In the world of lawn maintenance, a well-functioning machine is essential for achieving a pristine outdoor space. Each element of this machinery plays a crucial role in overall performance, ensuring efficiency and longevity. A comprehensive grasp of these components can empower users to make informed decisions about maintenance and repairs.

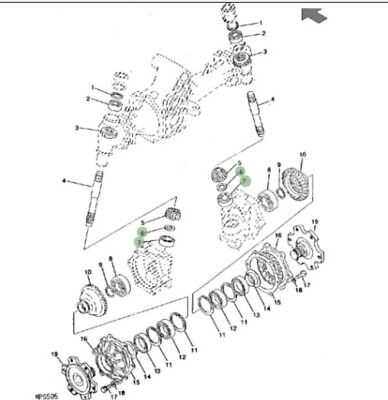

When exploring the intricacies of these tools, one often encounters a visual representation that illustrates the various sections and their respective functionalities. This schematic is invaluable for both seasoned professionals and hobbyists alike, offering insights into assembly and troubleshooting.

With the right knowledge, individuals can delve into the specifics of machinery upkeep, enhancing their experience and outcomes. Understanding these components ultimately leads to better performance and satisfaction in lawn care endeavors.

Understanding John Deere 755 Mower Deck

This section aims to provide a comprehensive overview of the cutting system associated with a specific model of outdoor equipment. A thorough understanding of its components is essential for effective maintenance and optimal performance. Recognizing how each element contributes to the overall functionality can enhance the user experience and prolong the life of the machinery.

Components Overview: The assembly consists of several crucial elements that work together seamlessly. From the housing to the blades, each part has a distinct role. Knowing how these components interact can aid in troubleshooting and repairs, ensuring the unit operates efficiently.

Maintenance Practices: Regular upkeep is vital for maintaining peak performance. Familiarizing oneself with the maintenance schedule and recommended practices can prevent common issues and ensure that the equipment remains in excellent working condition. Simple tasks such as cleaning and lubrication can make a significant difference over time.

Common Issues: Understanding potential problems that may arise with the assembly can save time and resources. Identifying symptoms early on can lead to quicker resolutions, minimizing downtime and improving overall productivity.

In summary, grasping the intricacies of this specific cutting system not only enhances operational efficiency but also empowers users to take proactive measures in maintenance and troubleshooting.

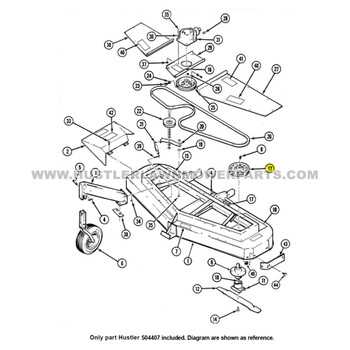

Components of the Mower Deck

The assembly of a cutting apparatus encompasses various essential elements that work in harmony to achieve optimal performance. Each component plays a crucial role in ensuring effective operation, from enhancing cutting efficiency to providing stability during use.

At the core of this assembly lies the rotating mechanism, which is responsible for the cutting action. Surrounding this mechanism are protective barriers that safeguard users while ensuring durability. Additionally, support structures provide necessary reinforcement, allowing for robust functionality even under challenging conditions.

Furthermore, the integration of height adjustment systems facilitates customization based on specific needs, contributing to the versatility of the equipment. Maintenance features are also incorporated to simplify upkeep, ensuring longevity and reliability over time.

Importance of Maintenance for Longevity

Proper upkeep is essential for extending the lifespan of any equipment. Regular attention not only enhances performance but also prevents potential issues that can arise from neglect. A consistent maintenance routine ensures that all components function smoothly and efficiently.

Timely inspections can identify wear and tear before they escalate into serious problems. By addressing minor repairs early, owners can avoid costly replacements and downtime. Additionally, routine cleaning and lubrication help maintain optimal performance, reducing the risk of mechanical failure.

Furthermore, adhering to a maintenance schedule promotes safety and reliability. Equipment that is well-maintained is less likely to malfunction, which can prevent accidents and injuries. Investing time in care also contributes to better fuel efficiency and overall productivity, making it a wise choice for anyone looking to maximize the value of their investment.

Common Issues with Mower Decks

Maintaining a well-functioning cutting mechanism is crucial for optimal lawn care. Various challenges can arise, impacting performance and efficiency. Understanding these common problems can help users identify and resolve issues promptly.

One prevalent concern is uneven cutting, often caused by improper height adjustments or blade wear. This can lead to an unsightly lawn and may necessitate frequent corrections. Another issue is the buildup of grass clippings and debris, which can hinder functionality and lead to overheating. Regular cleaning and maintenance can mitigate this problem.

Additionally, noise during operation can signal mechanical wear or misalignment. Addressing such sounds early on can prevent more severe damage and costly repairs. Lastly, the deterioration of belts and bearings can impact movement and cutting precision, making it essential to monitor these components regularly for signs of wear.

How to Identify Replacement Parts

Understanding how to recognize components that need to be substituted is crucial for effective maintenance. This process ensures the longevity and efficiency of your equipment. Knowing the specific features and characteristics of each element will help you find the right match for any required replacement.

Start by examining your equipment. Look for any identifying numbers or codes that may be present on the component itself. This information often provides insight into the specifications needed for an accurate replacement. Keep a record of these identifiers to facilitate your search.

Consult the manufacturer’s resources. User manuals or official websites frequently offer detailed lists and illustrations of each component. These resources are invaluable for verifying the exact match you need and can guide you in understanding how different parts interact with one another.

Utilize online databases and forums. Many enthusiasts and professionals share their experiences and knowledge in dedicated online communities. Engaging in these platforms can provide you with insights on where to find parts, as well as tips on installation and compatibility.

Measure dimensions when in doubt. If you’re unable to find specific identifiers, taking accurate measurements can help you locate a suitable replacement. Ensure you measure length, width, and any relevant mounting points to ensure a proper fit.

Seek expert advice if needed. If you’re struggling to identify a particular component, don’t hesitate to reach out to professionals. They can offer guidance and assist you in making informed decisions regarding your equipment’s upkeep.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing issues with your equipment, ensuring optimal performance and longevity. Follow these systematic steps to effectively address common challenges.

- Assess the Problem:

- Identify any unusual noises or performance issues.

- Check for visible signs of wear or damage.

- Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches and sockets

- Replacement components as needed

- Disassemble Carefully:

- Follow the manual instructions for disassembly.

- Keep track of all screws and parts removed.

- Inspect Components:

- Look for any broken or worn-out elements.

- Clean parts to remove debris and dirt.

- Replace or Repair:

- Substitute any damaged components with new ones.

- Make necessary adjustments to ensure proper fit.

- Reassemble:

- Carefully put all parts back together in reverse order.

- Ensure everything is securely fastened.

- Test the Equipment:

- Run the machine to confirm repairs were successful.

- Observe for any unusual activity during operation.

By following these structured steps, you can ensure your machinery remains in top condition and ready for use.

Tools Needed for Mower Deck Repair

Repairing the cutting apparatus of your lawn care equipment requires the right set of tools to ensure efficiency and precision. Having the appropriate instruments not only simplifies the process but also enhances the quality of the repair, leading to better performance in the long run.

Here’s a list of essential tools you should gather before starting your repair work:

- Wrenches: A set of adjustable wrenches is crucial for loosening and tightening various bolts.

- Sockets: A socket set will help you tackle nuts and bolts in tight spaces.

- Ratchet: A ratchet tool makes the job quicker, especially when dealing with multiple fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for different types of screws.

- Pliers: Use pliers for gripping, twisting, or cutting wires and small components.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

- Hammer: A rubber or plastic hammer is useful for tapping components into place without damaging them.

- Safety Gear: Always wear gloves and goggles to protect yourself during repairs.

Having these tools at hand will prepare you for most repairs, enabling a smoother and more efficient workflow.

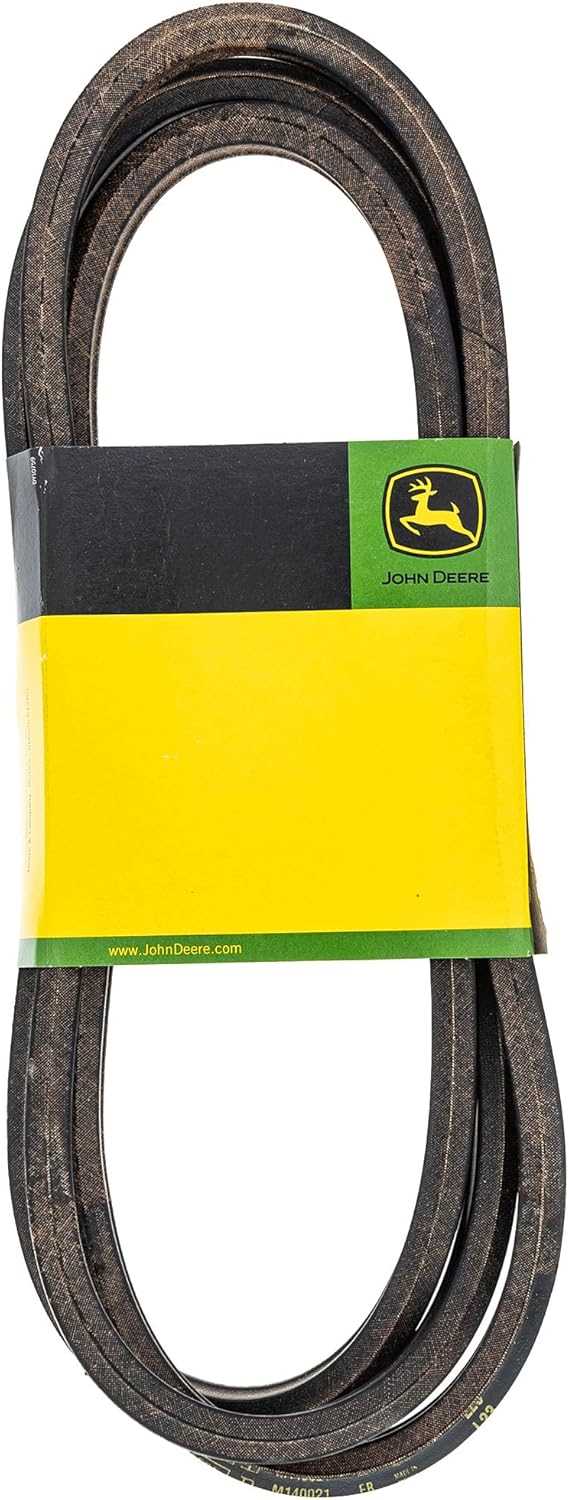

Benefits of Using Genuine Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These high-quality items are designed to fit perfectly and work harmoniously with existing systems, leading to reduced wear and tear.

Enhanced Reliability

Genuine components are manufactured to stringent standards, guaranteeing consistent functionality. This reliability minimizes the risk of breakdowns and costly repairs, providing peace of mind for operators.

Improved Efficiency

Original equipment parts contribute to better overall efficiency. Their precise engineering allows for smoother operation, which can result in lower fuel consumption and enhanced productivity.

Where to Buy Replacement Parts

When it comes to sourcing components for your outdoor equipment, finding reliable vendors is essential. There are several avenues available, each offering unique advantages. Whether you’re looking for genuine items or quality alternatives, exploring the right channels can save time and ensure you get the best fit for your machine.

Authorized Dealers are a great starting point. They typically stock original components, ensuring compatibility and quality. Visiting a local dealer can also provide personalized service and expert advice tailored to your needs.

Online Retailers have become increasingly popular due to their convenience. Websites specializing in outdoor equipment often offer a vast selection, competitive prices, and the ability to compare multiple options. Reading customer reviews can also guide you toward the most reliable choices.

Aftermarket Suppliers provide alternative solutions, often at lower prices. While these options can be appealing, it’s crucial to ensure that the quality meets your standards. Look for reputable brands and check for warranty or return policies to protect your investment.

Local Repair Shops might also carry the items you need. Establishing a relationship with a nearby technician can not only provide access to parts but also facilitate maintenance and repairs, keeping your equipment in peak condition.

Ultimately, whether you choose to shop in-store or online, ensuring you’re purchasing from reputable sources will lead to a more efficient and satisfying experience.

Customer Reviews of Parts Suppliers

When seeking components for equipment maintenance, user feedback can significantly influence decision-making. Understanding the experiences of fellow customers provides insights into the reliability and service quality of various suppliers.

Quality Assurance: Many customers emphasize the importance of receiving high-quality items. Positive reviews often highlight durability and proper fit, while negative ones frequently point out issues with materials or compatibility.

Customer Service: A responsive and helpful support team can enhance the purchasing experience. Users appreciate suppliers who address inquiries promptly and resolve problems efficiently, fostering trust and repeat business.

Delivery Times: Timeliness of shipments is a common concern. Customers often share their experiences regarding promptness, noting that delays can impact maintenance schedules and overall satisfaction.

Ultimately, exploring customer reviews helps potential buyers make informed choices, ensuring they find trustworthy sources for their equipment needs.

DIY vs. Professional Repairs

When it comes to maintaining your equipment, deciding between do-it-yourself fixes and hiring a professional can be challenging. Each approach has its advantages and potential drawbacks, depending on various factors.

Here are some points to consider:

- Cost: DIY can save money, while professional services may provide expertise.

- Time: Repairs may take longer if you’re learning as you go compared to a skilled technician.

- Skill Level: Evaluate your own abilities. Some tasks may require specialized knowledge.

- Tools: DIY repairs might need specific tools that you may not already own.

- Warranty: Professional repairs might help maintain warranty conditions.

Ultimately, weighing these aspects will help you decide the best path for your situation.

Cost Analysis of Repairs

Evaluating the expenses associated with maintenance and restoration is crucial for informed decision-making. Understanding the financial implications can help in anticipating potential costs and determining the most efficient course of action.

Factors influencing repair costs include the availability of components, labor rates, and the complexity of the work needed. Budgeting for these elements can prevent unexpected financial strain.

Additionally, comparing the costs of professional services versus DIY repairs offers insight into the most economical solutions. Thorough research on pricing can lead to significant savings over time.

Ultimately, a well-planned approach to analyzing repair costs enhances longevity and performance, ensuring that investments yield optimal results.

Tips for Preventative Maintenance

Regular upkeep is essential for prolonging the lifespan and efficiency of your equipment. By implementing a consistent maintenance routine, you can avoid unexpected breakdowns and costly repairs. Here are some effective strategies to ensure optimal performance.

Routine Inspections

- Check fluid levels regularly to prevent overheating.

- Inspect belts and blades for wear and tear.

- Look for loose bolts or connections that may need tightening.

Cleaning and Storage

- Clean debris from components after each use to avoid buildup.

- Store equipment in a dry, sheltered location to protect it from the elements.

- Apply protective coatings to metal surfaces to prevent rust.