The efficiency and performance of your lawn maintenance equipment heavily rely on its internal mechanisms. A comprehensive grasp of these elements not only enhances functionality but also extends the lifespan of your machine. This section delves into the intricate components that contribute to a seamless grass-cutting experience, ensuring that you achieve a pristine lawn with minimal effort.

Each element plays a pivotal role, from the blades that perform the actual cutting to the supporting structures that ensure stability and effectiveness. Recognizing the interplay between these parts can empower users to make informed decisions about maintenance and upgrades. An insightful look into these components helps users appreciate the engineering behind their mowing systems, leading to better care and operation.

By familiarizing yourself with these critical aspects, you’ll be better equipped to troubleshoot issues, perform necessary repairs, and optimize the performance of your equipment. This understanding not only boosts your confidence as a user but also allows for more efficient lawn care, transforming the way you approach yard work.

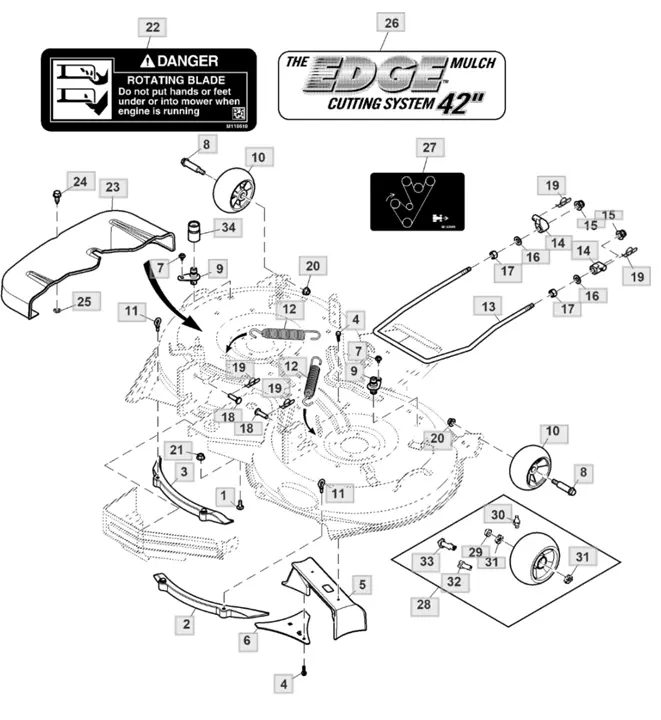

Understanding the Freedom 42 Model

This section explores a specific mower model that has garnered attention for its innovative features and performance. Designed for efficiency and ease of use, it caters to various lawn care needs, making it a preferred choice for homeowners and professionals alike.

Key Features

The model showcases a robust design, integrating advanced technology to enhance cutting precision. Its user-friendly interface ensures seamless operation, while the durable components contribute to longevity and reliability.

Maintenance and Care

Proper upkeep is essential for optimal performance. Regular inspections and timely replacements of worn-out components are vital. Adhering to maintenance guidelines can significantly extend the lifespan of this exceptional machine.

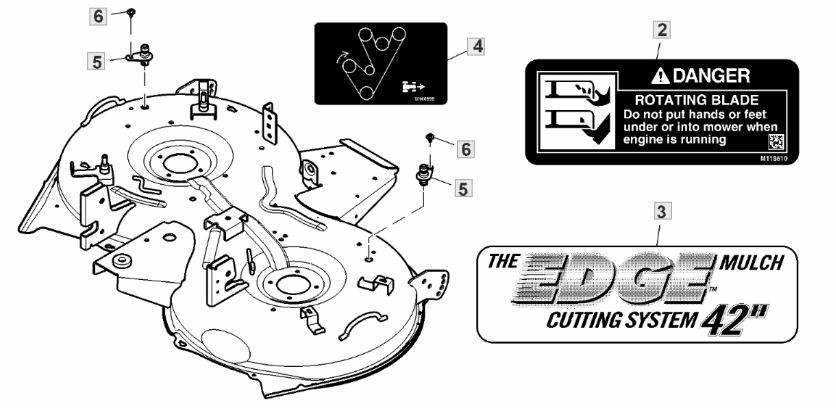

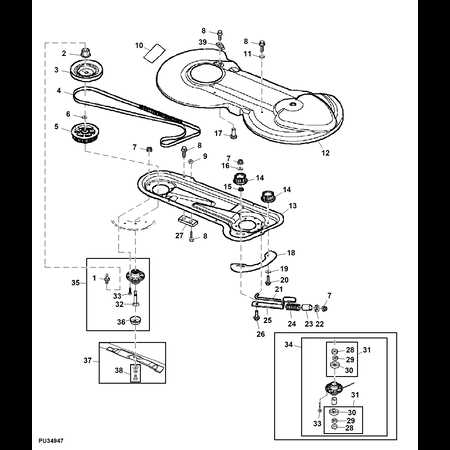

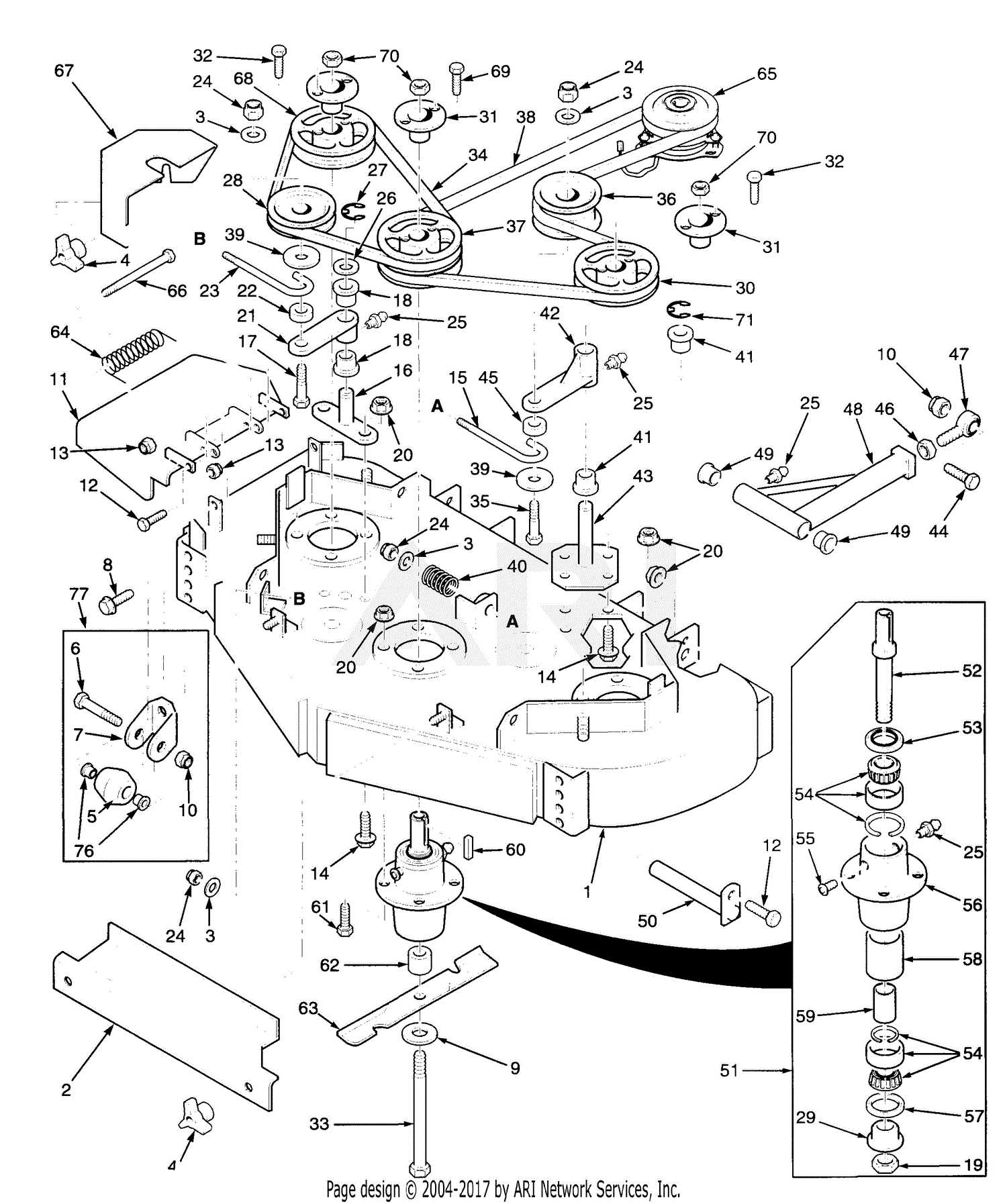

Components of the Mulching Deck

The assembly designed for effective grass cutting and nutrient recycling consists of several essential elements. Each part plays a crucial role in ensuring optimal performance and maintaining the health of the lawn.

The primary feature is the blade system, which efficiently shreds grass clippings into fine particles. These small fragments decompose quickly, returning valuable nutrients to the soil. Alongside the blade, a robust housing structure ensures that clippings remain contained, preventing any mess during operation.

Another significant component is the discharge baffle, which controls the flow of cut material. This feature aids in the even distribution of clippings, allowing for a more uniform appearance across the lawn. Additionally, the roller or wheel assembly provides stability and ease of maneuvering, ensuring that the equipment operates smoothly over various terrains.

Lastly, a well-designed height adjustment mechanism allows users to customize the cutting height, adapting to different grass types and growth conditions. Together, these elements form an integrated system that enhances both functionality and efficiency in lawn maintenance.

Benefits of Mulching with John Deere

Utilizing a specific cutting method provides numerous advantages for lawn care enthusiasts. This approach not only enhances the aesthetic appeal of green spaces but also contributes significantly to their overall health and sustainability.

Improved Soil Health

- Returning clippings enriches the soil with nutrients.

- Reduces the need for chemical fertilizers.

- Enhances microbial activity, promoting a thriving ecosystem.

Environmental Benefits

- Minimizes yard waste sent to landfills.

- Conserves moisture in the soil, reducing the need for watering.

- Promotes a natural recycling process, contributing to a healthier environment.

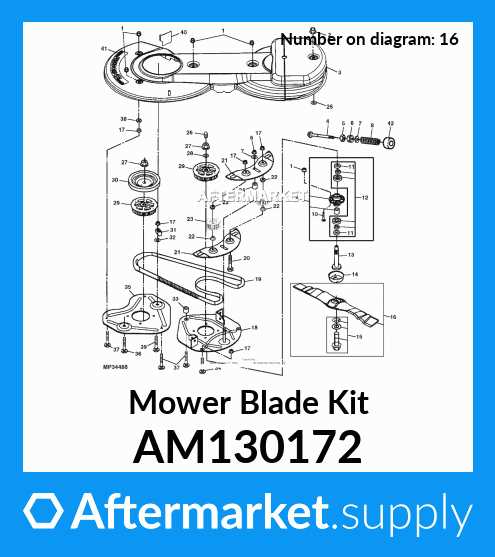

Essential Replacement Parts Explained

Understanding the crucial components that require periodic substitution is vital for maintaining optimal performance in your lawn care equipment. These elements not only ensure the longevity of your machinery but also enhance its efficiency, making it essential for users to familiarize themselves with them.

Key Components for Maintenance

Among the most important elements are the cutting implements, which play a significant role in achieving a clean and precise cut. Over time, these can wear down or become damaged, necessitating replacement to maintain the desired quality of work. Additionally, drive belts are critical for power transmission, and any signs of wear should prompt immediate attention.

Benefits of Regular Replacement

Regularly substituting worn or damaged components not only improves functionality but also reduces the risk of further mechanical issues. Proactive maintenance can save time and costs associated with major repairs, ensuring that your equipment remains reliable and effective throughout the season.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the best functionality and longevity of your equipment. By implementing a consistent maintenance routine, you can significantly enhance its efficiency and reliability.

- Inspect Regularly: Check all components for wear and tear.

- Clean Thoroughly: Remove debris and buildup after each use to prevent issues.

- Lubricate Moving Parts: Ensure smooth operation by applying appropriate lubricants.

- Sharpen Blades: Keep cutting edges sharp for effective performance.

- Replace Worn Components: Swap out any damaged or aged parts promptly.

Adhering to these practices will help you achieve the ultimate performance from your machinery, allowing for optimal results throughout its lifespan.

How to Identify Part Numbers

Understanding the identification of component numbers is essential for effective maintenance and repair of equipment. Recognizing the correct identifiers can help ensure that you acquire the right replacements, enhancing performance and longevity. This guide outlines key strategies to accurately find and confirm these numbers.

Begin by examining the equipment thoroughly. Often, the required identifiers are located on the unit itself, either on a label or stamped into the material. If you have access to the user manual or service guide, these documents typically include a comprehensive list of identifiers for all essential components.

Another useful method involves visiting the manufacturer’s official website or contacting customer support. They can provide information based on the model and serial numbers, guiding you to the correct identifiers. Additionally, online forums and communities focused on equipment maintenance can offer insights and share experiences regarding part identification.

| Method | Description |

|---|---|

| Manual Inspection | Check labels or engravings on the equipment for specific identifiers. |

| Documentation | Refer to the user manual or service guide for a detailed list of identifiers. |

| Manufacturer Resources | Use the official website or contact support for model-specific information. |

| Community Input | Engage with online forums for advice and shared experiences on identification. |

By utilizing these methods, you can confidently determine the correct component numbers needed for your repairs, ensuring your equipment operates smoothly and efficiently.

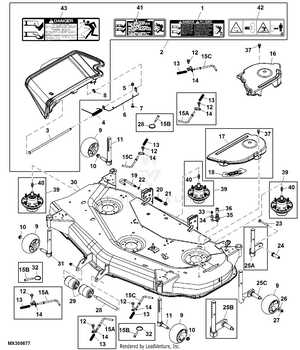

Installation Guide for Mulching Deck Parts

This section provides a comprehensive approach to assembling the components designed for efficient lawn care. Following these guidelines will ensure optimal performance and longevity of your equipment.

Preparation: Before beginning the installation, gather all necessary tools and components. Review the user manual for specific requirements and safety precautions.

Step-by-Step Assembly: Start by laying out all the elements on a clean surface. Identify each piece and match them with the corresponding slots on the main unit. It is crucial to follow the recommended sequence to avoid complications.

Fastening Components: Secure the items using the appropriate fasteners, ensuring each is tightened to the specified torque. This will prevent any loosening during operation, which could lead to performance issues.

Final Checks: After installation, inspect all connections and ensure there are no obstructions. Conduct a test run to confirm that everything operates smoothly, making adjustments as necessary.

Common Issues and Troubleshooting

This section aims to address frequent challenges that users may encounter with their lawn maintenance equipment, providing solutions to enhance performance and longevity.

Here are some typical problems and their potential fixes:

- Engine Not Starting:

- Check the fuel level and quality.

- Inspect the battery and connections.

- Examine the spark plug for wear or damage.

- Uneven Cutting:

- Ensure the blades are sharp and balanced.

- Adjust the cutting height settings.

- Inspect the wheel alignment for consistency.

- Excessive Vibration:

- Check for loose or damaged components.

- Inspect blades for chips or bends.

- Tighten all screws and bolts properly.

Addressing these issues promptly can lead to more efficient operation and a better overall experience.

Tools Required for Repairs

When undertaking maintenance or repair tasks, having the right instruments at hand is crucial for efficiency and safety. Utilizing the appropriate equipment not only streamlines the process but also enhances the quality of the work performed. Below is a list of essential tools needed for effective repairs.

Essential Tools

- Wrenches: A variety of sizes to accommodate different fasteners.

- Screwdrivers: Both flathead and Phillips for versatile applications.

- Socket Set: For tightening and loosening bolts and nuts with ease.

- Pliers: Useful for gripping, twisting, and cutting tasks.

- Torque Wrench: Ensures proper tightening to avoid damage.

Safety Equipment

- Gloves: Protect hands from cuts and abrasions.

- Safety Glasses: Shield eyes from debris and dust.

- Ear Protection: Necessary when working in noisy environments.

- Face Mask: Keeps inhalation of dust and particles to a minimum.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your outdoor machinery can significantly enhance its overall performance. By integrating advanced components and features, users can achieve a more effective operation, ensuring that tasks are completed with greater ease and precision. This section explores various enhancements that can lead to a superior experience.

Engine Optimization

One of the most impactful upgrades involves optimizing the engine. Upgrading to a high-performance air filter can improve airflow, enhancing combustion and efficiency. Additionally, using synthetic oils can reduce friction, resulting in smoother operation and prolonged engine life.

Cutting Efficiency

To elevate cutting efficiency, consider replacing standard blades with high-lift or specialty options. These alternatives can provide a cleaner cut and better discharge of clippings. Moreover, ensuring proper maintenance of the cutting mechanism will prevent wear and tear, contributing to consistent performance.

Investing in these enhancements can transform the operation of your equipment, providing a more enjoyable and effective user experience.

Where to Purchase Parts Online

Finding reliable sources for essential components is crucial for maintaining your equipment’s performance. The internet offers a variety of options, enabling users to access a wide range of suppliers and retailers specializing in outdoor machinery accessories.

Reputable Online Retailers

Consider shopping from well-known online platforms that cater specifically to machinery needs. Websites like Amazon and eBay provide extensive listings, often accompanied by customer reviews that can guide your purchasing decisions. These marketplaces frequently have competitive prices and delivery options.

Manufacturer Websites

Visiting the official websites of equipment manufacturers can be beneficial. They often have dedicated sections for accessories, ensuring you find the correct items for your model. Purchasing directly from the source may also provide peace of mind regarding authenticity and quality.

Customer Reviews and Feedback Analysis

Understanding customer opinions is crucial for assessing product performance and satisfaction. Analyzing reviews allows potential buyers to gauge the strengths and weaknesses highlighted by previous users, leading to informed purchasing decisions.

Common Praise

Many customers commend the durability and efficiency of the equipment, noting its reliability during various tasks. Ease of use and effective grass handling are frequently mentioned as significant benefits, making it a popular choice among homeowners and professionals alike.

Areas for Improvement

Some users have pointed out issues related to maintenance and specific functionalities. Regular upkeep and occasional adjustments have been cited as necessary for optimal performance. Addressing these concerns can enhance user experience and longevity.