The intricate assembly of cutting equipment is vital for achieving optimal performance in lawn maintenance. Understanding the various elements that make up this machinery allows users to ensure efficient operation and longevity. This section delves into the crucial components involved in the system, providing insights into their functions and interrelationships.

Identifying each individual component is essential for effective maintenance and troubleshooting. By familiarizing oneself with the specific roles and characteristics of these elements, operators can quickly diagnose issues and implement necessary repairs. This knowledge empowers users to enhance the reliability and functionality of their equipment, leading to a more productive gardening experience.

In addition, a comprehensive understanding of the assembly aids in accessing replacement parts and upgrades. Whether you are looking to optimize performance or replace worn components, knowing the structure and layout facilitates informed decisions. This guide serves as a valuable resource for anyone seeking to enhance their expertise in equipment management and care.

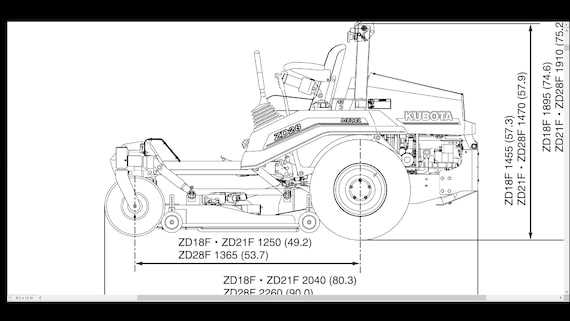

Overview of the ZD18 Lawn Care Equipment

This segment provides a comprehensive understanding of a specific model designed for efficient grass trimming and landscape maintenance. It highlights the key features, advantages, and operational aspects that make this equipment a reliable choice for both residential and commercial applications.

Key Features

The highlighted equipment offers several innovative characteristics that enhance its functionality. These include an advanced engine for robust performance, a precision cutting system for optimal grass management, and ergonomic controls for user-friendly operation. Additionally, its durable construction ensures longevity, making it suitable for various terrains.

Benefits of the Equipment

Utilizing this lawn care apparatus brings numerous advantages. Its efficiency reduces time spent on maintenance tasks, while the adjustable settings allow users to customize cutting heights. Moreover, its compact design facilitates easy maneuverability, ensuring effective operation even in tight spaces.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine ensuring reliability and strength. |

| Cutting System | Precision blades for a clean and even cut. |

| Control System | User-friendly controls for enhanced operation. |

| Durability | Robust materials designed to withstand various conditions. |

Key Features of the ZD18 Model

The ZD18 model stands out in its category due to a combination of advanced design and user-oriented features. It has been engineered to provide exceptional performance and reliability, making it a preferred choice for those seeking efficiency and durability in their equipment.

Performance and Efficiency

One of the most significant attributes of this model is its powerful engine, which ensures optimal performance across various terrains. Key aspects include:

- High horsepower output for robust cutting power.

- Fuel-efficient design that minimizes consumption without sacrificing performance.

- Quick acceleration capabilities for enhanced productivity.

User-Friendly Design

Another highlight is the model’s intuitive design that prioritizes user comfort and ease of operation. Features contributing to this include:

- Ergonomic controls that reduce operator fatigue.

- Adjustable seating for improved comfort during extended use.

- Easy maintenance access for quicker servicing and upkeep.

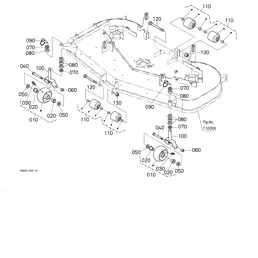

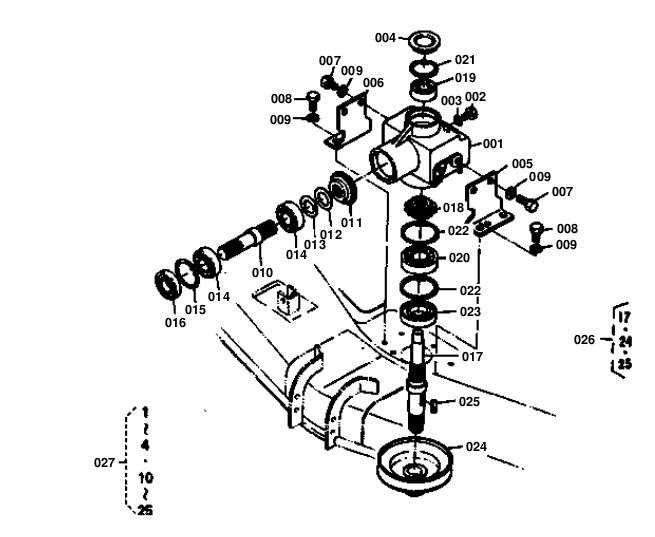

Understanding the Mower Deck Components

In the realm of lawn care machinery, comprehending the various elements that contribute to cutting efficiency is essential for optimal performance. Each component plays a pivotal role in ensuring that the equipment operates smoothly, enabling precise and effective trimming of grass and vegetation. This section delves into the key features that make up this crucial assembly, enhancing overall functionality and durability.

Key Elements of the Cutting Assembly

The primary elements within this assembly include the rotating blades, which are designed to efficiently slice through grass, and the housing that encases these blades. The design of the housing ensures proper airflow, facilitating an even cut while preventing clumping. Additionally, components such as the tensioning mechanisms and height adjustment systems allow users to customize the cutting height according to their specific needs, promoting versatility and adaptability in various mowing conditions.

Maintenance Considerations

Regular upkeep of these components is vital to prolonging the lifespan of the equipment. Users should routinely inspect and sharpen the blades to maintain their cutting effectiveness. Furthermore, ensuring that all connections are secure and that any wear and tear is promptly addressed will contribute to optimal performance. By understanding these critical elements, operators can enhance their overall experience and achieve a well-manicured lawn.

Common Issues with Mower Decks

Regular maintenance is essential for keeping cutting equipment in optimal condition. However, users often encounter various challenges that can affect performance. Understanding these common problems can help in diagnosing issues early and implementing effective solutions.

Uneven Cutting

One prevalent concern is uneven cutting. This can arise from dull blades, improper leveling, or uneven tire pressure. Maintaining sharp blades and ensuring all components are aligned correctly can significantly improve the quality of the cut.

Clogging and Buildup

Another frequent issue is the buildup of grass and debris, which can hinder functionality. Regular cleaning of the underside of the unit is crucial to prevent clogs that can impede the cutting process. Using appropriate cleaning tools will help maintain efficiency and prolong the lifespan of the machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a few straightforward guidelines, you can enhance its lifespan and reliability. Regular maintenance not only prevents unexpected breakdowns but also helps to maintain efficiency, saving you time and money in the long run.

Regular Inspection: Conduct routine checks to identify any signs of wear or damage. Early detection can prevent minor issues from escalating into significant problems, ensuring your equipment operates smoothly.

Cleaning: Keep the machinery clean from debris, grass, and dirt. A clean environment helps in preventing corrosion and ensures that all components function effectively.

Lubrication: Regularly lubricate moving parts to reduce friction and wear. This simple step can significantly improve performance and extend the life of your equipment.

Sharp Blades: Ensure that cutting edges are sharp and well-maintained. Dull blades not only compromise performance but can also lead to unnecessary strain on the machinery.

Proper Storage: When not in use, store your equipment in a dry, sheltered area to protect it from the elements. This practice can help prevent rust and deterioration over time.

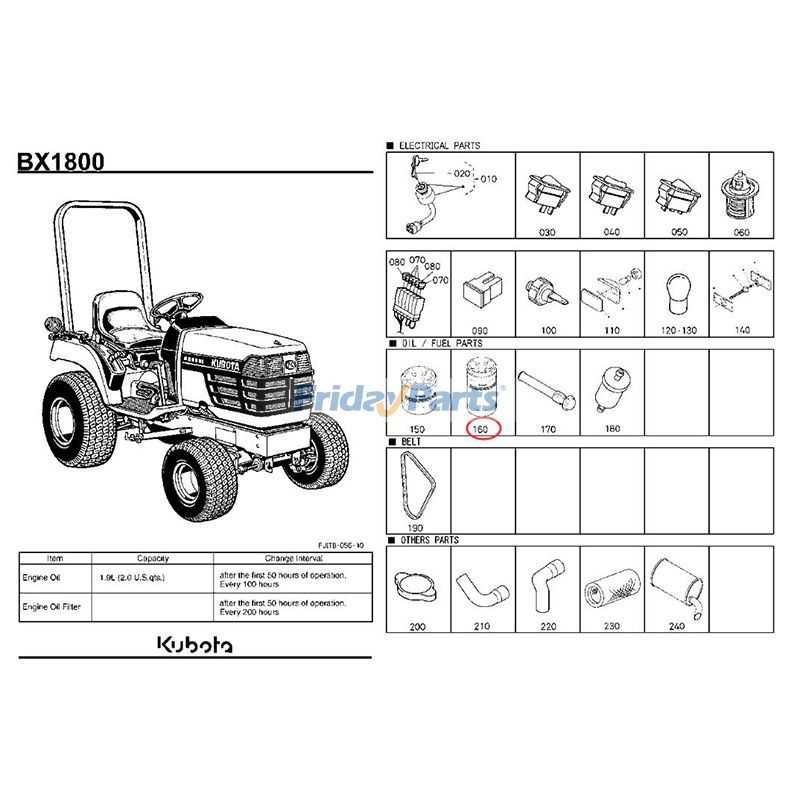

Identifying Replacement Parts

When it comes to maintaining outdoor equipment, recognizing essential components is crucial for ensuring optimal performance. Knowing how to identify the right elements can streamline the repair process and prolong the life of your machinery. Understanding the specific requirements for your equipment will facilitate the selection of suitable alternatives when repairs are necessary.

Understanding Component Functions

Each element within the machinery serves a distinct function, contributing to the overall efficiency of the device. Familiarizing yourself with these roles not only aids in troubleshooting but also assists in determining which items need replacement. Regular inspections can reveal wear and tear, allowing for proactive replacements rather than reactive repairs.

Locating Reliable Resources

To find accurate information regarding necessary components, consult reputable resources. Manufacturer websites, user manuals, and dedicated forums often provide detailed insights into the specifications and compatibility of various elements. Engaging with a community of enthusiasts can also offer valuable advice and support in sourcing the right items for your equipment.

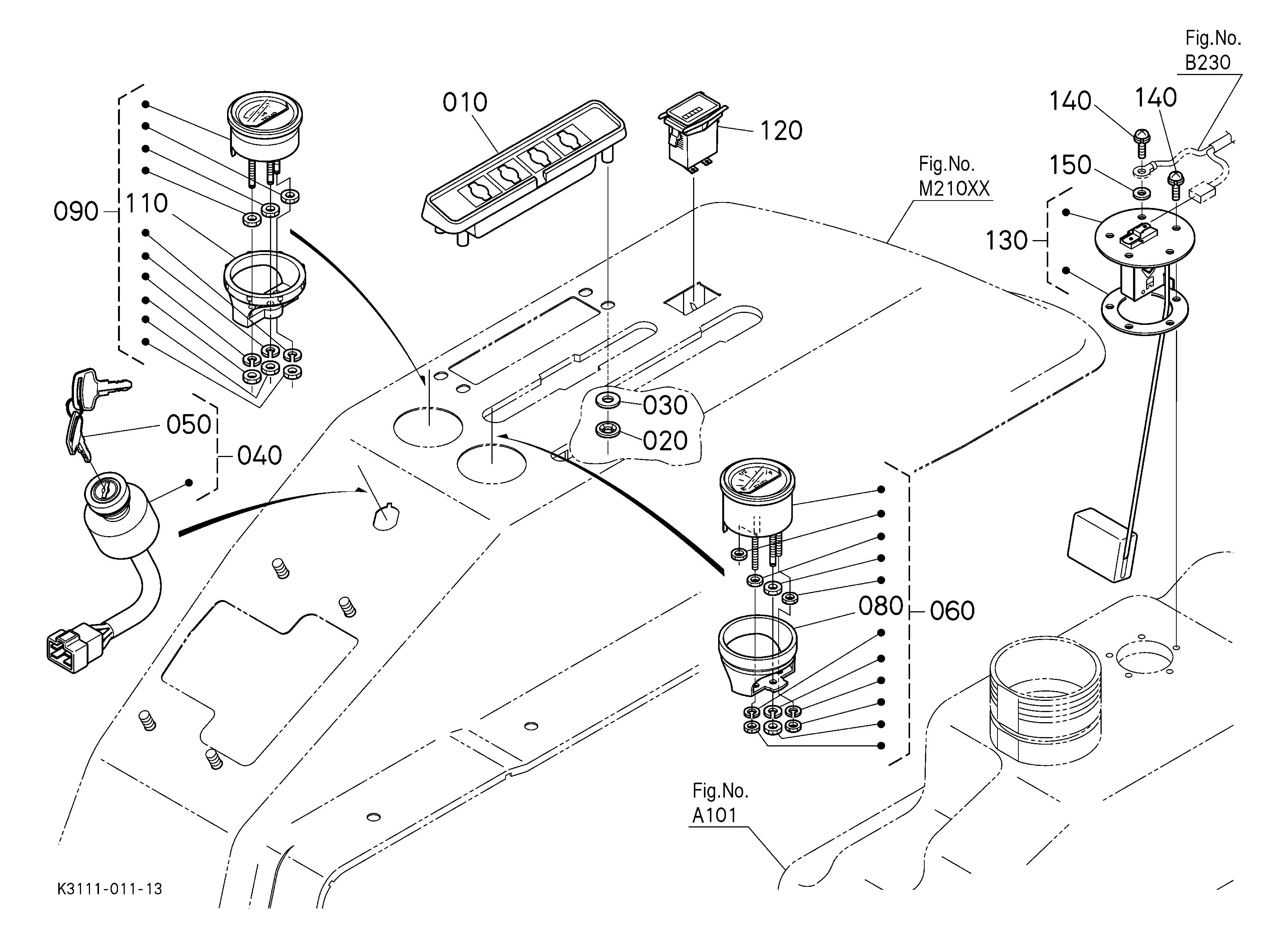

How to Access the Parts Diagram

Gaining insight into the components of your equipment can greatly enhance maintenance and repair tasks. Understanding the layout and functionality of each element allows for more effective troubleshooting and part replacement. Here’s a guide to help you easily find the relevant illustrations that depict the various sections and components of your machinery.

Finding the Right Resources

The first step in locating the necessary illustrations is to visit the official website or authorized dealer that specializes in your type of machinery. These resources often provide detailed visual guides and manuals that can aid in identifying the essential elements for maintenance. Look for sections labeled as support, manuals, or product documentation.

Using Online Platforms

In addition to official resources, numerous online platforms and forums dedicated to machinery enthusiasts may host shared documents and diagrams. Engaging with these communities can also provide insights and tips from experienced users who have encountered similar situations. Utilize search engines to find these platforms by using terms related to equipment maintenance.

| Resource Type | Details |

|---|---|

| Official Websites | Manufacturer’s site for manuals and support documentation. |

| Online Forums | Community-driven platforms for shared knowledge and experience. |

| Parts Retailers | Stores specializing in machinery parts often have diagrams available. |

Benefits of Genuine Kubota Parts

Using authentic components in equipment maintenance ensures optimal performance and longevity. Genuine products are designed specifically for the machinery, providing a perfect fit and seamless integration. This commitment to quality translates into enhanced reliability and efficiency, ultimately leading to better outcomes for users.

Quality Assurance

One of the primary advantages of selecting original components is the assurance of quality. These items undergo rigorous testing and meet the highest manufacturing standards. Users can trust that they are investing in durable solutions that will withstand the demands of regular use.

Compatibility and Performance

Authentic components are engineered to work harmoniously with existing machinery. This compatibility minimizes the risk of malfunction and ensures peak performance. Users can enjoy peace of mind knowing that their equipment operates at its best, reducing downtime and maintenance costs.

| Benefit | Description |

|---|---|

| Durability | Manufactured to withstand heavy use, ensuring long-lasting functionality. |

| Reliability | Engineered to perform consistently, minimizing unexpected breakdowns. |

| Warranty Protection | Purchasing original items often includes warranty benefits, providing extra security. |

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining outdoor equipment, the choice between replacement components from original manufacturers and those produced by third-party suppliers is crucial. Understanding the differences can significantly impact performance, durability, and overall satisfaction.

Quality and Reliability

Original components are designed specifically for certain models, ensuring compatibility and performance. In contrast, aftermarket alternatives may vary widely in quality. Here are some factors to consider:

- Material Quality: OEM options typically use high-grade materials that match the original specifications.

- Testing Standards: Original manufacturers often adhere to strict testing processes to guarantee reliability.

- Longevity: Genuine replacements may offer better longevity, as they are engineered for specific equipment requirements.

Cost Considerations

While original components can be more expensive, the cost is often justified by their benefits. Here are some financial aspects to consider:

- Initial Investment: Aftermarket items may present a lower upfront cost, appealing to budget-conscious consumers.

- Long-Term Value: Investing in OEM components might save money over time due to reduced failures and less frequent replacements.

- Warranty Implications: Some warranties may require the use of original items, which could affect overall repair expenses.

Steps for Mower Deck Repair

Repairing your cutting apparatus requires careful attention to detail and a methodical approach. By following a structured process, you can ensure that your equipment is restored to optimal condition, enhancing its performance and longevity.

Here are the essential steps to effectively carry out the repair:

- Gather Necessary Tools:

- Wrenches and sockets

- Screwdrivers

- Pliers

- Replacement components

- Lubricants

- Inspect for Damage:

Carefully examine the entire structure for signs of wear or breakage. Look for:

- Cracks or dents

- Worn-out bearings

- Loose fasteners

- Disassemble Components:

Using the appropriate tools, carefully disassemble the affected sections. Keep track of all fasteners and small parts to facilitate reassembly.

- Replace Damaged Parts:

Install new components as needed. Ensure that each part is compatible with the existing structure.

- Reassemble the Structure:

Carefully put all parts back together in reverse order of disassembly, ensuring a secure fit.

- Lubricate Moving Parts:

Apply suitable lubricant to moving components to ensure smooth operation.

- Test Functionality:

After reassembly, perform a test run to ensure everything operates correctly. Listen for unusual noises and check for proper operation.

By adhering to these steps, you can effectively address any issues with your cutting apparatus, ensuring it operates efficiently for many more seasons.

Best Practices for Mower Safety

Ensuring safety while operating lawn maintenance equipment is crucial for preventing accidents and injuries. Adopting effective practices can significantly reduce risks associated with the operation of these powerful machines. Whether you are a seasoned professional or a novice, following these guidelines will enhance your safety and the safety of those around you.

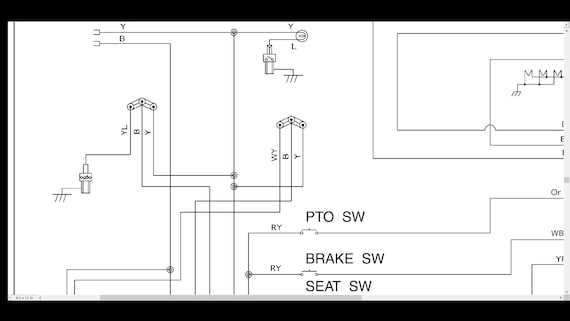

Pre-Operation Checks

Before using any landscaping machinery, conducting a thorough inspection is essential. Check for any signs of wear or damage, ensuring that all components are functioning correctly. Ensure that safety features, such as guards and emergency shut-off mechanisms, are in place and operational. This proactive approach helps to identify potential hazards before they result in accidents.

Proper Operating Techniques

Familiarize yourself with the operational guidelines provided by the manufacturer. Always wear appropriate protective gear, including sturdy footwear, gloves, and eye protection. Maintain a clear work area free of obstacles, debris, or bystanders. Additionally, avoid operating machinery in wet or slippery conditions to prevent loss of control. By employing these techniques, operators can ensure a safer working environment.

Resources for Mower Owners

Maintaining a cutting machine requires access to reliable resources that provide essential information and support. Owners can benefit from various materials, including guides, manuals, and online forums that facilitate the upkeep and troubleshooting of their equipment. Utilizing these resources not only enhances performance but also extends the lifespan of the machinery.

Online Forums and Communities

Engaging with fellow enthusiasts through online forums can be invaluable. These platforms offer a space for users to share experiences, tips, and solutions to common challenges. Participating in discussions allows individuals to gain insights from others who may have faced similar issues, fostering a sense of community.

User Manuals and Guides

Access to comprehensive user manuals is crucial for understanding the functionality of the equipment. These documents typically include detailed instructions, maintenance schedules, and safety precautions. Furthermore, online resources often provide downloadable versions, enabling users to keep essential information at their fingertips.