Understanding the configuration of essential mechanisms in lawn maintenance equipment is crucial for ensuring optimal performance. By familiarizing yourself with the structure of these tools, users can maintain their equipment with ease, ensuring smooth and efficient operation during demanding tasks.

In the world of lawn care, proper upkeep of mechanical assemblies helps extend the lifespan of machinery. A clear understanding of how different segments are connected and function together provides valuable insight, making routine maintenance and repair significantly more manageable.

Whether you’re dealing with mechanical adjustments, cleaning, or replacing key elements, having a clear overview of the structural arrangement will guide you through the process. This knowledge is key to preventing unexpected breakdowns and optimizing the equipment’s longevity.

Kubota Mower Deck Components Overview

Understanding the individual elements that make up a cutting system is crucial for ensuring its efficient operation. These components work together to provide a smooth and precise grass-cutting experience.

Below is a breakdown of the essential features:

- Blades: Sharp edges responsible for cutting the grass evenly.

- Spindles: Mechanical parts that rotate the blades for smooth operation.

- Belt System: Transfers power from the engine to the rotating parts.

- Deck Shell: The frame that houses the cutting mechanism, providing protection and stability.

- Discharge Chute: Directs the cut grass away from the machinery.

Each of these parts contributes to the overall performance, and regular maintenance helps in avoiding common operational issues.

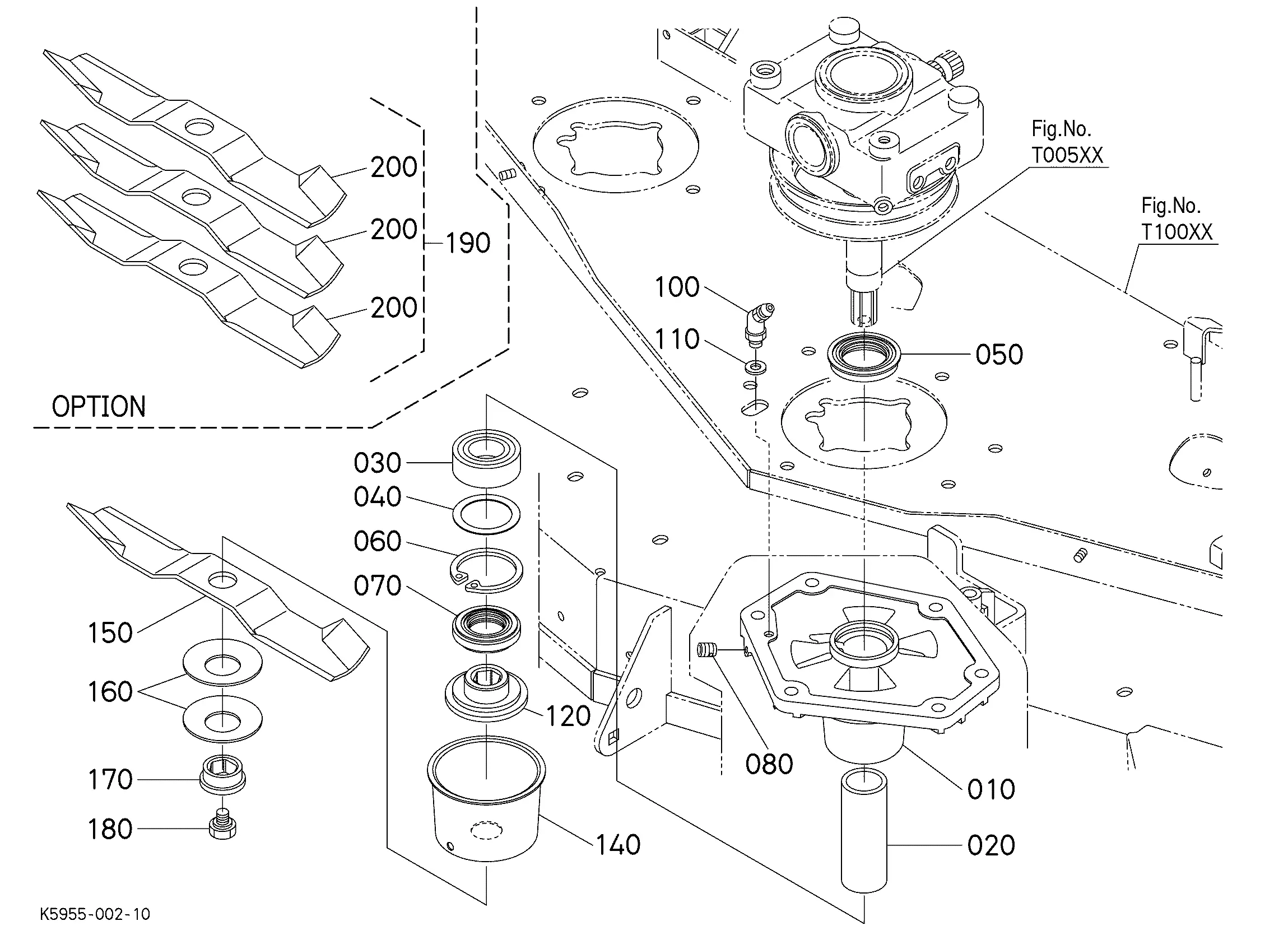

Understanding the Blade Assembly Setup

The arrangement of cutting components plays a crucial role in the overall performance and efficiency of the machine. Ensuring each element is properly aligned and securely fastened guarantees smooth operation and consistent results during use.

- Blade Positioning: Properly aligning the cutting edges is essential for even trimming and preventing damage to the ground surface.

- Mounting Bolts: These fasteners must be securely tightened to maintain stability during operation and reduce wear on the system.

- Spacer Placement: Spacers ensure the correct height of the blades, impacting cutting height and precision.

- Balancing: Regular checks for balance prevent vibration and uneven cuts, contributing to the longevity of the equipment.

Exploring the Belt System Layout

The belt configuration plays a crucial role in ensuring efficient operation, seamlessly transferring power between key components. Understanding the overall arrangement is essential for maintaining smooth functionality and preventing unnecessary wear. With the correct layout in place, tension is evenly distributed, reducing the risk of slippage or damage during operation.

Proper alignment of the belt system ensures that all elements work in harmony, minimizing friction and optimizing performance. Regular inspection and adjustment can prevent potential issues, prolonging the lifespan of the machinery.

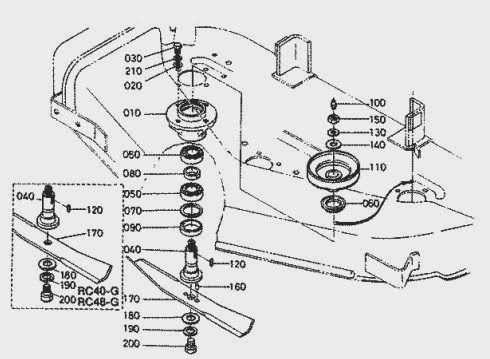

Identifying the Pulley and Spindle Parts

Understanding the essential mechanisms involved in driving and rotating the cutting blades is key to maintaining the performance of the cutting system. Key components include the pulley system and the spindle assembly, both of which play a crucial role in ensuring smooth operation.

- Pulley: This component is responsible for transferring power from the engine to the rotating blades. It works by redirecting the motion of the belts, allowing the blades to spin efficiently.

- Spindle: The spindle serves as the central shaft that holds the cutting blades in place. It is designed to rotate with the help of bearings, ensuring the blades maintain their optimal speed and alignment.

- Bearings: These small yet essential elements within the spindle allow smooth rotation, reducing friction and wear. Worn-out bearings can lead to uneven cutting and additional strain on the engine.

Proper identification and routine maintenance of these parts will significantly enhance the system’s longevity and performance.

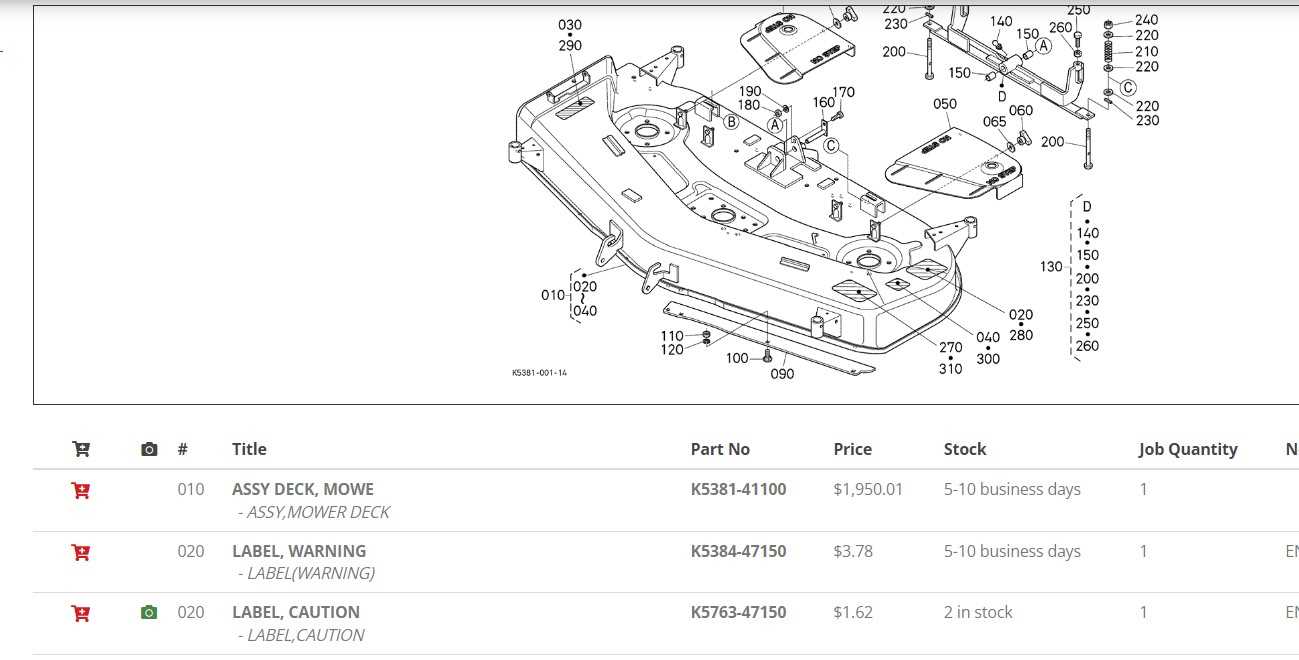

Inspecting the Mower Deck Shell Design

The overall framework of the cutting platform plays a critical role in both the performance and longevity of the equipment. A well-constructed shell ensures efficient grass cutting, protects internal components, and resists wear from prolonged use. Regular inspection of the structure helps identify any potential weak points or damage that could impact functionality. Close attention to the material quality, thickness, and structural integrity is essential to maintaining peak performance during operation.

Comprehending the Discharge Chute Placement

The position of the exit chute plays a crucial role in the overall efficiency of grass cutting equipment. Understanding its placement can significantly enhance the performance and user experience. A well-positioned chute ensures that clippings are directed away from the machine and the operator, minimizing the risk of obstruction and promoting a clean work area.

Importance of Proper Orientation

Proper orientation of the discharge chute is essential for optimal operation. If misaligned, it can cause clippings to accumulate around the equipment, potentially leading to overheating or clogging. Additionally, an accurate angle allows for better dispersion of cut material, preventing buildup in specific areas of the lawn and promoting healthy growth.

Adjusting the Chute for Efficiency

Adjusting the exit chute to fit varying cutting conditions can enhance the functionality of the equipment. For instance, when mowing in wet conditions, altering the chute’s direction can help prevent clogging. Operators should also consider the terrain and grass height to ensure the discharge is efficient, reducing the need for excessive cleanup after cutting.

Recognizing Safety Shielding Components

Understanding the various components designed to enhance safety is essential for the effective operation of equipment. These elements are specifically engineered to protect users from potential hazards that may arise during operation, ensuring both functionality and security.

Importance of Safety Features

Safety features are critical in minimizing the risk of accidents and injuries. They are strategically placed to provide barriers against moving parts, thereby preventing unintended contact. Familiarizing oneself with these protective components allows for a safer working environment.

Identifying Protective Elements

When examining the various safeguarding elements, look for coverings, shields, and guards that encase mechanical parts. These structures are typically constructed from durable materials to withstand wear and tear. Recognizing these components not only helps in understanding their function but also in maintaining compliance with safety regulations. Awareness of these elements contributes significantly to overall safety during usage.

Analyzing the Deck Height Adjustment Mechanism

The ability to modify the cutting height of a lawn care implement is crucial for achieving optimal results in various grass types and environmental conditions. Understanding how this adjustment system functions can significantly enhance both performance and user experience. This section delves into the intricacies of the mechanism responsible for altering the height, focusing on its components, functionality, and importance in lawn maintenance.

Components of the Adjustment System

Central to the adjustment mechanism are several key elements that work in tandem to facilitate height changes. These typically include a lever or dial, which allows the operator to set the desired elevation, along with a series of linkages that translate this input into movement. The incorporation of springs may also play a role in providing resistance and stability during operation, ensuring consistent cutting performance.

Importance of Proper Adjustment

Maintaining the correct height is essential for promoting healthy grass growth and preventing damage to the turf. Improper settings can lead to uneven cutting, which may stress the plant and result in a patchy lawn. Furthermore, understanding the adjustment mechanism empowers users to adapt to varying conditions, ensuring efficient operation throughout the mowing process.

Reviewing the Anti-Scalp Wheel Configuration

The configuration of the anti-scalp wheels plays a crucial role in maintaining a healthy and attractive lawn. These components are designed to prevent the cutting apparatus from scalping the ground, ensuring an even cut across various terrains. Understanding their arrangement and functionality can significantly impact the performance of the equipment.

Proper placement and adjustment of the anti-scalp wheels are essential for optimal operation. Here are key aspects to consider:

- Height Adjustment: Ensuring the wheels are set at the correct height prevents the cutting mechanism from digging into the soil.

- Material Quality: Selecting durable materials for these wheels enhances their longevity and effectiveness.

- Positioning: The strategic placement of wheels across the width of the cutting system minimizes the risk of scalping.

In addition, regular inspections and maintenance of the anti-scalp wheels contribute to their reliability. Here are some tips for upkeep:

- Check for wear and tear regularly.

- Adjust the height as needed based on terrain changes.

- Clean the wheels to prevent debris buildup.

By focusing on these aspects, users can ensure that their equipment operates efficiently, resulting in a pristine and healthy lawn.

Evaluating the Idler and Tensioner Parts

When maintaining lawn care equipment, it is essential to assess components that ensure optimal performance and durability. These elements play a crucial role in managing the tension of drive belts, which directly impacts the efficiency of the overall system. Understanding their functionality and condition is vital for effective upkeep and long-term reliability.

Idler components are designed to guide and support the movement of belts, while tensioning devices maintain appropriate tension levels to prevent slippage or excessive wear. Regular inspection of these components helps identify signs of wear, misalignment, or damage. By keeping them in good condition, users can enhance the reliability and efficiency of their equipment, ensuring smooth operation during use.

Locating the Deck Support Brackets

Identifying the support components for the cutting platform is crucial for proper maintenance and functionality. These brackets play a vital role in securing the assembly, ensuring stability during operation. Understanding their placement and purpose will assist in effective repairs and replacements.

Understanding the Structure

Before beginning the search, familiarize yourself with the overall configuration. The support brackets are typically situated at specific locations, providing essential reinforcement to the structure. Here are some common characteristics to consider:

- Made of durable metal to withstand stress.

- Bolted securely to the main framework.

- Designed to connect with the cutting assembly.

Steps to Locate the Brackets

To find these support components efficiently, follow these guidelines:

- Inspect the underside of the cutting unit for visible mounting points.

- Look for any accompanying diagrams in the maintenance manual that illustrate bracket placement.

- Check for signs of wear or damage around the connections, which may indicate the brackets’ locations.

Inspecting the Grass Clipping Deflector System

The grass clipping deflector system plays a crucial role in maintaining a clean and efficient cutting operation. This component directs clippings away from the blades and prevents them from accumulating on the surface, ensuring an even finish. Regular inspection of this system is essential for optimal performance and longevity of the equipment.

Key Components to Examine

During the inspection, focus on the following elements:

| Component | Purpose | Signs of Wear |

|---|---|---|

| Deflector Shield | Directs clippings away from the cutting area | Cracks, bends, or excessive wear |

| Mounting Brackets | Secures the deflector in place | Loose fittings or rust |

| Spring Mechanism | Controls the movement of the deflector | Weakness or breakage |

Inspection Steps

Follow these steps for an effective inspection:

- Turn off the equipment and disconnect the power source.

- Visually check the deflector shield for any physical damage.

- Ensure that all mounting brackets are secure and free from corrosion.

- Test the spring mechanism for proper functionality.

Maintaining the Mower Deck Fasteners and Bolts

Proper care and attention to the securing elements of your cutting equipment are essential for ensuring optimal performance and longevity. Regular inspection and maintenance of these components can prevent wear and potential failures, ensuring that the machinery operates efficiently and safely. Understanding the significance of these fixtures and their upkeep is crucial for any equipment owner.

Importance of Regular Inspections

Conducting routine checks on the fasteners and screws helps identify any signs of damage or corrosion. Early detection of issues allows for timely repairs and replacements, preventing more significant problems down the line.

Maintenance Tips

To keep the securing elements in top condition, follow these maintenance tips:

| Action | Frequency | Description |

|---|---|---|

| Visual Inspection | Every Use | Check for any visible wear or looseness. |

| Tightening | Monthly | Ensure all fixtures are securely fastened. |

| Cleaning | As Needed | Remove dirt and debris that may cause rust. |

| Replacement | Annually | Replace any damaged or worn components. |