Maintaining a well-manicured landscape requires not only dedication but also an understanding of the essential equipment that keeps everything in perfect order. The right tools can make the task of caring for large areas significantly easier, ensuring an even cut and smooth operation. However, for your equipment to perform at its best, understanding the key elements that ensure efficient functioning is crucial.

Each machine relies on a combination of carefully designed elements that work in harmony to deliver precise results. From the cutting mechanism to the drive systems, the arrangement and condition of these components play a vital role in the machine’s overall performance. When it’s time to replace or service any of these elements, it’s essential to know exactly where each fits within the system.

In this section, we will explore the critical elements that make up your lawn care equipment, focusing on the intricate relationships between the various parts. By the end of this guide, you’ll have a comprehensive understanding of how each piece contributes to the overall functionality, helping you keep your equipment in top shape for years to come.

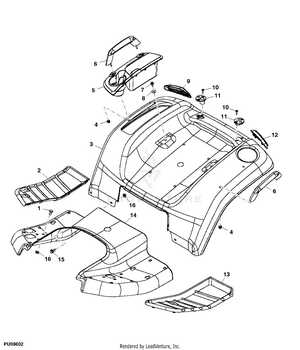

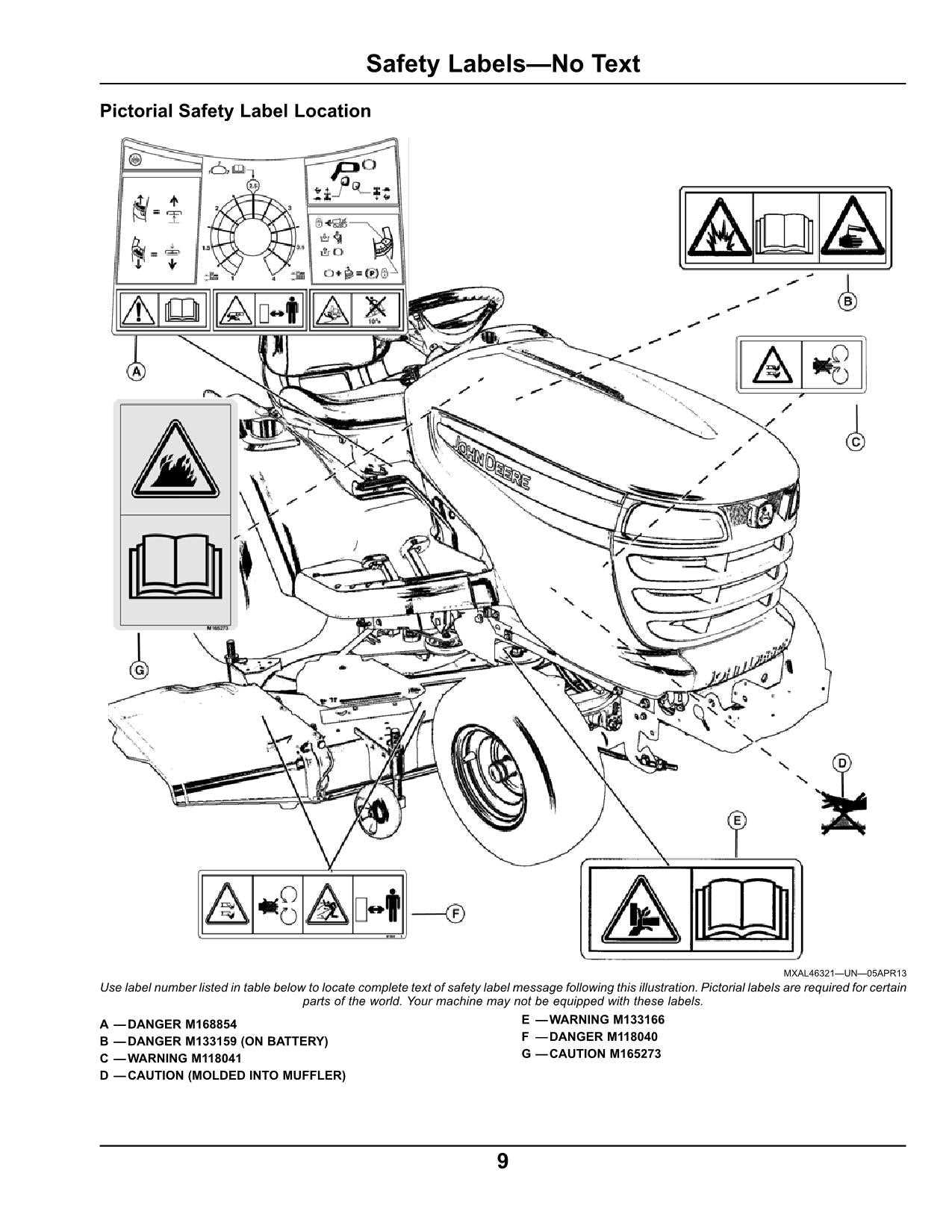

Understanding the John Deere X500 Mower Deck

The cutting system of this machine plays a crucial role in achieving a precise and efficient trim across different terrains. It combines multiple components that work in harmony to ensure an optimal grass-cutting experience. Each element of the system is designed to handle varying conditions, making it suitable for both residential and commercial use. Durability, smooth performance, and ease of maintenance are key aspects of this intricate assembly.

Blade arrangement within the cutting unit is engineered to deliver a clean and even trim. The positioning and movement of the blades ensure consistent cutting results while minimizing the need for frequent adjustments.

Another essential part is the spindle mechanism, which serves as the rotational hub that powers the blades. Proper maintenance of this component guarantees extended lifespan and uninterrupted functionality, critical for long-term performance.

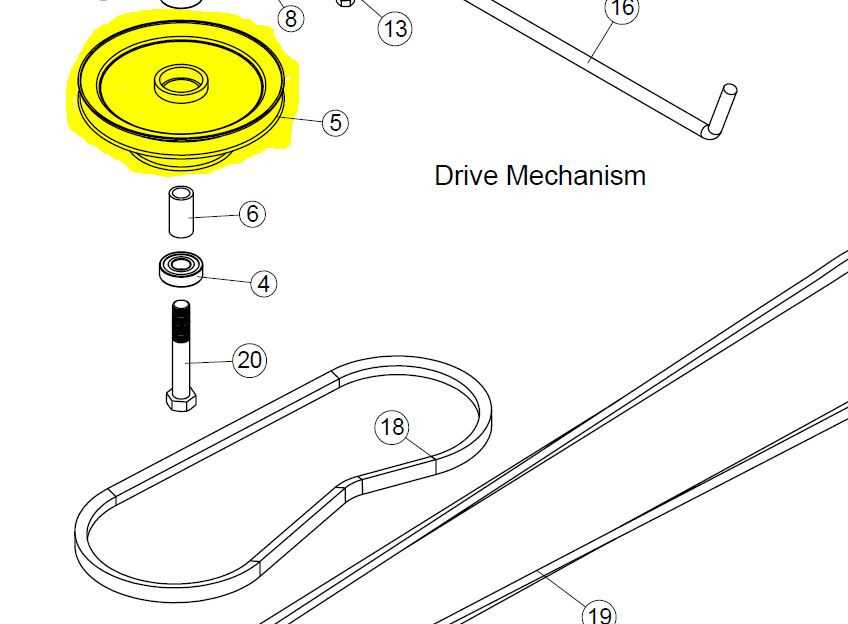

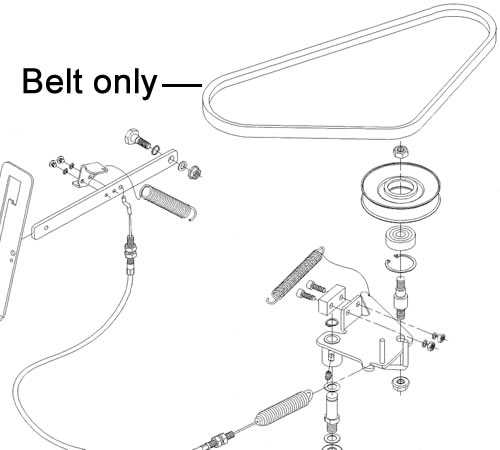

The overall structure is supported by a belt-driven system that connects all moving parts. This design enables efficient power transfer, ensuring that the entire system operates smoothly under load.

Regular care and timely inspection of the components are crucial to preserving the machine’s longevity and reliability, ensuring a continuous high-standard cutting performance.

Essential Components of the X500 Deck

The cutting platform of this versatile machine includes several key elements that work in harmony to deliver precise trimming and smooth performance. Understanding these fundamental parts ensures optimal functionality and prolonged lifespan of the system.

- Blades: Responsible for the actual cutting process, these sharp, rotating elements slice through grass efficiently.

- Spindles: These are the components that connect the cutting blades to the platform, ensuring smooth rotation and proper alignment.

- Belt System: A system of belts and pulleys that transfers engine power to the blades, facilitating their movement and ensuring consistent operation.

- Anti-scalp Wheels: These wheels prevent the cutting surface from digging into uneven ground, maintaining an even trim across all terrains.

- Discharge Chute: A mechanism that directs the trimmed grass away from the cutting surface, keeping the area clear and reducing the likelihood of clogs.

- How to Identify Worn Out Parts

Regular maintenance is essential for keeping your equipment running smoothly. Over time, some components will inevitably wear down, leading to reduced efficiency and potential damage. Being able to recognize the signs of deterioration can help prevent more serious issues and extend the lifespan of your machine.

Visual Signs of Wear

One of the easiest ways to spot a deteriorating component is by visually inspecting it. Look for cracks, bends, or discoloration that differ from the part’s usual appearance. Components showing unusual wear patterns or signs of rust are likely candidates for replacement.

Performance Indicators

Pay attention to how your machine performs. If there is a noticeable drop in efficiency, strange noises, or increased vibration, this could signal that certain elements are no longer functioning optimally. Consistently uneven operation is another strong indication that a specific component may need attention.

Steps to Maintain Your Mower Deck

Regular upkeep of your cutting platform is essential to ensure optimal performance and extend its lifespan. Proper care not only enhances the efficiency of your equipment but also minimizes long-term repair costs. Follow these fundamental steps to keep your machine running smoothly.

Step Description 1. Clean Regularly Remove grass clippings and debris after each use to prevent buildup that can cause rust and reduce performance. Use a hose or air blower for hard-to-reach areas. 2. Inspect Blades Check the sharpness and balance of your blades frequently. Dull or unbalanced blades can tear grass and stress the machine. Sharpen or replace them as needed. 3. Lubricate Moving Parts Ensure all moving parts Replacing the X500 Mower Blades

Over time, cutting tools can wear out, resulting in uneven trimming and reduced efficiency. Timely replacement ensures optimal performance and prolongs the lifespan of the machine. Proper maintenance and correct installation are essential for achieving a clean and even finish across any terrain.

Step 1: Safety First

Before beginning the process, ensure the engine is completely off, and the key is removed. This minimizes any risks of accidental starts while handling the cutting components. It’s also advisable to wear protective gloves to avoid injuries from sharp edges.

Step 2: Lifting the Machine

To access the cutting tools, carefully raise the machine using an appropriate jack or a lift. Ensure it is securely supported to prevent any movement while working underneath.

Step 3: Removing the Old Blades

Once the machine is lifted, locate the bolts securing the cutting tools. Use a wrench to carefully loosen and remove them. Note the positioning and orientation of each component to ensure proper reinstallation later.

Step 4: Installing New Blades

Position the new components in place, making sure they are aligned correctly. Reinse

Common Issues with the X500 Deck

Maintaining a high-performance cutting apparatus is crucial for achieving optimal results in lawn care. However, various complications can arise, affecting functionality and efficiency. This section highlights prevalent challenges that users may encounter, as well as potential remedies to enhance longevity and performance.

Uneven Cutting

One frequent complaint is uneven cutting, which can result from several factors. Issues with blade height adjustment, dull blades, or imbalances in the attachment can lead to an inconsistent appearance of the lawn. Regular inspections and proper calibration of the height settings are essential. Additionally, ensuring that blades are sharp and balanced can significantly improve cutting performance.

Clogging Problems

Another common issue involves the buildup of debris, which can obstruct the flow of grass clippings and hinder overall performance. This often occurs in wet conditions or when the grass is particularly thick. To combat this, users should clean the underside of the apparatus after each use and consider operating in drier conditions. Implementing a routine maintenance schedule can prevent these clogs from becoming a recurring problem.

Cleaning Techniques for Optimal Performance

Regular maintenance of your equipment is essential for ensuring its longevity and efficiency. Proper cleaning techniques not only enhance performance but also prevent wear and tear, leading to reduced repair costs over time. This section outlines effective strategies for keeping your machinery in top condition.

Essential Cleaning Methods

- Routine Washing: Regularly rinse off dirt, grass clippings, and debris using water. A pressure washer can be particularly effective for removing stubborn buildup.

- Brush Cleaning: Use a stiff-bristled brush to scrub areas that are difficult to reach. Focus on crevices where dirt accumulates, ensuring that all surfaces are addressed.

- Drying: After washing, dry the components with a clean cloth to prevent rust and corrosion. This step is crucial in maintaining metal surfaces.

Preventive Measures

- Protective Coatings: Consider applying a protective spray or wax to shield surfaces from dirt and moisture, making future cleaning easier.

- Seasonal Deep Cleaning: At the beginning and end of each season, conduct a thorough cleaning to remove any build-up that may have occurred during use.

- Storage Considerations: Store your equipment in a clean, dry area to minimize exposure to the elements, which can lead to accelerated deterioration.

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is crucial to maintaining its performance and longevity. Properly matched elements ensure efficiency and can prevent unnecessary wear and tear. Understanding the variety of options available and knowing how to choose the correct replacements can make a significant difference in functionality.

Identifying Compatibility

Before making a purchase, it’s essential to verify that the replacements align with your specific model. Compatibility guarantees that the new components will function as intended, thereby avoiding potential issues. Referencing a reliable source that outlines specifications is advisable for accurate identification.

Quality vs. Cost

When evaluating options, consider both quality and price. While lower-cost items may seem appealing, they often lack the durability and reliability of higher-quality alternatives. Investing in premium components can lead to better performance and reduce the frequency of replacements over time.

Factor Considerations Compatibility Check specifications and model numbers. Quality Evaluate material durability and brand reputation. Cost Balance between budget and long-term value. Warranty Look for guarantees that protect your investment. How to Install a New Mower Belt

Replacing a worn or damaged belt is essential for maintaining optimal performance of your cutting machine. A new belt ensures efficient operation and extends the life of the equipment. This guide provides step-by-step instructions for a successful installation, ensuring that your equipment runs smoothly and effectively.

Before beginning the installation process, gather the necessary tools and replacement belt. Ensure the machine is turned off and parked on a flat, stable surface to prevent accidents. Below are the steps to follow:

Step Action 1 Disconnect the power source to ensure safety during the procedure. 2 Remove any guards or covers that obstruct access to the belt area. 3 Take out the old belt by loosening the tension and sliding it off the pulleys. 4 Position the new belt around the pulleys, following the correct routing as indicated in the manual. 5 Tighten the tensioner to ensure the belt is secure and properly aligned. 6 Reattach any guards or covers that were removed earlier. 7 Reconnect the power source and perform a test run to verify proper operation. Following these steps will help you install the new belt efficiently, contributing to the overall functionality of your machine. Regular maintenance and timely replacements are key to keeping your equipment in peak condition.

Diagnosing Problems with Deck Height

Ensuring the correct elevation of the cutting apparatus is essential for optimal performance and achieving a well-manicured lawn. Variations in the height setting can lead to uneven cutting results and can significantly impact the health of the grass. This section will delve into common issues related to height adjustments and provide insights on how to effectively identify and address these challenges.

Common Symptoms of Height Issues

Various signs can indicate that the cutting mechanism’s height is not set correctly. Recognizing these symptoms early can prevent further complications and ensure efficient operation. Here are a few typical indicators:

Symptom Possible Cause Uneven Grass Cutting Inconsistent height settings or worn-out components Scalped Lawn Areas Height set too low or damaged cutting components Excessive Grass Clumping Improper height leading to grass not being cut cleanly Increased Engine Strain Height set too low, causing excessive resistance Steps for Troubleshooting Height Problems

To accurately diagnose and rectify issues related to the cutting height, follow these essential steps:

- Inspect the current height setting against manufacturer recommendations.

- Examine components for wear and tear that may affect performance.

- Test the adjustment mechanism to ensure it operates smoothly.

- Check for any debris that might obstruct height adjustments.

Upgrading the X500 for Better Efficiency

Enhancing the performance of your outdoor equipment can lead to significant improvements in productivity and satisfaction. By implementing strategic upgrades, you can optimize functionality, reduce operational costs, and extend the lifespan of your machinery. This section explores key modifications that can transform your existing unit into a more efficient and reliable tool for yard maintenance.

Performance Enhancements

One effective way to boost efficiency is by upgrading the engine and transmission components. Replacing stock parts with high-performance alternatives can increase power output and improve fuel efficiency. Additionally, considering modifications such as air filters and exhaust systems can enhance airflow, resulting in better combustion and overall performance.

Cutting Precision

Investing in improved cutting technology is essential for achieving a cleaner and more efficient operation. Upgraded blades can provide sharper cuts and reduce the need for multiple passes, ultimately saving time and energy. Furthermore, ensuring proper maintenance of the cutting apparatus will contribute to consistent results and a well-kept landscape.

Long-Term Care Tips for Your Mower

Maintaining your landscaping equipment is essential for its longevity and performance. With proper care, you can ensure that your machine runs efficiently and serves you well for years to come. Below are some vital tips to help you keep your equipment in optimal condition.

- Regular Cleaning: After each use, clean the exterior to remove grass clippings, dirt, and debris. This prevents rust and ensures all components function correctly.

- Inspect Components: Regularly check for wear and tear on blades, belts, and other moving parts. Replace any damaged items promptly to avoid further issues.

- Sharpen Blades: Keep blades sharp for a clean cut. Dull blades can damage the grass and require more effort from the machine.

In addition to these basic maintenance practices, consider the following long-term care strategies:

- Oil Changes: Change the oil according to the manufacturer’s recommendations to keep the engine running smoothly.

- Battery Maintenance: If applicable, check the battery regularly for corrosion and ensure it is charged. Replace it if it shows signs of deterioration.

- Storage: During off-seasons, store your equipment in a dry place. Use a cover to protect it from dust and moisture.

By implementing these long-term care tips, you can significantly extend the life of your equipment and maintain its performance, ensuring a beautiful lawn for years to come.