When working with outdoor equipment, the efficiency and reliability of the machine often depend on how well its essential mechanisms are understood. Proper maintenance and timely replacement of various components can significantly extend the lifespan of the equipment. By gaining a deeper knowledge of how these elements are organized, users can ensure optimal performance throughout its use.

The arrangement of different elements plays a crucial role in the overall functionality. Knowing the correct setup and alignment helps avoid common issues that could arise from wear and tear. For those who regularly maintain their machinery, being familiar with the structure and its connections simplifies the troubleshooting process, leading to more effective repairs.

Regular inspections and an awareness of how different sections interact will allow users to address potential problems before they escalate. This knowledge is key to maintaining the performance and reliability of the equipment over time, ensuring it operates smoothly for years to come.

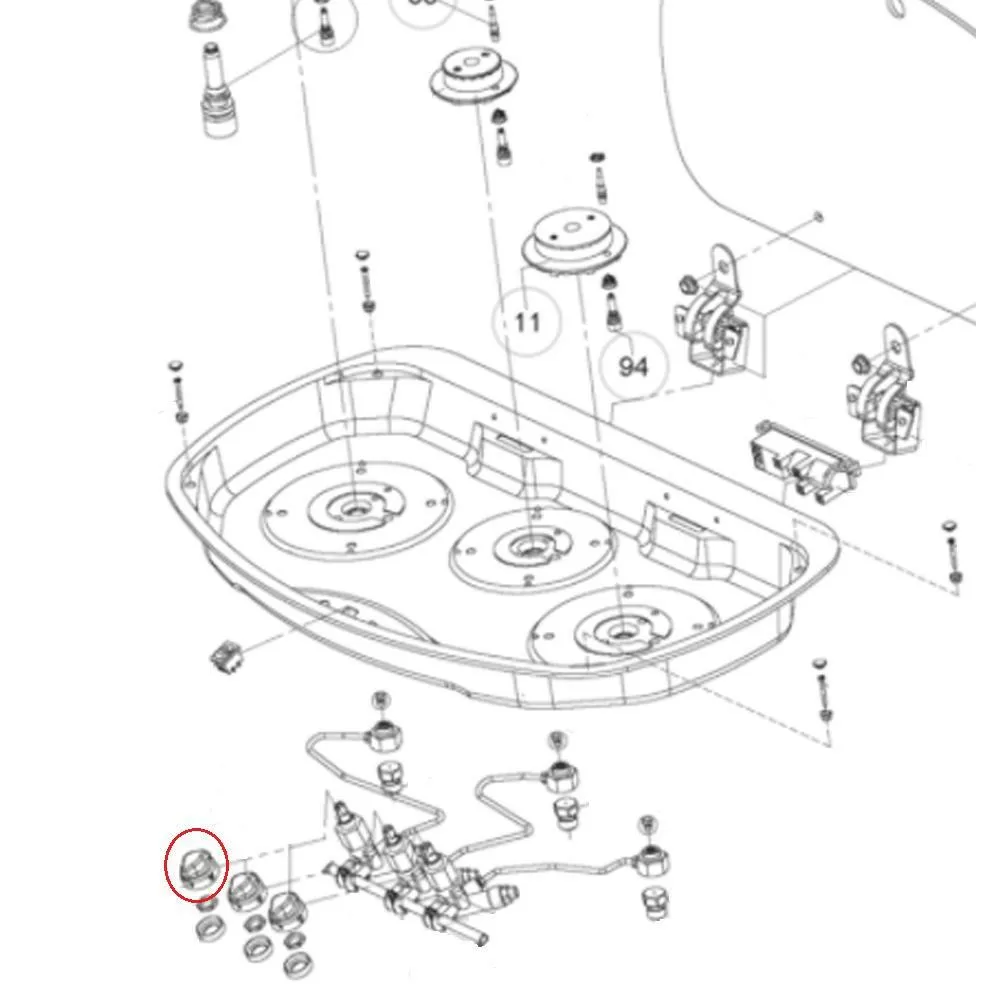

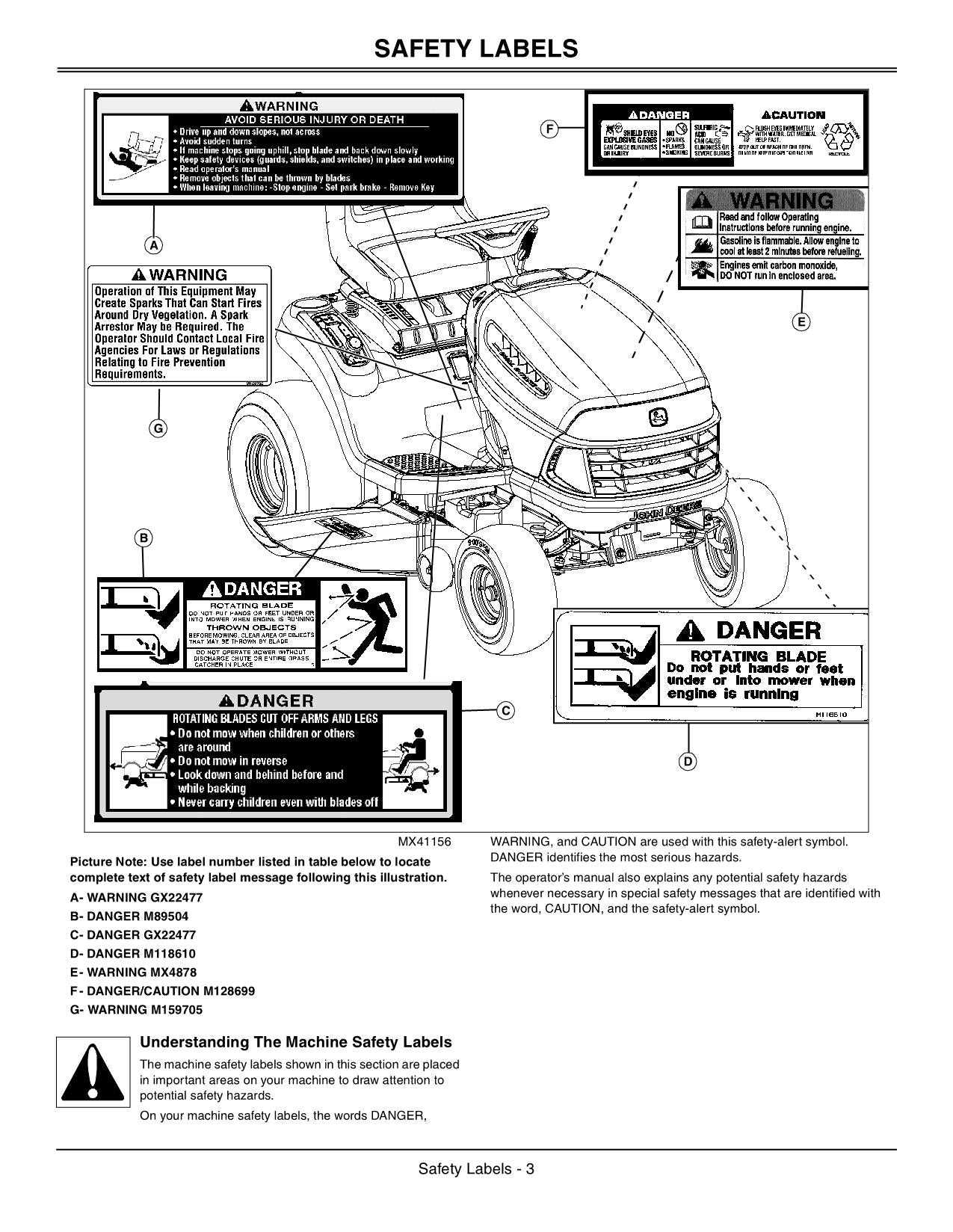

John Deere LA125 Mower Deck Overview

This section provides a comprehensive understanding of the cutting platform found in this particular model. The design focuses on delivering efficient grass cutting performance through a well-structured mechanism. Known for its durability, the system incorporates precise engineering, ensuring consistent results during operation.

The structure consists of multiple components working in harmony to maintain a clean and even cut. Its versatility allows for smooth maneuverability across different terrain types, offering both reliability and ease of use. Designed with the user in mind, the setup is built to last and withstand frequent use without sacrificing performance.

Additionally, the configuration promotes effective maintenance and long-term functionality, ensuring that each part can be easily accessed and serviced. With attention to detail in its assembly, the setup ensures that every operation delivers optimal cutting results, no matter the conditions.

Key Components of the Mower Deck

Understanding the critical elements of a lawn maintenance machine is essential for ensuring efficient operation and durability. The cutting system relies on multiple interconnected components that work in harmony to achieve a smooth and precise grass-cutting performance. Each piece plays a vital role in maintaining functionality, enabling the device to operate at its best.

Blades and Their Importance

The blades are the most crucial part of the cutting mechanism, directly responsible for trimming the grass to the desired height. They must be sharp and well-maintained to provide an even cut. Regular inspection ensures that the grass is cut cleanly, preventing damage and promoting healthy lawn growth.

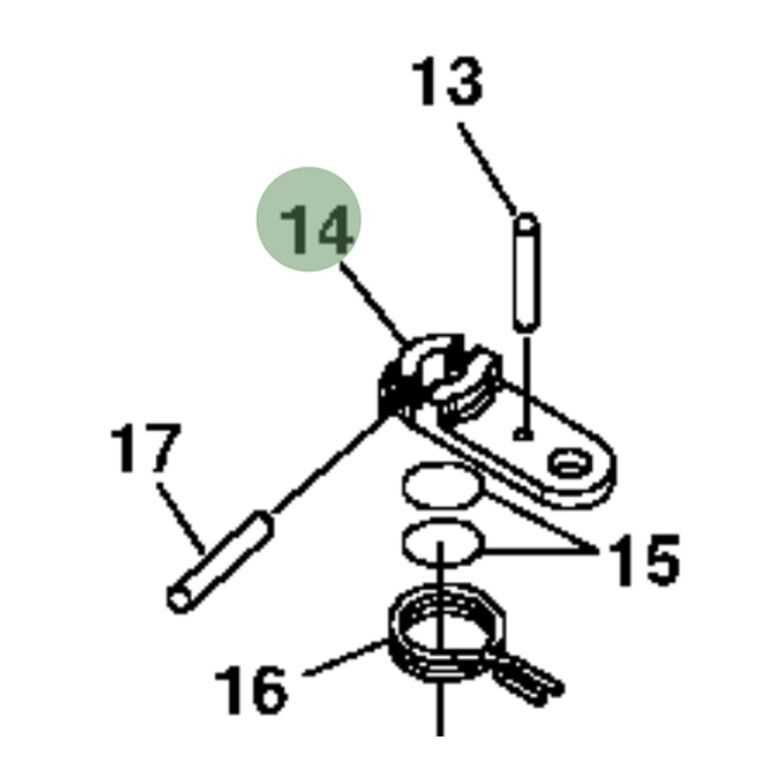

Belt and Pulley System

The belt and pulley system ensures smooth power transmission from the engine to the cutting mechanism. This setup allows for consistent rotation and efficient operation, minimizing wear and tear. Proper tension and alignment of the belt are necessary for optimal performance and longevity of the machinery.

How to Maintain Your LA125 Deck

Proper care of your cutting system ensures long-lasting performance and efficient grass cutting. Regular attention and upkeep are essential to prevent wear and maintain smooth operation.

- Inspect the blades frequently for any signs of dullness or damage. Sharpen or replace them as necessary to ensure an even cut.

- Clear any grass buildup or debris from the underside of the cutting platform to avoid clogging and uneven performance.

- Check belt tension regularly to make sure it’s neither too loose nor too tight, adjusting when required to maintain optimal function.

- Lubricate all moving parts to minimize friction and prevent excessive wear on bearings and pulleys.

- Ensure all fasteners are securely tightened to avoid rattling or loosening during operation.

By following these simple steps, you can extend the lifespan of your equipment and guarantee smooth performance throughout the season.

Identifying Mower Deck Wear Signs

Over time, equipment used for maintaining lawns can show signs of deterioration that affect performance. Recognizing these indicators early helps prevent further damage and ensures smoother operation. Routine checks and attention to various components are essential to maintaining optimal efficiency.

Visible Damage: Look for any cracks, bends, or rust on the cutting system. These issues can impact functionality and result in uneven grass cutting, which is a key sign of wear.

Unusual Noises: If you start hearing grinding or rattling sounds, it’s important to inspect the mechanical parts for wear or loosening. Unusual sounds often point to friction or imbalance.

Vibration Issues: Excessive vibrations during operation can be an indication that certain components are misaligned or damaged. This can lead to further issues if left unaddressed.

Regular inspection and immediate attention to these warning signs will help extend the lifespan of your lawn equipment and maintain its efficiency.

Common Deck Issues and Solutions

Many outdoor cutting machines experience various operational issues over time, especially when they are used frequently or under demanding conditions. Recognizing and addressing these issues promptly can help maintain efficiency and prevent costly repairs in the future. Below are some of the most frequent problems encountered, along with practical advice on how to resolve them.

Uneven Cutting Patterns

If your machine is producing an inconsistent cut, the problem could stem from a misalignment or imbalance. Inspect the blades regularly to ensure they are properly adjusted. Worn-out or dull blades may need sharpening or replacement. Additionally, check the ground height to verify it is even across the surface.

Vibration and Noise

Excessive vibration or strange noises during operation can indicate an issue with the equipment’s internal components. Loose or damaged elements can cause rattling, leading to greater wear. Tighten bolts and screws and ensure all parts are securely fastened. If the issue persists, it may require a deeper

Adjusting Blade Height for Optimal Cut

Ensuring the correct height of the cutting blade is crucial for achieving a clean and even trim. By adjusting the blade position appropriately, you can maintain the health of your lawn and avoid scalping or uneven cuts. It’s important to consider various factors such as grass type and terrain when setting the cutting level to ensure the best results.

Steps to Adjust Blade Height

To modify the cutting height, locate the adjustment mechanism, which can vary depending on the machine. Gradually raise or lower the blade using the appropriate controls, ensuring it’s even on both sides. Test the height on a small section of grass to confirm the desired result.

Factors to Consider

The ideal height for cutting depends on the type of grass and weather conditions. Taller grass may provide more shade for the soil, helping to retain moisture, while shorter blades offer a more manicured appearance. Adjust

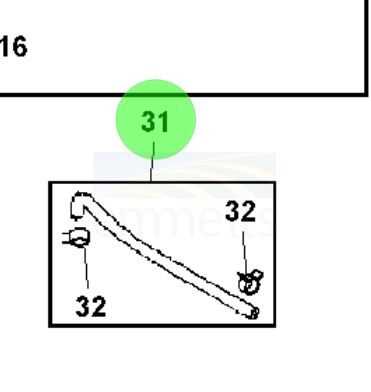

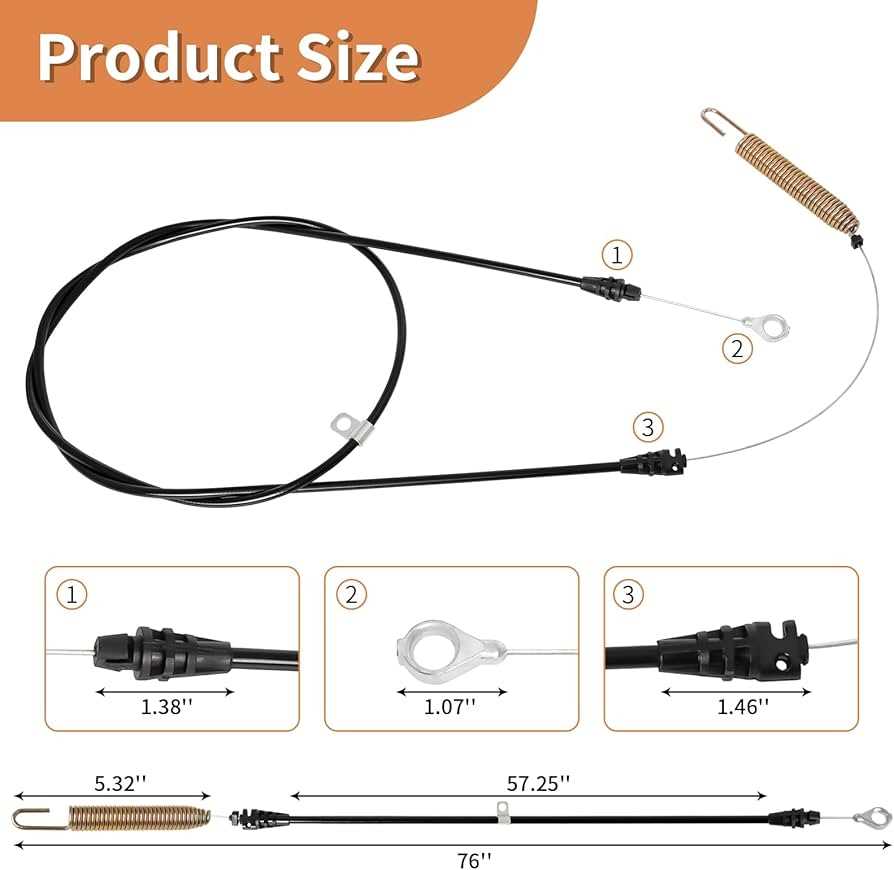

Replacing LA125 Deck Belts

The belt system plays a vital role in ensuring the efficient operation of the cutting unit. Over time, these belts can wear down or become damaged, leading to reduced performance. Regular maintenance, including timely replacement, helps to maintain optimal functionality and prolongs the overall life of the machine.

Steps for Removing the Worn Belt

Before starting the replacement, ensure the machine is turned off and safely secured. Begin by loosening the tension on the belt. This can usually be done by adjusting the tensioner pulley. Once loose, carefully remove the belt from the pulleys, taking note of its routing for proper reinstallation later.

Installing the New Belt

To install the new belt, align it with the appropriate pulleys, ensuring the correct routing. Once in place, adjust the tensioner to apply the right amount of pressure to the belt. After installation, test the machine to confirm

Best Practices for Deck Cleaning

Maintaining the cleanliness of your equipment’s cutting platform is essential for both its longevity and performance. A clean surface ensures smooth operation, prevents buildup that can cause wear, and promotes a healthier lawn. Regular attention to this area will help you avoid costly repairs and keep the machine running at its best.

Tools and Techniques

Using the right tools can make the cleaning process easier and more efficient. A soft brush, water hose, and mild detergent are often sufficient to remove grass clippings and dirt. Avoid using high-pressure washers, as they can damage sensitive components.

Frequency of Maintenance

It is recommended to clean the equipment after each use, especially during wet conditions. This prevents moisture and debris from

Choosing the Right Blades for Your Deck

Selecting the appropriate cutting tools for your equipment is essential for achieving optimal performance and maintaining a well-groomed lawn. The right blades can significantly influence the quality of the cut, the health of your grass, and the overall efficiency of the machine. Understanding the various options available and their specific functions will help you make an informed choice.

Types of Blades

There are several types of cutting implements designed for different tasks. Standard blades are ideal for general mowing, providing a clean cut on various grass types. Mulching blades, with their unique design, chop clippings into finer pieces, allowing them to decompose quickly and return nutrients to the soil. For those tackling tougher vegetation, high-lift blades are recommended, as they create increased airflow to efficiently discharge clippings.

Factors to Consider

When choosing the right blades, consider factors such as blade material, size, and shape. High-quality steel blades offer durability and longevity, while the size and shape must match your equipment’s specifications for optimal performance. Additionally, think about the mowing conditions–different environments may require different blade types to achieve the best results.

Troubleshooting Deck Alignment Problems

Ensuring proper alignment of cutting components is crucial for optimal performance and a clean cut. Misalignment can lead to uneven cutting, increased wear, and potential damage. This section outlines common issues and solutions to help maintain alignment effectively.

Common Symptoms of Misalignment

- Uneven cutting height across the lawn

- Increased vibration during operation

- Excessive wear on specific blades

- Visible gaps between the blades and the ground

Steps to Diagnose and Correct Alignment Issues

- Inspect the overall condition of the cutting components for any visible damage.

- Check the mounting brackets for looseness or wear.

- Measure the height of each blade to ensure consistency.

- Adjust the height settings according to manufacturer specifications.

- Perform a test run to confirm the effectiveness of the adjustments.

Upgrading Parts for Better Performance

Enhancing components can significantly boost the efficiency and functionality of your equipment. By selecting high-quality replacements, users can experience improved performance and extended lifespan. It’s essential to assess the current features and identify areas where upgrades can lead to a smoother operation.

Investing in superior components not only increases reliability but also contributes to achieving optimal results during usage. For instance, upgrading specific mechanisms can reduce wear and tear, leading to less frequent maintenance. Additionally, enhanced features can improve overall user experience, making tasks easier and more efficient.

Incorporating advanced technology into your equipment can also provide significant advantages. Modern alternatives often come with innovations that improve precision and efficiency, allowing for better handling and more effective operation. Prioritizing upgrades ensures that your machinery remains competitive and functional for various applications.

Seasonal Care for the Mower Deck

Regular maintenance of your cutting equipment is essential to ensure optimal performance and longevity. This involves several seasonal tasks that help prevent wear and tear, as well as enhance the efficiency of the machine. By following a consistent care routine, you can keep your equipment in prime condition throughout the year.

During the spring, it’s crucial to inspect the blades for any signs of damage and sharpen them if necessary. Clean the underside of the unit to remove any grass clippings and debris that can hinder performance. In the summer, ensure that all moving parts are well-lubricated and check for any loose components that may need tightening.

As autumn approaches, prepare your equipment for the cooler months by performing a thorough cleaning and applying protective coatings where needed. Additionally, check the belts and cables for any signs of wear. Finally, during winter, store the machine in a dry place, covering it to protect it from dust and moisture. Regular seasonal checks will enhance the reliability and lifespan of your equipment.