Maintaining a well-kept lawn requires reliable machinery designed for efficiency and effectiveness. Knowing the various elements that comprise these machines can greatly enhance their performance and longevity. Familiarity with the individual components allows users to troubleshoot issues, perform necessary repairs, and ensure optimal functionality.

This section provides an overview of the essential components associated with specific mowing equipment. Each part plays a crucial role in the overall operation, contributing to the machine’s ability to deliver a precise and uniform cut. Understanding these elements helps users make informed decisions about maintenance and upgrades.

Additionally, having a visual reference can aid in identifying parts during repairs or replacements. This understanding not only facilitates smoother operation but also extends the lifespan of the equipment, ensuring it remains a valuable asset in lawn care.

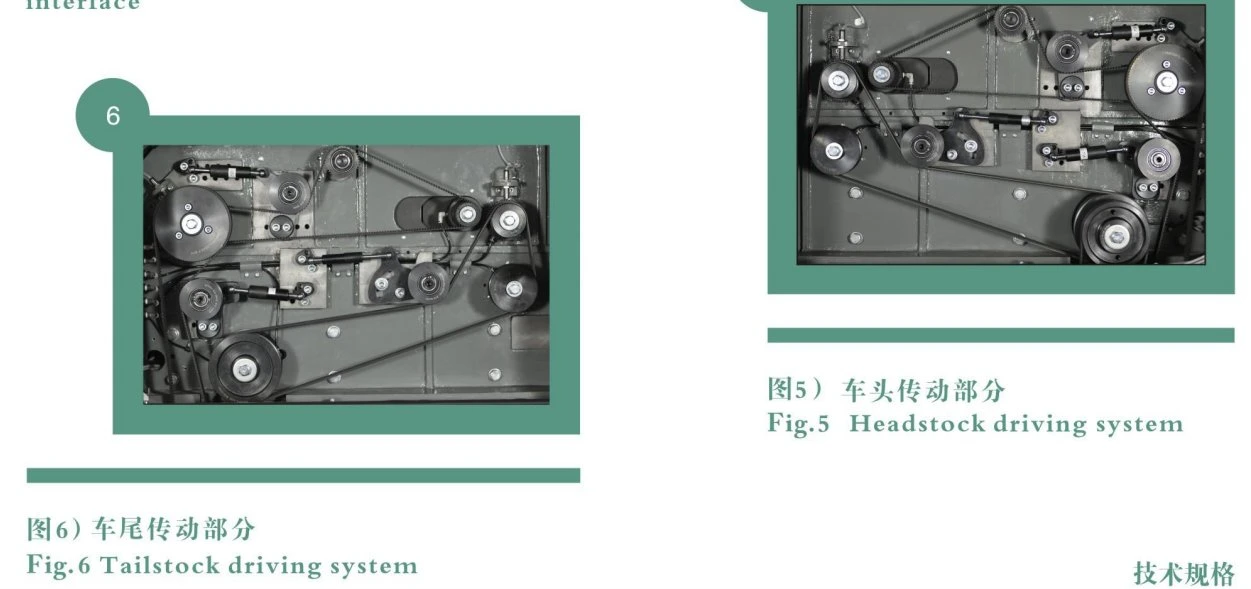

John Deere 62D Mower Deck Overview

This section provides an insightful exploration of a specific cutting mechanism utilized in landscaping. Designed for efficiency, it plays a vital role in ensuring a clean and precise finish while maintaining durability and ease of use.

Key Features

Noteworthy aspects include its robust construction, adjustable components, and compatibility with various models, making it a preferred choice for many users. Understanding these features can enhance operational effectiveness and maintenance.

Maintenance Considerations

Regular upkeep is essential to prolong its lifespan and performance. Users should pay attention to wear indicators and ensure components are properly aligned to avoid potential issues.

| Component | Description |

|---|---|

| Blade | Ensures effective cutting action. |

| Spindle | Supports the blade and allows rotation. |

| Housing | Protects internal components from debris. |

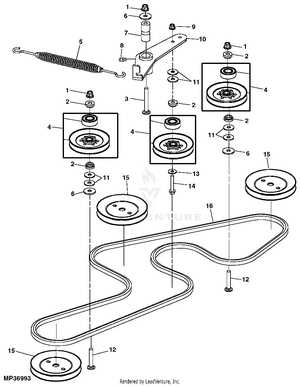

Key Components of the Mower Deck

The essential elements of a cutting assembly play a crucial role in ensuring effective operation and maintenance. Understanding these fundamental components can significantly enhance the performance and longevity of the equipment.

Blades: The sharp edges are vital for a clean cut, influencing the overall quality of the grass finish. Regular inspection and sharpening are necessary for optimal performance.

Spindle Assembly: This mechanism supports the rotation of the cutting edges. Its durability directly impacts the efficiency of the entire system, making it crucial for regular checks and maintenance.

Housing: The protective casing encases the inner workings, shielding them from debris and external damage. A well-maintained housing contributes to the longevity of the assembly.

Lift System: This component enables the adjustment of the cutting height, allowing for flexibility depending on grass conditions. Regular assessment ensures accurate height settings.

Belts: These transmit power from the engine to the cutting assembly. They should be inspected periodically for wear and tension to maintain effective operation.

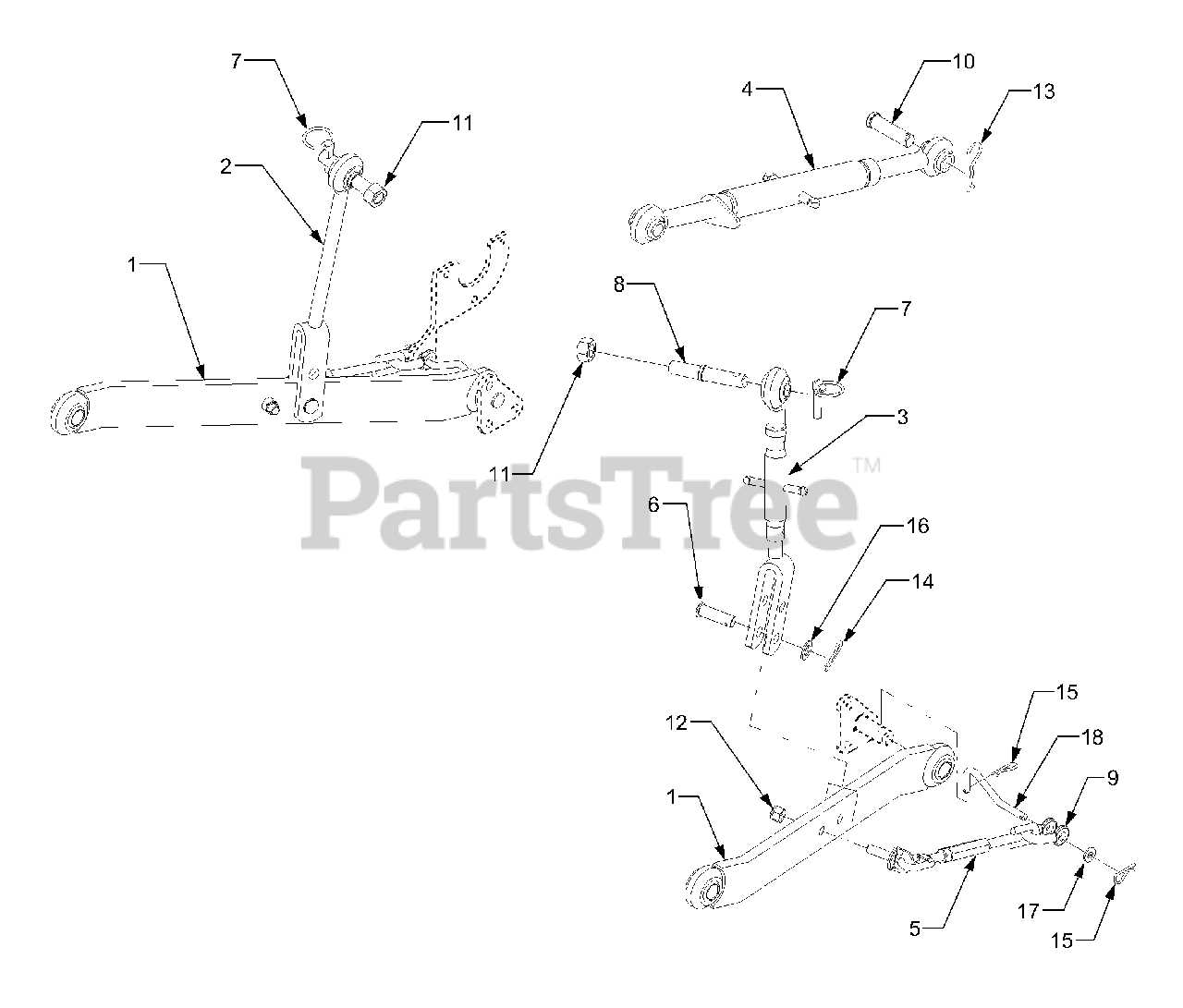

Understanding the Parts Diagram

Comprehending the schematic representation of components is essential for effective maintenance and repair. This visual guide provides clarity on the various elements involved, allowing users to identify and troubleshoot issues efficiently.

Key Components Overview

The illustration typically highlights crucial sections, facilitating a better understanding of each part’s function and relation to others. Familiarity with these components aids in ensuring optimal performance and longevity.

Utilizing the Diagram for Repairs

When addressing malfunctions, referring to this schematic can significantly streamline the repair process. By pinpointing specific areas, users can acquire the necessary replacements or adjustments, enhancing overall reliability.

Maintenance Tips for Mower Deck

Proper upkeep of your cutting apparatus is essential for optimal performance and longevity. Regular attention to various components can prevent costly repairs and ensure a smooth operation.

- Regular Cleaning: Remove grass clippings and debris after each use to prevent buildup.

- Inspect Blades: Check for wear and sharpen as needed to maintain cutting efficiency.

- Check Fasteners: Ensure all bolts and screws are tight to avoid vibrations and instability.

- Lubrication: Apply grease to moving parts to reduce friction and enhance functionality.

- Leveling: Ensure the cutting mechanism is level for an even cut across the lawn.

By following these guidelines, you can maximize the effectiveness and lifespan of your cutting equipment.

Common Issues and Solutions

Maintaining lawn care equipment can present various challenges that affect performance and efficiency. Identifying and addressing common problems early can prolong the lifespan of your machinery and ensure optimal operation. This section explores frequent issues encountered and their corresponding solutions.

Frequent Problems

Operators may experience several recurring issues, such as uneven cutting, difficulty starting, or unusual noises during operation. Understanding these problems can help in troubleshooting and maintenance.

Effective Solutions

Here are some common solutions to frequent issues:

| Issue | Solution |

|---|---|

| Uneven cutting | Check blade sharpness and adjust tire pressure. |

| Difficulty starting | Inspect battery connections and clean spark plugs. |

| Unusual noises | Examine belts and pulleys for wear or misalignment. |

| Loss of power | Replace air filter and ensure fuel lines are clear. |

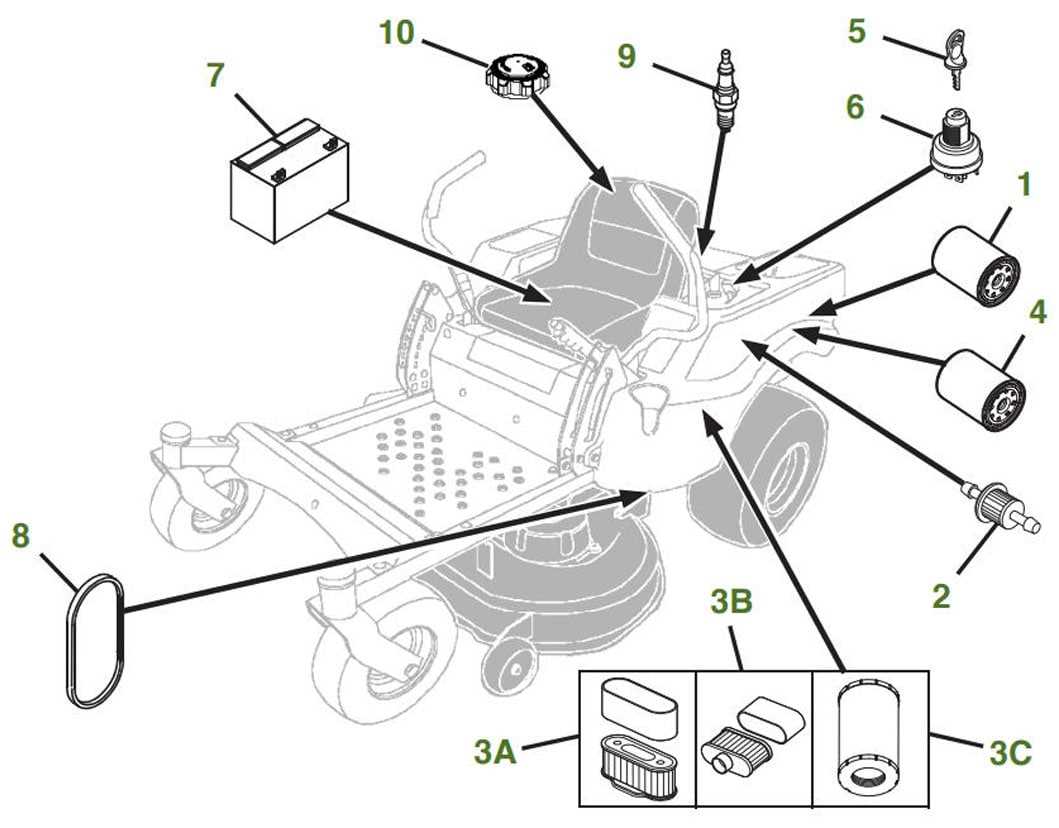

Replacement Parts for Mower Deck

Maintaining optimal performance requires timely replacement of essential components. Understanding which elements need to be exchanged can greatly enhance efficiency and extend the lifespan of the equipment.

Key Components to Consider

Various items contribute to the smooth operation of the apparatus. Identifying worn or damaged elements is crucial for effective upkeep.

| Component | Description | Replacement Frequency |

|---|---|---|

| Blades | Sharp edges for efficient cutting. | Every 25 hours of use |

| Belts | Transmit power from the engine. | Check annually |

| Spindles | Support the cutting mechanism. | Every 100 hours of use |

Benefits of Regular Replacement

Consistently replacing worn components enhances performance and reliability. It also reduces the risk of unexpected breakdowns, ensuring smoother operation overall.

How to Identify Part Numbers

Understanding how to locate identification numbers for components is essential for effective maintenance and repair. This knowledge helps in ensuring compatibility and availability of the necessary items for your equipment.

Check the Manufacturer’s Website

Visit the official site of the manufacturer to access resources like manuals and online diagrams. These tools often contain detailed lists of item codes, allowing for accurate identification.

Consult a Parts Catalog

A parts catalog can provide a comprehensive view of all available components along with their respective identification numbers. Utilizing these catalogs simplifies the process of finding the correct items needed for repairs.

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is essential for efficient and effective repairs. Proper tools not only facilitate the process but also ensure safety and accuracy during the work.

Essential Hand Tools

A variety of hand tools are crucial for completing repairs. Common items include wrenches, screwdrivers, and pliers, which help in loosening or tightening components. Additionally, a good quality hammer can assist in assembling parts securely.

Power Tools and Accessories

In some cases, power tools can significantly speed up the repair process. Drills and saws may be required for more complex tasks. Always ensure to have the appropriate bits and blades for your specific needs, as they enhance precision and performance.

Steps for Proper Installation

Following correct procedures during the setup of components is essential for optimal performance and longevity. This section outlines the essential phases to ensure a seamless assembly process.

Preparation Before Assembly

Before commencing the installation, ensure that all necessary tools and materials are readily available. Familiarize yourself with the components involved and review the installation guidelines thoroughly.

Step-by-Step Assembly Process

Begin by aligning the elements according to the provided specifications. Secure each piece firmly, ensuring that connections are tight and stable. Double-check each step to prevent future complications.

| Step | Description |

|---|---|

| 1 | Gather all tools and components. |

| 2 | Review assembly guidelines. |

| 3 | Align and secure each component. |

| 4 | Double-check connections for stability. |

Seasonal Care for Mower Deck

Proper maintenance throughout the year is essential for the longevity and performance of your cutting apparatus. By following a seasonal care routine, you can ensure that your equipment remains in optimal condition, providing efficient operation during the mowing season.

Spring Maintenance Tasks

As the growing season approaches, it’s crucial to prepare your machine for heavy usage. Consider the following tasks:

- Inspect blades for sharpness and replace if necessary.

- Check for any wear and tear on the undercarriage.

- Clean the entire assembly to remove debris and grass clippings.

- Lubricate all moving parts to ensure smooth operation.

Fall Preparation Steps

As the mowing season ends, taking steps to protect your equipment for winter is vital. Here are some recommendations:

- Thoroughly clean and dry the entire system.

- Remove and sharpen the cutting blades.

- Store in a dry, sheltered area to prevent rust and damage.

- Perform a full inspection for any repairs needed before the next season.

Compatibility with Other Models

This section explores the adaptability of specific components across various equipment models. Understanding the interchangeability can enhance maintenance efficiency and expand the usability of different machinery types.

Commonly Compatible Units

Several models are designed to work seamlessly with the components in question. These alternatives provide similar functionalities, allowing users to utilize their existing parts without the need for extensive modifications.

Factors Influencing Compatibility

When assessing compatibility, consider factors such as the design specifications, dimensions, and connection types. Ensuring these elements align can significantly impact performance and overall satisfaction.

Where to Purchase Replacement Parts

Finding suitable components for your equipment can significantly enhance its performance and longevity. Whether you’re looking for original or aftermarket options, knowing where to search is crucial for a successful maintenance experience.

Here are some reliable sources for obtaining quality components:

| Source | Description |

|---|---|

| Manufacturer’s Website | Offers genuine components with warranties and guarantees. |

| Local Dealers | Provide personalized service and immediate availability of items. |

| Online Retailers | Often have competitive pricing and a wide selection, including customer reviews. |

| Specialty Stores | Focus on specific brands and may offer expert advice on installation and use. |

Customer Reviews and Feedback

This section provides an overview of user experiences and evaluations regarding the equipment in question. Feedback from customers highlights the performance, durability, and overall satisfaction with the product.

Positive Experiences

Many users appreciate the reliability and efficiency of the device, noting its ease of use and maintenance. Customers often mention how well it handles various tasks, making it a valuable addition to their gardening tools.

Areas for Improvement

Some feedback points out that there are aspects that could be enhanced, such as the ease of obtaining replacement components. Users suggest that better availability would improve their overall satisfaction.

| Review Source | Rating | Comment |

|---|---|---|

| Customer A | 4.5 | Great performance and easy to use! |

| Customer B | 3.8 | Good product, but parts could be easier to find. |

| Customer C | 5.0 | Highly recommend for anyone with a large yard. |