Exploring the intricate framework of vintage agricultural equipment provides invaluable insights for enthusiasts and operators alike. Knowing the individual elements that make up these robust machines enhances maintenance and repair practices, ensuring longevity and optimal performance.

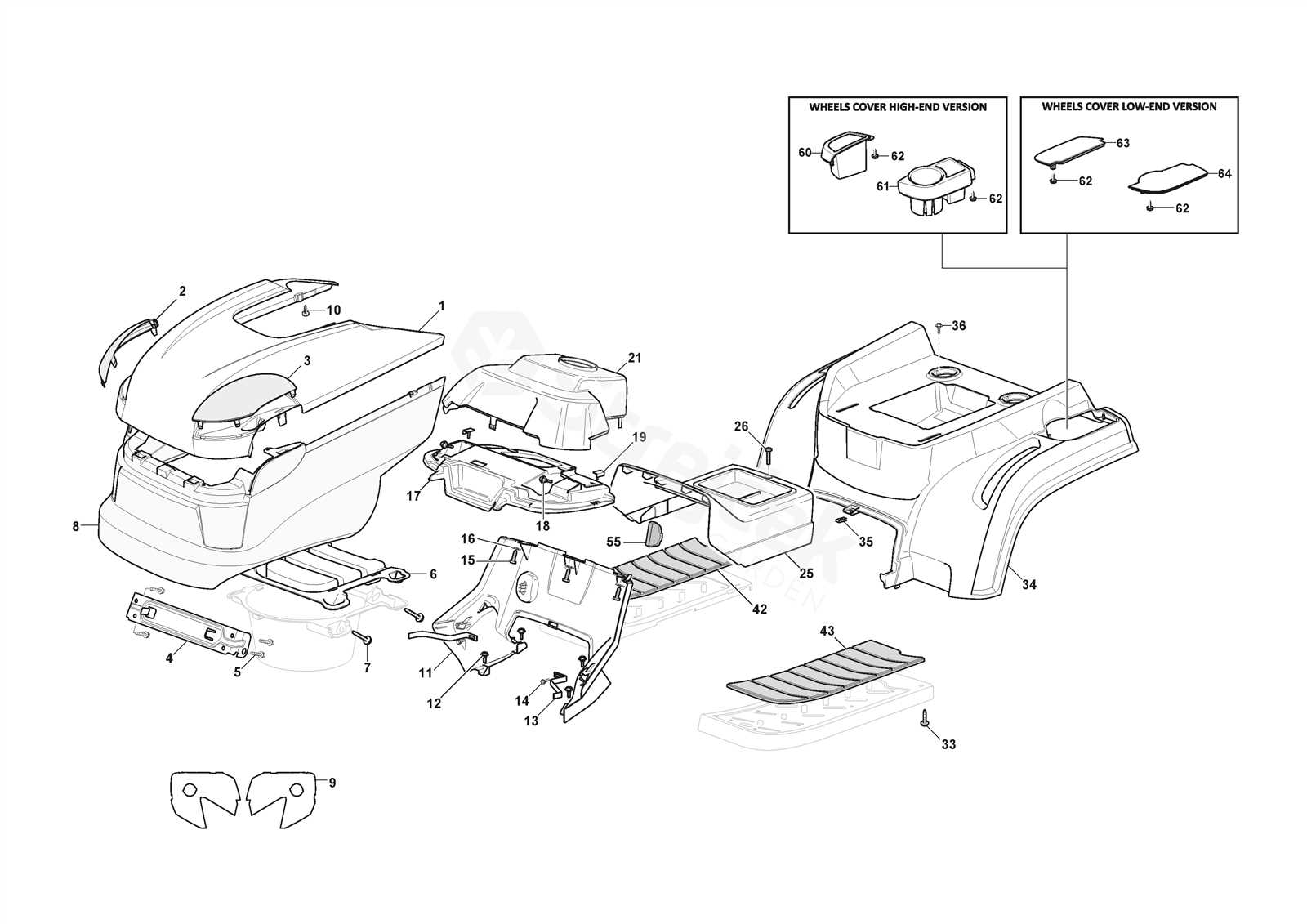

In this section, we will delve into a comprehensive overview of the essential components and their interrelationships. A well-organized visual representation can serve as the ultimate guide for identifying and accessing each vital piece, simplifying the restoration process and enhancing functionality.

Whether you are a seasoned mechanic or a curious beginner, mastering the layout of these assemblies is crucial. Familiarity with these elements not only aids in troubleshooting but also empowers users to make informed decisions about upgrades and replacements, ultimately maximizing efficiency and reliability.

Understanding the John Deere 140

This section explores the essential components and features of a well-known garden tractor that has gained a reputation for durability and performance. By examining its key attributes, users can appreciate how this machine has become a favorite among enthusiasts and professionals alike.

Key Features

The tractor is equipped with a powerful engine, offering reliable operation for various tasks. Its robust build ensures longevity, while ergonomic design enhances user comfort during prolonged use.

Maintenance Insights

Regular upkeep is crucial for optimal functioning. Familiarity with the core components can greatly assist owners in troubleshooting and performing essential repairs, ultimately extending the lifespan of their equipment.

Essential Components of the 140 Model

This section explores the key elements that contribute to the functionality and efficiency of this iconic piece of machinery. Understanding these components is crucial for both maintenance and optimal performance.

Core Functional Parts

- Engine Assembly

- Transmission System

- Hydraulic Components

- Chassis and Frame

Auxiliary Elements

- Electrical System

- Steering Mechanism

- Cooling System

- Fuel Delivery System

Each of these essential parts plays a vital role in ensuring the overall efficacy and reliability of the equipment, allowing users to tackle various tasks with ease.

Benefits of Using Original Parts

Utilizing authentic components in machinery maintenance ensures optimal performance and longevity. These genuine items are specifically designed to fit perfectly and operate seamlessly with the equipment, leading to enhanced efficiency and reduced risk of malfunction.

Quality Assurance

One of the primary advantages of selecting original components is the assurance of quality. Here are key aspects to consider:

- Durability: Authentic items are manufactured to high standards, ensuring they can withstand demanding conditions.

- Precision Fit: Original components are engineered to match the specifications of the machinery, minimizing wear and tear.

- Reliability: Trustworthy performance is guaranteed, reducing the likelihood of breakdowns.

Cost-Effectiveness

Investing in genuine components can lead to significant savings over time:

- Lower Maintenance Costs: Fewer breakdowns mean reduced repair expenses.

- Increased Resale Value: Equipment with original components retains its value better in the market.

- Warranty Protection: Many manufacturers offer warranties on their authentic products, providing peace of mind.

Common Issues with John Deere 140

This section explores typical challenges faced by owners of a well-known lawn tractor model, highlighting frequent problems and their implications on performance and maintenance.

Engine Performance Problems

Owners often report issues related to engine efficiency, which can stem from factors such as improper fuel quality or clogged filters. Regular maintenance is essential to avoid these complications and ensure optimal functionality.

Transmission Troubles

Another prevalent concern involves the transmission system, where operators may experience difficulty in shifting gears. Identifying early signs of wear can help in addressing these matters before they escalate, preserving the machine’s longevity.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to troubleshooting and repairing your equipment. By following these structured steps, you will ensure that the maintenance process is efficient and effective, allowing you to restore functionality without unnecessary complications.

Preparation and Tools

Before you begin, gather all necessary tools and materials. A well-organized workspace is essential for a smooth repair process. Ensure you have items like wrenches, screwdrivers, and replacement components ready at hand. Additionally, reviewing the manual or schematic can offer valuable insights into the assembly and disassembly process.

Step-by-Step Process

1. Safety First: Always prioritize safety. Wear appropriate gear and ensure the equipment is turned off and disconnected from power sources.

2. Disassembly: Carefully remove any panels or covers to access the internal mechanisms. Keep track of screws and components, possibly using labeled containers for organization.

3. Inspection: Examine all parts for wear and tear. Identify any damaged or malfunctioning elements that require replacement.

4. Replacement: Install new or repaired components, ensuring they fit properly and are securely attached.

5. Reassembly: Follow the disassembly steps in reverse to reassemble the equipment. Ensure all parts are correctly aligned and fastened.

6. Testing: Once reassembled, conduct a test run to confirm that the repairs were successful. Monitor for any unusual sounds or issues.

By adhering to this methodical approach, you can effectively manage repairs and maintain the longevity of your machinery.

Where to Find Replacement Parts

Locating suitable components for your machinery is essential for maintaining optimal performance and longevity. Numerous resources are available to help enthusiasts and professionals alike find what they need efficiently.

Online Retailers

Many websites specialize in agricultural and machinery supplies, offering a vast selection of alternatives. Popular platforms often provide user-friendly search features, allowing you to quickly identify the right items based on your specific model.

Local Dealers and Repair Shops

Connecting with nearby distributors and service centers can yield valuable insights. These establishments often stock essential components and may offer personalized recommendations based on experience with various equipment.

Importance of Proper Maintenance

Regular upkeep of machinery is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues, from decreased efficiency to costly repairs. By prioritizing proper care, operators can enhance the functionality and reliability of their equipment.

Benefits of Regular Maintenance

- Increased Efficiency: Well-maintained machinery operates more smoothly, leading to better productivity.

- Extended Lifespan: Routine checks and timely repairs can significantly prolong the life of the equipment.

- Cost Savings: Preventative maintenance often costs less than dealing with major breakdowns or replacements.

- Safety Assurance: Regular inspections can help identify potential hazards, ensuring safer operation.

Key Maintenance Practices

- Conduct regular inspections to identify wear and tear.

- Change fluids and filters as recommended by the manufacturer.

- Keep machinery clean to prevent dirt and debris from causing damage.

- Address minor issues promptly to prevent escalation.

In conclusion, committing to consistent maintenance practices is essential for achieving the best outcomes from any piece of equipment. This proactive approach not only enhances performance but also ensures safety and cost-effectiveness over time.

Identifying Specific Part Numbers

Understanding how to locate precise identifiers for components is crucial for effective maintenance and repairs. Each element of machinery comes with a unique code that ensures compatibility and efficiency during replacement. This section will explore the strategies for pinpointing these identifiers accurately.

To begin, it’s essential to refer to the manufacturer’s documentation. Official manuals typically include detailed listings that correlate with specific components, providing a reliable source for identification. Additionally, utilizing online resources can yield valuable insights, as many forums and websites are dedicated to machinery enthusiasts and parts identification.

Another effective approach is to inspect the existing components closely. Often, these elements have markings or numbers engraved directly onto them, which can be cross-referenced with online databases or catalogues. This method not only confirms the part number but also helps in understanding the component’s function within the overall system.

Moreover, consulting with authorized dealers or service providers can provide further clarity. These professionals are usually equipped with extensive knowledge and resources, making them a great asset in the search for the correct identifiers.

In conclusion, identifying specific component numbers involves a combination of documentation, online research, and expert consultation. By leveraging these strategies, one can ensure they obtain the right elements for optimal performance and longevity of their machinery.

DIY Tips for Part Installation

Installing components on your equipment can be a rewarding experience, enhancing both functionality and performance. With the right approach and preparation, you can tackle these tasks efficiently, ensuring everything fits perfectly and operates smoothly.

Preparation is Key

Before starting, gather all necessary tools and components. Familiarize yourself with the installation process by reviewing manuals or online resources. Take note of any specific steps or warnings to avoid potential issues during installation.

Step-by-Step Approach

Divide the installation into manageable steps. Carefully remove existing components before adding new ones. Labeling wires and pieces can save time and prevent confusion later. Always double-check connections and fittings to ensure they meet specifications for optimal performance.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in diagnosing mechanical issues. They allow users to quickly identify components and their relationships, simplifying the process of locating faults. By referencing these visual aids, operators can enhance their understanding and streamline repairs effectively.

Benefits of Visual Aids

Utilizing graphical tools can significantly reduce the time spent on repairs. These illustrations provide clarity and help in recognizing potential problems before they escalate. Furthermore, they foster a more efficient workflow, making it easier to assemble or disassemble parts as needed.

Effective Troubleshooting Steps

To maximize the benefits of visual resources, follow these essential steps:

| Step | Description |

|---|---|

| 1 | Examine the visual aid to understand the component layout. |

| 2 | Identify the area of concern based on symptoms. |

| 3 | Compare the real setup with the illustration. |

| 4 | Pinpoint discrepancies and potential failure points. |

| 5 | Implement necessary repairs based on findings. |

Connecting with Online Communities

Engaging with digital platforms focused on specific interests can provide valuable resources and support. These communities offer a space for enthusiasts to share knowledge, seek advice, and collaborate on projects. By tapping into these networks, individuals can enhance their understanding and improve their skills.

Benefits of Online Engagement

Participating in virtual groups fosters connection and access to diverse perspectives. Members often share experiences, tips, and best practices that can lead to greater proficiency. Moreover, these platforms encourage problem-solving through collective brainstorming.

Finding the Right Community

Identifying the most suitable online groups involves considering your specific needs and interests. Here are some factors to evaluate when choosing a community:

| Criteria | Description |

|---|---|

| Focus Area | Look for groups that align with your specific interests or projects. |

| Activity Level | Choose communities that are active, ensuring frequent engagement and fresh content. |

| Member Support | Evaluate the willingness of members to offer assistance and share knowledge. |

| Resources Available | Consider the types of resources shared, such as guides, tutorials, and discussions. |