In the world of lawn maintenance, the efficiency of equipment relies heavily on its individual elements. Familiarity with each component not only enhances performance but also extends the lifespan of the machine. This guide aims to provide clarity on essential elements that contribute to the overall functionality of these tools.

When tackling outdoor tasks, it’s crucial to have a clear visual representation of how parts interact. A comprehensive overview allows users to quickly identify issues and understand assembly or disassembly procedures. This knowledge empowers enthusiasts and professionals alike to achieve optimal results in their landscaping endeavors.

By delving into the specifics of each segment, users can make informed decisions regarding maintenance and upgrades. Understanding these intricacies is key to ensuring that your lawn care equipment operates at its ultimate potential, delivering the best results possible. Whether you are a seasoned user or a newcomer, grasping these details is essential for effective lawn management.

Understanding the GX345 Mower Deck

Exploring the functionality and components of a lawn care implement is essential for optimal performance. This piece of machinery is designed to facilitate efficient grass trimming, and its construction involves several critical elements that contribute to its overall effectiveness.

Key Components

- Blades: Essential for cutting grass efficiently.

- Housing: Provides structural support and protects internal parts.

- Spindles: Connect the blades and allow them to rotate smoothly.

- Belts: Transfer power from the engine to the blades.

Maintenance Tips

- Regularly inspect and sharpen blades to ensure clean cuts.

- Check belts for wear and replace if necessary.

- Clean the housing to prevent buildup of grass and debris.

- Lubricate moving parts to maintain optimal performance.

Key Components of the Mower Deck

The efficiency and performance of a grass cutting machine rely heavily on its essential elements. Understanding these components helps in maintaining optimal functionality and prolonging the lifespan of the equipment. Each part plays a crucial role in achieving a precise cut and ensuring smooth operation.

| Component | Description |

|---|---|

| Blades | Sharp instruments designed for effective cutting of grass, requiring regular sharpening or replacement. |

| Spindles | Rotate the blades and provide stability, ensuring consistent performance during operation. |

| Chassis | The framework that supports all other components, crucial for structural integrity and durability. |

| Belt | Transfers power from the engine to the spindles, enabling blade movement and cutting action. |

| Anti-Scalp Wheels | Help prevent the cutting elements from scalping the ground, maintaining an even grass height. |

Maintenance Tips for GX345 Parts

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular attention to various components can help prevent costly repairs and enhance efficiency. Below are some valuable suggestions to maintain your machinery effectively.

Regular Inspection

Conducting routine checks is crucial for identifying wear and tear. Here are some areas to focus on:

- Examine belts for cracks or fraying.

- Check blades for sharpness and damage.

- Inspect wheels and tires for proper inflation and wear.

- Look for any loose screws or bolts.

Cleaning and Lubrication

Keeping your equipment clean and well-lubricated can significantly extend its lifespan. Consider these practices:

- Remove debris after each use to prevent buildup.

- Lubricate moving parts regularly to reduce friction.

- Use the appropriate cleaning solutions to avoid damage.

- Ensure drainage holes are clear to prevent rusting.

By following these maintenance tips, you can help ensure that your machinery operates smoothly and remains in good condition for years to come.

How to Identify Worn Parts

Recognizing signs of wear is crucial for maintaining optimal performance in any mechanical system. Over time, components may degrade due to regular usage, exposure to elements, or inadequate maintenance. Early identification can prevent further damage and ensure efficient operation.

Signs of Wear

- Visual Damage: Look for cracks, chips, or discoloration on surfaces.

- Unusual Noises: Listen for grinding or rattling sounds during operation.

- Decreased Performance: Notice any drop in efficiency or power output.

Inspection Tips

- Regular Checks: Schedule routine inspections to catch issues early.

- Use Reference Guides: Compare your components with reference materials to spot differences.

- Consult Experts: Seek professional advice if you’re unsure about the condition of any part.

Benefits of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring optimal performance and longevity. Engaging in regular servicing not only enhances functionality but also mitigates potential issues before they escalate into costly repairs. By prioritizing maintenance, users can enjoy a more efficient and reliable experience with their machinery.

Enhanced Performance

Routine maintenance plays a crucial role in maintaining peak operational efficiency. Keeping all components in good condition allows machines to perform their tasks effectively, leading to better results and increased productivity.

Cost Savings

Investing time in regular servicing can significantly reduce long-term expenses. Preventive care helps identify wear and tear early, allowing for timely interventions that can prevent more serious damage and the need for expensive replacements.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Improves engine longevity and performance |

| Blade Sharpening | Every 25 hours | Enhances cutting efficiency and quality |

| Air Filter Check | Every 100 hours | Ensures optimal airflow and engine efficiency |

Finding Replacement Parts Online

Locating suitable components for outdoor equipment has become increasingly convenient through various online platforms. With just a few clicks, users can explore an extensive range of options, ensuring they find the ideal match for their machinery needs.

Benefits of Online Shopping

Shopping online offers unparalleled convenience and flexibility. Consumers can access a vast selection of items at any time, often discovering competitive prices. Additionally, reviews and ratings provide valuable insights, helping buyers make informed decisions.

Tips for Successful Searches

To enhance your search experience, utilize specific keywords related to the components required. Familiarize yourself with various suppliers, as some may specialize in particular brands or types of equipment. Always verify the compatibility of items before making a purchase to ensure a seamless fit.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing and maintaining your lawn equipment efficiently. Following a structured method ensures that you address all issues thoroughly and effectively.

- Gather Tools and Materials:

- Wrenches and sockets

- Screwdrivers

- Replacement components

- Lubricants and cleaners

- Review the User Manual:

Consult the manual for specific instructions related to your model, including safety precautions.

- Remove the Equipment:

Detach the unit from the power source and prepare your workspace for safety.

- Inspect and Identify Issues:

Check all parts for wear and damage. Make a list of items needing repair or replacement.

- Replace Damaged Components:

Follow the manual’s guidance for removing and installing new parts carefully.

- Reassemble and Test:

Put everything back together and ensure all connections are secure. Test the equipment to confirm functionality.

By adhering to these steps, you’ll enhance the longevity and performance of your lawn machinery.

Common Issues with Mower Decks

Maintaining the cutting assembly of your lawn care equipment is essential for optimal performance. Various challenges can arise, impacting the efficiency and effectiveness of the equipment. Understanding these common problems can help in timely troubleshooting and repairs.

- Uneven Cutting: A frequent issue that leads to uneven grass length, often caused by misalignment or damaged components.

- Clumping: Grass clippings may accumulate if the blades are dull or if the design does not promote proper airflow.

- Noisy Operation: Unusual sounds can indicate loose bolts or worn-out bearings, requiring immediate attention.

- Vibration: Excessive shaking can result from an unbalanced blade or frame, affecting the overall stability of the equipment.

- Difficulty in Height Adjustment: Problems with height settings can stem from worn or damaged lift mechanisms.

Addressing these common concerns proactively can enhance the lifespan of your lawn care tools and ensure a neat and tidy landscape.

Tools Needed for Repairs

For effective maintenance and restoration, having the right instruments is essential. Proper tools not only streamline the repair process but also ensure safety and precision. Before starting any work, gather the necessary equipment to facilitate a smooth and efficient experience.

Essential Hand Tools

Basic hand tools such as wrenches, pliers, and screwdrivers are crucial for disassembly and reassembly. A strong socket set will help tackle stubborn bolts, while pliers can assist in gripping and twisting components with ease.

Power Tools and Accessories

Incorporating power tools can significantly enhance efficiency. A drill with various bits is invaluable for quick fastening, while a multimeter can aid in diagnosing electrical issues. Always ensure that your tools are well-maintained to achieve the ultimate results in your repair efforts.

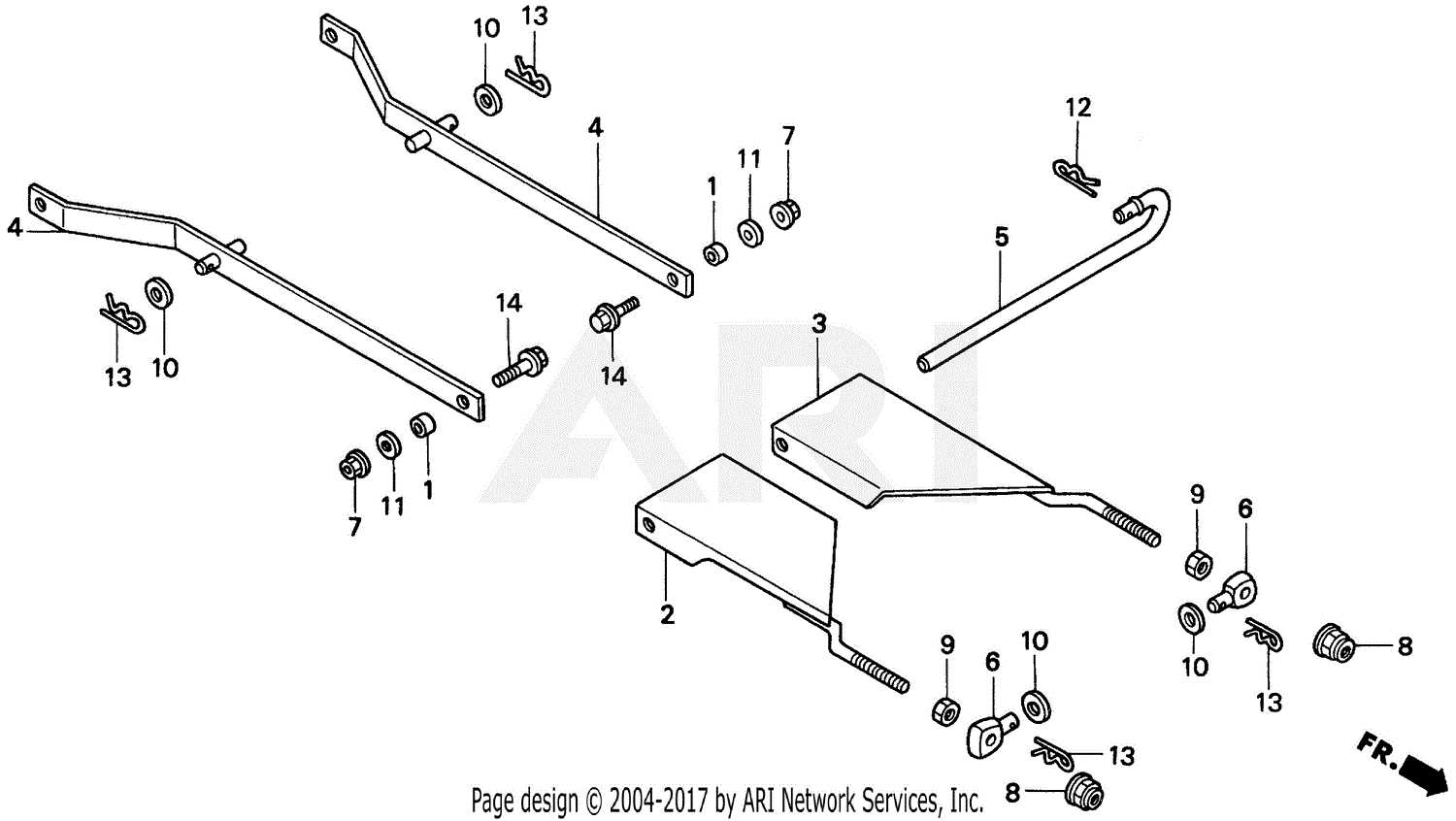

Understanding the Parts Diagram

A visual representation of components is crucial for effective maintenance and repair. It provides clarity on how different elements interact and facilitates troubleshooting by highlighting essential connections.

Components Overview

Each section of the illustration corresponds to specific functionalities, making it easier to identify what needs attention. Familiarity with this layout enables efficient navigation through the intricate systems involved.

Importance of Clarity

Clear identification of each element aids in ensuring that replacements are accurate and timely. This ultimately leads to improved performance and longevity of the entire system.