In the world of lawn maintenance, having a clear understanding of the various components that make up a mower can significantly enhance its performance and longevity. Each section plays a crucial role, and recognizing how these elements work together can simplify maintenance tasks and repairs. This knowledge empowers users to make informed decisions regarding upkeep and troubleshooting.

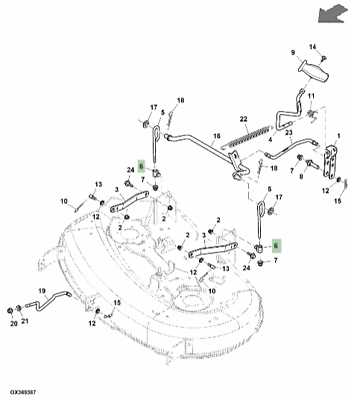

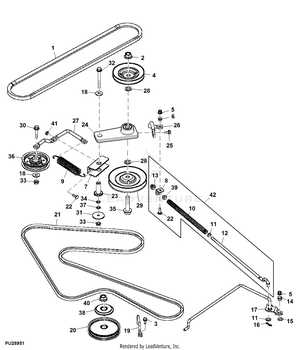

Exploring the schematic of a specific mowing unit reveals the intricate arrangement of its features. From the cutting blades to the drive systems, each part is designed to function harmoniously, ensuring optimal operation. Identifying these components allows operators to pinpoint issues quickly and understand how each element contributes to the overall efficiency of the machine.

In this guide, we delve into the intricacies of a 42-inch mowing apparatus. By examining its various components and their configurations, readers will gain valuable insights into maintenance practices. Whether you’re a seasoned professional or a novice, grasping these details will facilitate smoother operations and enhance your gardening experience.

Understanding the John Deere X300

This section aims to provide insight into a popular model known for its efficiency and reliability in maintaining lawns. By examining its components and functions, one can appreciate the engineering behind its performance and how it meets the needs of homeowners.

| Component | Description |

|---|---|

| Engine | Powerful and efficient, designed for optimal performance. |

| Transmission | Provides smooth operation and ease of maneuvering. |

| Chassis | Sturdy construction ensuring durability and stability. |

| Cutting Mechanism | Advanced design for precise and even trimming. |

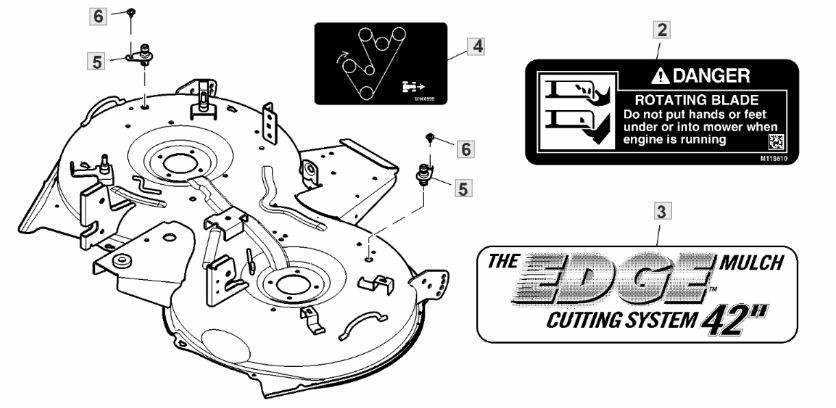

Components of the 42-Inch Deck

This section explores the essential elements that comprise a 42-inch mowing platform, highlighting their functions and significance in achieving optimal performance. Each component plays a vital role in enhancing efficiency and ensuring a smooth cutting experience.

Blade Assembly

The blade assembly is critical for effective grass cutting. Sharp blades ensure a clean cut, promoting healthy grass growth. Regular maintenance of this assembly is necessary to maintain peak performance.

Chassis and Support Structure

The chassis provides the necessary stability and support for the entire assembly. Its robust design withstands wear and tear, ensuring longevity. Proper alignment of the support structure is essential for uniform cutting and overall functionality.

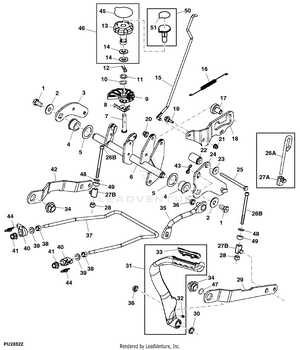

Parts Diagram Overview

This section provides a comprehensive look at the various components associated with the machine, helping users understand their structure and function.

Understanding the layout and relationship of each element is essential for effective maintenance and repair. Here are key points to consider:

- Identification of each component.

- Overview of assembly and disassembly procedures.

- Importance of proper alignment and connections.

By examining the schematic representation, users can:

- Gain insights into functionality.

- Make informed decisions regarding replacements.

- Enhance overall operational efficiency.

Maintenance Tips for Longevity

Proper care is essential for maximizing the lifespan of your equipment. Regular attention to various components ensures optimal performance and reduces the likelihood of unexpected failures. Here are some practical suggestions to keep your machinery running smoothly.

1. Regular Cleaning: Keep surfaces clean and free from debris. Accumulation of dirt can lead to wear and tear, impacting functionality.

2. Routine Inspections: Conduct frequent checks of critical elements. Early detection of wear can prevent costly repairs and extend operational life.

3. Lubrication: Ensure all moving parts are adequately lubricated. This reduces friction and enhances efficiency, promoting longevity.

4. Seasonal Care: Prepare your equipment for different seasons. Proper storage and adjustments can prevent damage from environmental factors.

5. Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations. This ensures you’re meeting the specific needs of your machinery.

By incorporating these practices into your routine, you’ll enhance performance and ensure your equipment serves you well for years to come.

Common Issues with the X300 Deck

The mower platform often encounters a variety of challenges that can affect its performance and efficiency. Understanding these common problems can help users maintain their equipment better and avoid unnecessary downtime.

Typical Problems

- Uneven Cutting: Many users report issues with inconsistent grass height after mowing. This can be caused by:

- Improper blade height adjustment.

- Worn or damaged blades.

- Uneven tire pressure.

- Clogging: Debris buildup is a frequent issue, particularly in damp conditions. This can lead to:

- Reduced cutting efficiency.

- Increased strain on the engine.

lessCopy code

Maintenance Tips

- Regularly inspect and sharpen blades to ensure clean cuts.

- Check tire pressure to maintain level operation.

- Clean the underside of the platform frequently to prevent buildup.

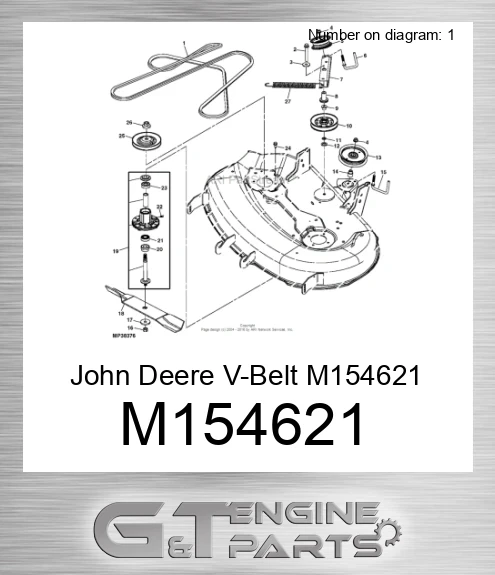

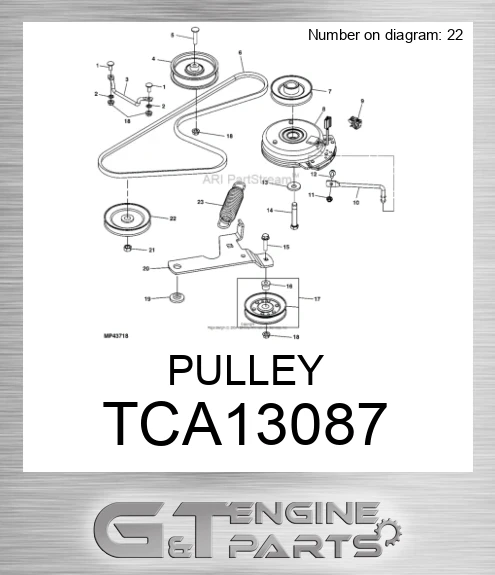

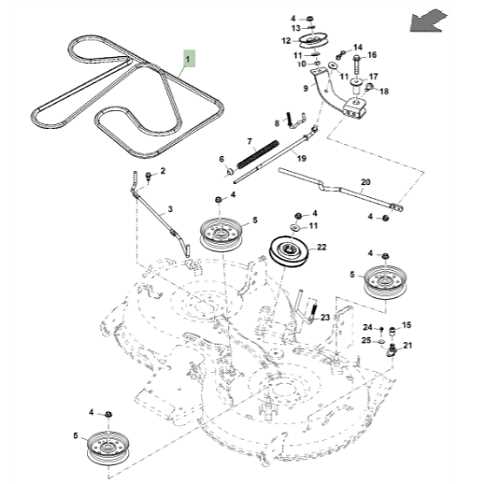

How to Replace Key Parts

Maintaining your machinery requires occasional replacements of essential components to ensure optimal performance. Understanding the process can save time and enhance efficiency.

- Identify the components that need replacement.

- Gather necessary tools and new items.

- Follow the manufacturer’s guidelines for removal and installation.

Here are some common components you may need to replace:

- Belt

- Blade

- Filter

- Battery

By keeping your equipment in good shape, you can prolong its lifespan and improve functionality.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining its efficiency and longevity. Numerous avenues exist for sourcing these vital elements, ensuring you have access to the best options available.

Authorized Retailers

One of the most reliable methods is to visit authorized retailers. These establishments often stock genuine items, guaranteeing compatibility and quality. Moreover, their staff can provide expert advice on selection and installation.

Online Marketplaces

The digital landscape offers a plethora of online marketplaces where you can search for specific components. Websites dedicated to machinery often feature user-friendly interfaces, allowing you to delve into various options and read reviews, helping you make informed decisions.

Upgrades for Enhanced Performance

Improving the functionality of your lawn care equipment can significantly elevate its efficiency and durability. By incorporating various enhancements, you can optimize performance, ensuring a smoother and more effective operation.

Key Areas for Improvement

- Engine Enhancements

- Cutting Mechanism Upgrades

- Transmission Adjustments

- Comfort and Control Features

Recommended Modifications

- Upgrade the air filter for better airflow.

- Install high-performance blades for a cleaner cut.

- Adjust tire pressure for improved traction.

- Enhance seat cushioning for a more comfortable ride.

By focusing on these modifications, you can delve into a range of enhancements that contribute to the ultimate performance of your equipment.

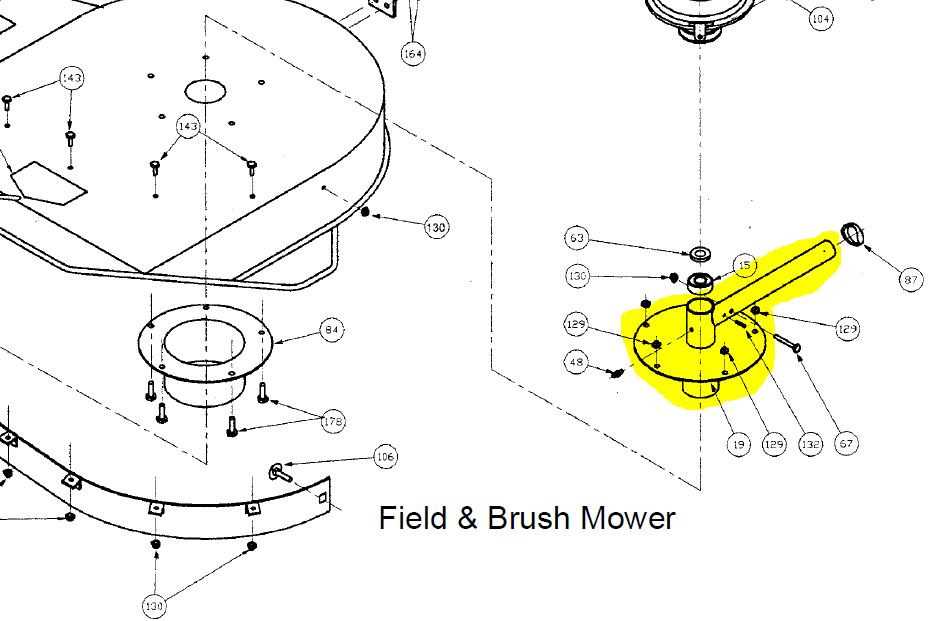

Compatibility with Other Models

Understanding the interchangeability of components across different models is essential for effective maintenance and repair. This section explores how certain elements may be shared among various machines, providing insight into their compatibility and potential for cross-utilization.

Compatibility is often determined by design similarities and manufacturing standards. Many pieces from one series can fit seamlessly into another, allowing users to save on costs and time when sourcing replacements. However, it is crucial to verify specific measurements and attachment points before proceeding, as even slight variations can affect performance and safety.

Some components from related models can serve as alternatives, making it easier for owners to find suitable options without needing to rely solely on original equipment manufacturers. This flexibility can enhance the longevity and efficiency of the machines in question, ensuring they continue to operate effectively.

Tools Needed for Repairs

When it comes to maintenance and fixing machinery, having the right equipment is crucial for effective and efficient repairs. Proper tools not only facilitate the process but also ensure safety and precision during the task.

Essential Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle-nose and regular)

- Torque wrench

- Utility knife

Safety Equipment

- Safety goggles

- Work gloves

- Dust mask

- Hearing protection

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and components of a specific lawn care machine. Here, we provide clarity on frequently encountered topics to assist users in understanding their equipment better.

What should I consider when replacing components?

When replacing elements of your lawn equipment, it’s essential to check compatibility, quality, and manufacturer recommendations. Always opt for high-quality replacements to ensure optimal performance and longevity.

How can I find the right specifications for my model?

You can locate the specifications by consulting the user manual, visiting the manufacturer’s website, or checking reliable online resources that focus on lawn maintenance machinery. Detailed information is crucial for successful maintenance.