In the world of lawn maintenance, comprehending the intricate assembly of machinery is essential for effective upkeep and repairs. Familiarity with various elements and their interrelations not only enhances performance but also prolongs the lifespan of the equipment. This knowledge empowers users to tackle issues proactively, ensuring their tools operate at peak efficiency.

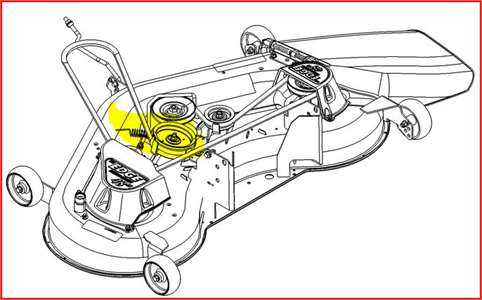

For anyone invested in the proper functioning of their gardening equipment, having a visual representation of the different sections can prove invaluable. Such a resource allows for quick identification of parts, simplifying the process of troubleshooting and replacement. With the right information at hand, even the most daunting maintenance tasks can become manageable.

Moreover, engaging with these resources can foster a deeper appreciation for the engineering behind the machinery. As enthusiasts delve into the specifics, they uncover the ultimate potential of their equipment, transforming routine maintenance into an opportunity for learning and skill enhancement.

D140 John Deere Parts Diagram Overview

This section provides a comprehensive look at the essential components of a well-known lawn care machine, offering insights into their arrangement and functionality. Understanding these elements is crucial for effective maintenance and repairs, ensuring the equipment operates smoothly and efficiently.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire system. |

| Transmission | Controls the speed and torque delivered to the wheels. |

| Cutting Deck | The assembly responsible for grass cutting, featuring blades and housing. |

| Wheels | Support the machine’s movement and provide traction on various terrains. |

| Control Panel | Interface for the operator to manage functions and settings. |

Key Components of the D140 Model

This section explores the essential elements of a popular lawn care machine, focusing on the intricate systems and features that enhance performance and usability. Understanding these components is crucial for maintaining optimal functionality and achieving efficient lawn maintenance.

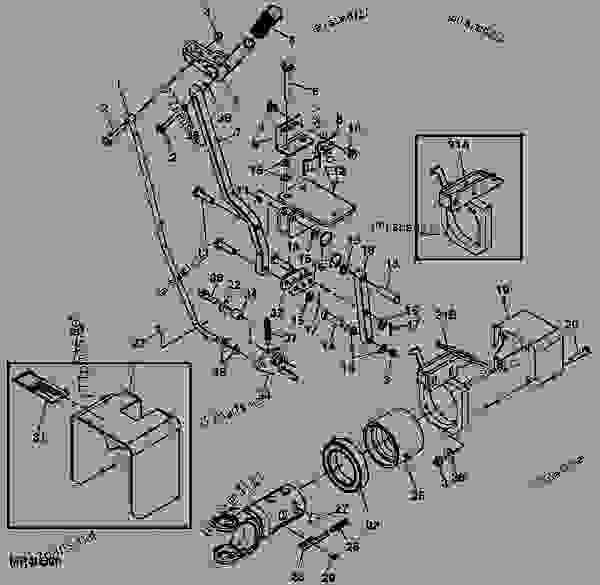

Engine and Powertrain

The engine serves as the heart of the equipment, providing the necessary power for various tasks. It is designed for efficiency and reliability, ensuring smooth operation even under heavy loads. The powertrain, which includes the transmission and drive system, translates engine output into effective ground speed, allowing for seamless navigation across different terrains.

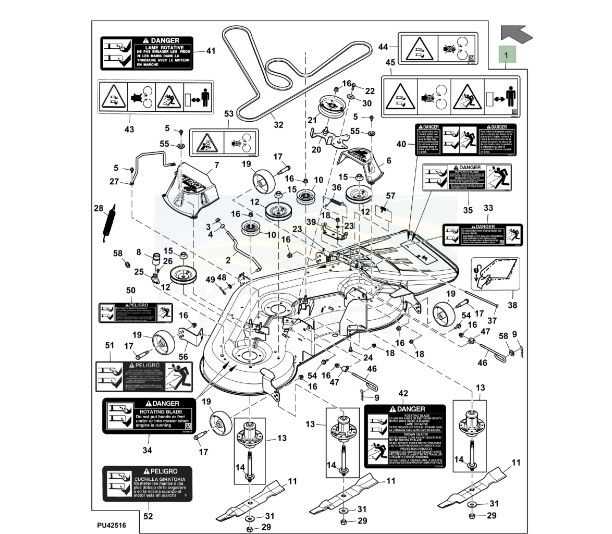

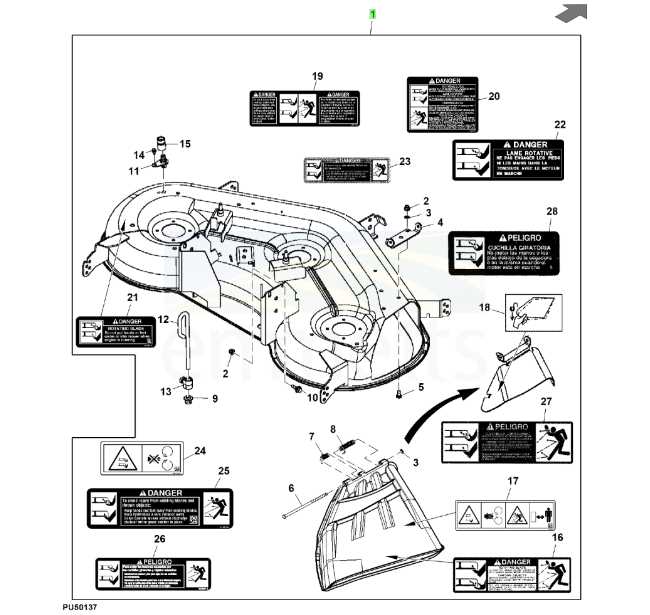

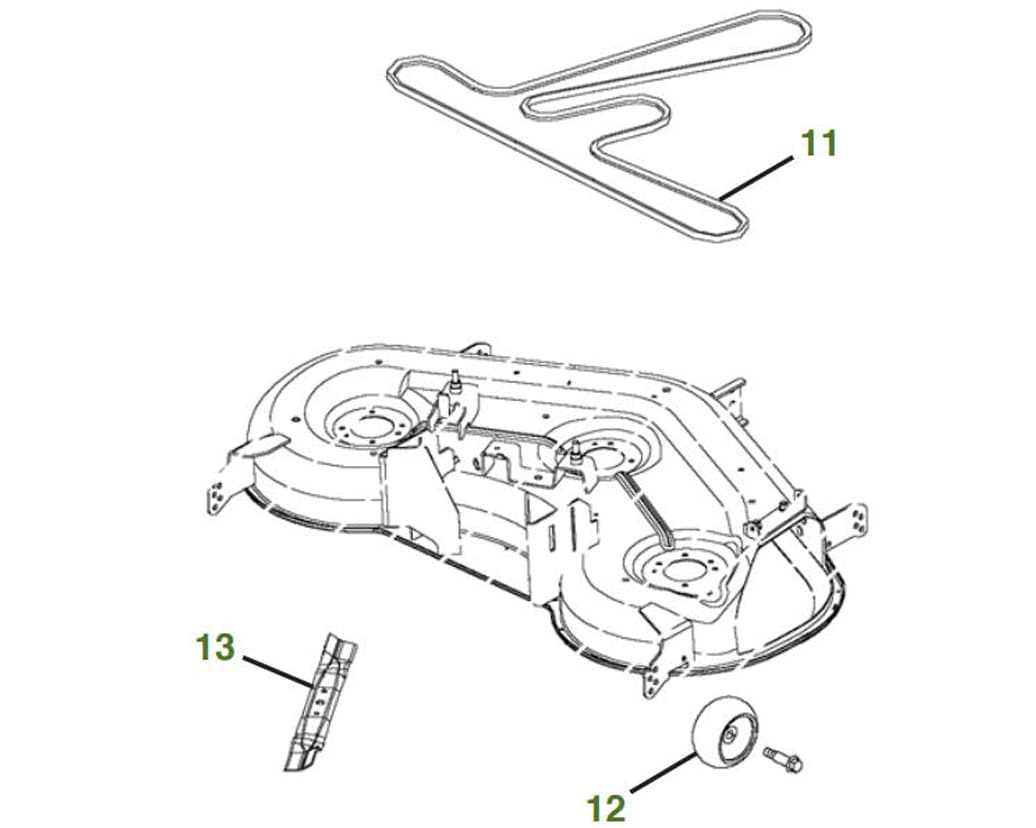

Mowing Deck and Blade System

The mowing deck is a critical feature that influences cutting performance. Its design allows for an even cut, promoting a healthy lawn. The blade system is engineered for durability, capable of handling diverse grass types and conditions. Regular maintenance of these components is essential to ensure longevity and optimal performance.

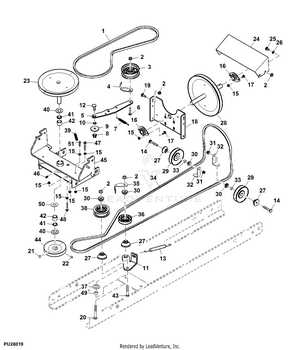

Understanding the Parts Layout

Comprehending the arrangement of components is essential for effective maintenance and repair. A well-structured overview allows users to identify specific elements easily, ensuring efficient troubleshooting and part replacement. Familiarity with the layout enhances the overall experience and performance of the machinery.

Key Components Overview

The primary sections of the arrangement include various functional elements that work in tandem. Recognizing these sections can facilitate better management of the equipment and extend its operational lifespan.

| Component | Description |

|---|---|

| Engine | Drives the machinery and powers other components. |

| Transmission | Transfers power from the engine to the wheels. |

| Chassis | Provides structural support and houses various systems. |

| Electrical System | Controls lighting, ignition, and other electronic functions. |

Maintenance Tips

Regular inspections of each section can prevent major issues. Keeping components clean and lubricated, along with replacing worn parts promptly, will enhance the machinery’s efficiency and reliability. Understanding the layout plays a crucial role in successful maintenance efforts.

Maintenance Tips for D140 Owners

Proper upkeep of your lawn equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. By following a structured maintenance routine, owners can keep their machines in top shape and enjoy a smooth mowing experience.

Routine Checks

Conducting routine inspections is crucial. Start by checking the oil level and quality, as clean oil is vital for the engine’s health. Additionally, inspect air filters and replace them if they appear dirty. Regularly examining the blades for sharpness is also important; dull blades can damage your grass and hinder performance.

Seasonal Maintenance

Seasonal care should include a thorough cleaning of the machine. Remove any debris, grass clippings, or dirt from the chassis and undercarriage. At the start of the mowing season, ensure that belts and cables are in good condition. Furthermore, storing the equipment properly during off-seasons will protect it from the elements and prolong its lifespan.

By adhering to these guidelines, owners can ensure their equipment remains reliable and effective for years to come.

Common Issues and Replacement Parts

When maintaining machinery, certain challenges frequently arise that necessitate the substitution of components. Understanding these common problems can help users identify when it’s time to act, ensuring optimal performance and longevity of the equipment.

Engine Overheating: One prevalent issue is overheating, which can be caused by coolant leaks or a malfunctioning thermostat. Regular inspection of the cooling system is essential.

Belt Wear: Another concern involves wear and tear on belts, leading to slippage or breakage. Timely replacement of these components is crucial for maintaining efficient operation.

Battery Failure: Electrical failures are often linked to battery issues. Ensuring a clean and secure connection can prevent premature battery drainage.

By proactively addressing these concerns and replacing necessary components, users can enhance the performance and reliability of their machinery.

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for optimal performance and longevity. Trusted sources ensure that you receive high-quality items that fit seamlessly and operate effectively. Various avenues exist to procure these essentials, catering to different preferences and needs.

Authorized dealers provide a reliable option, as they often stock a comprehensive range of genuine products. Additionally, online platforms can offer convenience and competitive pricing, allowing for easy comparison of options. Local repair shops may also carry legitimate supplies or assist in ordering them directly, ensuring that you receive the correct fit for your equipment.

Participating in dedicated forums and communities can be invaluable, as members often share recommendations for reputable suppliers and sources. By exploring these avenues, you can confidently acquire the necessary components to keep your equipment running smoothly.

DIY Repair Guide for D140

This section aims to empower enthusiasts and owners to tackle maintenance and repair tasks effectively. By understanding the essential components and common issues, individuals can enhance their machine’s performance and longevity. Whether you’re a seasoned mechanic or a beginner, this guide provides valuable insights into troubleshooting and resolving typical challenges.

Identifying Common Issues

Begin by familiarizing yourself with frequent problems encountered in lawn care equipment. These may include starting difficulties, uneven cutting, or unusual noises. Observing these symptoms closely can help pinpoint the underlying cause.

Essential Tools and Equipment

Having the right tools is crucial for any repair. Basic items such as wrenches, screwdrivers, and pliers should be on hand. Additionally, consider acquiring specialized tools for more complex tasks, such as a torque wrench or a multimeter for electrical diagnostics.

Step-by-Step Repair Process

Once you’ve identified the issue and gathered your tools, follow a systematic approach. Start by consulting the user manual for specific guidance on disassembly and reassembly. Always ensure the equipment is powered off and disconnected from any power source before starting repairs.

Regular Maintenance Tips

Preventive measures can significantly reduce the need for extensive repairs. Regularly check fluid levels, replace air filters, and keep blades sharp. Establishing a maintenance schedule will help in prolonging the lifespan of your machine and maintaining optimal performance.

By following this DIY repair guide, users can confidently address challenges and maintain their equipment effectively, ensuring it operates at its best throughout the seasons.

Comparing D140 with Similar Models

When evaluating various lawn care machines, it’s essential to consider how different models stack up against one another in terms of features, performance, and user satisfaction. This comparison sheds light on the key similarities and differences, helping potential buyers make informed decisions based on their specific needs.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 20 HP | 22 HP | 19 HP |

| Cutting Width | 42 inches | 48 inches | 42 inches |

| Transmission Type | Automatic | Hydrostatic | Automatic |

| Fuel Capacity | 1.5 gallons | 2.0 gallons | 1.5 gallons |

| Weight | 450 lbs | 475 lbs | 430 lbs |

By comparing specifications such as engine power, cutting width, and weight, users can better assess which machine aligns with their landscaping requirements. Understanding these nuances facilitates a more tailored selection process, ultimately enhancing the mowing experience.

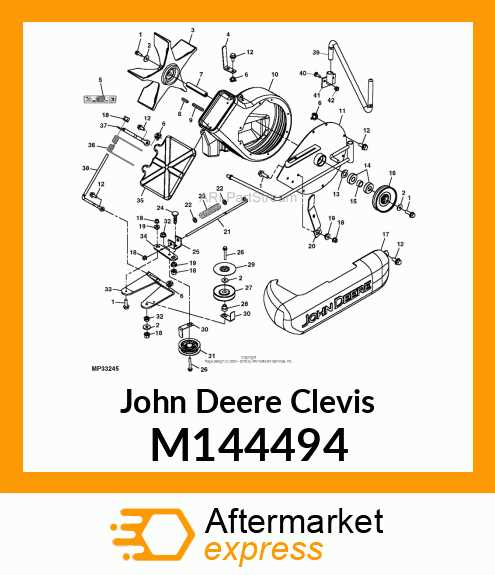

Parts Compatibility with Other John Deere

Understanding the interchangeability of components across different models can significantly enhance maintenance and repair efficiency. This knowledge allows users to optimize their machinery’s performance while potentially reducing costs through the use of compatible elements.

Many components are designed to work seamlessly across a range of machinery. This compatibility not only simplifies the sourcing of replacements but also expands the options available for upgrades. Ensuring that the right components are selected can lead to improved functionality and longevity of the equipment.

Moreover, it is crucial to consult the manufacturer’s guidelines or expert resources to confirm compatibility, as variations can exist even among similar models. By delving into these details, users can achieve the ultimate satisfaction in their machinery’s operation.

Upgrading Performance Features

Enhancing the functionality and efficiency of your equipment can significantly improve its overall performance. By focusing on key areas such as power, handling, and comfort, you can achieve a more robust and reliable machine tailored to your needs.

- Engine Modifications: Consider upgrading to a more powerful engine or optimizing the current one. Improved horsepower can lead to better performance in various tasks.

- Transmission Enhancements: Installing a more efficient transmission system can enhance speed and control, making operations smoother.

- Suspension Upgrades: A better suspension system improves stability and handling, especially on uneven terrains.

In addition to mechanical improvements, incorporating modern technology can provide significant benefits:

- GPS and Precision Farming Tools: Utilizing advanced navigation systems can enhance efficiency and productivity during operations.

- Smart Controls: Implementing user-friendly interfaces allows for easier management of various functions and settings.

- Performance Monitoring Systems: Installing diagnostic tools can help track performance metrics and identify areas for improvement.

By investing in these upgrades, you can achieve a remarkable increase in the overall capabilities and longevity of your machinery.

Community Resources and Support Networks

Access to community resources and support networks is essential for individuals seeking assistance with maintenance and repair tasks. These groups provide valuable information, shared experiences, and access to various tools and components, fostering a collaborative environment for enthusiasts and professionals alike.

Local Groups and Workshops

Many communities host local gatherings where individuals can learn from one another, share insights, and participate in hands-on workshops. These events often feature experienced members who can guide newcomers through troubleshooting and repair processes. Engaging with these groups not only enhances skills but also builds lasting connections among participants.

Online Forums and Social Media

Digital platforms have become invaluable for exchanging knowledge and resources. Numerous online forums and social media groups cater to enthusiasts, offering a space to ask questions, share tips, and access a wealth of information. Active participation in these virtual communities can significantly boost one’s confidence and expertise in handling various tasks.