The efficient functioning of a compact digger relies heavily on its various components, each playing a crucial role in the overall performance. Gaining insight into these elements helps operators ensure optimal maintenance and timely repairs, ultimately extending the lifespan of the machinery.

Identifying the specific pieces that comprise this type of equipment enables users to recognize potential wear and tear. With proper knowledge, one can make informed decisions regarding replacements and upgrades, enhancing operational efficiency.

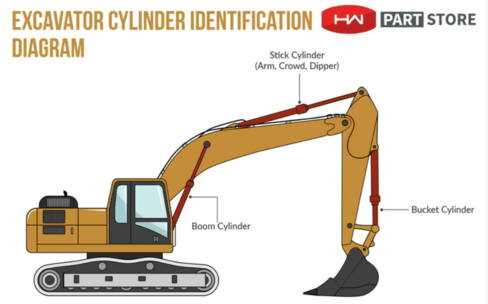

Utilizing detailed visual representations of the internal mechanisms serves as a valuable resource for mechanics and operators alike. Such illustrations provide clarity, making it easier to understand the relationship between different components and how they contribute to the machine’s capabilities.

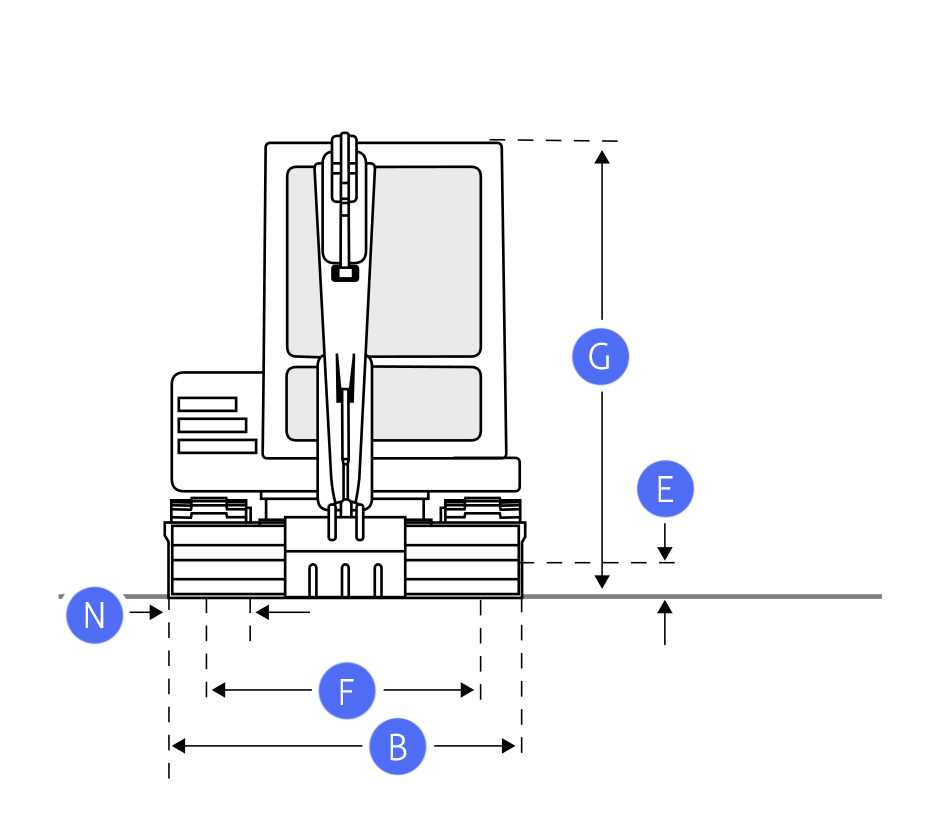

This section aims to provide a comprehensive overview of a compact machinery model, emphasizing its key components and functionalities. Understanding the structure and elements of this equipment is essential for effective maintenance and operation.

| Component | Description |

|---|---|

| Engine | Drives the machine, providing the necessary power for various tasks. |

| Hydraulic System | Facilitates movement and operation of attachments through fluid power. |

| Cab | Provides operator comfort and protection from environmental factors. |

| Tracks | Ensures stability and mobility across diverse terrains. |

| Attachments | Enhances functionality by allowing the machine to perform various tasks. |

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools in this process, enabling users to identify and locate individual elements efficiently.

- Enhanced Clarity: Visual aids simplify complex systems, making it easier to comprehend their functionality.

- Accurate Identification: Users can quickly recognize components, reducing the likelihood of errors during maintenance.

- Improved Communication: Diagrams facilitate discussions among technicians, ensuring everyone is on the same page.

- Streamlined Repair Processes: With clear references, repair tasks can be executed more swiftly and accurately.

- Training and Education: New users can learn about machinery layouts and components effectively through visual guides.

Incorporating these visuals into maintenance routines leads to better outcomes and extended equipment lifespan.

Main Components of the 26G

This section explores the essential elements that contribute to the functionality and efficiency of the mini excavator. Understanding these components is vital for effective maintenance and operation.

| Component | Description |

|---|---|

| Engine | Powers the machine and provides necessary force for operations. |

| Hydraulic System | Facilitates movement and control of the arm and attachments. |

| Tracks | Ensure stability and mobility over various terrains. |

| Cab | Offers operator comfort and control during operation. |

| Bucket | Used for digging and moving materials effectively. |

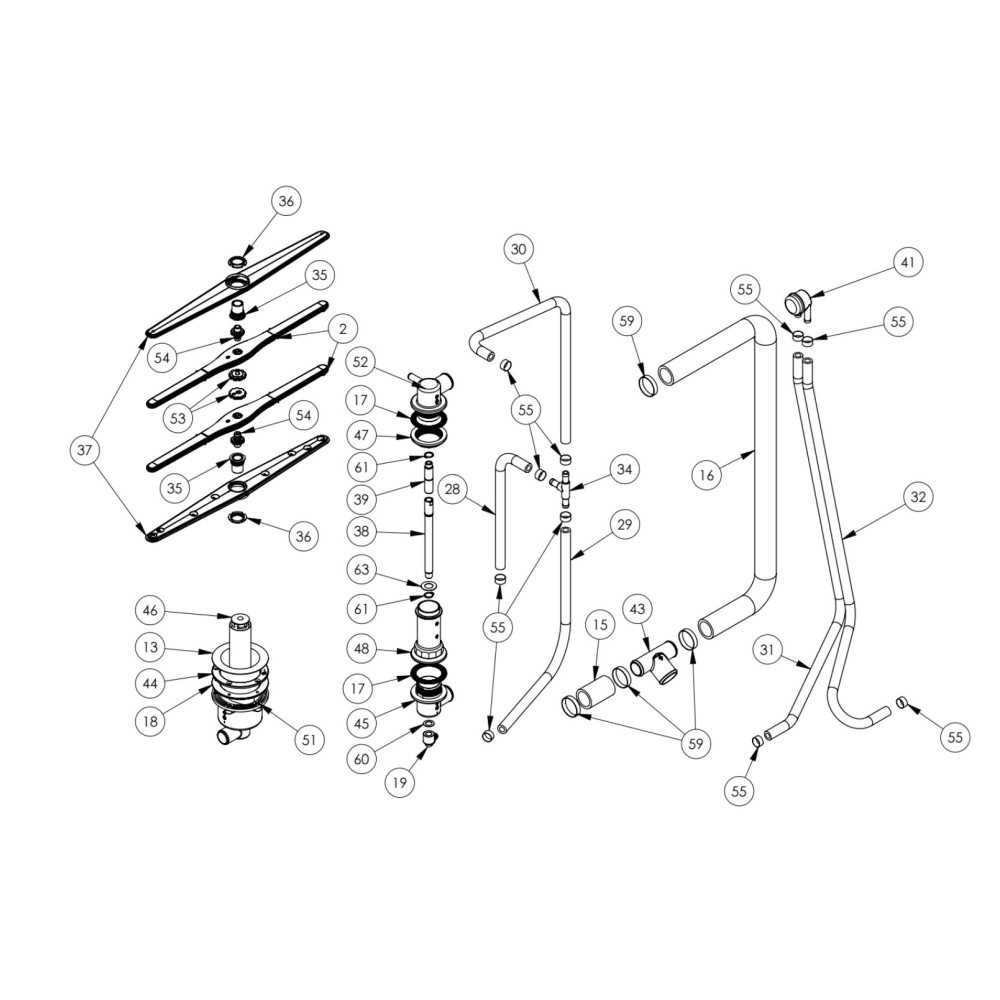

Understanding Hydraulic System Parts

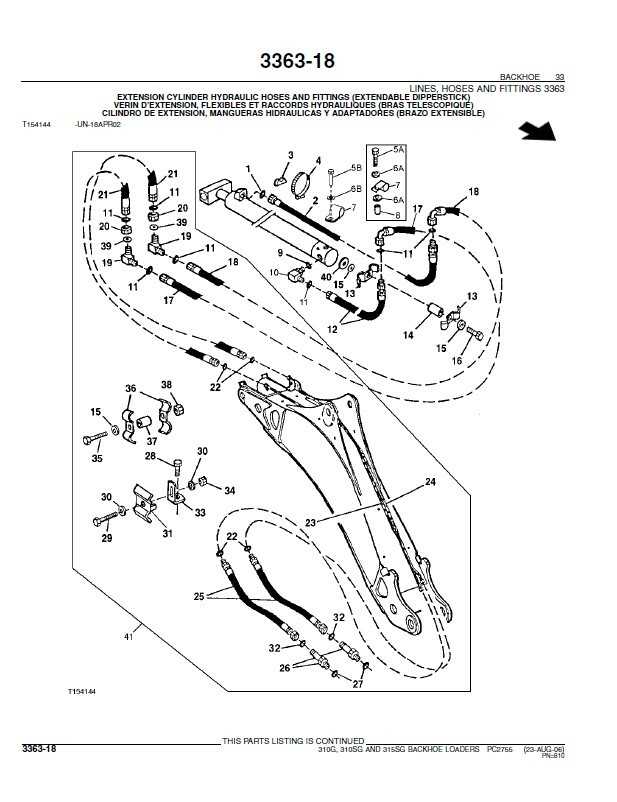

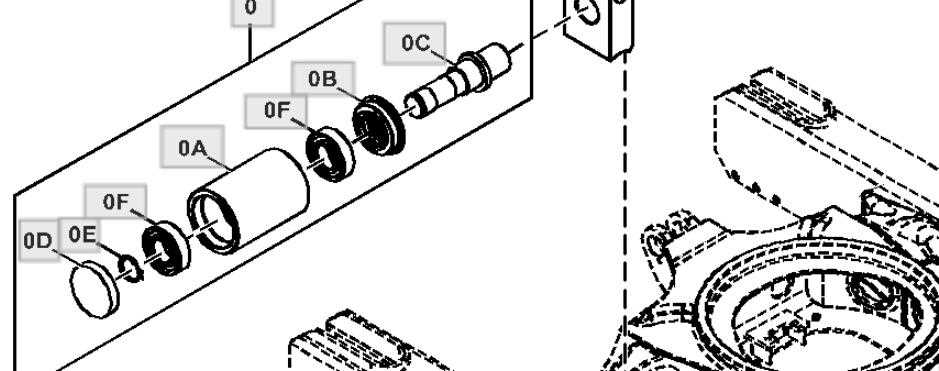

The hydraulic system is a crucial component in many machinery, allowing for the efficient transfer of power through fluid movement. Understanding its elements can enhance maintenance and troubleshooting, ensuring optimal performance.

Key Components of the Hydraulic System

Each part of the hydraulic system plays a specific role. The pump generates flow, transferring fluid through the system. Valves control this flow, directing it to various components as needed. Additionally, hoses and pipes transport the hydraulic fluid, while cylinders convert hydraulic energy into mechanical work.

Importance of Regular Maintenance

Regular inspection and maintenance of hydraulic components are essential. Identifying wear or damage early can prevent larger issues and reduce downtime. Keeping the hydraulic fluid clean and ensuring all connections are secure enhances system efficiency and longevity.

Common Wear and Tear Parts

Regular maintenance is essential for any machinery, as certain components tend to degrade over time. Understanding which elements are prone to wear can help in scheduling timely replacements and ensuring optimal performance.

- Tracks: Often subjected to significant stress, tracks can wear down due to constant friction and exposure to rough terrains.

- Hydraulic hoses: These are critical for fluid transfer but can develop leaks or fractures over time, impacting efficiency.

- Filters: Air and oil filters must be replaced regularly to maintain the cleanliness of fluids and prevent engine damage.

- Seals and gaskets: These components can degrade, leading to leaks that affect the functionality of hydraulic systems.

Monitoring these key elements will help prolong the life of the machinery and reduce the likelihood of costly repairs.

Replacement Options for Key Components

When considering the replacement of essential elements in machinery, it’s crucial to explore various alternatives that can enhance performance and ensure longevity. Different components may require specific attention based on wear and functionality.

Here are some common alternatives for key parts:

- Aftermarket Components: Often more affordable, these parts are manufactured by third-party companies and can offer similar performance levels.

- OEM Parts: Original equipment manufacturer components guarantee compatibility and quality, often at a premium price.

- Reconditioned Parts: Used components that have been refurbished can provide a cost-effective solution without compromising on quality.

Choosing the right replacement option depends on factors such as budget, availability, and performance requirements. It’s essential to evaluate each alternative to determine the best fit for your needs.

Tools Needed for Maintenance

Proper upkeep of equipment requires a variety of essential implements to ensure efficiency and longevity. Utilizing the right tools can significantly simplify the maintenance process and enhance overall performance.

Essential Tools

Commonly needed implements include wrenches, screwdrivers, and pliers. These tools assist in making necessary adjustments and repairs effectively. Additionally, having a set of socket tools can facilitate easier access to hard-to-reach areas.

Protective Equipment

Don’t forget the importance of safety gear. Using gloves and safety glasses is crucial to protect yourself during maintenance tasks. This ensures a safe working environment while handling various components and tools.

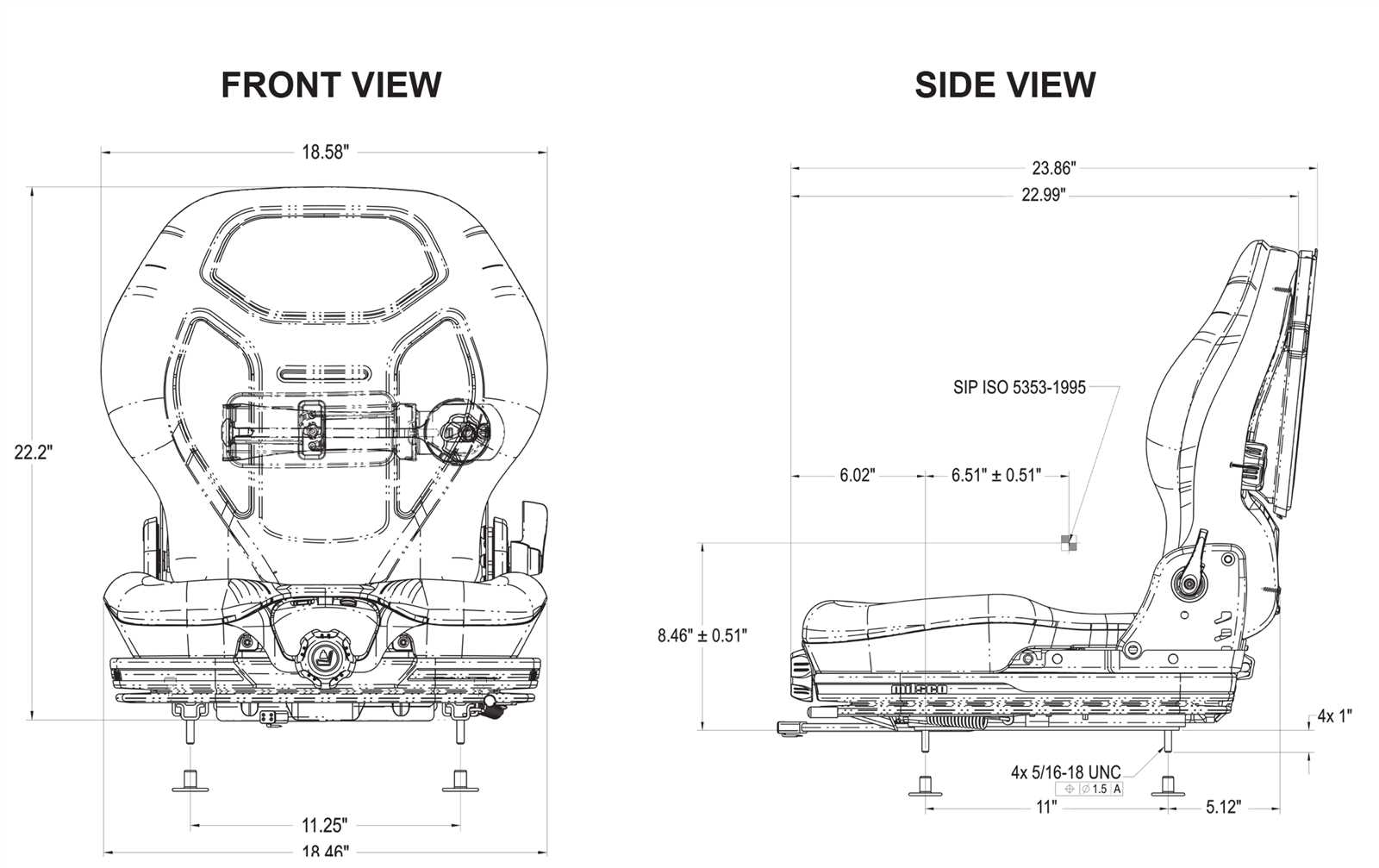

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of how each element interacts within a machine, making it easier to identify necessary items for replacements or upgrades.

Key Symbols and Notations

Familiarize yourself with common symbols used in these visuals. Each part is typically labeled with a unique identifier, which correlates to the accompanying list. Recognizing these notations can significantly enhance your ability to pinpoint specific components quickly.

Step-by-Step Approach

Start by examining the overall layout before focusing on individual sections. It is beneficial to trace connections and relationships between various elements. Pay attention to any notes or legends provided, as they often contain crucial information about installation or compatibility. By following this systematic approach, you can efficiently navigate through the visual representation.

Identifying Genuine John Deere Parts

Recognizing authentic components is crucial for maintaining the efficiency and longevity of machinery. Ensuring that the right replacements are used can significantly impact performance and durability. This section will guide you through essential indicators that distinguish original items from imitations.

Key Characteristics of Authentic Components

Genuine items typically exhibit distinct features such as precise fitting, high-quality materials, and specific branding elements. Here are some factors to consider:

| Feature | Genuine Item | Counterfeit Item |

|---|---|---|

| Brand Markings | Clear and precise logos | Faded or misspelled logos |

| Material Quality | High-grade materials | Substandard materials |

| Fit and Finish | Exact specifications | Poor fitting and finish |

Verifying Authenticity

To further ensure the reliability of components, always purchase from reputable sources. Check for official documentation and packaging that accompany the items, as these are vital indicators of authenticity.

Aftermarket Parts: Pros and Cons

Aftermarket components can offer an alternative to original equipment, often appealing to those seeking cost-effective solutions. These alternatives come with a mix of advantages and disadvantages that can impact overall performance and maintenance.

Advantages

One of the main benefits of choosing aftermarket options is their affordability. Many users find that these products provide similar functionality at a lower price. Additionally, a wider variety of choices allows for customization based on personal preferences and specific requirements.

Disadvantages

However, there are potential downsides to consider. Quality can vary significantly, and some aftermarket items may not meet the same standards as original counterparts. This inconsistency can lead to compatibility issues or reduced longevity.

| Pros | Cons |

|---|---|

| Cost-effective | Variable quality |

| Wide selection | Potential compatibility issues |

| Customization options | Reduced durability |

Common Repairs for the 26G

Regular maintenance is essential for ensuring optimal performance and longevity of your machinery. Addressing common issues promptly can prevent more significant problems and costly repairs down the line. Here are some frequent repairs you might encounter.

One of the most typical concerns involves the hydraulic system. Regularly checking and replacing fluid can prevent leaks and ensure smooth operation. Additionally, inspecting hoses for wear and tear is crucial, as damaged hoses can lead to system failure.

Another area often requiring attention is the undercarriage. Worn tracks or rollers can cause decreased performance and should be monitored closely. Replacing these components when necessary can enhance stability and maneuverability.

Electrical issues can also arise, often manifesting as starting problems or intermittent power loss. Checking battery connections and ensuring all wiring is secure can resolve many of these issues effectively.

Finally, keeping an eye on the engine’s performance is vital. Regular oil changes and air filter replacements can prevent engine strain and maintain efficiency. Properly caring for these components can significantly extend the life of your equipment.

Where to Find Parts Diagrams

Accessing comprehensive visual guides for components is essential for effective maintenance and repair of machinery. These resources help users identify specific elements and understand their functions within the overall system.

Here are several reliable sources to locate these valuable resources:

- Manufacturer’s Website: Most manufacturers provide downloadable visual guides on their official websites. Check the support or resources section.

- Online Retailers: Many online shops that sell equipment and accessories often feature visual references for their products.

- Forums and Community Groups: Engaging with online forums dedicated to machinery enthusiasts can yield shared diagrams and personal insights.

- Service Manuals: Purchasing or accessing service manuals often includes detailed visual aids that are beneficial for repairs.

- Local Dealerships: Contacting authorized dealers can provide access to official resources and expert assistance.

Utilizing these avenues can enhance understanding and facilitate smoother repair processes, ensuring optimal performance of your equipment.