: Websites like eBay, Amazon, and specialized parts suppliers provide a vast range of options, often at competitive prices.

- Manufacturer’s Website: Visit the official site of the brand for a dedicated section on replacement components. This ensures compatibility and quality.

- Local Repair Shops: Local technicians often have access to parts and can provide guidance on what is needed for repairs.

- Forums and Community Groups: Engaging with online communities can lead to recommendations for reliable sources and possibly second-hand options.

Regardless of where you choose to look, always verify the specifications to ensure a perfect fit for your equipment.