Maintaining outdoor machines can often seem daunting, especially when it comes to understanding how various elements fit and work together. By familiarizing yourself with the key elements involved, you can significantly improve both the performance and longevity of your equipment. In this section, we will explore the essential mechanisms that drive modern lawn machinery and how these pieces collaborate to provide a smooth, efficient operation.

Each machine is built with precision and purpose, incorporating a variety of interconnected elements. Knowing how these individual components function and the role they play in the overall structure can help you quickly identify and resolve any issues that may arise during use. Whether you are performing routine maintenance or need to replace worn-out pieces, this guide will serve as a valuable resource.

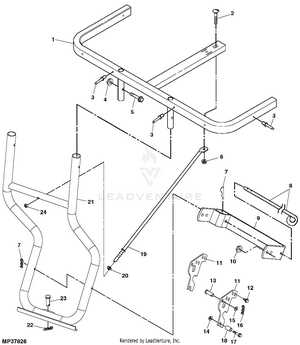

Exploring the Structure of the Mower Deck

The system responsible for cutting grass on this model is a robust and carefully designed mechanism. It features a combination of precision components, all working together to ensure efficient and even trimming across various terrain types. Understanding the arrangement of these elements is crucial for proper maintenance and maximizing performance.

Key Components and Their Roles

- Blades: The cutting tools, arranged in a specific pattern, are designed to handle thick and uneven grass, providing a smooth result.

- Belt System: This vital part connects the engine to the cutting tools, ensuring synchronized rotation and consistent power transmission.

- Spindles: Mounted to hold and rotate the blades, these parts are crucial for maintaining balance and reducing vibrations during operation.

- Blades: These are the primary elements that perform the cutting action. Their sharpness and alignment affect the overall efficiency and quality of the cut.

- Spindles: The spindles rotate the blades at high speeds, powered by the engine. Proper maintenance ensures that they deliver consistent power to the

Overview of the Belt System Configuration

The belt setup is a critical aspect of ensuring smooth and efficient operation. Proper alignment and tension within the system allow the machine to function optimally by transmitting power between components. Understanding the layout and how various elements interact is essential for both performance and maintenance.

Component Function Drive Belt Transmits power to the blades, enabling cutting action. Idler Pulleys Maintain tension and guide the belt through its path. Spindle Assembly Connects the belt to the blades, ensuring rotation. Tensioner Adjusts the tightness of the belt to avoid slipping Spindle Placement and Its Role in Performance

The arrangement of rotating components in cutting machinery directly influences its efficiency and overall performance. By understanding how the positioning of these critical parts impacts the operation, users can optimize their equipment for better precision and durability. Proper alignment ensures a balance between cutting speed and accuracy, which is essential for achieving consistent results.

Impact on Cutting Efficiency

One of the key benefits of strategically placed spindles is enhanced cutting efficiency. The balanced distribution of rotating elements allows for smoother operation, minimizing strain on the machine while maintaining even pressure across the surface. This results in more uniform cutting and reduced wear on individual components, extending their lifespan.

Maintaining Stability and Reducing Vibration

Another critical factor in spindle placement is stability. Proper alignment reduces vibrations, which not only

Tips for Maintaining Deck Stability and Balance

Ensuring the equilibrium and sturdiness of your cutting apparatus is crucial for optimal performance and longevity. A well-maintained setup not only enhances cutting efficiency but also minimizes wear and tear, leading to fewer repairs and extended service life. Here are some key considerations to keep your equipment in top shape.

Regular Inspection and Adjustment

Routine checks are essential for identifying any misalignment or wear that could affect the stability of your machinery. Ensure that all fasteners are tight and components are properly aligned. Adjustments may be necessary to achieve the ideal level of performance. Performing these checks frequently can prevent larger issues from arising.

Maintaining Proper Height Settings

Ensuring the correct height settings is vital for achieving an even cut. Adjust the height according to the type of terrain and grass conditions. Keeping the cutting mechanism at an appropriate level helps in maintaining balance while reducing stress on the entire assembly. This simple step can make a significant difference in the overall functionality of the system.

Exploring the Tensioner System for Smooth Operation

The tensioning mechanism plays a crucial role in ensuring optimal performance and reliability of cutting equipment. This system is designed to maintain the proper tension on the drive belts, which are essential for the efficient transfer of power from the engine to the cutting components. By facilitating a seamless connection, the tensioner enhances the overall functionality and extends the lifespan of the machinery.

In this setup, a well-functioning tensioner prevents slippage, which can lead to reduced efficiency and uneven cutting results. Regular maintenance of this component is vital, as wear and tear can compromise its effectiveness. Identifying signs of wear, such as unusual noises or inconsistent performance, is essential for timely interventions.

Additionally, understanding the installation and adjustment processes can empower users to achieve optimal tension levels, thereby promoting smoother operation. Proper calibration of the tensioning system not only improves performance but also minimizes the risk of damage to other parts of the equipment. Overall, investing time in exploring and maintaining the tensioner system is key to achieving excellent results in lawn care and maintenance tasks.

Identifying the Role of the Discharge Chute

The discharge chute plays a crucial role in the efficient operation of a lawn maintenance machine. Its primary function is to direct clippings away from the cutting area, ensuring a clean and well-manicured lawn. This component significantly contributes to the overall effectiveness of the machine, impacting both performance and aesthetics.

Proper Functionality: A well-designed chute aids in the even distribution of clippings, preventing them from clumping or obstructing the blades. This enhances the machine’s ability to maintain a consistent cutting height and quality. Additionally, it minimizes the risk of blockages, allowing for uninterrupted operation.

Impact on Maintenance: Regular inspection of the discharge chute is essential for optimal performance. Any obstructions or damages can lead to decreased efficiency and potentially cause strain on the engine. By ensuring that this component remains clear and intact, operators can extend the lifespan of their equipment and achieve better results.

Essential Bearings and Their Maintenance

Bearings play a vital role in the functionality and longevity of machinery by reducing friction between moving components. Regular upkeep of these critical elements ensures smooth operation and prevents unexpected breakdowns. Understanding the various types of bearings and their specific maintenance needs is essential for optimal performance.

Types of Bearings

There are several types of bearings commonly used in equipment, each designed for specific applications and load capacities. Below are some of the most prevalent types:

Type Description Ball Bearings Suitable for moderate loads and speeds, offering minimal friction. Cylindrical Bearings Designed for high radial loads and can accommodate axial loads in one direction. Needle Bearings Ideal for applications requiring compact design and high load capacity. Tapered Bearings Allow for both radial and axial load support, commonly used in wheel assemblies. Maintenance Practices

Proper maintenance practices are crucial for extending the lifespan of bearings. Key steps include:

- Regularly inspecting for signs of wear or damage.

- Ensuring proper lubrication to minimize friction and heat.

- Replacing bearings at the first sign of failure to prevent further damage to surrounding components.

Optimizing Deck Adjustments for Improved Cutting

Achieving a precise cut involves careful calibration of the cutting assembly’s height and angle. Proper adjustments ensure an even trim across varying terrain, enhancing both the appearance and health of the lawn. This section will explore essential techniques for optimizing these configurations to maximize efficiency and effectiveness.

Understanding Cutting Height

Setting the correct cutting height is crucial for a clean finish. Different grass types thrive at specific heights; thus, adjusting the cutting assembly to the ideal level promotes healthier growth. Regularly inspecting and modifying this height according to seasonal changes can significantly impact the overall performance of the equipment.

Angle and Leveling Techniques

In addition to height, the angle at which the cutting assembly operates plays a vital role in performance. Ensuring the assembly is level not only improves cutting precision but also minimizes the risk of uneven wear and tear. Periodic checks and adjustments are recommended to maintain optimal conditions, thus prolonging the lifespan of the equipment.

Troubleshooting Common Deck Issues

Maintaining the efficiency of cutting equipment is essential for achieving optimal performance. Various problems may arise that hinder the functionality of the cutting mechanism. Identifying and resolving these common issues can enhance the longevity and reliability of the equipment, ensuring a seamless operation.

Uneven Cutting Results

If the cutting results are inconsistent, several factors may be at play. Check the height settings to ensure they are uniform across all blades. Inspect the sharpness of the blades, as dull blades can lead to jagged edges. Additionally, examine the leveling of the attachment; an imbalanced assembly may contribute to uneven performance.

Excessive Vibration or Noise

Unusual vibrations or sounds during operation may indicate a problem with the cutting assembly. Start by tightening any loose bolts and fasteners. If vibrations persist, inspect the condition of the blades and spindles, as damaged components can exacerbate noise levels. Lubricating moving parts can also help reduce friction and improve overall performance.

Key Components of the Mower Assembly

The assembly responsible for cutting grass effectively consists of several interconnected elements designed to ensure smooth operation. These components work together to provide consistent performance and durability, allowing the machine to handle various types of terrain and vegetation with ease.

One of the main elements is the rotating system responsible for trimming, which is driven by a mechanism that transfers power from the engine. This system includes multiple cutting edges and fasteners that help maintain balance during operation. Proper alignment and maintenance of these parts are critical to ensure optimal functionality and longevity.

Another essential feature is the frame structure, which holds the entire assembly together. It supports the various attachments and ensures stability during movement. This structure must be built to withstand the vibrations and impact that occur during use.

The height adjustment mechanism also plays a pivotal role in controlling the cutting range. This feature allows for precise changes in cutting

Understanding Blade Mechanisms and Their Functions

Efficient operation of cutting systems relies on the precision and synchronization of various components. To ensure proper performance, it’s crucial to understand how the different parts interact to achieve seamless functionality. The mechanisms responsible for cutting are designed to handle various terrains and workloads, and each element plays a vital role in maintaining smooth and effective operation.